A Practical Guide to the Cable That Keeps Elevators Connected

In modern buildings—whether commercial towers, hospitals, hotels, or residential complexes—elevators operate so seamlessly that most users never think about what makes them work. Beyond motors, rails, and control systems, there is one component that quietly keeps everything connected while the car moves: the elevator traveling cable.

This article explains what an elevator traveling cable is, why it exists, how it is built, and how it functions inside the hoistway. Rather than focusing on theory alone, the goal here is to give a clear, real-world understanding that is useful for engineers, facility managers, project planners, and anyone responsible for elevator reliability.

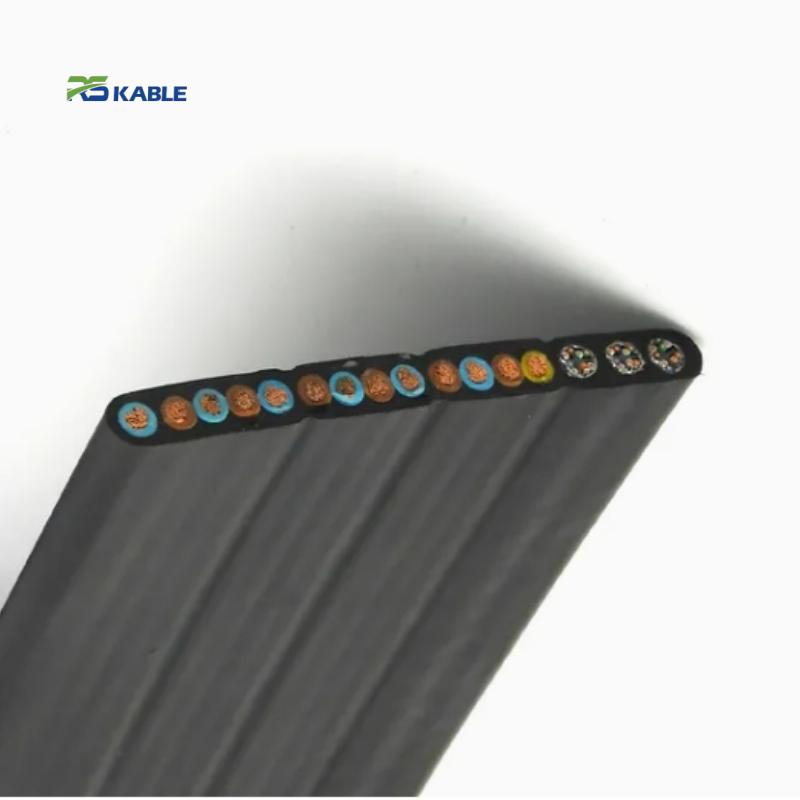

TVVBPG Dual-Steel Reinforced Shielded Flat Elevator Traveling Cable – High Tensile Wear-Resistant Lift Cable

A heavy-duty, shielded flat traveling cable designed for elevator and lift applications, featuring dual steel wire reinforcement for superior tensile strength and a braided shield to protect against electromagnetic interference. Flexible yet wear-resistant PVC construction ensures dependable performance in demanding elevator environments. :contentReference

- Dual steel reinforcement for enhanced mechanical support and tensile capacity.

- Shielded structure reduces signal interference in elevator/shaft environments.

- Flexible flat design ideal for continuous vertical travel.

- Wear-resistant PVC sheath for long service life. :contentReference

- Suitable for power, control and communication lines in elevator systems.

The Role of the Elevator Traveling Cable in an Elevator System

An elevator traveling cable is a flexible electrical cable designed to move continuously with the elevator car. Its primary function is to maintain uninterrupted electrical and communication connections between the moving car and the fixed control systems of the building.

Unlike hoisting ropes—which are steel wire ropes responsible for lifting and balancing the elevator—the traveling cable does not carry structural load. Instead, it carries:

-

Electrical power for car lighting, ventilation, and door systems

-

Control signals between the car and controller

-

Communication lines for intercoms, alarms, CCTV, and monitoring systems

In practical terms, without a traveling cable, an elevator car would lose power and control the moment it began to move.

Traveling Cable vs. Hoisting Ropes: A Necessary Distinction

The term “elevator cable” is often used loosely, leading to confusion. It is important to clearly separate these two components:

-

Hoisting ropes

-

Made of steel wire

-

Support and lift the elevator car and counterweight

-

Governed by mechanical safety and traction standards

-

-

Traveling cable

-

Electrical and data cable

-

Moves freely with the car

-

Supplies power, signals, and communication only

-

The 【Elevator Traveling Cable】 is inspected and evaluated under electrical and fire-safety standards rather than mechanical load criteria. Treating it as a structural cable is a common misconception—and an expensive one when it leads to improper selection or maintenance.

Why Traveling Cables Must Be Specially Designed

A standard electrical cable is meant to stay in place. An elevator traveling cable, by contrast, bends thousands of times every day. Over years of operation, this adds up to millions of flex cycles.

To survive in this environment, the cable must handle:

-

Continuous bending in a confined vertical space

-

Self-weight over long travel distances

-

Vibration from acceleration and deceleration

-

Temperature variation inside the shaft

-

Possible exposure to oil, dust, or moisture

This is why elevator traveling cables are engineered very differently from fixed installation cables used in walls or conduits.

Common Types of Elevator Traveling Cables

Flat Traveling Cables

Flat traveling cables are now the industry standard for most passenger and high-rise elevators. Conductors are arranged in parallel layers, creating a flat profile that bends in a controlled direction.

Advantages include:

-

Reduced twisting during movement

-

Smaller bending radius

-

Easier routing in narrow hoistways

-

Longer service life in high-travel applications

Round Traveling Cables

Round cables were widely used in older installations. While mechanically robust, they tend to rotate during travel, which increases stress over time.

Today, round cables are mainly found in:

-

Older elevator retrofits

-

Low-rise buildings

-

Installations with limited signal requirements

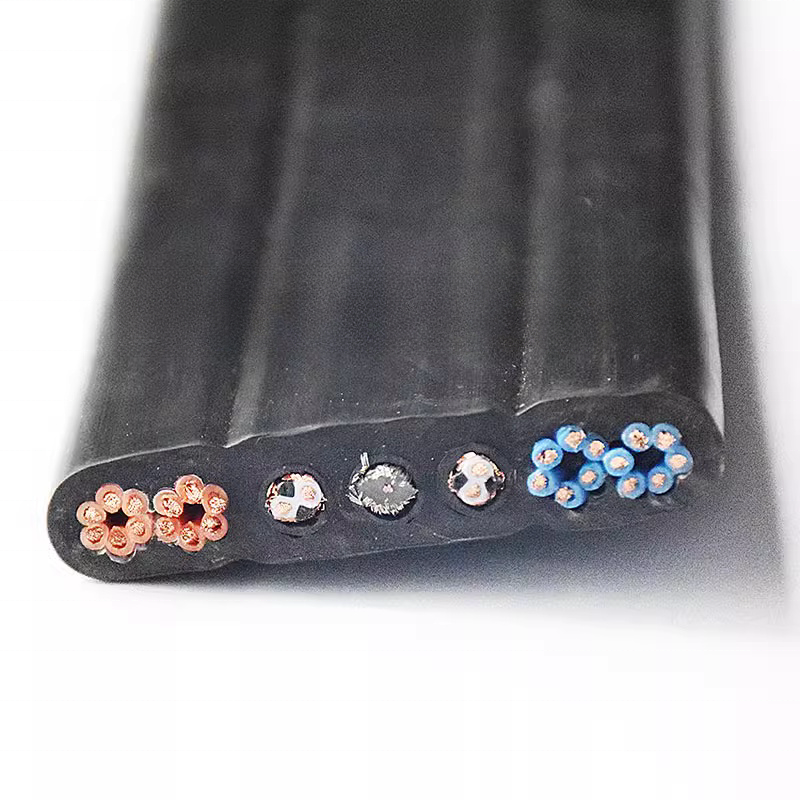

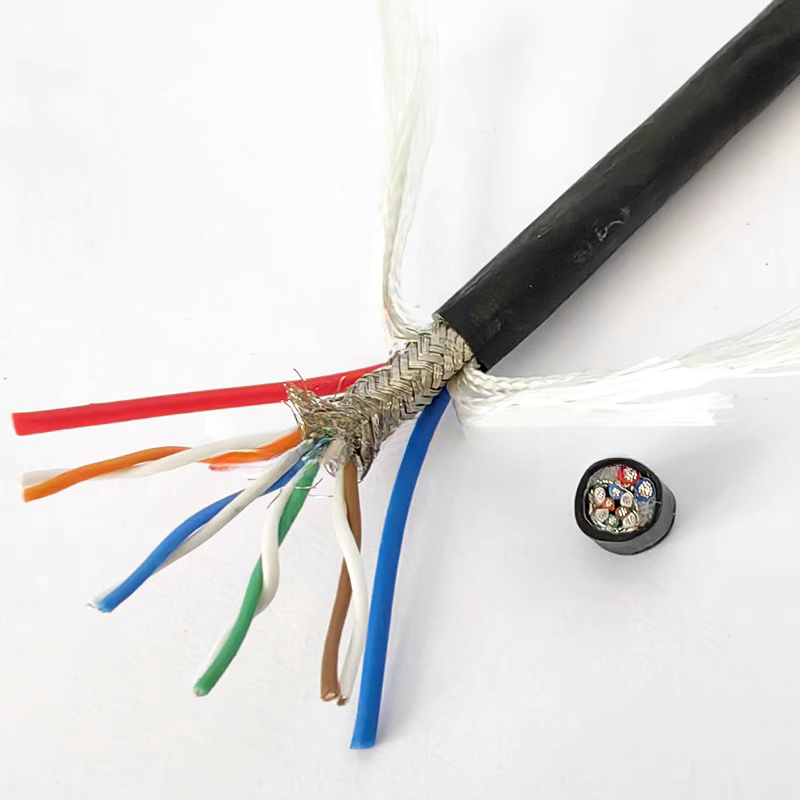

Hybrid and Composite Traveling Cables

Modern elevators often rely on a single cable that combines multiple functions. These hybrid designs may integrate:

-

Power conductors

-

Shielded signal pairs

-

Ethernet (Cat5e / Cat6) lines

-

Coaxial cables for cameras

-

Fiber optics for high-speed data

In smart buildings, the 【Elevator Traveling Cable】 increasingly serves as both a power backbone and a data highway.

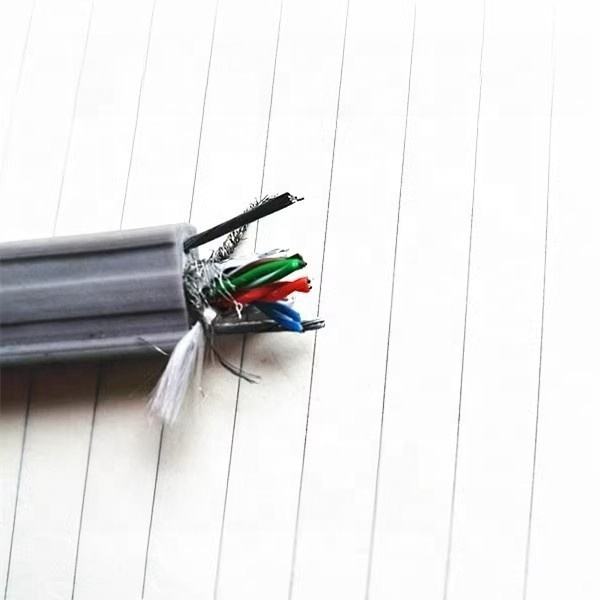

Internal Construction: What’s Inside the Cable

The performance of a traveling cable depends on its internal structure. While designs vary, most high-quality cables share the following elements:

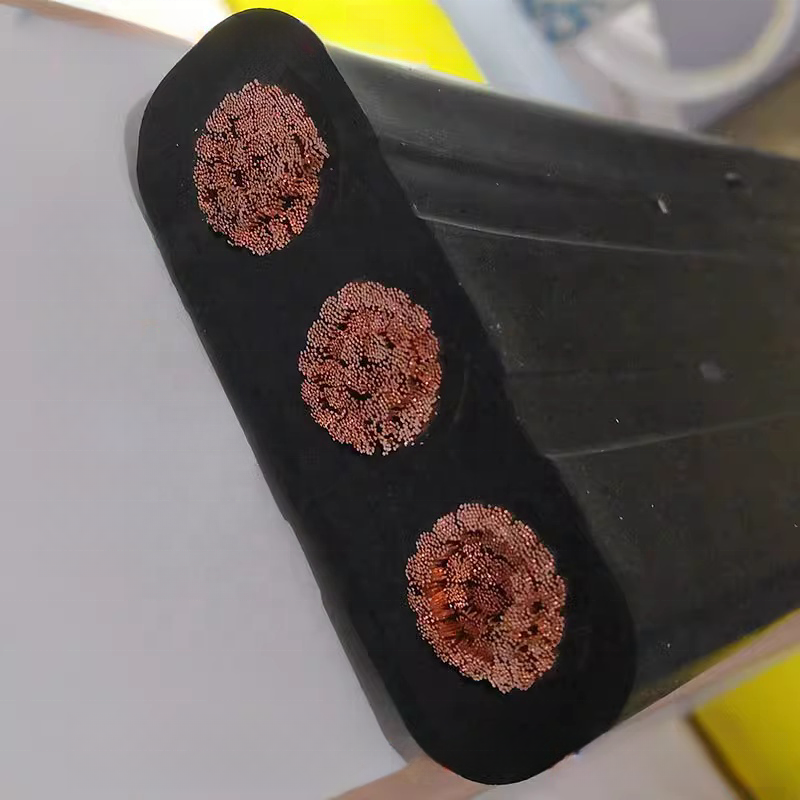

Conductors

Finely stranded copper conductors are used to maximize flexibility. Tinned copper is common in environments where corrosion resistance is required.

Insulation

Each conductor is individually insulated using PVC, PE, or silicone rubber, depending on temperature, flexibility, and fire-safety requirements.

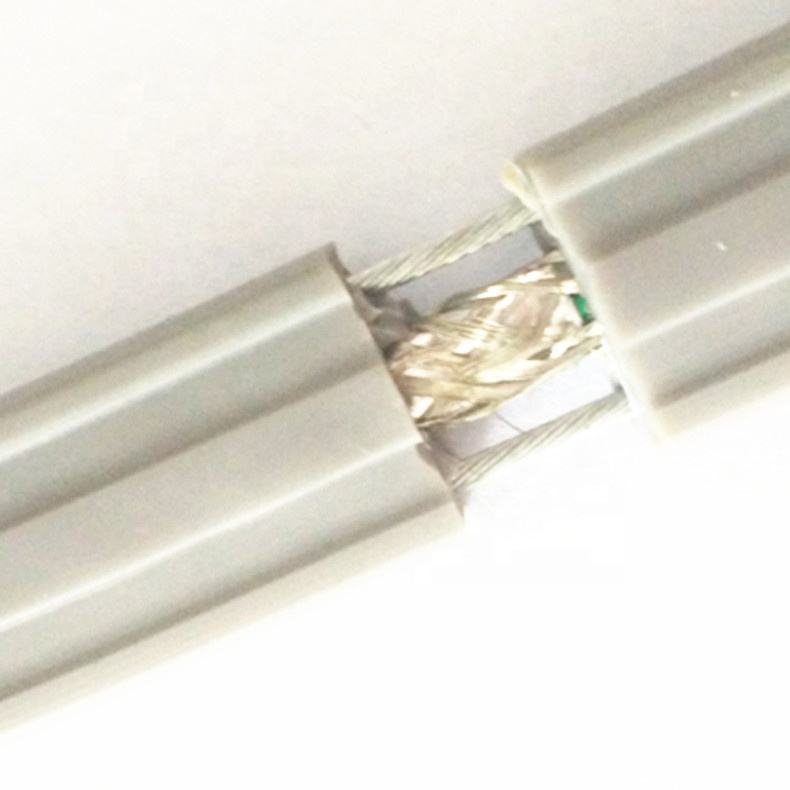

Shielding

Sensitive signal lines are protected by foil or braided shielding to minimize electromagnetic interference, especially important for CCTV and data transmission.

Strength Members

Steel wires or aramid fibers are embedded to support the cable’s own weight and prevent elongation in long travel distances.

Outer Jacket

The outer sheath protects against abrasion and environmental exposure. Flame-retardant and low-smoke materials are often specified for public buildings.

The result is a compact, layered structure optimized for motion rather than static installation.

How the Traveling Cable Works During Elevator Movement

Inside the hoistway, the traveling cable is attached to the elevator car at one end and anchored at a fixed point along the shaft. Between these points, the cable forms a hanging loop.

As the elevator moves:

-

The loop shifts position rather than stretching

-

The cable bends smoothly along its designed axis

-

Electrical connections remain continuous

Proper loop length and alignment are critical. If the loop is too long, the cable may sway or rub against the shaft wall. If too short, mechanical stress increases dramatically.

This is why installation quality directly affects cable lifespan.

Installation Practices and Support Systems

Correct installation involves more than simply connecting the cable.

Key considerations include:

-

Controlled loop geometry

-

Proper strain relief at termination points

-

Anti-twist measures to prevent rotation

-

Adequate clearance from shaft components

Professional installers follow elevator safety codes such as EN 81 or ASME A17.1 to ensure the cable moves freely without interference.

Safety Standards and Compliance

Because traveling cables are essential to passenger safety, they are subject to strict regulatory requirements. Common standards include:

-

UL standards for flexible cables

-

IEC and EN standards for lift applications

-

Flame-retardancy and smoke emission requirements

A compliant 【Elevator Traveling Cable】 is designed not only to function reliably, but also to limit fire spread and maintain circuit integrity during emergencies.

Maintenance and Typical Failure Modes

Even well-designed cables wear over time. Common issues include:

-

Conductor fatigue from repeated bending

-

Insulation cracking due to age or heat

-

Signal instability caused by shield damage

-

Mechanical abrasion from poor routing

Best practice maintenance includes:

-

Regular visual inspection

-

Electrical continuity checks

-

Replacement planning before end-of-life failure

Most traveling cables are replaced proactively after 10–20 years, depending on usage and environment.

Where Elevator Traveling Cables Are Used

Applications extend far beyond standard passenger elevators:

-

High-speed office towers

-

Hospital bed elevators

-

Freight and service lifts

-

Observation and panoramic elevators

-

Industrial vertical transport platforms

In each case, cable design is tailored to travel distance, speed, and functional requirements.

As elevators become more connected, traveling cables are evolving as well. Current trends include:

-

Increased use of fiber optics

-

Lightweight materials to reduce moving mass

-

Enhanced shielding for dense electronic environments

-

Compatibility with predictive maintenance systems

Despite interest in wireless alternatives, physical traveling cables remain the most reliable solution for power and safety-critical communication.

FAQ

What is the average lifespan of an elevator traveling cable?

Most traveling cables last between 10 and 20 years, depending on travel distance, speed, and maintenance quality.

Can an old round traveling cable be replaced with a flat one?

In many retrofit projects, yes. Flat cables often improve performance and reduce mechanical stress.

Do traveling cables carry both power and data?

Modern designs frequently integrate power, control, Ethernet, CCTV, and even fiber optic lines in one cable.

What causes premature cable failure?

Poor installation, incorrect loop length, excessive twisting, and environmental exposure are the most common causes.

Are traveling cables custom-made?

Yes. Core count, conductor size, shielding, and jacket materials are often customized for specific elevator systems.