What Is a Cable Elevator? A Practical Guide to Elevator Cables in Modern Buildings

In everyday conversation, the term “cable elevator” is often used loosely to describe any elevator that moves using cables. In practice, professionals mean something more specific: the integrated elevator cable system that delivers power, control signals, and data between the elevator car and the control equipment.

These cables operate quietly in the background, bending and moving thousands of times every day. Without them, modern elevators—especially those in high-rise and smart buildings—simply would not function. Understanding how elevator cables work, what types exist, and how to select the right one is essential for developers, facility managers, and engineers alike.

This guide explains the role of elevator cables in plain terms, while grounding every section in real-world engineering and industry standards.

What Does “Cable Elevator” Actually Mean?

From a technical standpoint, a cable elevator usually refers to a traction elevator—a system where steel ropes or belts suspend and move the car. However, when discussing cabling, the focus shifts to the traveling cable, the flexible assembly that connects the moving car to fixed control systems.

An Elevator Cable is designed to move continuously with the car while carrying multiple functions at once:

-

Electrical power for lighting, doors, and ventilation

-

Control signals for operation and safety systems

-

Communication lines for intercoms, CCTV, and monitoring

-

Data transmission for modern building management systems

Unlike standard electrical cables, elevator cables must withstand constant motion, vibration, and torsion while maintaining stable signal quality.

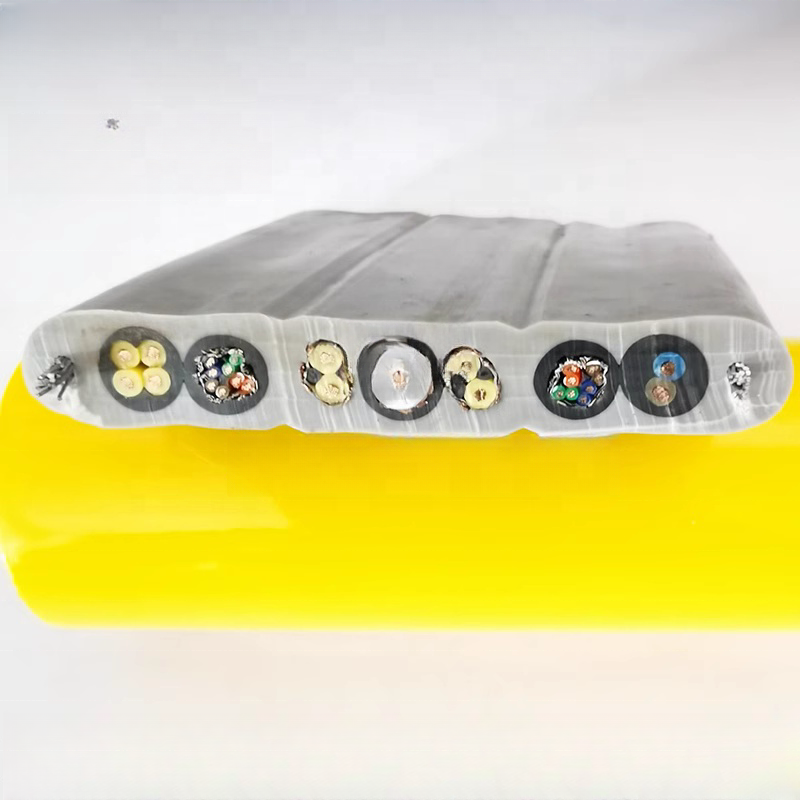

Custom TVVB Flexible Flat Lift Cable 0.75 mm – 3/4/7/12 Core Elevator Cable

A customizable TVVB flat flexible cable designed for elevator and lift applications with 0.75 mm² conductors in configurations of 3, 4, 7 and 12 cores. Engineered for continuous flexing in travelling and lifting environments, with PVC insulation and robust flat profile ideal for elevator systems.:contentReference

- Flexible flat TVVB design for elevator travelling cable applications

- Available in 3, 4, 7 and 12 core options at 0.75 mm² conductor size

- PVC insulation and sheath for wear and cold resistance

- Suitable for elevator, lift and hoist travelling systems

- Customizable specifications on request

Why Elevator Cables Are More Complex Than They Look

At first glance, an elevator cable appears to be a simple bundle of wires. In reality, it is a carefully engineered system built to survive millions of bending cycles over decades of service.

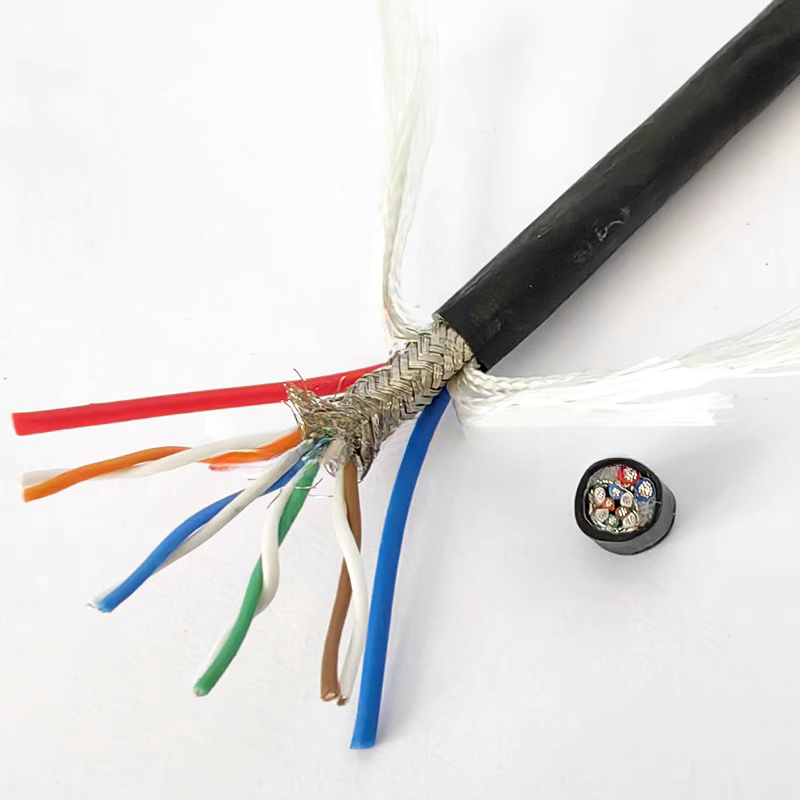

A single cable may contain:

-

Dozens of fine-stranded copper conductors

-

Shielded twisted pairs for data transmission

-

Coaxial lines for video signals

-

Fiber optics in advanced or high-rise installations

-

Integrated steel or aramid support elements

Flat or round profiles are selected not for aesthetics, but to control twisting, manage weight, and extend service life. This is why elevator cables are governed by strict standards such as EN 50214, EN 81, UL, and ASME A17.1.

Main Types of Elevator Cables Used Today

Different buildings place very different demands on their elevator systems. As a result, several cable configurations are widely used.

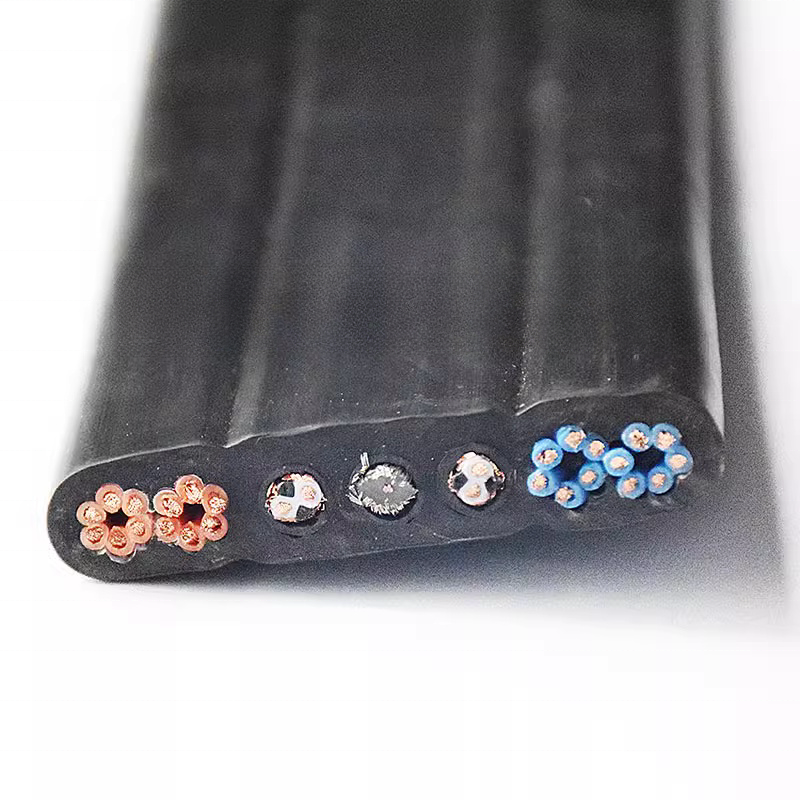

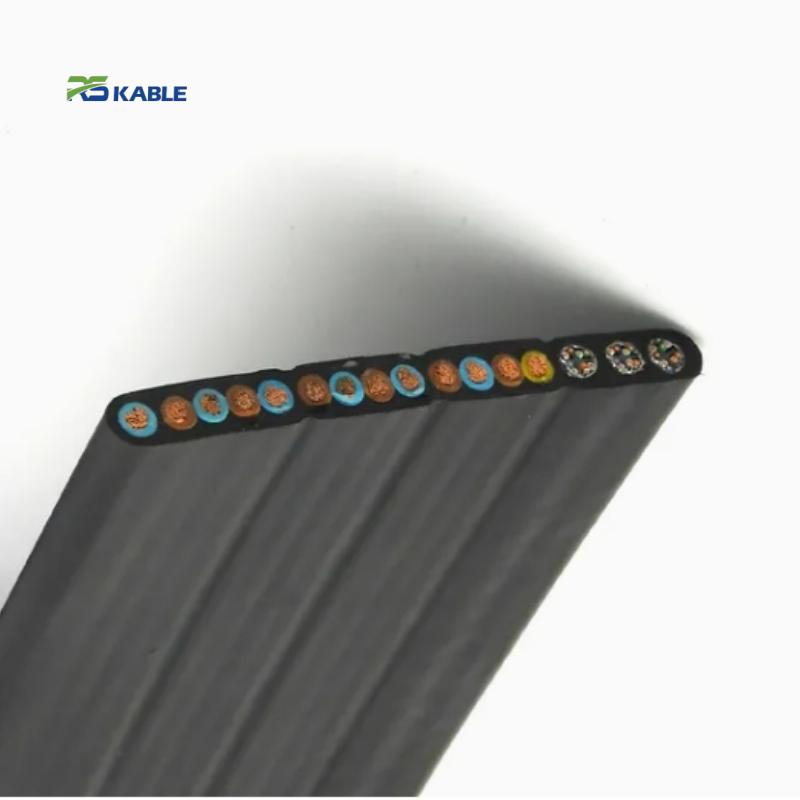

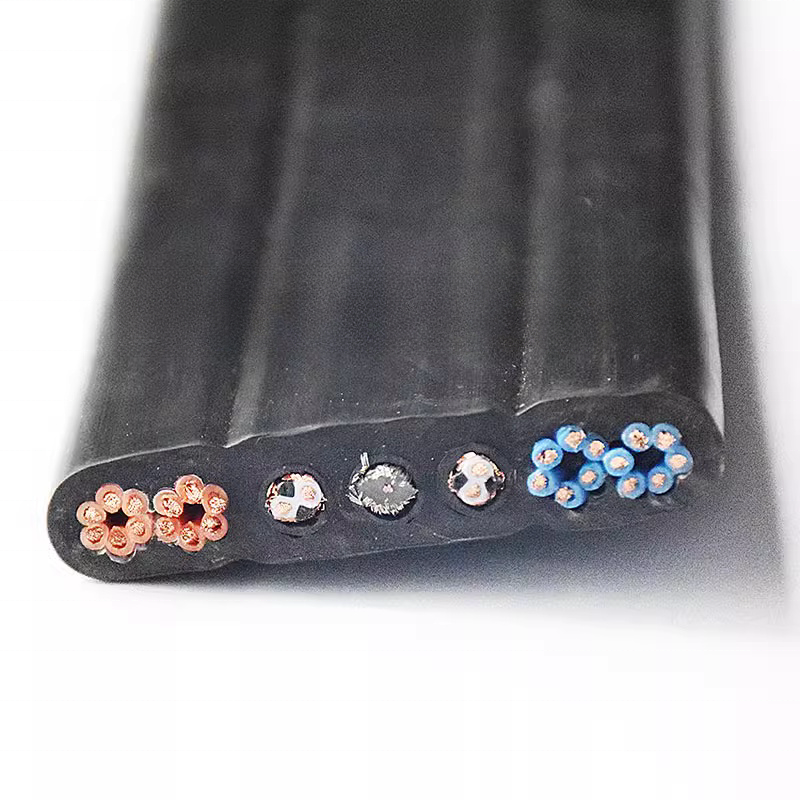

Flat Traveling Cables

Flat traveling cables are the most common solution in residential and mid-rise commercial buildings. Their shape minimizes torsion and allows the cable to hang naturally in the shaft. They are typically used for moderate speeds and travel heights.

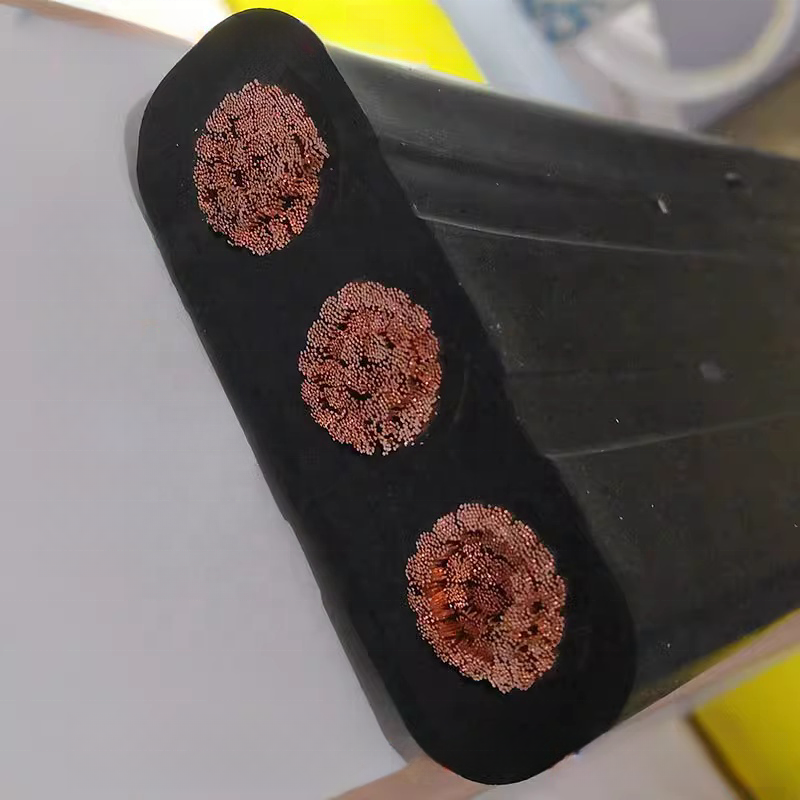

Round Traveling Cables

Round designs are favored in high-rise or high-speed elevators. Built-in support elements help carry the cable’s own weight over long vertical runs, reducing mechanical stress on conductors.

Hybrid Elevator Cables

Modern elevators often combine power, control, data, and video into a single hybrid cable. This reduces installation complexity and supports features such as remote diagnostics, access control, and in-car displays.

High-Flex Specialty Cables

For demanding environments—such as freight elevators or ultra-tall buildings—special jackets and conductor designs allow extreme flexibility and resistance to abrasion, oil, and electromagnetic interference.

Each option balances durability, compliance, and cost, making proper selection critical.

Key Performance Characteristics That Matter

Not all elevator cables perform equally. Long-term reliability depends on several design factors:

-

Flex life: Fine-stranded conductors and optimized lay lengths reduce metal fatigue.

-

Torsion control: Flat geometry or counter-twisted cores prevent kinking.

-

Fire safety: Flame-retardant and low-smoke materials protect occupants.

-

Signal integrity: Shielding protects data lines from motor interference.

-

Mechanical support: Steel or aramid elements absorb tensile load.

A properly specified Elevator Cable is tested for bending radius, tensile strength, and cycle endurance long before it reaches the job site.

Where Elevator Cables Are Used

Elevator cables play a role in nearly every vertical transport scenario:

-

Residential buildings: Quiet, compact cables for smooth daily operation

-

Office towers: Hybrid cables supporting security and building automation

-

Hospitals and hotels: Reliable communication and emergency signaling

-

Industrial facilities: Heavy-duty designs for harsh conditions

As buildings become smarter, elevator cables increasingly serve as data highways, not just power lines.

How to Select the Right Elevator Cable

Choosing the wrong cable can lead to premature failure, signal issues, or costly retrofits. Key selection criteria include:

-

Travel height and elevator speed

-

Number and type of conductors required

-

Environmental exposure inside the shaft

-

Local regulatory and certification requirements

-

Allowance for future system upgrades

Working with experienced suppliers who provide full technical documentation is essential, especially for custom projects.

Installation and Maintenance Considerations

Even the best cable can fail if installed incorrectly. Proper installation includes:

-

Respecting minimum bend radius

-

Supporting cable weight correctly in the shaft

-

Avoiding torsional stress during hanging

-

Periodic inspections for jacket wear or fatigue

With correct handling, an elevator cable typically remains in service for 15–25 years.

How Elevator Cables Are Evolving

The future of elevator technology is closely tied to cable development. Trends include:

-

Increased use of fiber optics

-

Integrated condition monitoring

-

Halogen-free and environmentally friendly materials

-

Compatibility with machine-room-less systems

These innovations support safer, more efficient vertical transportation in modern cities.

Frequently Asked Questions (FAQ)

Is a cable elevator the same as a hydraulic elevator?

No. Cable elevators use traction systems, while hydraulic elevators rely on fluid pressure.

How often should elevator cables be replaced?

Replacement depends on inspection results, but typically aligns with major modernizations.

Can one cable carry power and data together?

Yes. Hybrid designs are now common in modern elevators.

Are flat cables always better than round ones?

Flat cables suit most mid-rise buildings; round cables are preferred for long travel heights.

What standards should elevator cables meet?

Common references include EN 81, EN 50214, UL, and ASME A17.1.