What Cable Is Used in Elevators? A Practical Guide to Elevator Cables in Real Buildings

Elevators feel simple from the passenger’s perspective: press a button, doors close, and the car moves smoothly to the selected floor. Behind that experience, however, is a tightly coordinated system where mechanical, electrical, and digital components must work together without interruption. One of the least visible—but most critical—elements in that system is the elevator cable.

These cables are not standard building wires. They are engineered to move continuously inside a vertical shaft, carrying power, control signals, and data while bending thousands of times every day. Understanding what cable is used in elevators is essential not only for engineers and installers, but also for building owners, facility managers, and anyone involved in modernization projects.

This guide explains the types of cables used in elevator systems, how they differ from ordinary cables, where they are used, and how to select the right solution based on building conditions and standards.

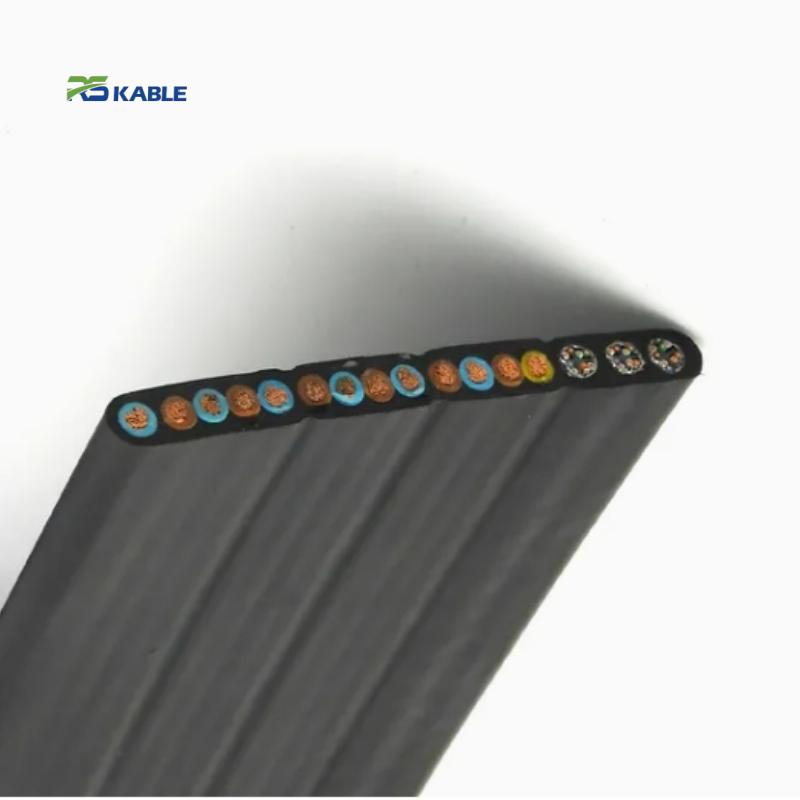

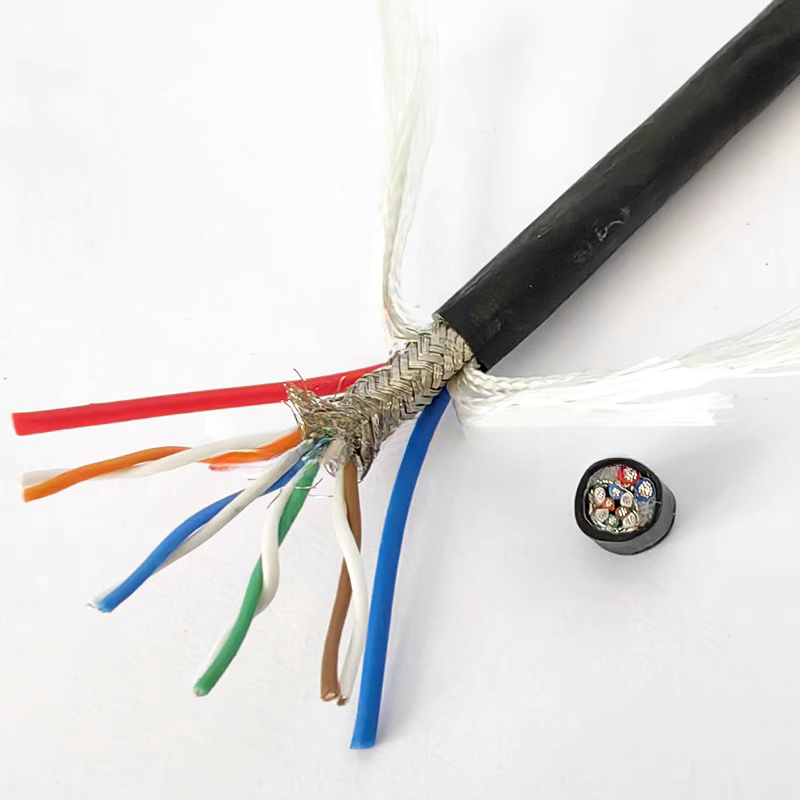

Cold‑Resistant Flat CCTV Elevator Cable – Dual‑Steel Reinforced, Dual‑Shielded Cat5e/6A, PE Insulated

A flexible flat CCTV/elevator cable engineered for cold environments, featuring dual‑steel reinforcement for high tensile strength and dual shielding for superior interference resistance. PE insulation ensures reliable performance for Cat5e and Cat6A signal transmission in elevator monitoring and network applications.

- Cold‑resistant flat profile for elevator CCTV and network cable applications

- Dual steel reinforcement for mechanical strength and durability

- Dual shielding to block electromagnetic interference for stable data transmission

- Supports Cat5e and Cat6A network performance standards

- PE insulation for enhanced environmental resistance

Why Elevator Cables Are Different from Ordinary Electrical Cables

Most electrical cables in a building are fixed in place. Once installed, they remain stationary for their entire service life. Elevator cables operate under completely different conditions.

A typical elevator cable must withstand:

-

Constant vertical movement

-

Repeated bending and flexing

-

Torsional forces caused by car motion

-

Electromagnetic interference from motors and drives

-

Strict fire and smoke regulations inside the shaft

Because of this, elevator cables are designed with fine-stranded conductors, optimized lay lengths, and specially formulated jackets that balance flexibility with mechanical strength.

Main Cable Types Used in Elevator Systems

Elevators do not rely on a single cable type. Instead, several specialized cables work together, each serving a distinct function.

Traveling Cables (The Core Elevator Cable)

The most important cable in an elevator is the traveling cable. It hangs freely in the hoistway and moves with the car, forming a controlled loop as the elevator travels.

This cable supplies:

-

Power for car lighting, fans, and doors

-

Control signals from buttons and sensors

-

Communication lines for alarms and intercoms

-

Data connections for CCTV, displays, or monitoring systems

Without a reliable traveling elevator cable, modern elevator functionality would simply not be possible.

Hoist Ropes and Belts (Mechanical, Not Electrical)

Often called “cables” in everyday language, hoist ropes are actually mechanical components. Made from steel wire or coated steel belts, they support and move the elevator car in traction systems. They do not transmit electrical signals.

Fixed Power and Control Cables

These stationary cables supply power to motors, controllers, and auxiliary equipment located in the machine room or control cabinet. Their design prioritizes current capacity and insulation rather than flexibility.

Flat vs. Round Traveling Cables: How the Choice Is Made

Traveling cables are generally manufactured in flat or round profiles. The decision between the two is based on building height, speed, and long-term performance requirements.

Flat Traveling Cables

Flat designs are common in residential and mid-rise commercial buildings. Their geometry naturally resists twisting, which helps maintain stable movement inside the shaft.

They are typically used where:

-

Travel height is moderate

-

Elevator speed is standard

-

Shaft space is limited

Flat traveling cables are cost-effective and widely accepted for most conventional passenger elevators.

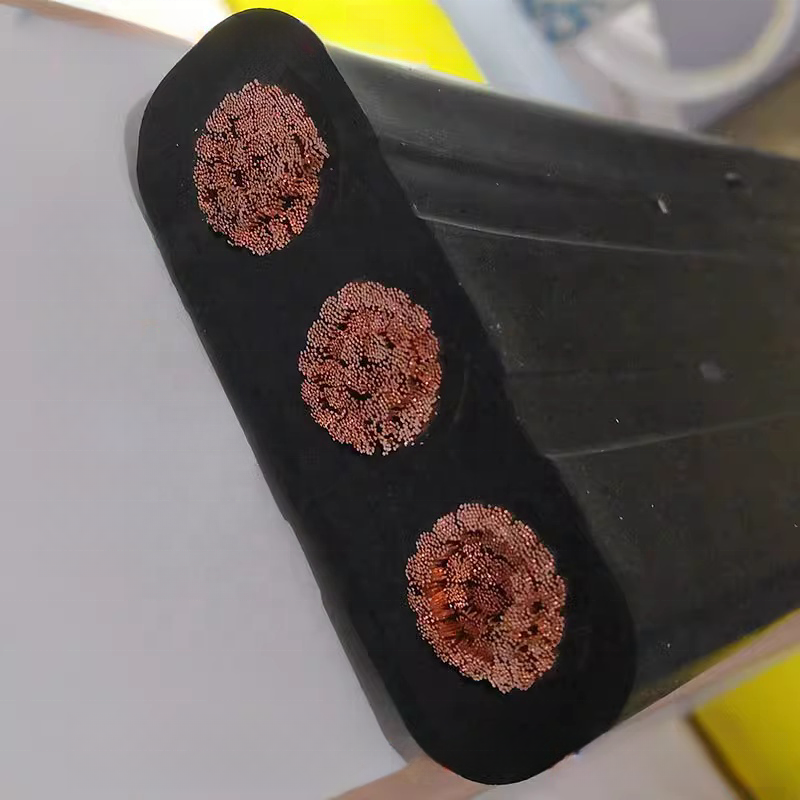

Round Traveling Cables

Round traveling cables are often selected for high-rise or high-speed installations. They usually incorporate steel support wires or aramid elements to carry the cable’s own weight over long vertical distances.

They are preferred when:

-

Travel height exceeds 150 meters

-

Higher speeds increase mechanical stress

-

Additional durability is required

Both designs can perform reliably when properly specified and installed.

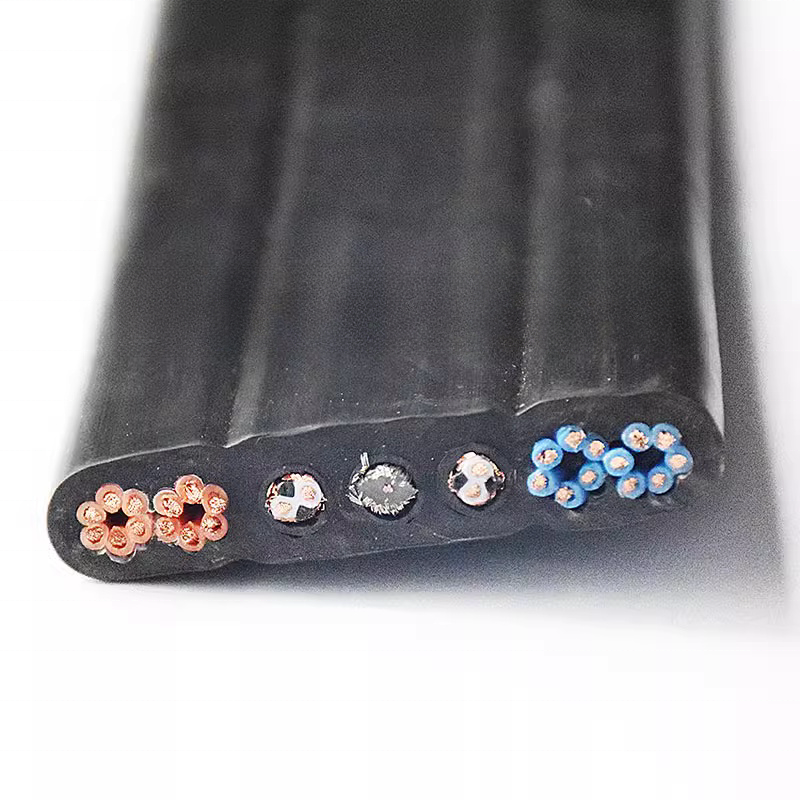

Hybrid Elevator Cables for Modern Buildings

As elevators become smarter, the role of the elevator cable has expanded beyond basic power and control.

Hybrid cables combine multiple functions in a single sheath, often including:

-

Power conductors

-

Shielded twisted pairs for control signals

-

Coaxial lines for video

-

Fiber optics for high-speed data

These cables are increasingly used in office towers, hotels, and smart buildings where elevators integrate with building management systems and remote diagnostics platforms.

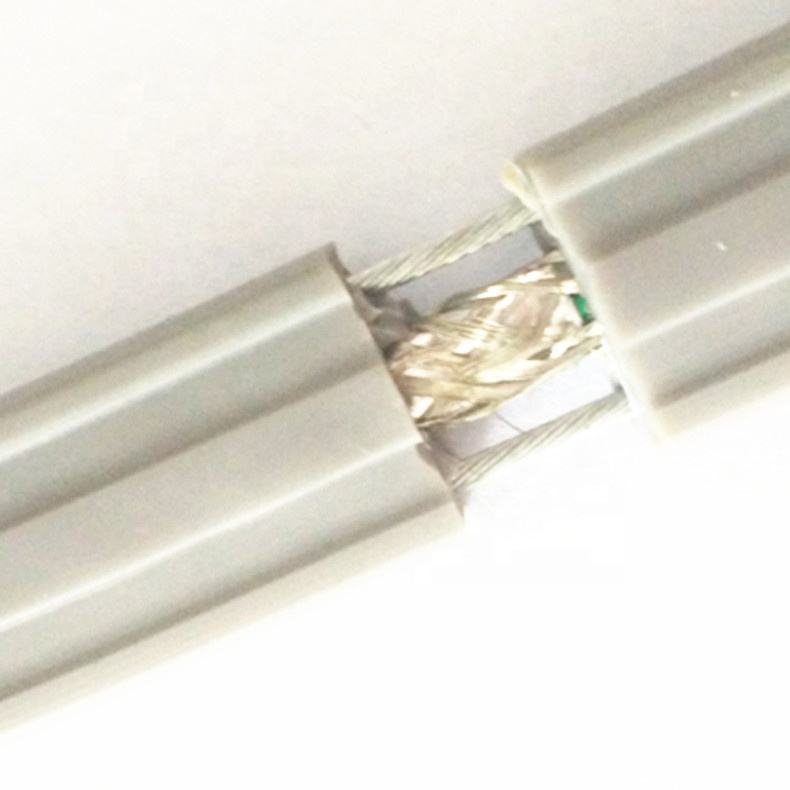

Key Design Features That Determine Cable Performance

Not all elevator cables are equal. Long-term reliability depends on several technical factors:

-

Conductor construction: Fine-stranded copper improves flexibility and fatigue resistance

-

Anti-torsion design: Prevents twisting during continuous travel

-

Support elements: Steel wires or aramid fibers relieve tensile stress

-

Shielding: Protects sensitive signals from electromagnetic noise

-

Jacket materials: PVC, TPE, or PUR chosen based on fire rating and environment

A well-designed elevator cable is tested for bend radius, tensile load, and flex life, often exceeding one million movement cycles.

Standards and Compliance Requirements

Elevator cables are governed by strict international and regional standards to ensure safety and performance.

Common references include:

-

EN 81 series (Europe)

-

EN 50214 for traveling cables

-

ASME A17.1 / CSA B44 (North America)

-

IEC flame retardancy tests

Compliance is not optional. Using non-certified cables can lead to inspection failures, increased risk, and costly retrofits.

Choosing the Right Cable for a Specific Elevator Project

Selecting the correct cable requires more than matching voltage ratings. Practical considerations include:

-

Total travel height and shaft layout

-

Elevator speed and duty cycle

-

Number of conductors required today and in the future

-

Environmental conditions inside the hoistway

-

Local regulatory requirements

Early coordination between designers, installers, and cable suppliers helps avoid compromises later in the project.

Installation and Maintenance Considerations

Even the best cable can fail prematurely if installed incorrectly.

Best practices include:

-

Maintaining minimum bending radii

-

Properly supporting cable loops to avoid tension

-

Preventing twisting during installation

-

Scheduling periodic visual and electrical inspections

In many cases, intermittent faults such as button failures or signal noise can be traced back to aging traveling cables.

How Elevator Cables Are Evolving

The elevator industry continues to push cable technology forward. Current developments include:

-

Increased use of fiber optics

-

Low-smoke, halogen-free materials

-

Embedded monitoring elements

-

Designs optimized for machine-room-less systems

These trends reflect the growing importance of reliability, sustainability, and data connectivity in vertical transportation.

Frequently Asked Questions

What cable is mainly used in elevators?

The traveling cable is the primary electrical cable used, supplying power, control, and data to the moving car.

Is an elevator cable the same as a hoist rope?

No. Hoist ropes are mechanical components; elevator cables carry electrical and communication signals.

How long does an elevator cable usually last?

With proper installation and maintenance, typically 15–25 years.

Can elevator cables support CCTV or internet?

Yes. Many modern designs include coaxial lines or fiber optics.

Are flat cables always the best choice?

Flat cables suit most mid-rise buildings, while round cables are better for high-rise or high-speed elevators.