Underwater Fiber Optic Cable: Everything You Need to Know

In an increasingly connected world, underwater fiber optic cables—also known as submarine fiber optic cables or subsea optical cables—form the invisible backbone of global communications. These advanced cable systems carry more than 99% of international internet traffic, enabling real-time video conferencing, cloud computing, financial transactions, streaming services, and global data exchange.

Unlike satellite communication, which supports only limited bandwidth and suffers from high latency, underwater fiber optic cables provide ultra-high capacity, low latency, and long-term reliability across oceans and seas. As demand from 5G, AI, cloud computing, and big data continues to rise, the strategic importance of underwater fiber optic infrastructure has never been greater.

This comprehensive guide explains what underwater fiber optic cables are, how they are built, where they are used, and why they matter, combining perspectives from global submarine networks and specialized subsea applications such as ROV and offshore systems.

What Is an Underwater Fiber Optic Cable?

An underwater fiber optic cable is a specialized optical cable designed to operate fully submerged in water—ranging from shallow coastal zones to the deepest parts of the ocean. These cables transmit data as pulses of light through ultra-thin strands of glass (optical fibers), achieving data rates far beyond traditional copper cables.

Broadly, underwater fiber optic cables fall into two categories:

-

Long-Haul Submarine Cables

These transoceanic systems span thousands of kilometers, connecting continents and global data hubs (e.g., transatlantic and transpacific routes). -

Short-Distance and Functional Subsea Cables

Used for offshore platforms, marine monitoring systems, renewable energy projects, and ROV (Remotely Operated Vehicle) umbilical cables, where fiber optics support real-time video and sensor data.

Modern underwater fiber optic cables can transmit terabits of data per second, supporting millions of simultaneous connections with minimal signal loss.

|

ROV Zero Buoyancy Composite Cable |

A Brief History of Underwater Fiber Optic Cables

The evolution of underwater communication began in the mid-19th century with copper telegraph cables. The first successful transatlantic cable in 1858 revolutionized global communication despite its limited reliability.

The real breakthrough came with fiber optics. In 1988, the TAT-8 system became the world’s first transoceanic fiber optic cable, instantly outperforming all copper predecessors in capacity and signal quality.

Since then, technologies such as:

-

Dense Wavelength Division Multiplexing (DWDM)

-

Erbium-Doped Fiber Amplifiers (EDFA)

-

Low-loss G.652 / G.654 fibers

have driven exponential growth in capacity. Today’s systems—such as Google’s Dunant or the 2Africa cable—deliver hundreds of terabits per second and define the modern internet.

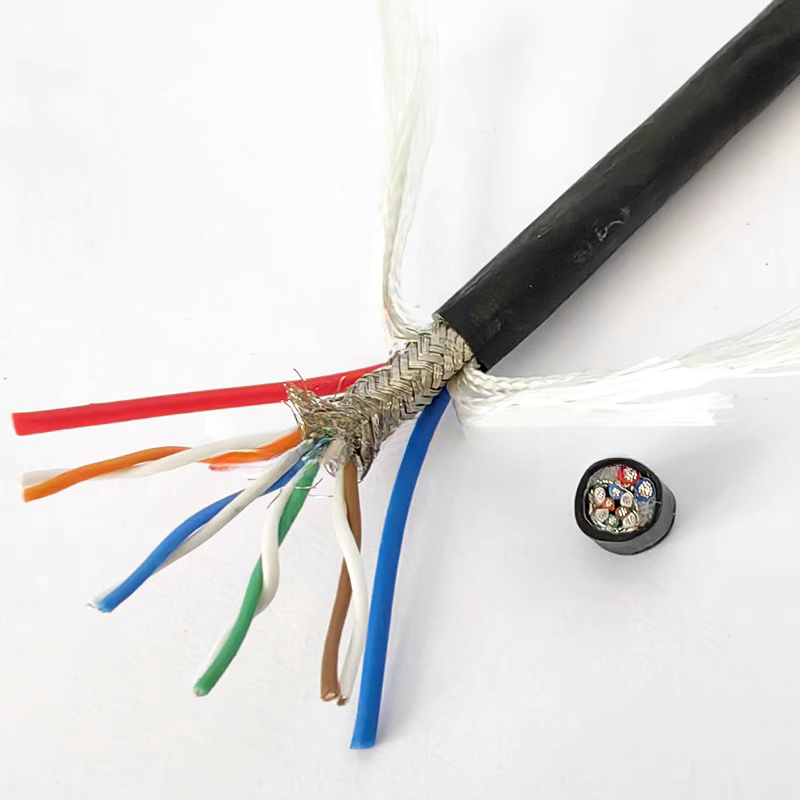

Structure of an Underwater Fiber Optic Cable

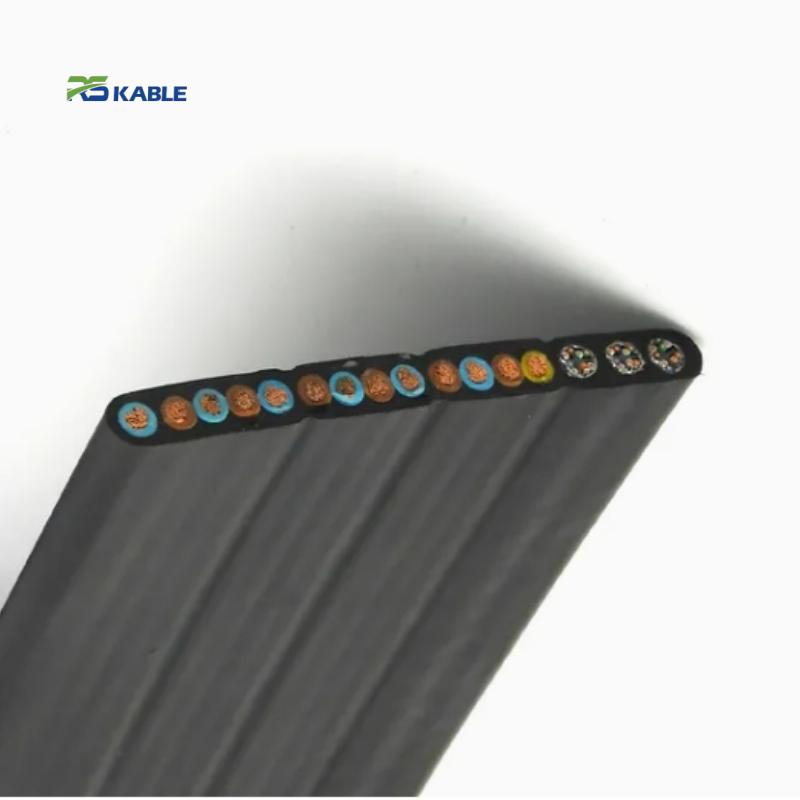

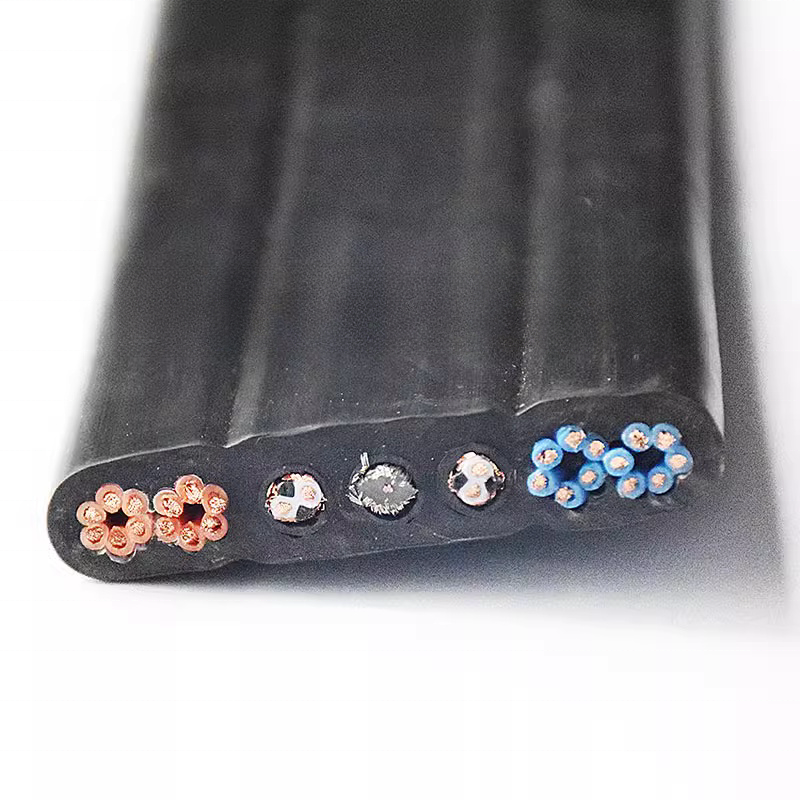

The ability of underwater fiber optic cables to survive extreme conditions lies in their multi-layered engineering design. Depending on depth and risk exposure, cable diameter typically ranges from 17 mm to over 70 mm, with weights from 1 to 10 kg per meter.

Typical Layer-by-Layer Construction

1. Optical Fiber Core

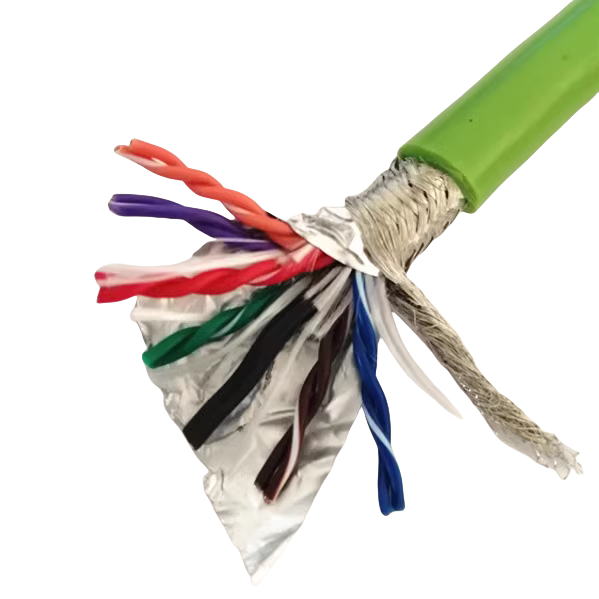

At the center are 4 to 192+ optical fibers, each about 125 microns in diameter. These high-purity silica fibers carry light signals with extremely low attenuation. Fibers are color-coded, gel-filled, and often housed in stainless steel tubes for water blocking.

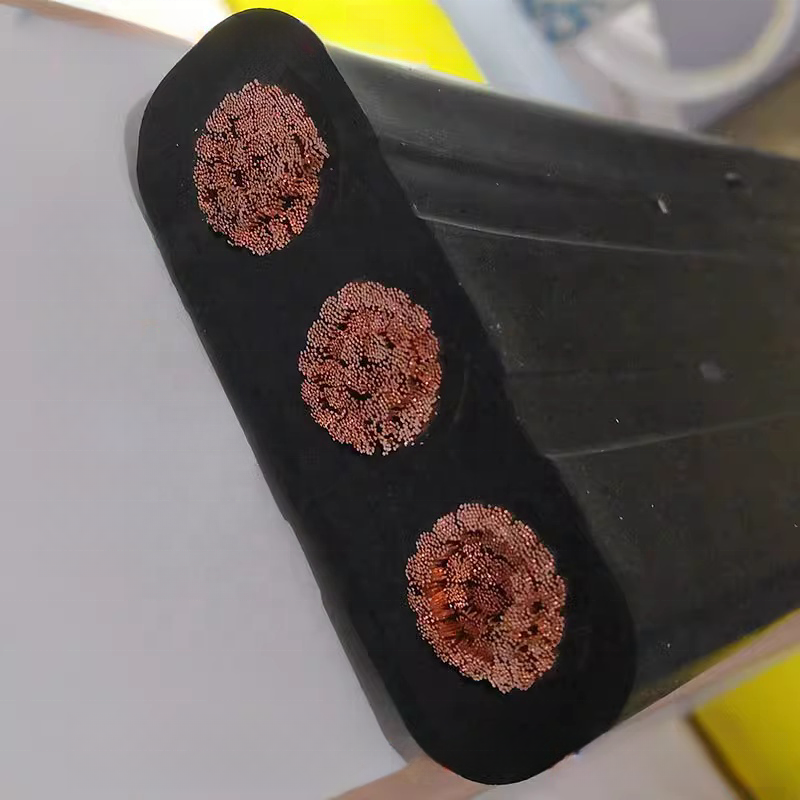

2. Strength Members and Power Conductors

Steel wires or aramid fibers (Kevlar®) provide tensile strength, enabling cables to withstand installation loads exceeding 100 tons. Copper conductors supply power to optical repeaters placed every 50–100 km in long-haul systems.

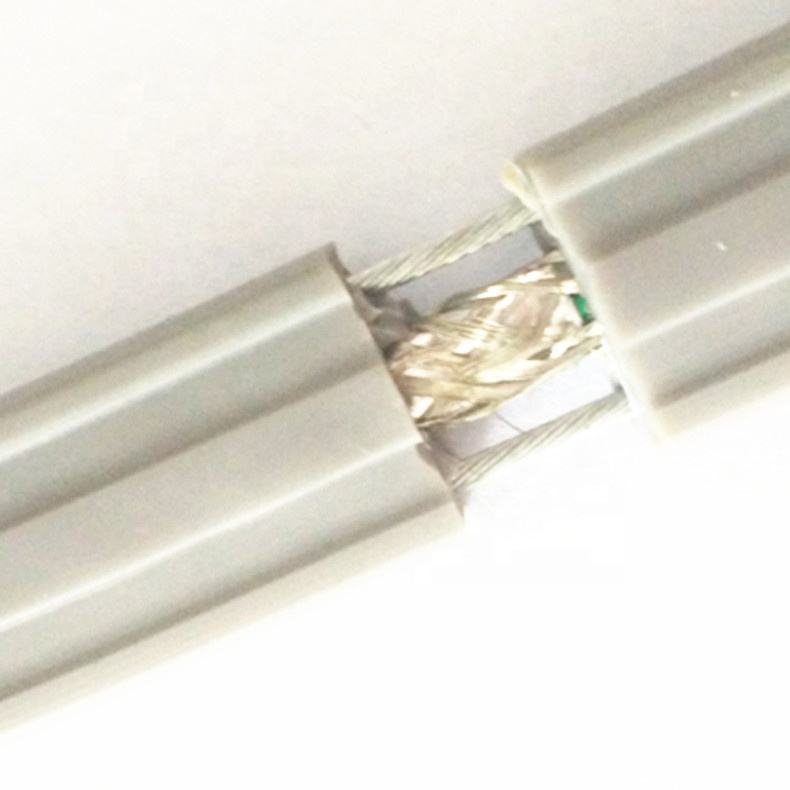

3. Water and Hydrogen Barriers

Metallic layers (aluminum or copper) and specialized compounds prevent moisture ingress and hydrogen penetration, which can degrade optical performance over time.

4. Insulation and Buoyancy Control

Polyethylene insulation protects internal components. In dynamic systems such as ROV fiber optic cables, foamed materials or syntactic compounds are added to achieve neutral buoyancy, reducing drag and improving maneuverability.

5. Armoring Layers

-

Lightweight (LW): Used in deep ocean where human activity is minimal

-

Single or Double Armored (SA/DA): Galvanized steel wires for shallow waters exposed to anchors and fishing

-

Kevlar-reinforced designs: Common in ROV and offshore applications for flexibility and cut resistance

6. Outer Jacket

The outer sheath—typically marine-grade polyethylene or polyurethane—protects against corrosion, abrasion, and biological growth.

Performance Characteristics of Underwater Fiber Optic Cables

Underwater fiber optic cables are designed for extreme performance:

-

Bandwidth Capacity: Up to 800+ Tbps per cable using DWDM

-

Latency: ~60–70 ms transatlantic (far lower than satellites)

-

Signal Loss: As low as 0.15–0.20 dB/km

-

Depth Capability: Exceeding 10,000 meters

-

Service Life: Typically 25–40 years in static installations

In ROV and dynamic subsea systems, neutral buoyancy fiber optic cables significantly reduce hydrodynamic drag, enabling precise control and longer operational life.

Applications of Underwater Fiber Optic Cables

1. Global Telecommunications

The primary application—supporting international internet traffic, cloud services, and financial networks.

2. Offshore Energy and Renewables

Used for monitoring and control in offshore oil & gas platforms, wind farms, and tidal energy systems.

3. Scientific Research and Ocean Observatories

Fiber optic subsea networks enable real-time seismic, environmental, and climate data collection.

4. ROV and AUV Operations

Hybrid electro-optical underwater cables combine fiber optics with power conductors, supporting HD video, sonar, and telemetry for deep-sea exploration, inspection, and salvage.

5. Defense and Security

Secure communication lines and underwater surveillance systems rely heavily on fiber optic technology.

Installation, Risks, and Maintenance

Installing underwater fiber optic cables requires specialized cable-laying vessels. In shallow water, cables are often buried 1–2 meters below the seabed, while deep-sea sections are laid directly on the ocean floor.

Common Threats

-

Fishing and anchoring (responsible for most faults)

-

Seismic activity and seabed movement

-

Abrasion and mechanical impact

Modern designs and routing strategies greatly reduce risks, while repairs are performed using grapnels and ROV-assisted splicing operations.

The Future of Underwater Fiber Optic Cable Technology

As global data demand accelerates, innovation continues:

-

Space Division Multiplexing (SDM) with multi-core fibers

-

Higher fiber counts in smaller diameters

-

Advanced composite materials for lighter, stronger cables

-

Integrated sensing for temperature, strain, and vibration monitoring

-

Increased use in offshore renewables and blue-economy projects

New routes in the Arctic and Asia-Pacific regions are also reshaping global connectivity.

FAQ

What is the difference between underwater and submarine fiber optic cables?

“Submarine” usually refers to long-haul ocean-crossing systems, while “underwater” also includes shorter subsea and ROV applications.

How much internet traffic do underwater fiber optic cables carry?

Over 99% of global international data traffic.

Can underwater fiber optic cables be damaged by sharks?

Early designs were vulnerable; modern armoring has largely eliminated this issue.

What is neutral buoyancy in underwater fiber optic cables?

A design where the cable has near-zero weight in water, reducing drag—critical for ROV systems.

How long do underwater fiber optic cables last?

Typically 25–40 years, depending on environment and maintenance.