Understanding Cable Types: Applications and Uses in Industry

In industrial operations, cables are rarely the center of attention—until something goes wrong. A production line stops, a sensor goes silent, or a motor behaves unpredictably. In many cases, the root cause is not the machine itself, but the cable connecting it.

Modern industrial systems depend on stable power delivery and reliable signal transmission across environments that are anything but forgiving. Heat, vibration, chemicals, constant motion, and electrical noise are everyday realities. This is why Industrial Cable solutions are engineered very differently from standard commercial wiring.

This article takes a practical look at industrial cable types, how they are actually used in real facilities, and what engineers and buyers should consider when selecting them. Rather than repeating catalog definitions, the focus here is on application-driven decisions, long-term reliability, and lessons learned from the field.

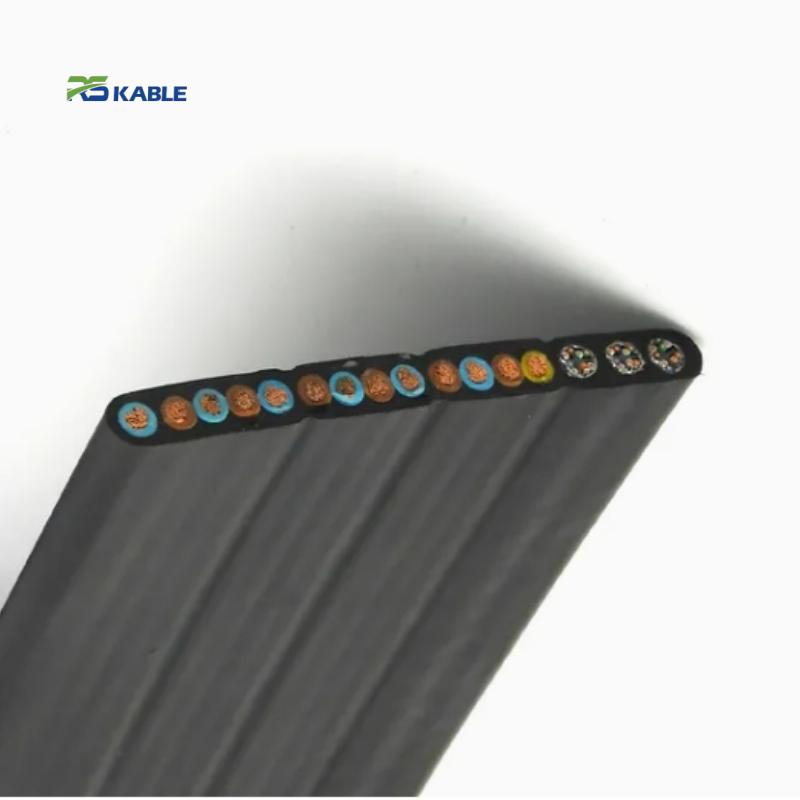

Custom TVVB Flexible Flat Lift Cable 0.75 mm – 3/4/7/12 Core Elevator Cable

A customizable TVVB flat flexible cable designed for elevator and lift applications with 0.75 mm² conductors in configurations of 3, 4, 7 and 12 cores. Engineered for continuous flexing in travelling and lifting environments, with PVC insulation and robust flat profile ideal for elevator systems.:contentReference

- Flexible flat TVVB design for elevator travelling cable applications

- Available in 3, 4, 7 and 12 core options at 0.75 mm² conductor size

- PVC insulation and sheath for wear and cold resistance

- Suitable for elevator, lift and hoist travelling systems

- Customizable specifications on request

The Role of Industrial Cables in Today’s Facilities

Industrial cables do far more than “carry electricity.” They connect control logic to physical action, transmit data that drives automation, and ensure safety systems respond instantly when conditions change.

As factories become smarter and more interconnected, cables must support:

-

Continuous operation with minimal downtime

-

Stable signals in electrically noisy environments

-

Mechanical movement without fatigue failure

-

Compliance with safety and fire regulations

A properly specified Industrial Cable becomes part of the system’s reliability strategy, not just a component on a bill of materials.

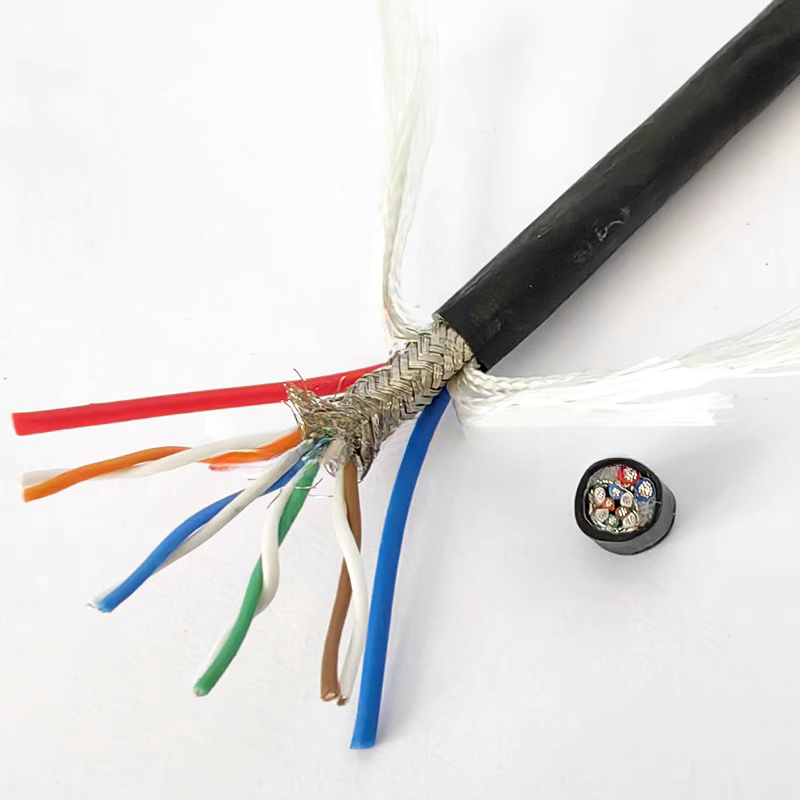

How Industrial Cables Differ from Standard Wiring

The difference between industrial and general-purpose cables lies in design intent.

Industrial cables typically feature:

-

Finely stranded conductors for flexibility and vibration resistance

-

Thicker or specialized insulation materials

-

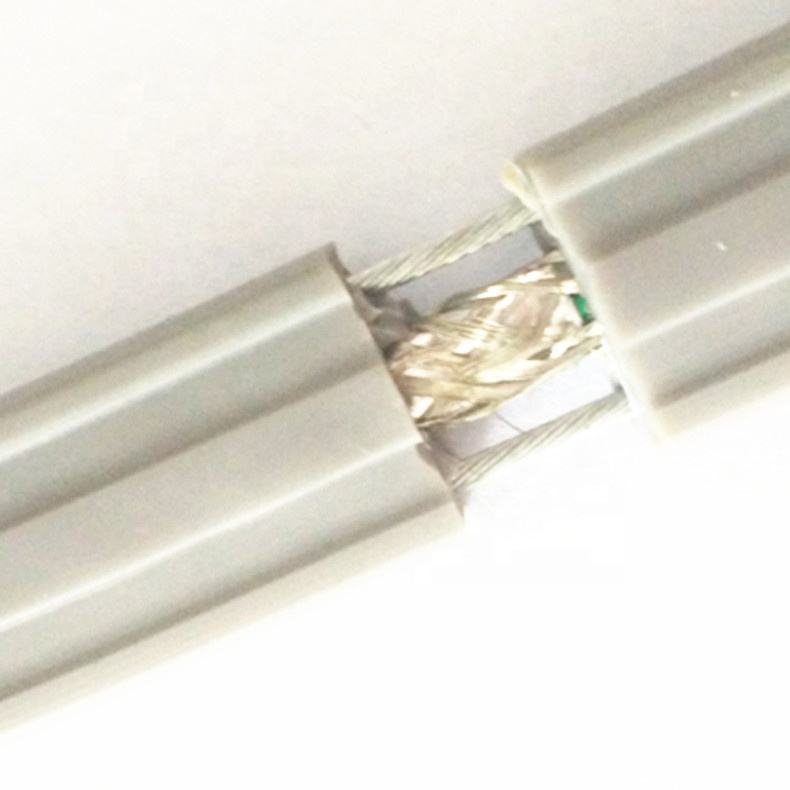

Shielding layers to control electromagnetic interference

-

Outer jackets resistant to oil, abrasion, UV, or chemicals

-

Defined performance limits tested against IEC or UL standards

These features are not optional upgrades—they are responses to real operating stresses found in factories, plants, and infrastructure projects.

Key Industrial Cable Types and Where They Are Used

Rather than listing cable types in isolation, it is more useful to understand them in the context of their working environments.

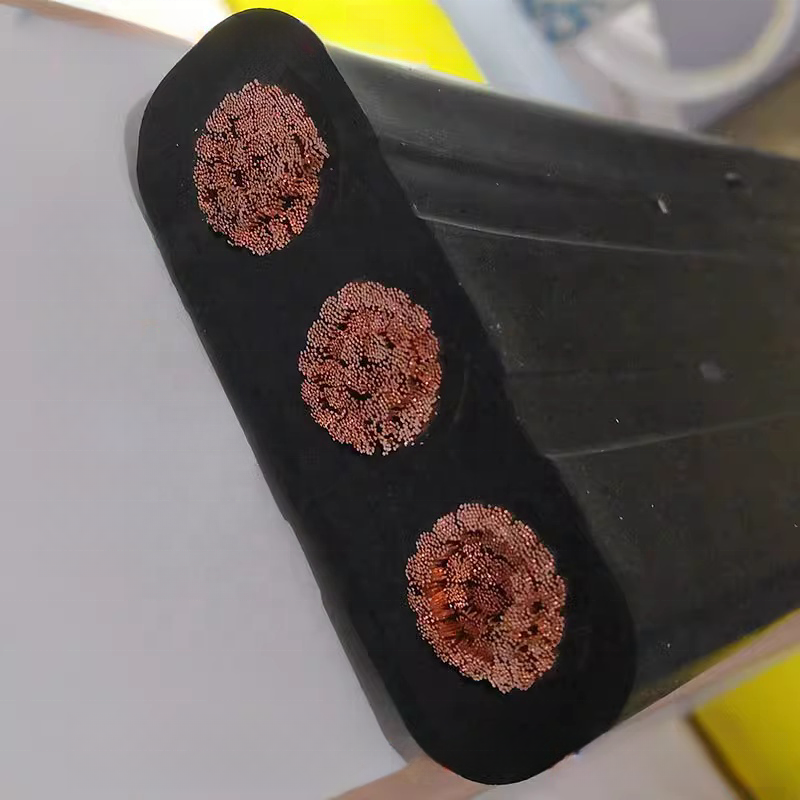

Power Cables for Equipment and Infrastructure

Power cables form the backbone of industrial energy distribution. They supply motors, transformers, switchgear, and fixed equipment.

In industrial settings, power cables are often:

-

Rated for higher temperatures than building wire

-

Installed in trays, conduits, or underground

-

Armored when exposed to impact or rodents

Applications range from manufacturing plants and mining operations to renewable energy installations.

Control Cables for Automation Systems

Control cables carry command signals between control panels, PLCs, and field devices. While voltage levels are lower, reliability is critical—signal loss can stop an entire process.

They are commonly used in:

-

Conveyor systems

-

Cranes and hoists

-

Packaging and assembly lines

Shielding is frequently required to prevent interference from nearby power cables or variable frequency drives.

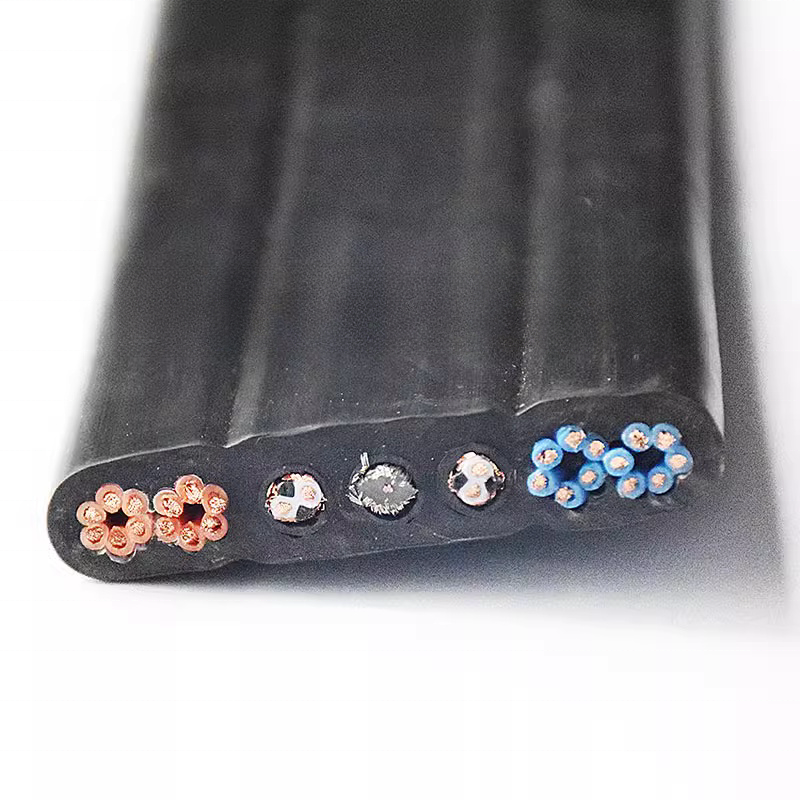

Instrumentation Cables for Accurate Measurement

Instrumentation cables support sensors and transmitters that monitor temperature, pressure, flow, or level. Signal integrity is essential, particularly in process industries.

Design features often include:

-

Twisted pair conductors

-

Individual or overall shielding

-

Low capacitance construction

These cables are widely used in power plants, chemical facilities, and oil and gas operations.

Flexible and Motion Cables in Dynamic Applications

Any application involving continuous movement demands special cable construction. Standard cables fail quickly when subjected to repeated bending or torsion.

High-flex industrial cables are found in:

-

Drag chain systems

-

Robotic arms

-

Automated storage equipment

They are tested for millions of movement cycles and represent one of the most technically demanding segments of the Industrial Cable market.

Data and Communication Cables in Smart Factories

With the growth of industrial networking, data cables are now as critical as power cables.

Industrial communication cables support:

-

Ethernet-based factory networks

-

Fieldbus systems

-

Fiber optic backbones

Compared to office-grade cables, industrial versions offer better noise immunity, temperature tolerance, and mechanical strength.

Specialty Cables for Extreme Conditions

Some environments require highly specialized solutions:

-

Elevator traveling cables designed for vertical motion

-

Marine and offshore cables with water-blocking layers

-

High-temperature cables for steel or glass production

-

VFD cables engineered to reduce motor stress and EMI

These applications highlight how application-specific industrial cable design can be.

Industrial Applications That Depend on Proper Cable Selection

Across industries, cable performance directly affects operational stability.

-

Manufacturing relies on flexible and shielded cables to keep automation synchronized.

-

Energy and utilities depend on durable power cables for long service life and safety compliance.

-

Oil, gas, and chemicals require resistance to heat, hydrocarbons, and hazardous atmospheres.

-

Infrastructure projects demand fire-resistant and weatherproof solutions.

In each case, cable failure can mean lost production, safety risks, or regulatory issues.

How to Choose the Right Industrial Cable

Selecting the right cable is less about finding the “best” product and more about matching specifications to reality.

Key questions include:

-

Will the cable move continuously or remain fixed?

-

Is it exposed to oil, chemicals, or UV radiation?

-

What temperature range will it experience?

-

Is electromagnetic interference a concern?

-

Which certifications are required by local regulations?

Balancing performance and cost is essential. Over-specification increases budget pressure, while under-specification leads to premature failure.

Common Cabling Challenges and How They Are Addressed

Industrial environments introduce predictable problems:

-

Electrical noise affecting signal stability

-

Mechanical fatigue in moving systems

-

Jacket degradation from oils or cleaning agents

Solutions often involve:

-

Improved shielding or fiber optics

-

High-flex conductor designs

-

Advanced jacket compounds such as PUR or LSZH

Experienced manufacturers typically validate these solutions through mechanical and environmental testing before release.

Installation and Maintenance Considerations

Even the best cable can fail if installed incorrectly.

Best practices include:

-

Respecting minimum bend radius

-

Providing strain relief at termination points

-

Separating power and signal routes where possible

-

Performing periodic inspections

Preventive maintenance often extends cable life far beyond initial expectations.

Frequently Asked Questions (FAQ)

What is the main difference between industrial and commercial cables?

Industrial cables are designed for harsher environments, with greater mechanical and environmental resistance.

Can one cable handle both power and data?

Hybrid cables exist, but they must be carefully designed to avoid interference.

Are industrial cables suitable for outdoor installation?

Yes, if they have UV-resistant and weather-rated jackets.

How long do industrial cables typically last?

Depending on conditions, service life can range from 10 to over 30 years.

Is shielding always necessary?

Not always, but it is critical in environments with high electrical noise.