The Ultimate Guide to ROV Cables: Everything You Need for Reliable Underwater Operations

Remotely Operated Vehicles (ROVs) have fundamentally changed how underwater work is carried out. Tasks that once required saturation divers or high-risk manned submersibles can now be completed remotely with greater precision and safety. Whether inspecting subsea pipelines, surveying offshore wind foundations, or documenting deep-sea ecosystems, ROVs depend on one critical component to function effectively—the ROV cable.

Often referred to as the umbilical or tether, this cable is far more than a simple connection between the vehicle and the surface. It is a carefully engineered system responsible for power delivery, real-time control, and high-bandwidth data transmission, all while operating under extreme mechanical and environmental stress.

This guide takes a practical, engineering-focused look at ROV cables: how they are designed, how they are used in real operations, what differentiates one type from another, and how to select and maintain the right cable for long-term reliability. If you work in subsea engineering, offshore operations, marine research, or ROV system integration, this article is written with your day-to-day realities in mind.

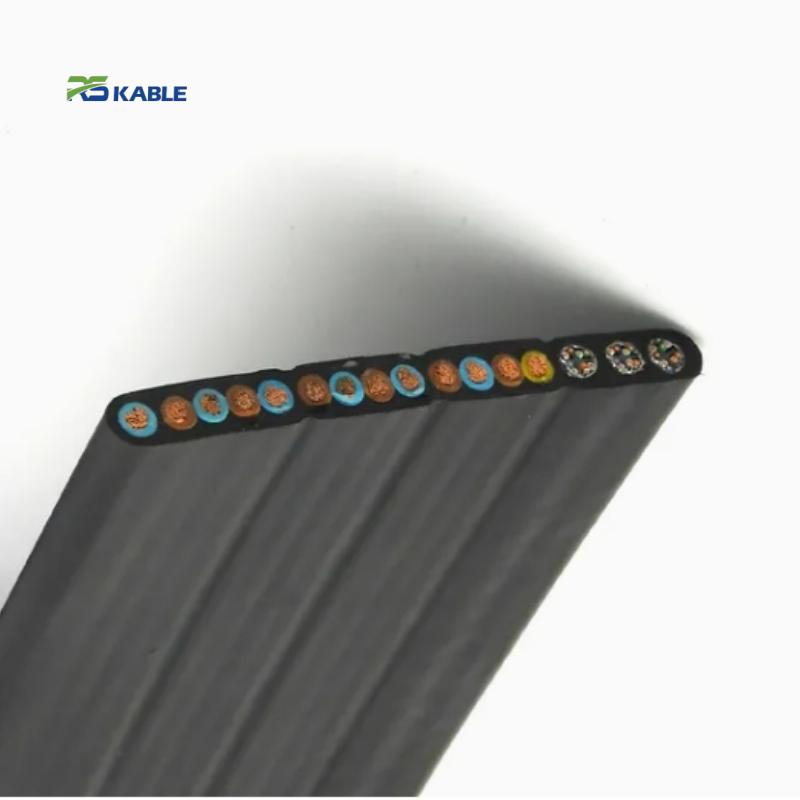

Neutral Buoyancy 2/4/6/8-core Underwater ROV Cable – 24AWG & 26AWG Power & Signal Tether

A neutrally buoyant underwater ROV tether cable integrating power and signal transmission with 24AWG and 26AWG cores, engineered for underwater robotics, subsea inspection, and marine exploration. Designed to balance buoyancy in water, ensuring reduced drag and stable operation under dynamic conditions.

- Neutral buoyancy design maintains balance and reduces drag in underwater deployment

- Multiple core configurations: 2, 4, 6 & 8 cores for versatile power and signal needs

- 24AWG & 26AWG twisted pair conductors for reliable power and signal transmission

- Durable waterproof jacket and insulation for subsea performance

- Ideal for ROV tether applications, marine inspections, and robotic control

Understanding the Role of an ROV Cable

At its core, an ROV cable forms the physical and functional link between a subsea vehicle and its control system. Through this single tether, multiple functions are handled simultaneously:

-

Electrical power is supplied to propulsion systems, lighting, and onboard tooling

-

Control commands are transmitted from the pilot to the vehicle

-

Video, sonar, and sensor data are returned to the surface in real time

Unlike static subsea cables that remain fixed on the seabed, an ROV cable is dynamic by nature. It must flex continuously, tolerate torsion as the vehicle rotates, and withstand tensile loads during launch, recovery, and operation in currents. This combination of electrical, mechanical, and environmental demands is what sets ROV cables apart from conventional underwater cabling.

Why ROV Cables Require Specialized Engineering

Standard industrial cables are not designed for the realities of subsea operations. In practice, an ROV cable must survive conditions that include:

-

Hydrostatic pressure increasing by approximately one bar every ten meters

-

Continuous exposure to saltwater and marine growth

-

Repeated bending cycles during maneuvering

-

Abrasion against seabed materials and offshore structures

Failure in any one of these areas can compromise an entire mission. As a result, cable design focuses on balancing durability, flexibility, signal integrity, and buoyancy—often with very tight tolerances.

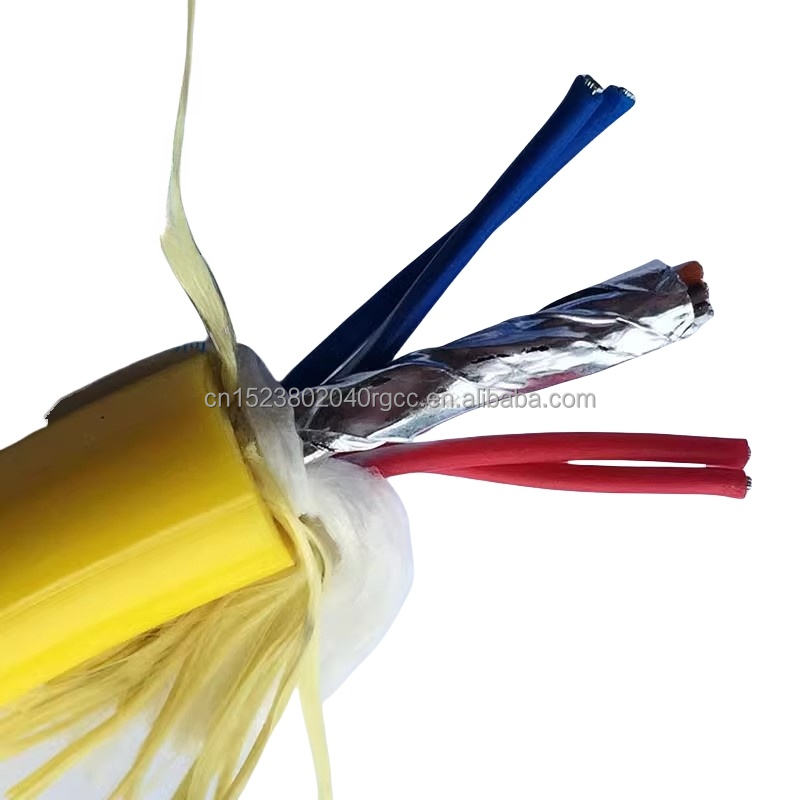

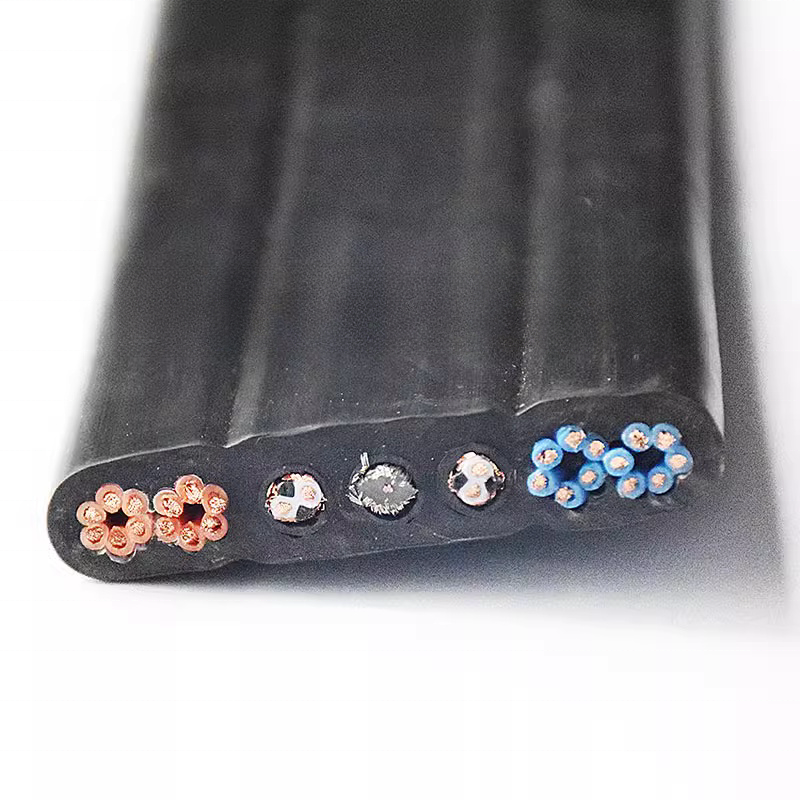

Key Structural Elements Inside an ROV Cable

While designs vary by application, most professional ROV cables share a common internal architecture.

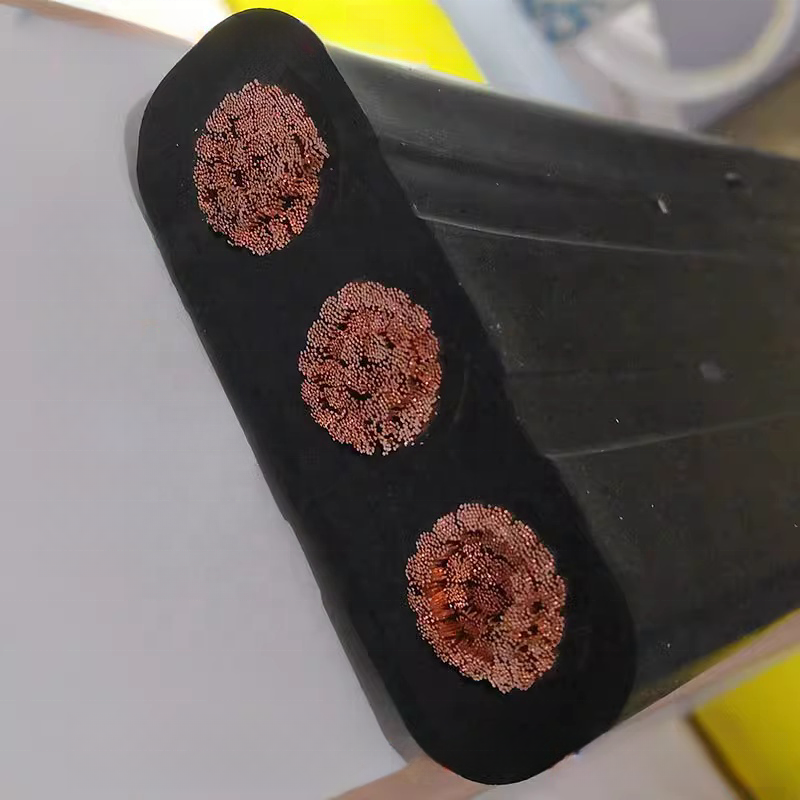

Power Conductors

Multi-stranded copper conductors deliver electrical power efficiently while remaining flexible. Tinned copper is frequently used to improve corrosion resistance in marine environments.

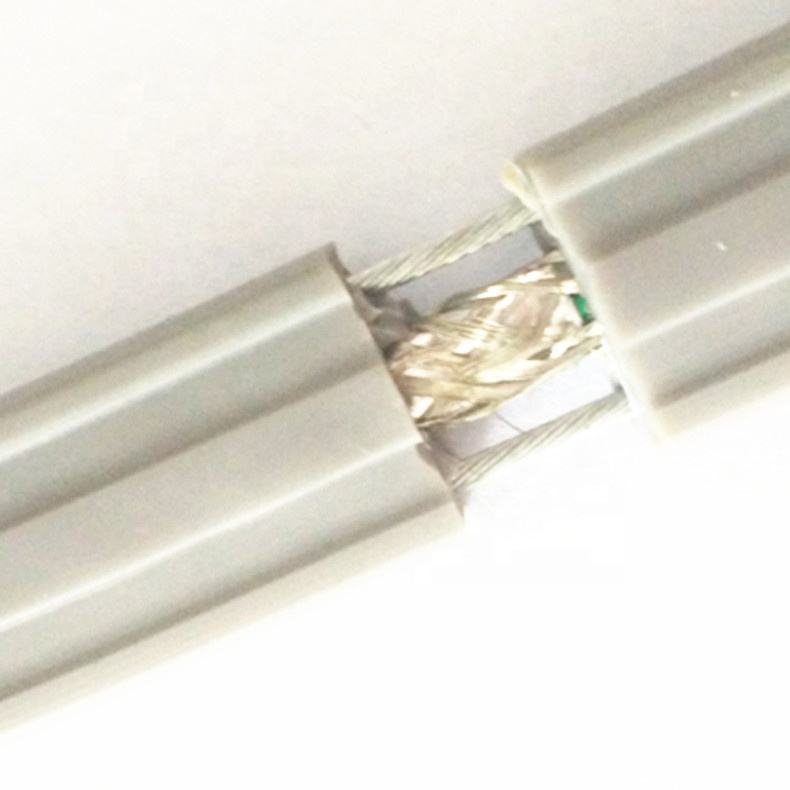

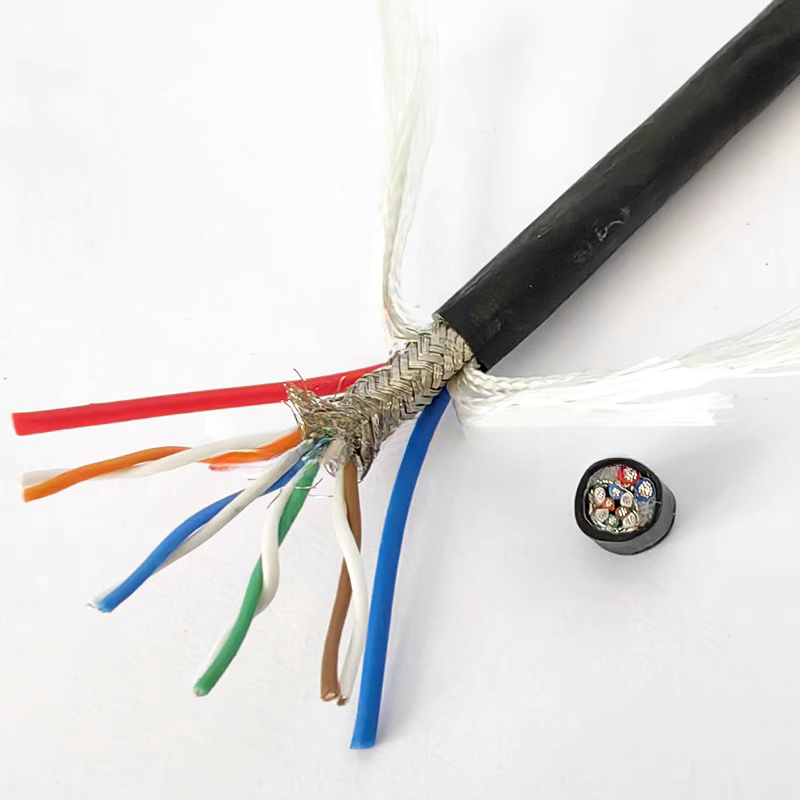

Data and Communication Cores

Modern systems increasingly rely on fiber optics to support high-definition video, low-latency control, and advanced sensor packages. Depending on system design, twisted pairs or coaxial elements may also be included.

Strength Members

To prevent mechanical loads from damaging conductors or fibers, tensile forces are absorbed by dedicated strength elements. These are typically aramid fibers for lightweight systems or steel wires in heavy-duty configurations.

Protective Outer Jacket

The outer sheath provides the first line of defense against abrasion, chemicals, and UV exposure during deck handling. Polyurethane and polyethylene remain the most common jacket materials due to their proven performance offshore.

Buoyancy Control and Its Impact on Performance

Buoyancy is one of the most critical—and often underestimated—factors in ROV cable performance.

A neutrally buoyant ROV cable neither sinks nor floats excessively in water. This balance reduces drag, minimizes stress on the vehicle’s thrusters, and improves pilot control, particularly during precision tasks. Achieving neutral buoyancy requires careful selection of materials, fillers, and jacket thickness, tailored to the intended operating depth.

In contrast, negatively buoyant or armored cables may be preferred for short-tether or high-abrasion environments, where robustness outweighs maneuverability.

Common Types of ROV Cables in Practice

Different missions call for different cable designs.

Observation-class ROVs typically use slim, lightweight tethers optimized for flexibility and video transmission. These are common in inspections, aquaculture monitoring, and shallow-water surveys.

Work-class ROVs require heavier umbilicals capable of transmitting higher power levels and supporting subsea tooling. These cables often include steel reinforcement and are designed for deepwater operations.

Hybrid electro-optical designs have become the industry standard, integrating power conductors and fiber optics within a single cable to reduce complexity and improve reliability.

Most commercial projects rely on custom configurations rather than generic off-the-shelf products, particularly when operating conditions are demanding.

Real-World Applications Across Industries

ROV cables enable a wide range of underwater activities:

-

Offshore oil and gas inspections, maintenance, and intervention

-

Installation and monitoring of subsea renewable energy infrastructure

-

Scientific research, including deep-sea sampling and habitat mapping

-

Search, recovery, and forensic investigations

-

Defense and security operations in ports and coastal zones

In each case, cable reliability directly affects operational efficiency, safety, and cost control. A damaged or poorly specified cable can halt operations entirely.

Selecting the Right ROV Cable for Your Project

Choosing an appropriate ROV cable starts with a clear understanding of operational requirements.

Key considerations include maximum operating depth, required length, power demand, data bandwidth, and environmental exposure. Handling characteristics—such as minimum bend radius and weight in water—are equally important, particularly for long-duration missions.

From a procurement standpoint, certifications and test data matter. Reputable manufacturers provide documentation covering tensile strength, fatigue performance, and compliance with relevant offshore standards.

Handling, Maintenance, and Common Failure Points

Even the best-designed cable will fail prematurely if mishandled.

Proper spooling, controlled deployment, and regular inspection significantly extend service life. Abrasion damage, water ingress, and conductor fatigue are among the most common failure modes, and all are preventable with disciplined operating procedures.

Routine electrical testing, visual inspections, and proper storage between campaigns should be considered standard practice rather than optional maintenance.

Frequently Asked Questions About ROV Cables

What makes an ROV cable different from a standard underwater cable?

Dynamic flexing, multi-function integration, and extreme pressure resistance set them apart from static power or communication lines.

How long do ROV cables typically last?

10–20 years with proper maintenance, depending on usage intensity.

Can ROV cables be repaired underwater?

Surface repairs are standard; deep splices require specialized ROV tools.

What’s the maximum depth for commercial ROV cables?

Over 10,000 meters for specialized systems, though most operate under 6,000 meters.

Are all ROV cables neutrally buoyant?

Not all—some are positively or negatively buoyant for specific handling needs.

How much power can an ROV cable transmit?

From hundreds of watts for small vehicles to several kilowatts for work-class systems.