Servo Cable vs. Motor Cable: What’s the Real Difference?

It’s a common scenario on the factory floor. You have a machine down, a deadline looming, and a spool of cable in the maintenance closet. It looks right, it feels heavy-duty, but is it the right tool for the job? Confusing a standard motor cable with a servo motor cable is an easy mistake to make, but the consequences can be expensive—ranging from signal interference and jittery machine performance to complete system failure.

While both cables share a similar job description—delivering power to an electric motor—their internal engineering is worlds apart. One is a blunt instrument designed for raw power; the other is a precision tool built for communication and control.

If you are building a new automated system or retrofitting a CNC machine, understanding these nuances is critical. This guide breaks down exactly what sets these two cable types apart, why the industry color-coding standards matter, and how to choose the right option for your specific application.

What is a Motor Cable?

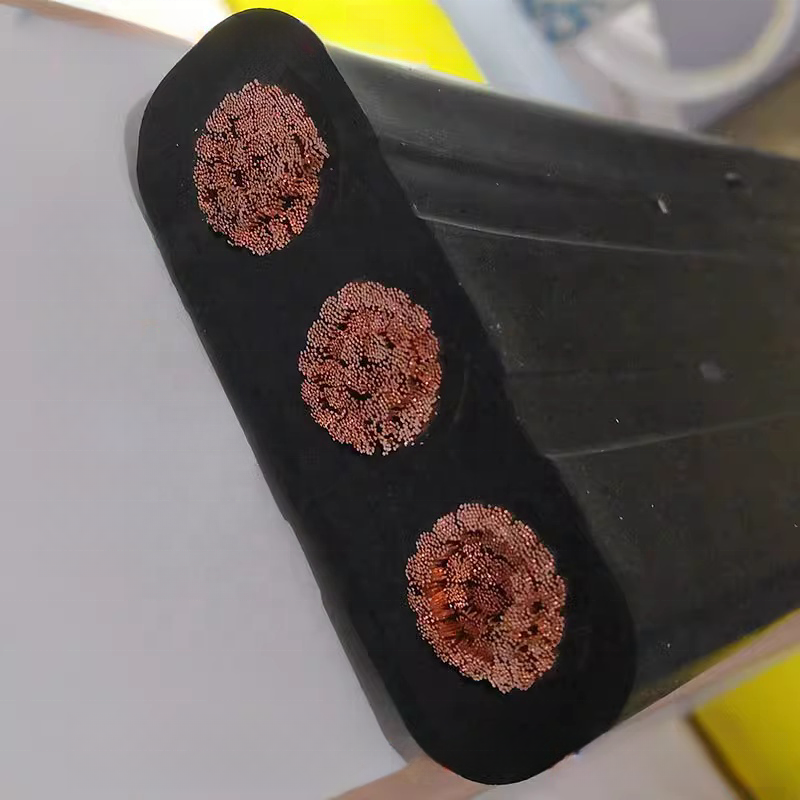

To understand the difference, we first need to look at the standard motor cable. In industrial automation, a “motor cable” typically refers to the cabling used to power three-phase induction motors. These are the workhorses of the industry, driving pumps, fans, conveyors, and compressors.

Construction and Design

A standard motor cable is relatively straightforward in its design. It generally consists of four main conductors:

- Three Phase Conductors: These carry the electrical current (L1, L2, L3) to drive the motor.

- One Ground Conductor: Usually green and yellow (PE), serving as the protective earth connection.

Because induction motors generally run continuously or effectively “blind” (without sending constant position data back to a drive), the cable’s primary job is simply to handle the voltage and current load.

Electrical Stress and VFDs

Modern motor cables, however, have to survive significant electrical stress. With the rise of Variable Frequency Drives (VFDs), motor cables must withstand the high-frequency voltage spikes caused by Pulse Width Modulation (PWM). If you use a standard building wire instead of a VFD-rated motor cable, the insulation can break down rapidly, leading to short circuits. Therefore, high-quality motor cables often feature specialized insulation materials like XLPE (Cross-linked Polyethylene) to handle these surges.

What is a Servo Motor Cable?

A Servo Motor Cable is a much more complex assembly. Servo systems are not designed just to spin; they are designed to move to a precise position, hold that position, and adjust speed with millisecond accuracy. To achieve this, the drive needs to know exactly what the motor is doing at all times.

The Feedback Loop

This is the defining feature of a servo system: the closed-loop feedback system. A servo motor doesn’t just receive power; it often has an integrated encoder, resolver, or temperature sensor that sends data back to the drive.

Consequently, a servo cable often has to do double duty. It must transmit high-energy power to the motor while simultaneously protecting sensitive low-voltage signals returning from the motor’s brakes or temperature sensors.

Internal Architecture

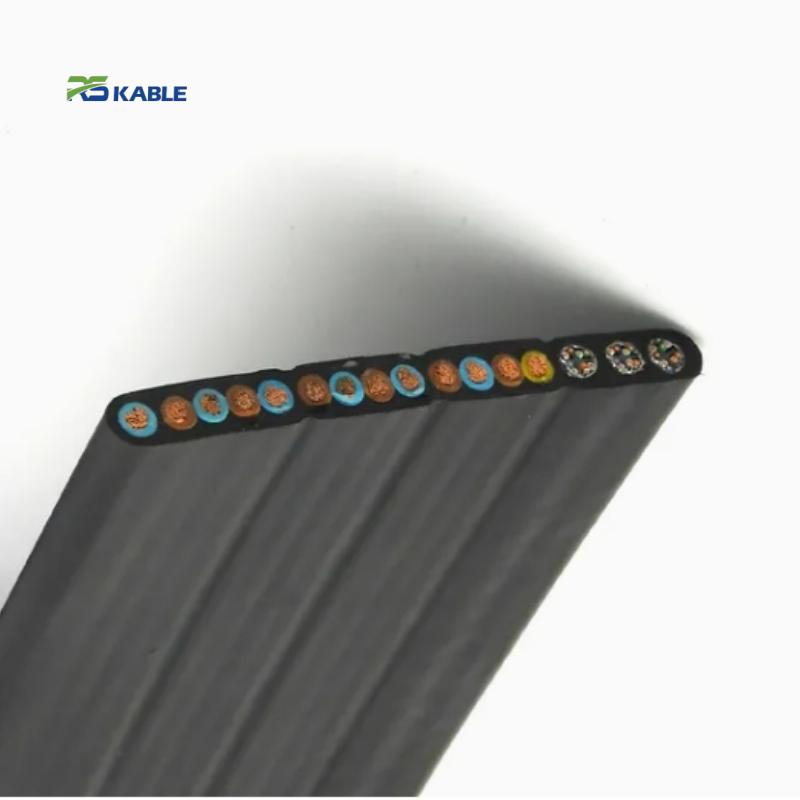

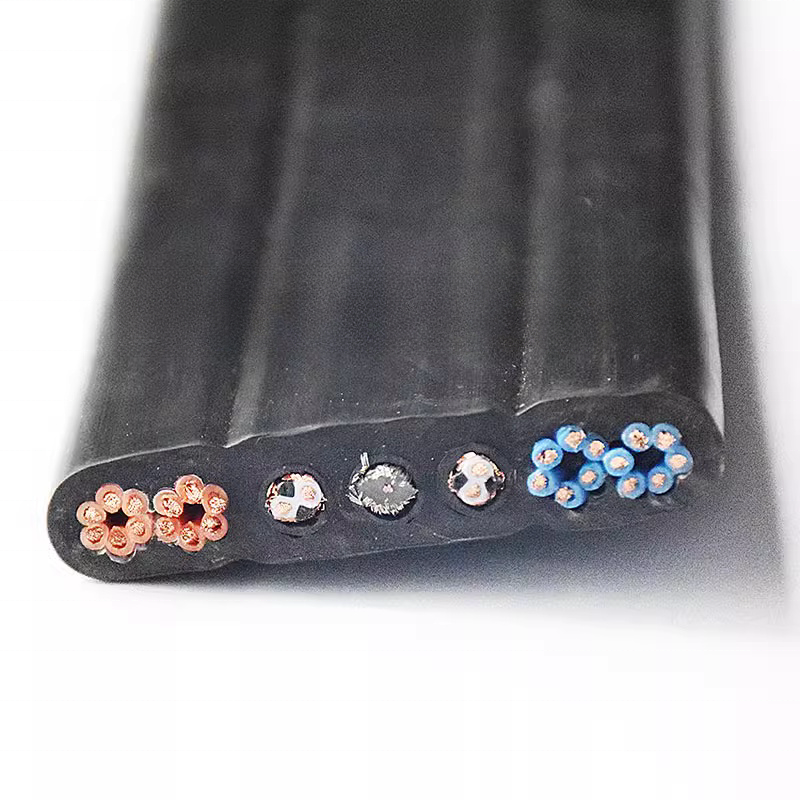

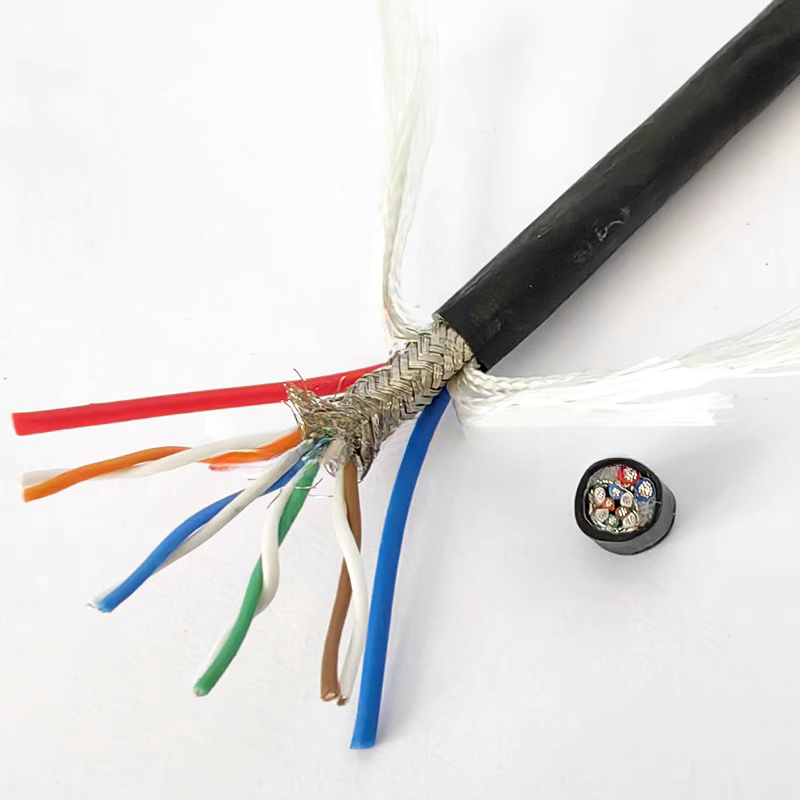

If you were to slice open a servo cable, you would likely see:

- Power Conductors: Four main cores for the motor power (just like the standard motor cable).

- Signal Pairs: One or two twisted pairs of smaller wires. These connect to the electromagnetic brake or temperature sensors.

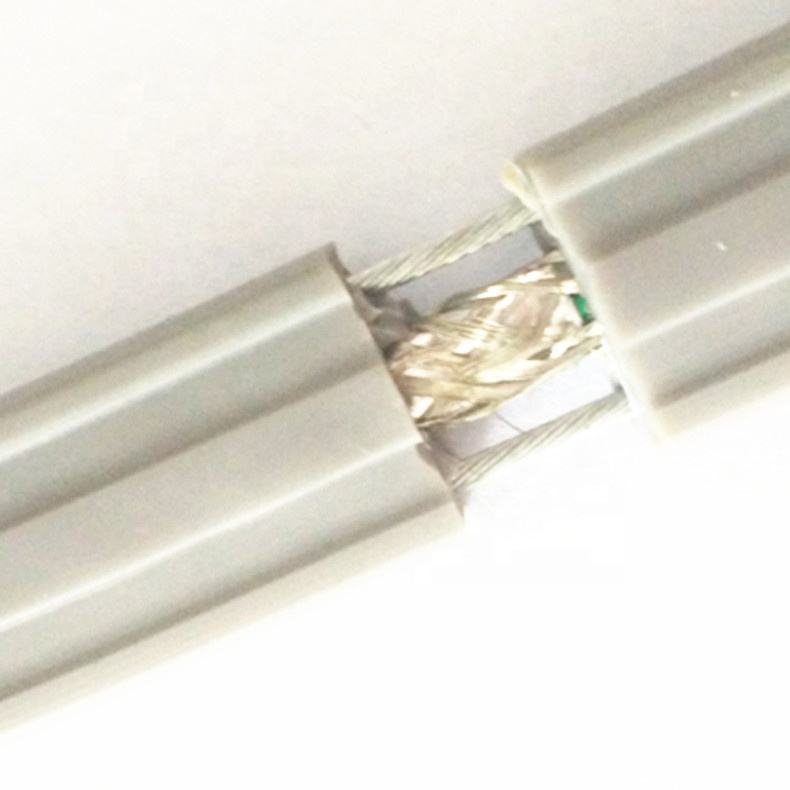

- Heavy Shielding: This is non-negotiable. Because the power wires are carrying noisy, high-voltage PWM signals right next to sensitive sensor wires, servo cables require an overall braided shield (and often individual foil shields on the signal pairs) to prevent Electromagnetic Interference (EMI).

The 4 Key Differences You Need to Know

When comparing a standard VFD cable against a servo option, four main distinctions stand out: Function, Shielding, Color Standards, and Flexibility.

1. Functionality: Power vs. Precision

The most fundamental difference lies in the application. Standard motor cables are designed for open-loop systems where the motor runs at a set speed. The drive sends power, and the motor spins.

Servo cables support closed-loop systems. They are part of a conversation between the drive and the motor. The drive commands the motor to move, and the motor’s feedback devices confirm the movement. If the cable fails to protect that feedback signal (due to poor shielding or crosstalk), the drive gets confused, leading to positioning errors or fault codes.

2. Shielding and EMC

Electromagnetic Compatibility (EMC) is the silent killer of industrial electronics. Servo drives switch voltage on and off thousands of times per second, creating massive amounts of electrical noise.

- Motor Cables: May be unshielded (if run in conduit) or have a basic foil/braid shield to keep noise from escaping and affecting nearby sensors.

- Servo Cables: Almost always feature a high-coverage tinned copper braid shield (often 85% coverage or higher). This is critical because the Servo Motor Cable often runs in long cable trays alongside data cables. Without robust shielding, the “noise” from the power conductors would corrupt the data signals, causing the machine to behave erratically.

3. The DESINA Color Standard

How do you tell them apart without cutting them open? The industry relies on the DESINA (Distributed and Standardized Installation Technology) standard to keep things organized.

- Motor Cables (Black): According to DESINA, power cables for standard motors typically have a black outer jacket (RAL 9005).

- Servo Cables (Orange): Servo cables are easily identified by their pastel orange jacket (RAL 2003).

While not every manufacturer follows this rule strictly—especially for custom or legacy installations—it is the dominant standard for modern CNC machines and automation cells. If you see an orange cable in a cable track, you can safely assume it is a shielded servo cable.

4. Flexibility and Drag Chains

Servo motors are frequently mounted on moving parts of a machine—think of a robotic arm or the gantry of a laser cutter. This means the cable isn’t static; it moves, bends, and twists millions of times over its lifespan.

High-performance servo cables are often engineered specifically for “continuous flex” or drag chain applications. They use ultra-fine copper stranding (Class 6) and low-friction jacket materials like PUR (Polyurethane) to withstand millions of cycles without the copper work-hardening and snapping. While you can buy flexible standard motor cables, dynamic flexibility is a more common requirement for servo applications.

Can You Use a Motor Cable for a Servo Motor?

This is a frequent question from technicians looking to save money or use stock on hand. The short answer is: It depends, but usually no.

You can physically connect a standard motor cable to the power terminals of a servo motor. The electricity will flow, and the motor will spin. However, you will face two major problems:

- Missing Connections: Standard motor cables lack the twisted signal pairs required for the servo’s holding brake or temperature thermistor. If your servo motor has these features, a standard 4-core motor cable cannot support them. You would need to run a second, separate cable for those signals, which is messy and inefficient.

- Interference: If you use an unshielded or poorly shielded motor cable, the electrical noise generated by the servo drive can interfere with the encoder feedback (even if the encoder runs on a separate cable). This “noise” can cause the drive to trip on over-current faults or lose its position.

The Exception: If your servo motor uses a separate connector for power and feedback (common in larger motors) and does not have a brake or thermal sensor wired through the power connector, you might be able to use a high-quality, shielded VFD motor cable. However, sticking to a dedicated orange servo cable is always the safer bet for reliability.

The Evolution: Hybrid Cables (One Cable Technology)

The automation industry hates clutter. Running two cables (one for power, one for feedback) to every motor on a 6-axis robot adds weight and complexity. This has led to the rise of Hybrid Cables, often called Single Cable Solutions or One Cable Technology (OCT).

In a hybrid setup, the digital encoder signal is robust enough to be transmitted over wires bundled inside the same jacket as the power wires. These advanced Servo Motor Cable designs integrate the power, brake control, and digital feedback into a single orange cable. This reduces installation time by 50% and allows for smaller cable chains, but it requires specialized cable engineering to prevent the high-power AC voltage from corrupting the digital data streams.

Selection Guide: Choosing the Right Cable

When selecting a cable for your machine, don’t just grab the first orange spool you see. Consider these factors to ensure longevity:

1. Static vs. Dynamic Installation

Is the motor stationary (bolted to the floor) or moving (on a gantry)?

- Static: A standard PVC jacket is usually sufficient and cost-effective.

- Dynamic: If the cable is moving inside a drag chain, you need a cable rated for continuous flex. Look for a PUR (Polyurethane) or TPE jacket, which resists abrasion and constant bending. Check the manufacturer’s “minimum bend radius”—ignoring this is the #1 cause of cable failure.

2. Chemical Environment

What is the environment like? If the cable is exposed to cutting fluids, coolants, or mineral oils (common in CNC machining), a PVC jacket might harden and crack over time. Polyurethane (PUR) is the gold standard for oil resistance in harsh machining environments.

3. Capacitance Matters

Long cable runs act like a capacitor. If you are running a Servo Motor Cable longer than 50 meters, the capacitance of the cable can cause voltage drops or drive faults. You may need a specialized “low capacitance” cable (often using Polypropylene insulation on the cores) to maintain signal integrity over long distances.

4. Certification

Are you shipping this machine to the US or Canada? Ensure the cable is UL or CSA listed. In Europe, CE and RoHS compliance are the standards to watch. Using a non-certified cable can cause significant headaches during final electrical inspections.

Frequently Asked Questions

What does the orange cable color mean in automation?

According to the DESINA standard, an orange jacket (RAL 2003) indicates a servo cable. This signals to maintenance personnel that the cable is shielded and likely carries both power and control signals for a servo system.

Why do servo cables need shielding?

Servo drives generate high-frequency electrical noise (EMI) due to their rapid switching. Shielding prevents this noise from escaping and interfering with sensitive electronics, sensors, and data cables nearby. It also protects the internal signal wires from external interference.

What is the difference between VFD cable and servo cable?

A VFD cable is a shielded power cable designed for AC motors controlled by variable frequency drives. It typically handles power only. A servo cable is similar but often includes additional twisted pairs for braking and temperature monitoring and is built to higher flexibility standards for motion control applications.

Can I repair a damaged servo cable?

It is not recommended to splice or repair a dynamic servo cable that moves in a drag chain. The splice changes the bend radius and creates a weak point that will likely fail again. For static cables, repairs are possible if the shielding is maintained 360 degrees around the splice to ensure EMC protection.

While they may look similar on the spec sheet, standard motor cables and servo cables are designed for different realities. The motor cable is a bulk power delivery system, while the Servo Motor Cable is a sophisticated component of a precision motion control system.

Cutting corners by using the wrong cable might save a few dollars upfront, but the cost of chasing down intermittent “ghost” faults or replacing a cable that cracked in a drag chain will far outweigh those savings. When in doubt, follow the orange standard—if it involves precision motion, it needs a precision cable.