Submarine Cable FAQs: Everything Businesses Need to Know About the Backbone of Global Internet

In today’s global economy, reliable international connectivity is not a luxury—it’s a strategic asset. Companies stream data across continents, coordinate supply chains in real-time, and manage cloud-based operations spanning multiple countries. Yet most decision-makers overlook the physical infrastructure that enables this: submarine cables lying quietly on the ocean floor.

These cables carry more than 99% of international data traffic. Satellites provide headline coverage, but their capacity and latency limitations make them unsuitable for enterprise-scale operations. Modern subsea fiber optic cable systems ensure predictable, high-speed connectivity, linking continents and islands to critical markets. This guide addresses the key questions business leaders should ask about submarine cables—their function, ownership, risks, and operational impact.

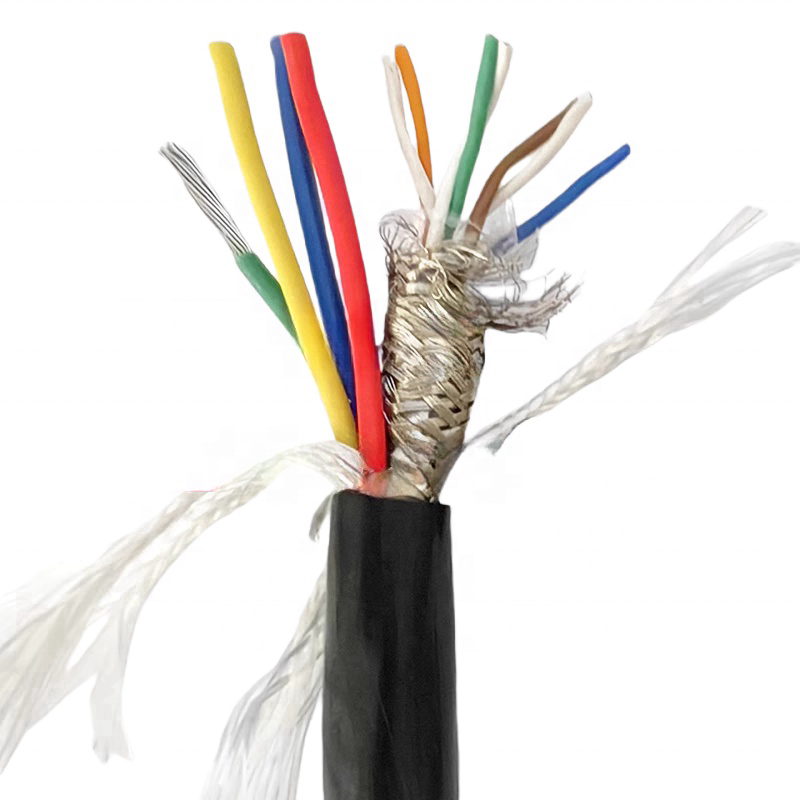

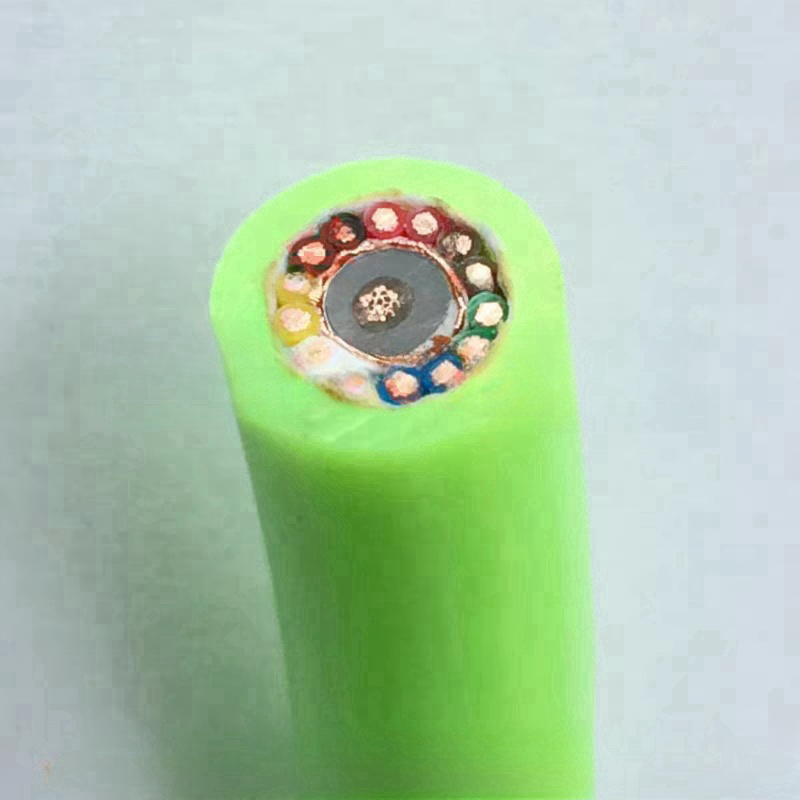

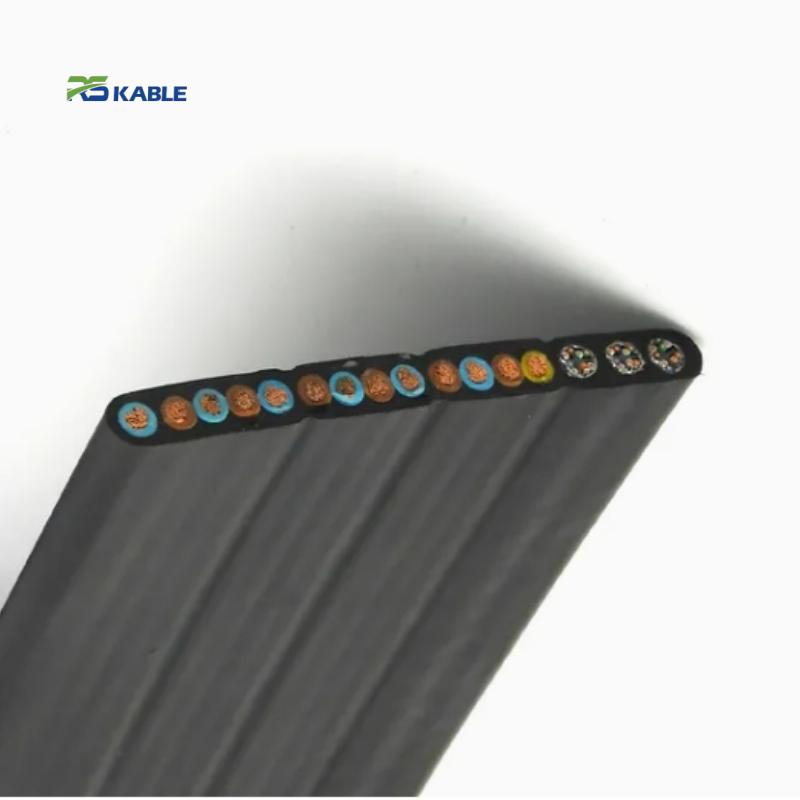

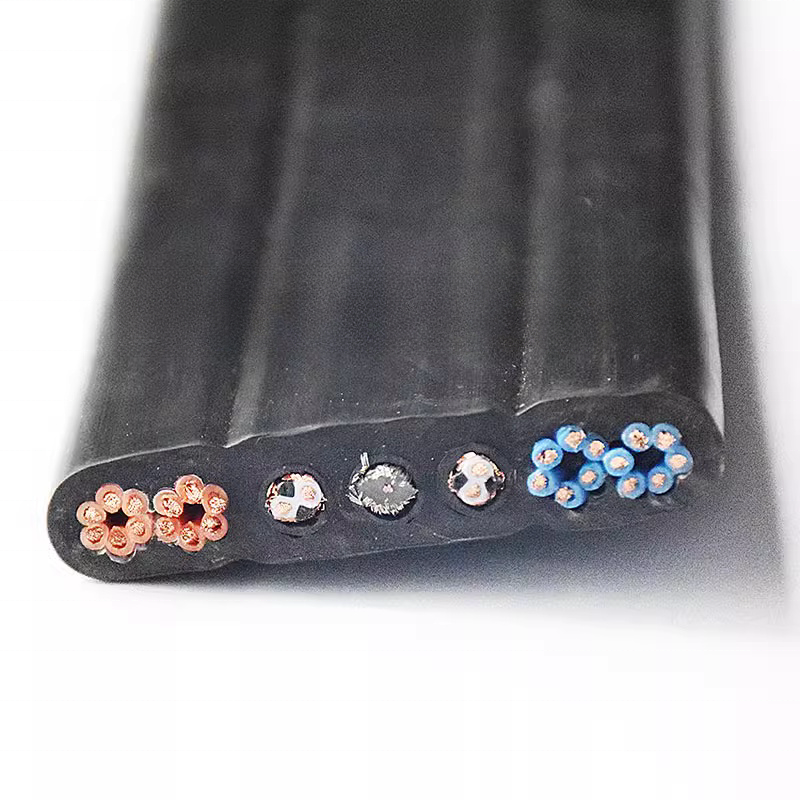

Wholesale Stranded Conductor Polyethylene Insulated Underwater ROV Cable – Neutral & Zero Buoyancy Features

A specialized underwater ROV tether cable featuring stranded conductors and polyethylene insulation for robust power and signal performance. Designed with neutral and zero buoyancy characteristics to maintain stable suspension in water without excess drag or flotation, ideal for marine operations, subsea robotics, and offshore deployments. :contentReference[oaicite:1]{index=1}

- Stranded conductor for enhanced flexibility and durability

- PE (Polyethylene) insulation for water resistance and longevity

- Neutral & zero buoyancy design for underwater stability

- Suitable for ROV tether, subsea robotics, and marine exploration

What Is a Submarine Cable and Why Does It Matter for Businesses?

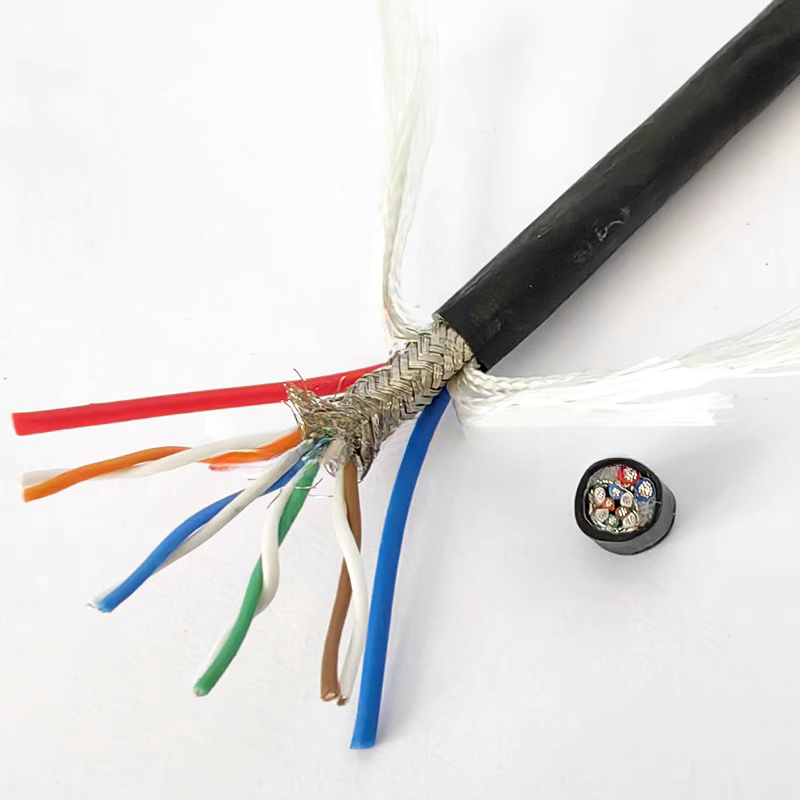

A submarine cable is an engineered system designed to transmit signals or data underwater between land points separated by oceans or seas. Today, nearly all are subsea fiber optic cables—bundles of ultra-pure glass fibers that carry data as pulses of light.

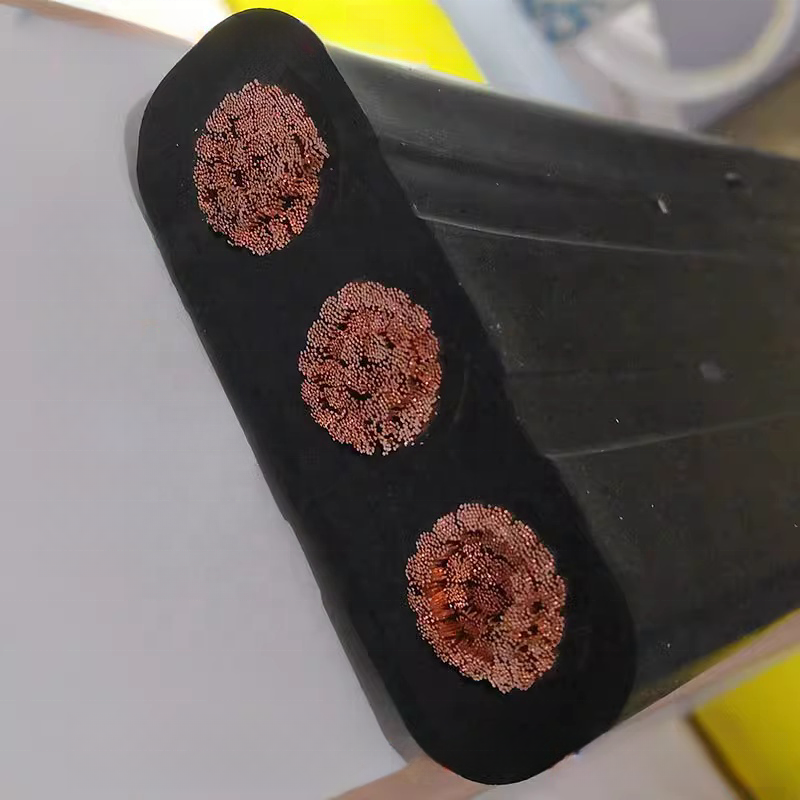

From a B2B perspective, the value is not just connectivity but predictable operational performance. Each cable typically has multiple fiber pairs (8–24), allowing redundancy and high-volume throughput. Protective layers—including gel-filled tubes, steel wire armoring, and polyethylene jackets—ensure durability under harsh marine conditions. For enterprises relying on continuous cloud access, financial transactions, or real-time logistics tracking, these cables are critical digital infrastructure.

Unlike terrestrial networks, submarine cables are hard assets: their placement, protection, and maintenance directly affect network risk management and operational costs.

Why Businesses Can’t Rely on Satellites Alone

Satellites excel for broadcast or remote monitoring, but for enterprise-grade traffic, they are inadequate. Latency-sensitive applications—like financial trading platforms, collaborative work environments, or high-frequency logistics management—cannot tolerate the delays inherent in geostationary or low-Earth-orbit links.

A trip from Asia to North America via satellite can exceed 240 milliseconds, while the same route over a subsea fiber optic cable typically takes 60–80 milliseconds. This difference directly impacts transaction speed, application responsiveness, and customer experience.

From a cost perspective, satellites are expensive to scale. Subsea cables, on the other hand, offer predictable long-term operational budgets, upgradeable capacity, and energy-efficient repeaters, making them a more strategic choice for enterprise network planning.

How Does Data Travel Through Subsea Fiber Optic Cable?

For business users, understanding the operational process informs investment and risk decisions. At shore landing stations, electrical signals are converted into light by lasers and transmitted through fiber pairs.

-

Repeaters every 50–100 km amplify the signal.

-

Copper conductors embedded in the cable provide power to repeaters.

-

Protective armoring and jackets mitigate mechanical and environmental risks.

For enterprises, the advantage is reliability at scale. Messages traverse oceans in milliseconds, with monitoring systems detecting and flagging faults automatically. Companies can plan mission-critical applications without worrying about unpredictable interruptions.

How Are Submarine Cables Installed and Maintained?

Submarine cable installation is a multi-year engineering project:

-

Route survey and planning: Avoid earthquake zones, shipping lanes, and sensitive habitats.

-

Cable manufacturing: Continuous lengths built to specification, then loaded onto cable-laying vessels.

-

Deployment: Shallow sections buried for protection; deep ocean sections laid on the seabed.

-

Branching and testing: Units added to serve multiple countries; end-to-end testing ensures operational readiness.

For businesses, maintenance strategy drives uptime and cost control. Most faults occur in shallow waters due to human activity—anchors, fishing, and dredging. Rapid-response repair ships equipped with ROVs (remotely operated vehicles) can restore service within days, minimizing disruption to enterprise operations.

Investing in redundancy—multiple cable paths, regional branching—allows businesses to mitigate risk and ensure continuous service even during localized failures.

Ownership, Security, and Strategic Considerations

Ownership has shifted from national telecoms to a mix of private tech giants and specialized operators:

-

Google, Meta, Microsoft, and Amazon invest in direct routes for their data centers.

-

SubCom, Alcatel Submarine Networks, and others handle manufacturing and deployment.

For enterprises, this translates into assured service quality and clear contractual accountability. Physical access in deep waters is tightly controlled, and data is protected end-to-end with encryption. Shallow landing stations are monitored and secured as critical infrastructure, ensuring compliance with corporate and regulatory standards.

Lifecycle, Upgrades, and Investment Value

Subsea fiber optic cables have a design life of 25 years, but capacity and performance can often be extended through terminal equipment upgrades. From a business perspective:

-

Predictable service life allows long-term network planning.

-

Upgrades without full replacement reduce capital expenditure.

-

Artificial reef effect provides environmental compliance benefits for corporate sustainability goals.

Knowing when to replace or expand cable routes is critical for enterprise planning—especially for companies dependent on continuous, high-volume international traffic.

Businesses must understand trends shaping subsea fiber optic cable infrastructure:

-

Higher fiber counts and modular upgrades enable scalable bandwidth for growing operations.

-

Diversified routing reduces vulnerability to localized faults.

-

Strategic investment by hyperscale cloud operators ensures routes are designed for decades, not just years.

For enterprise IT and network teams, these trends inform risk assessment, vendor selection, and investment in long-term connectivity infrastructure.

Frequently Asked Questions for Business Decision-Makers

How many submarine cables exist globally?

Over 500 active systems totaling more than 1.4 million kilometers—enough to circle Earth 35 times.

Can submarine cables be tapped?

Extremely difficult in deep water; end-to-end encryption secures enterprise data.

Do shark bites threaten cables?

Modern armoring has largely eliminated this risk.

What happens during major cuts?

Traffic automatically reroutes over parallel paths; isolated regions may experience temporary outages.

Are new cables being built for AI and cloud workloads?

Yes, enterprises and hyperscale operators are driving high-capacity direct routes to support these demands.

How much does a typical project cost?

$200 million to over $1 billion, depending on length, fiber count, and landing points.