ROV Neutral Buoyancy Tether Cable: Essential Guide for Underwater Precision

In underwater robotics, the performance of a Remotely Operated Vehicle (ROV) is shaped not only by thrusters, sensors, or control software, but also by the tether connecting the vehicle to the surface. For missions that demand stable positioning and fine maneuverability, the ROV neutral buoyancy tether cable plays a decisive role.

Unlike conventional tethers that either sink or float, a neutral buoyancy design is engineered to remain suspended in the water column. This balance allows the ROV to move naturally, without the tether introducing unwanted drag or vertical pull. For inspection, survey, and research operations, this difference is immediately noticeable in vehicle handling and data quality.

This guide explains how neutral buoyancy tether cables work, why they are used, how they are built, and what to consider when selecting one for real-world subsea operations.

High-Tensile Neutral Buoyancy ROV Umbilical Cable – Flexible Subsea Robotics Tether Cable

A high-tensile, neutrally buoyant ROV umbilical tether designed for subsea robotics and underwater operations. Built to provide robust power and signal transmission while remaining flexible and abrasion-resistant under dynamic underwater conditions such as marine exploration and offshore inspection.

- Neutrally buoyant design minimizes drag and improves handling in submerged environments

- High tensile strength for reliable performance under mechanical load

- Flexible subsea cable construction for dynamic movement and deployment

- Combines power, control and signal transmission for ROV and robotics systems

- Waterproof and durable outer jacket for long term marine use

Understanding Neutral Buoyancy in ROV Tethers

Every ROV cable has weight, stiffness, and hydrodynamic behavior that affects how the vehicle responds underwater. When a tether is negatively buoyant, it tends to pull the ROV downward, increasing thruster load and reducing depth control accuracy. When it is positively buoyant, it can rise into the water column, creating loops that interfere with maneuvering or snag on structures.

A neutral buoyancy tether is designed so that its weight in water is close to zero. This is achieved by balancing the density of internal conductors, strength members, and protective layers against the surrounding seawater. The goal is not perfect buoyancy under all conditions, but a predictable, stable behavior that minimizes external forces acting on the vehicle.

Why Neutral Buoyancy Matters in Practical Operations

In controlled test environments, almost any tether may seem adequate. In open water, the difference becomes clear. Neutral buoyancy tethers provide several operational advantages:

-

Improved vehicle control: The ROV responds directly to pilot commands without compensating for tether drag.

-

Lower mechanical stress: Reduced tension extends cable service life and lowers failure risk.

-

Cleaner inspection results: Stable positioning improves video clarity and sensor accuracy.

-

Energy efficiency: Thrusters consume less power maintaining position.

-

Safer operation near structures: Less risk of snagging or uncontrolled cable movement.

For operators working around offshore wind foundations, pipelines, or sensitive habitats, these benefits translate into higher productivity and reduced operational risk.

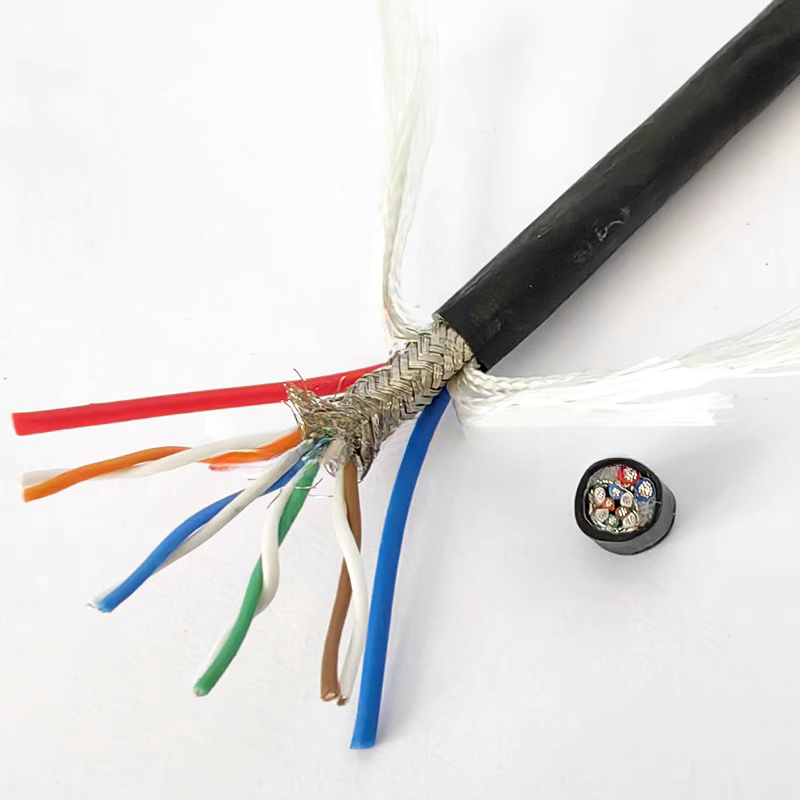

How Neutral Buoyancy Tether Cables Are Built

Achieving neutral buoyancy is the result of careful engineering rather than a single material choice. A typical neutral buoyancy ROV cable includes several coordinated elements:

-

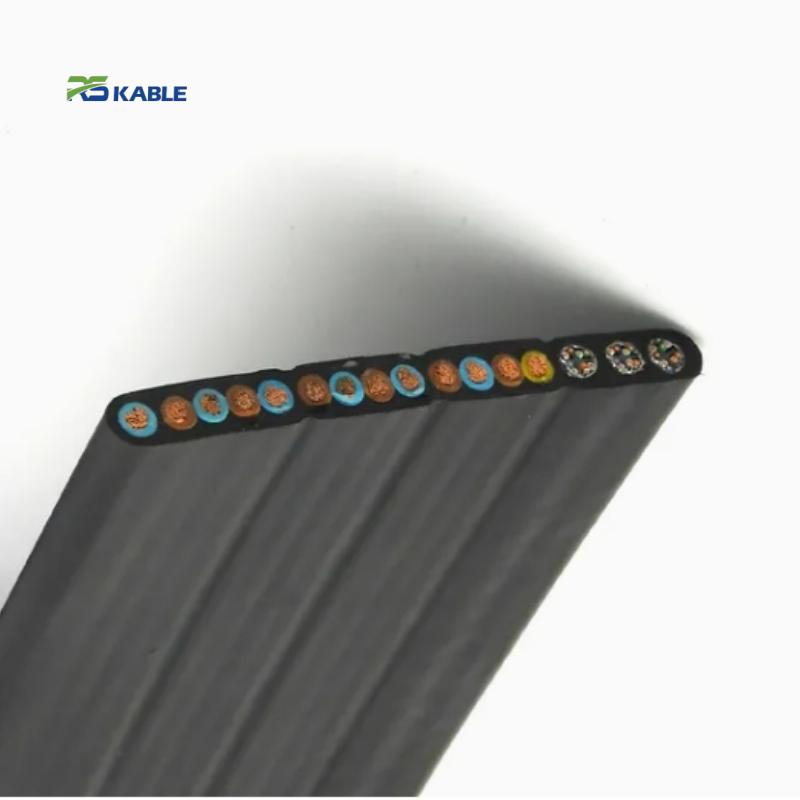

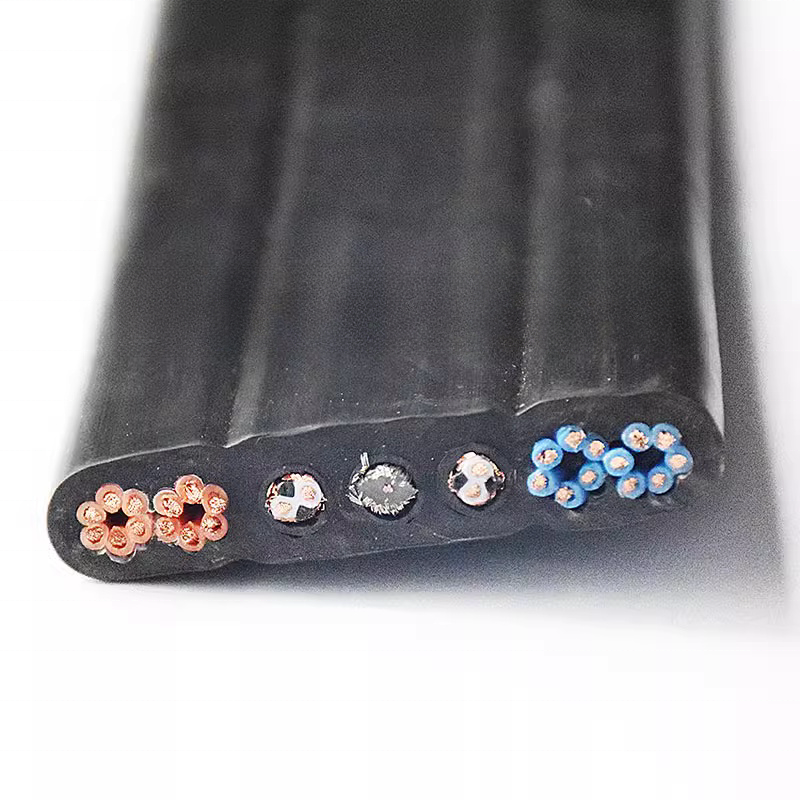

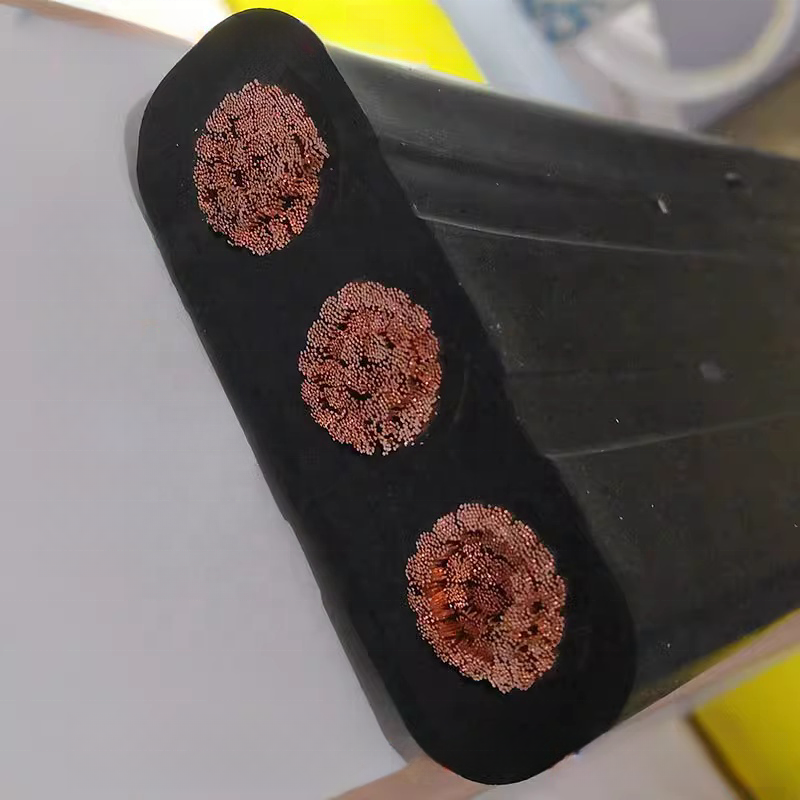

Electrical and data cores: Fine-stranded copper conductors supply power, while fiber optics or twisted pairs transmit video and telemetry.

-

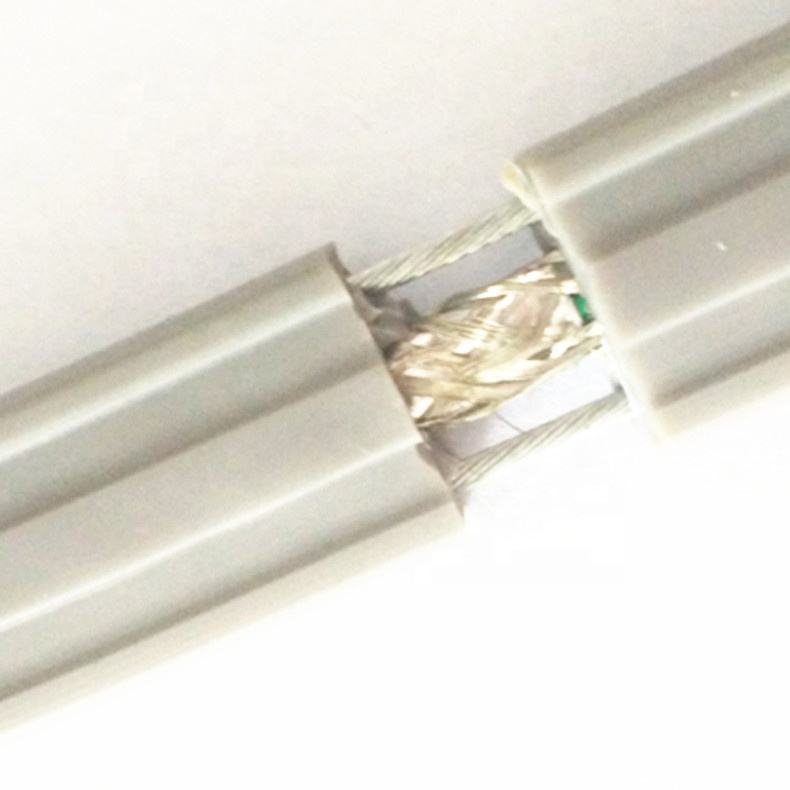

Lightweight strength members: Aramid fibers such as Kevlar provide tensile strength without excessive mass.

-

Buoyancy control layers: Syntactic foam or low-density fillers offset the weight of internal components.

-

Shielding and insulation: Protect signal integrity and prevent electrical interference.

-

Outer jacket: Polyurethane is commonly used for its abrasion resistance, flexibility, and stable density.

Manufacturers tune the final buoyancy by adjusting jacket thickness and filler distribution, often testing samples in controlled water conditions to confirm performance.

Neutral Buoyancy vs. Armored ROV Cables

Neutral buoyancy designs are not a universal replacement for armored tethers. Each serves a different purpose.

Armored cables, reinforced with steel wires, are preferred for heavy work-class ROVs performing intervention tasks where abrasion resistance and tensile strength are critical. Neutral buoyancy tethers, by contrast, are optimized for precision rather than load-bearing.

Many modern systems combine both approaches, using a heavier main umbilical to a tether management system (TMS), then deploying a shorter neutral buoyancy tether from the TMS to the vehicle. This hybrid setup balances protection with maneuverability.

Typical Applications for Neutral Buoyancy Tethers

Neutral buoyancy tether cables are widely used in applications where control and stability matter more than brute strength:

-

Offshore wind and renewable energy inspections

-

Pipeline and subsea cable surveys

-

Marine scientific research and environmental monitoring

-

Aquaculture and fisheries infrastructure inspections

-

Search, documentation, and light recovery work

In these environments, a predictable tether behavior allows pilots to focus on the task rather than compensating for cable-induced forces.

Selecting the Right Neutral Buoyancy Tether Cable

Choosing a suitable tether requires matching specifications to operational realities. Key considerations include:

-

Operating depth and pressure rating

-

Weight in water, specified for local salinity and temperature

-

Power delivery requirements and acceptable voltage drop

-

Data bandwidth, including fiber count for video and sensors

-

Minimum bend radius for winch and TMS compatibility

-

Environmental exposure, such as hydrocarbons or extreme temperatures

Experienced suppliers can provide buoyancy curves, fatigue data, and test reports to support selection decisions.

Handling, Maintenance, and Long-Term Reliability

Neutral buoyancy performance depends on maintaining the integrity of the cable structure. Best practices include proper spooling, avoiding sharp bends, rinsing after saltwater exposure, and routine visual inspections.

Damage to the outer jacket or water ingress can alter buoyancy characteristics over time. Regular electrical and optical testing helps identify issues before they affect operations.

Frequently Asked Questions (FAQ)

What is the main advantage of a neutral buoyancy tether cable?

It minimizes drag and vertical pull, improving vehicle control and reducing pilot workload.

Is a neutral buoyancy tether suitable for deep water?

Yes. Many designs are rated for depths exceeding 4,000 meters when properly engineered.

Are neutral buoyancy cables more expensive?

They typically cost more than standard tethers, but often reduce operational time and maintenance costs.

Do all ROVs need neutral buoyancy tethers?

Observation and inspection-class ROVs benefit most. Heavy intervention vehicles may require different balance characteristics.

How long does a neutral buoyancy ROV cable last?

With correct handling and maintenance, service life commonly ranges from 10 to 15 years.