Underwater Welding & Repair | ROV Cable | High Current Capacity | Abrasion-Resistant Outer Layer

Durable ROV Cable designed for subsea welding and repair, combining high current capacity, neutral buoyancy, and abrasion-resistant outer layers. Ensures stable power, control, and optional fiber communication for pipelines, offshore structures, and ROV operations. Flexible, shielded, and engineered for long-distance deployments up to 6,000 meters in harsh underwater conditions.

Underwater Welding & Repair | ROV Cable | High Current Capacity | Abrasion-Resistant Outer Layer

Our ROV Cable is engineered for underwater welding, cutting, and repair operations requiring high current capacity and long-term reliability. Featuring a robust abrasion-resistant outer jacket and optimized conductor design, it delivers stable power and signal transmission even in harsh subsea environments. Ideal for offshore maintenance, structural repairs, and industrial diving support systems.

Core Advantages of This ROV Cable

-

High Current Capacity: Supports demanding underwater welding and repair equipment.

-

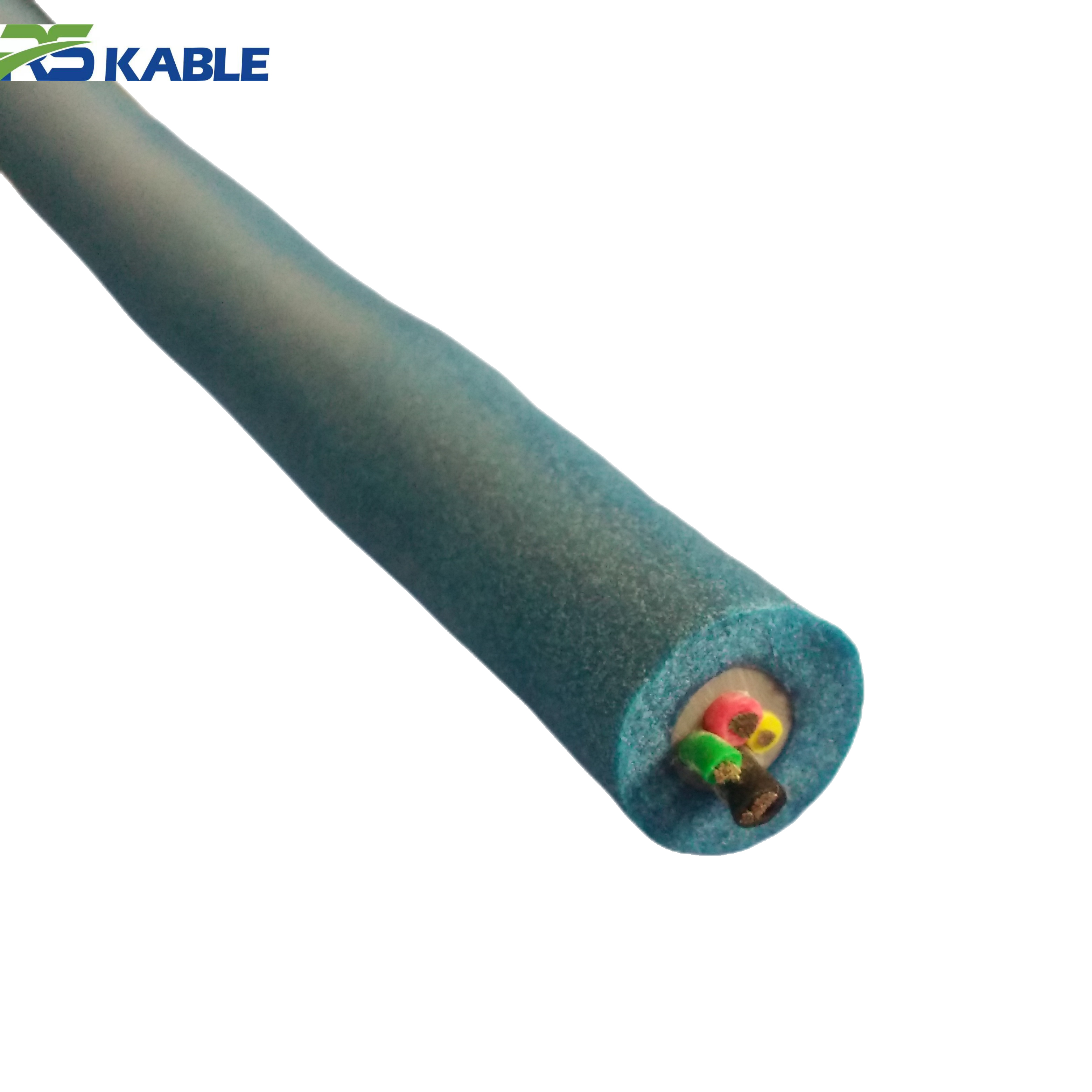

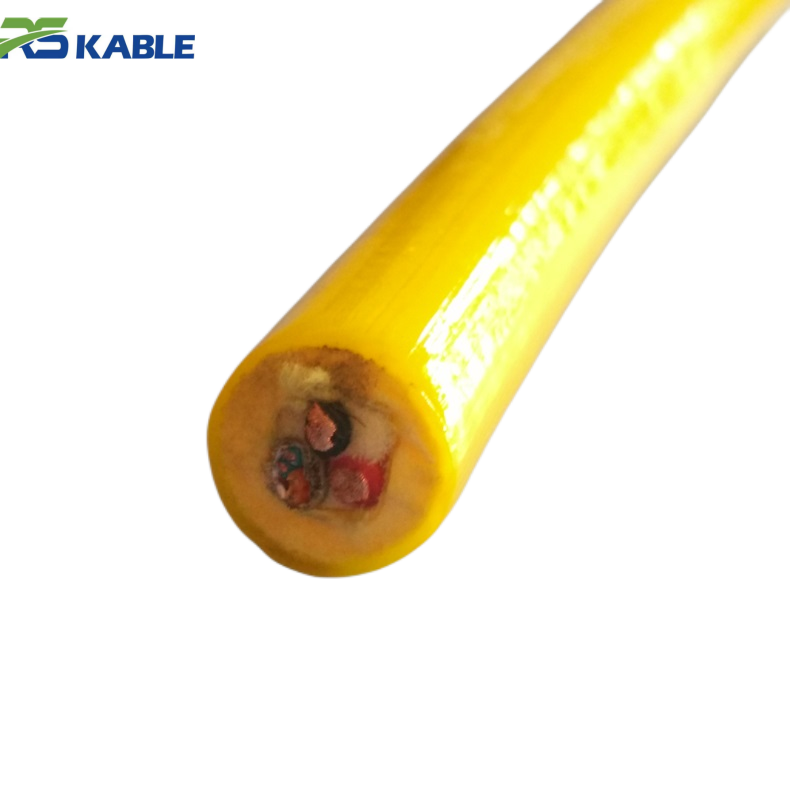

Abrasion & Crush Resistant: TPU or equivalent outer sheath protects against mechanical damage.

-

Neutral Buoyancy Design: Ensures smooth handling and reduces drag during ROV operations.

-

Shielded Construction: Minimizes interference for stable control and auxiliary signals.

-

Long-Distance Power Delivery: Reliable over extended subsea deployments up to 6,000 m.

Product Models & Key Attributes

| Model | Core Attributes | Conductor Configuration | Rated Depth | Outer Diameter | Weight in Water |

|---|---|---|---|---|---|

| ROV-WELD-4P | 4-core high-current, abrasion-resistant | 4 × 4.0 mm² multi-stranded Cu | 4,000 m | 18.2 mm | Neutral (~0 kg/m) |

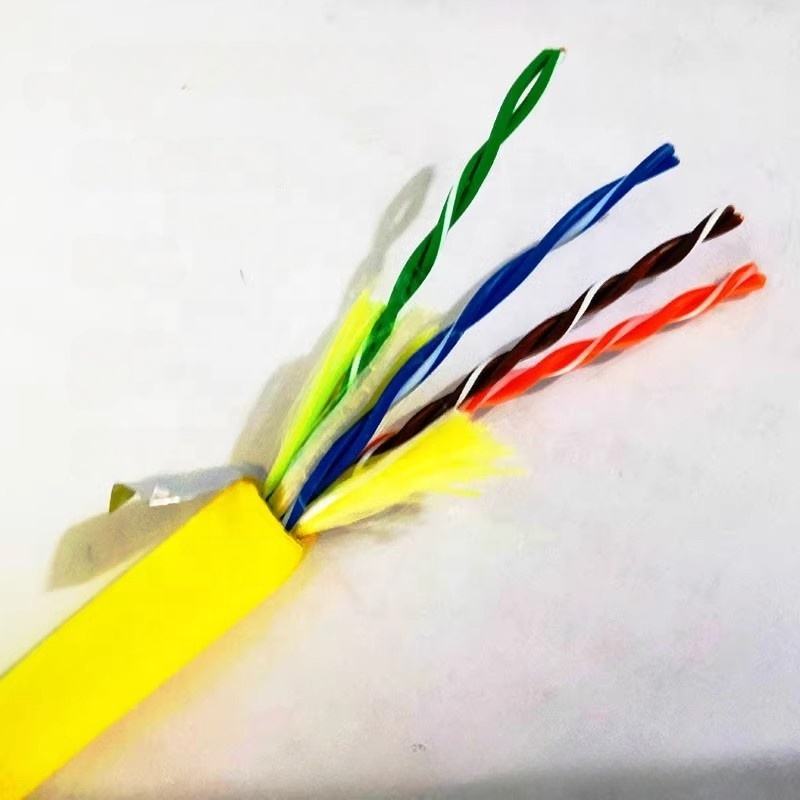

| ROV-WELD-6P | 6-core power + control, reinforced shielding | 6 × 2.5 mm² + 2 × twisted pair | 5,000 m | 21.0 mm | Neutral (~0 kg/m) |

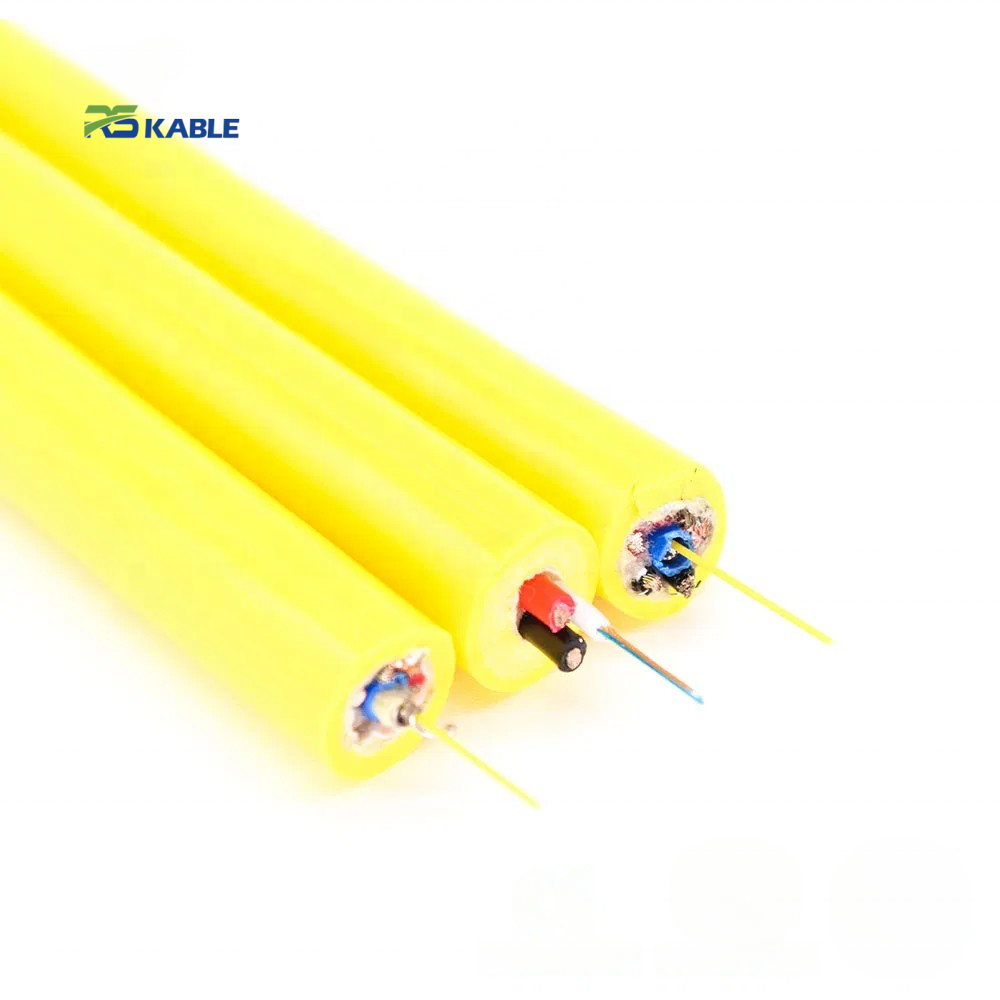

| ROV-WELD-4FP | 4-core + fiber hybrid, durable outer jacket | 4 × 3.0 mm² + 2–4 fiber elems | 6,000 m | 23.5 mm | Neutral (~0 kg/m) |

| ROV-WELD-HD | Heavy-duty, max abrasion & crush protection | 8 × 2.5 mm² + multi-pair shield | 6,000 m | 26.8 mm | Neutral (~0 kg/m) |

All models use high-quality TPU or seawater-resistant polymer jackets, multi-stranded copper conductors, and optional fiber for hybrid communication.

Typical Applications

-

ROV-assisted underwater welding and metal repair

-

Offshore platform and subsea structure maintenance

-

Pipeline welding, cutting, and inspection

-

Industrial diving support systems

-

Heavy-duty subsea construction and repair

Relevant long-tail keywords: “high current ROV cable for underwater welding,” “abrasion-resistant subsea welding tether,” “neutral buoyancy ROV cable for repair operations.”

Technical Specifications

| Parameter | Specification | Notes / Standard |

|---|---|---|

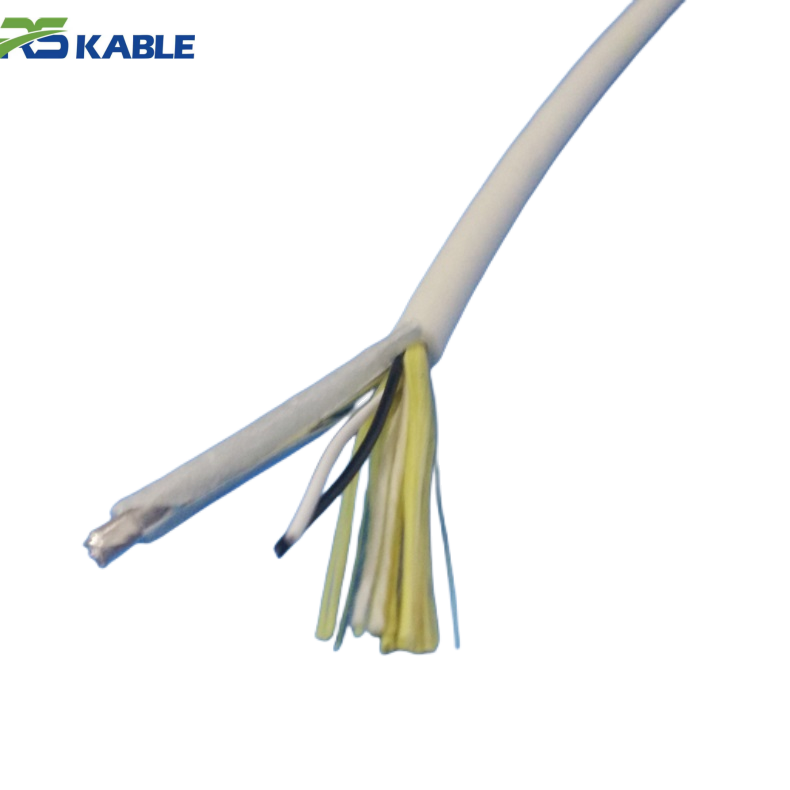

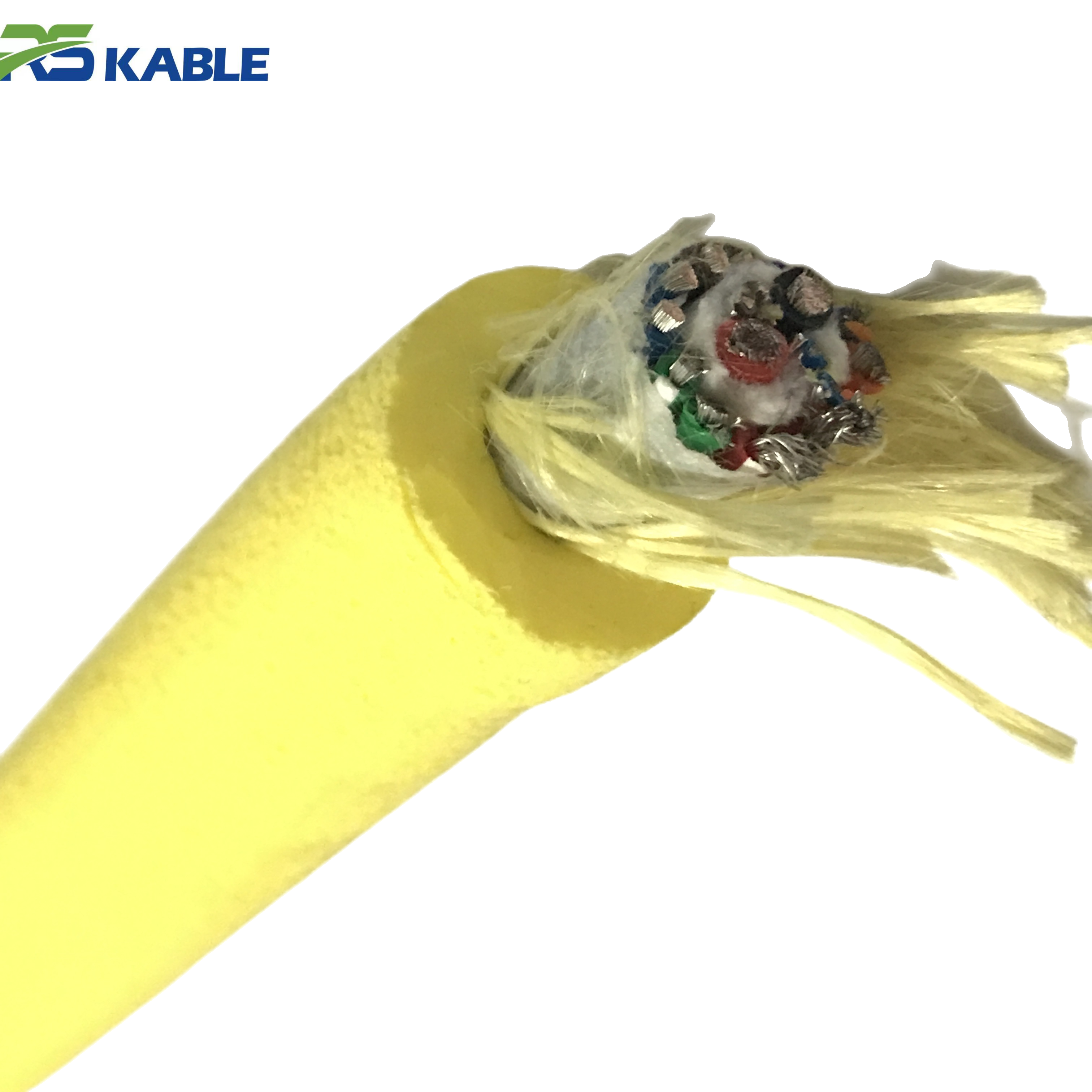

| Conductor | Multi-stranded tinned copper | IEC 60228 Class 5/6 |

| Insulation | PE or XLPE foamed for neutral buoyancy | Low dielectric loss |

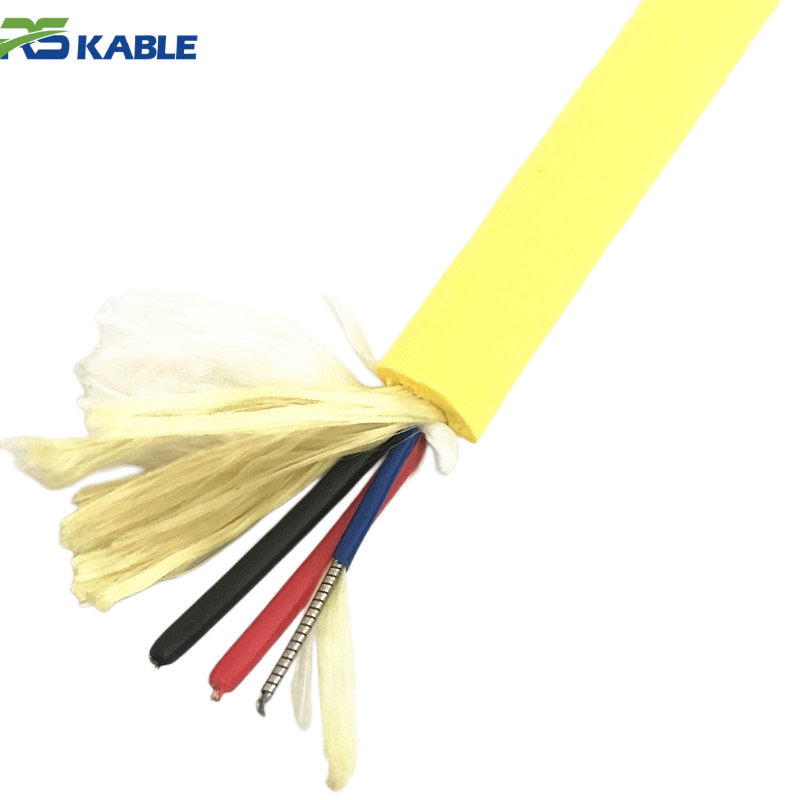

| Shielding | Aluminum foil + tinned copper braid (≥90%) | EMI/RFI protection |

| Strength Member | High-tenacity synthetic fibers (aramid/Kevlar) | Tensile strength ≥2,500 kg |

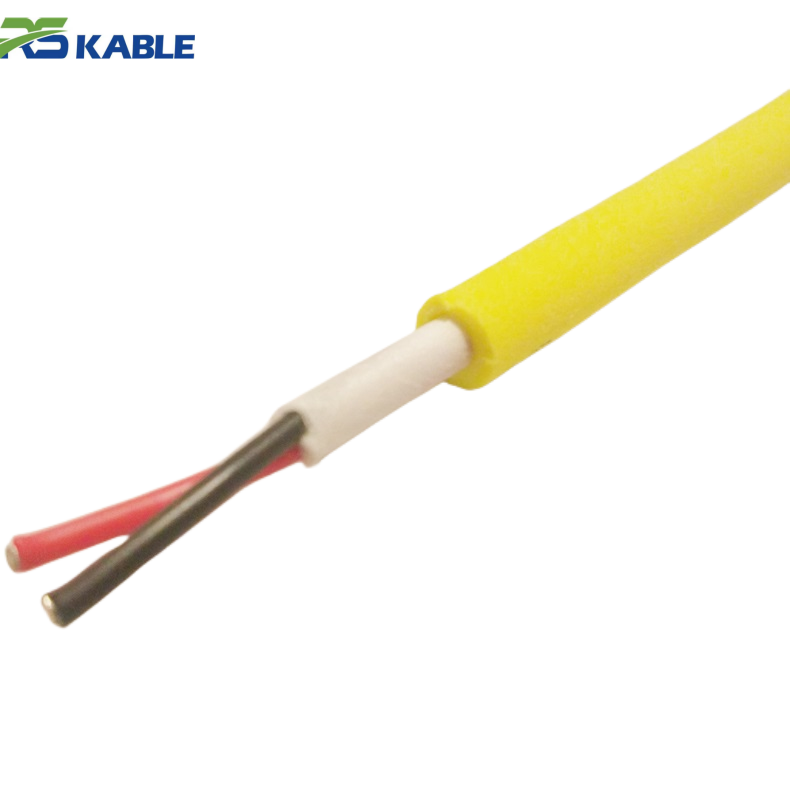

| Outer Jacket | TPU or equivalent abrasion & crush-resistant layer | Seawater & UV resistant |

| Buoyancy | Neutral in seawater | Density 1.01 ± 0.02 g/cm³ |

| Temperature Range | –40°C to +80°C | Suitable for deepwater operation |

| Voltage Rating | 500V–1,000V depending on model | High current applications |

| Certifications | ISO 9001, RoHS, optional ABS/DNV | Third-party verified |

Ready to Equip Your ROV?

Prepare your ROV for demanding underwater welding and repair missions with our high-performance ROV Cable. Engineered for long-distance power delivery, neutral buoyancy handling, and maximum abrasion resistance, this cable ensures reliable operation even in harsh subsea conditions. Choose the model that fits your project needs and get a tailored solution from our experienced team.

Frequently Asked Questions (FAQ)

Q: Can this cable handle continuous welding currents?

A: Yes, the high-current multi-stranded conductors are optimized for continuous underwater welding and repair operations.

Q: How does the abrasion-resistant jacket perform in harsh subsea conditions?

A: TPU or equivalent polymer provides excellent protection against rubbing, crushing, and impact while resisting seawater and UV exposure.

Q: Is this cable suitable for long-distance subsea deployment?

A: Absolutely. Designed for stable power and signal transmission up to 6,000 meters.

Q: Can custom lengths or conductor counts be provided?

A: Yes, fully customizable based on project requirements.

Q: Does it support hybrid power + communication?

A: Yes, select models include fiber optic or signal pairs integrated into the cable for hybrid applications.