Underwater ROV Power & Signal Cable with PUR Jacket and Polyethylene Insulation | High‑Flex Subsea Robotic Cable

.Designed for harsh subsea environments, offering superior hydrolysis and abrasion resistance.

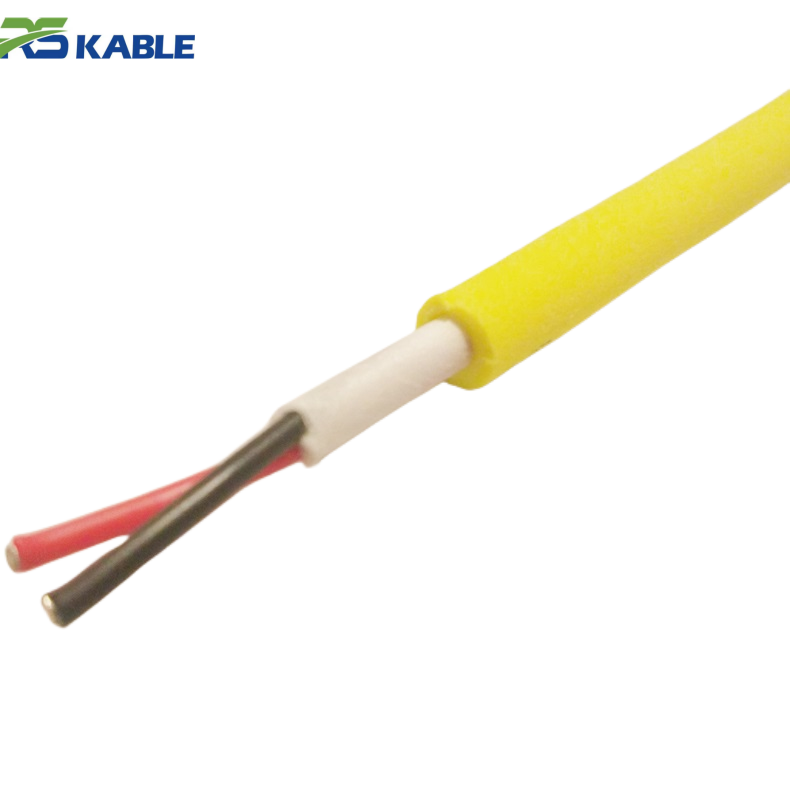

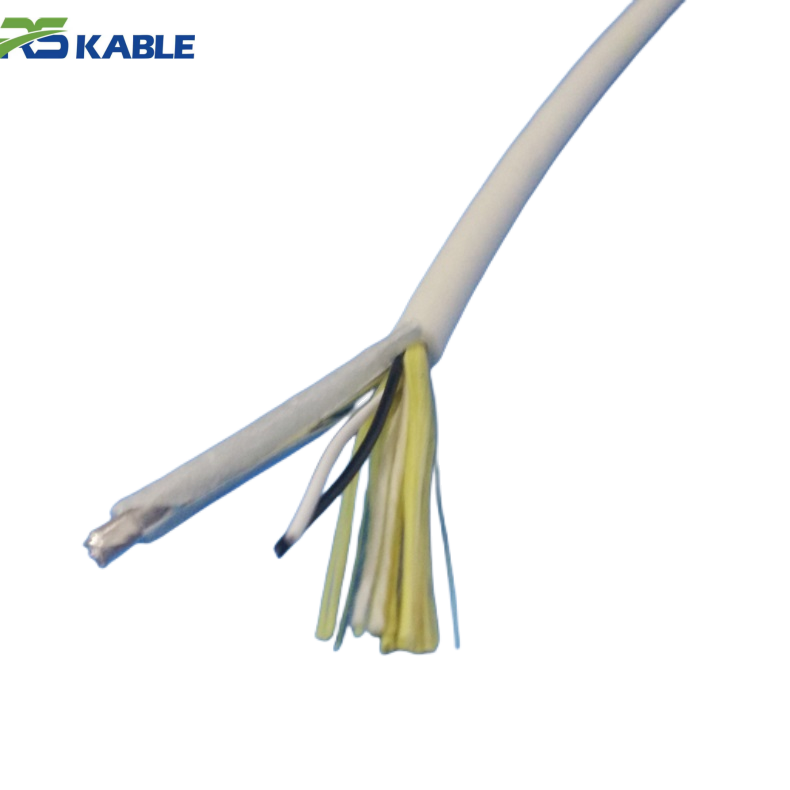

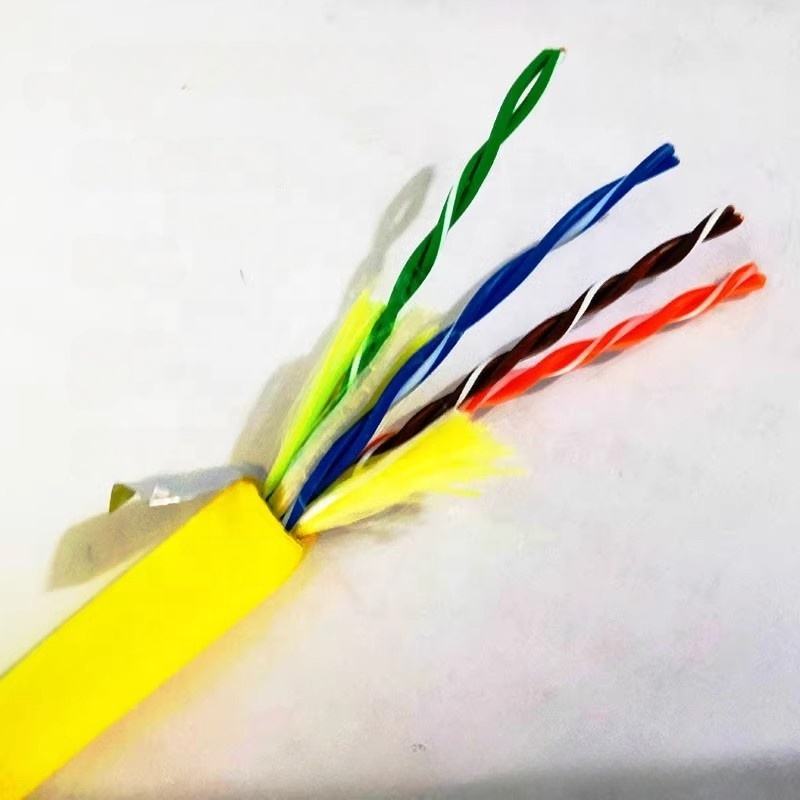

.Features tinned copper conductors and PE insulation for high-integrity data transmission.

.High-flexibility construction withstands constant motion and tight bending radii.

.Customizable buoyancy and tensile strength options available for specific mission profiles.

.Ideal for observation ROVs, pipe inspection robots, and oceanographic instrumentation.

Engineered for the Deep: Reliable Power & Data Transmission

When your equipment operates hundreds of meters below the surface, cable failure isn’t just an inconvenience—it’s a mission-critical loss. The Underwater ROV Power & Signal Cable by Shanghai Ruosheng Wire & Cable Co., Ltd. is purpose-built for the demanding environments of subsea robotics.

Drawing on our extensive background in high-flexible drag chain and special cables, we have engineered a tether solution that balances rugged durability with the extreme flexibility required for Remotely Operated Vehicles (ROVs). This cable isn’t just a conduit; it is the lifeline of your subsea operation, ensuring consistent power delivery and crystal-clear signal integrity in harsh saltwater conditions.

Why Material Matters: PUR & PE Construction

Standard cables degrade rapidly in marine environments. Our ROV cables utilize a specific material combination designed to resist the unique threats of the ocean.

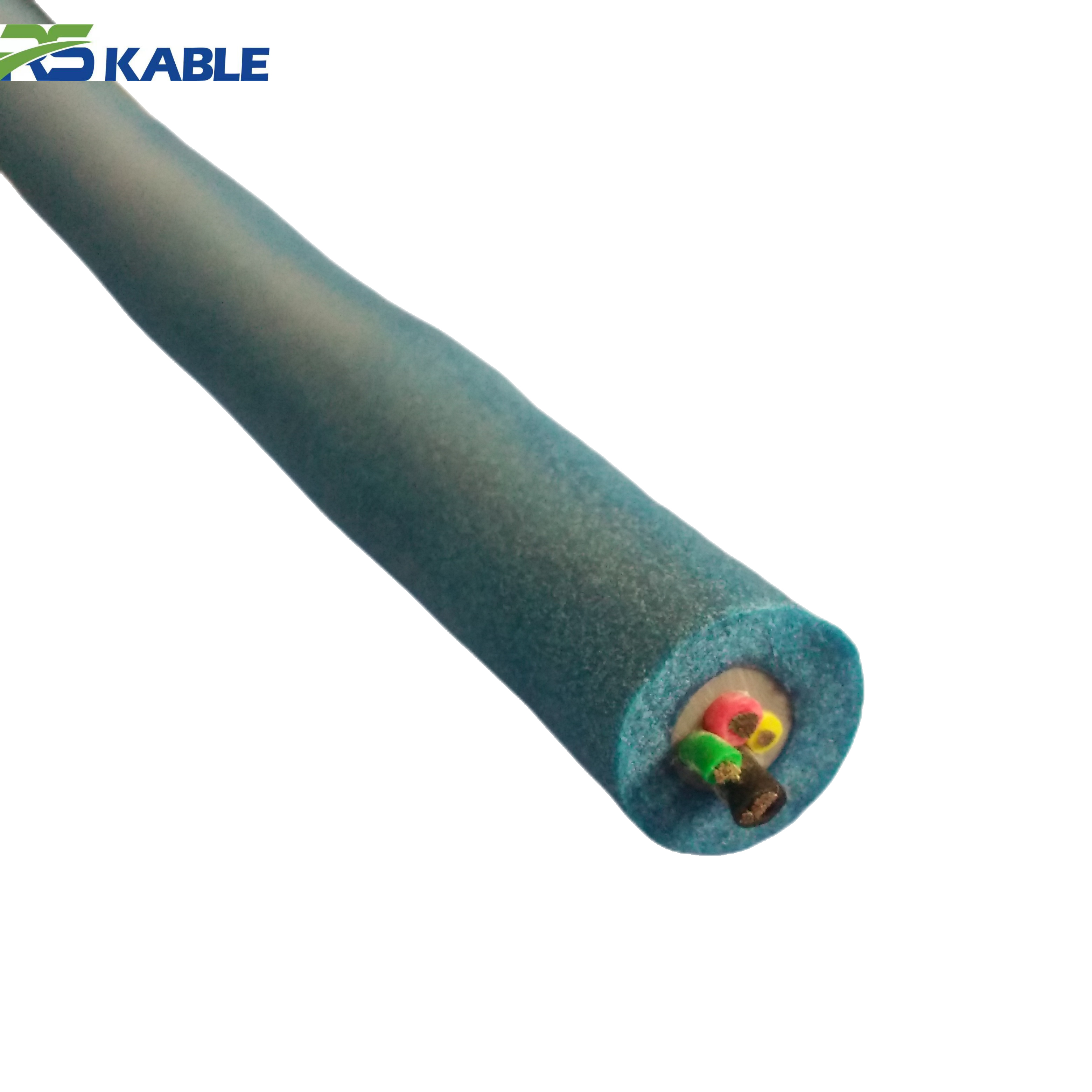

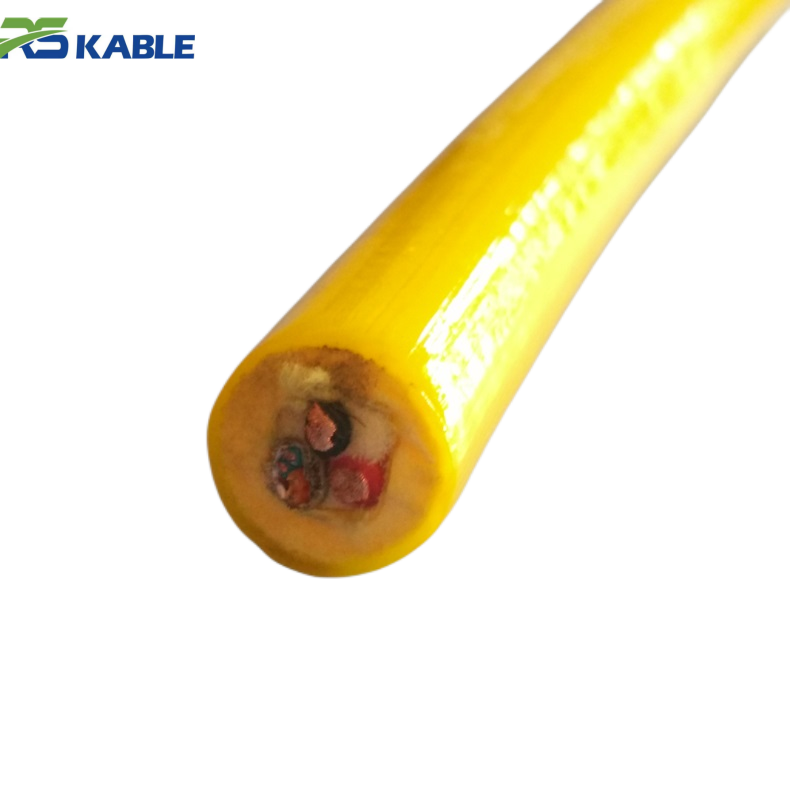

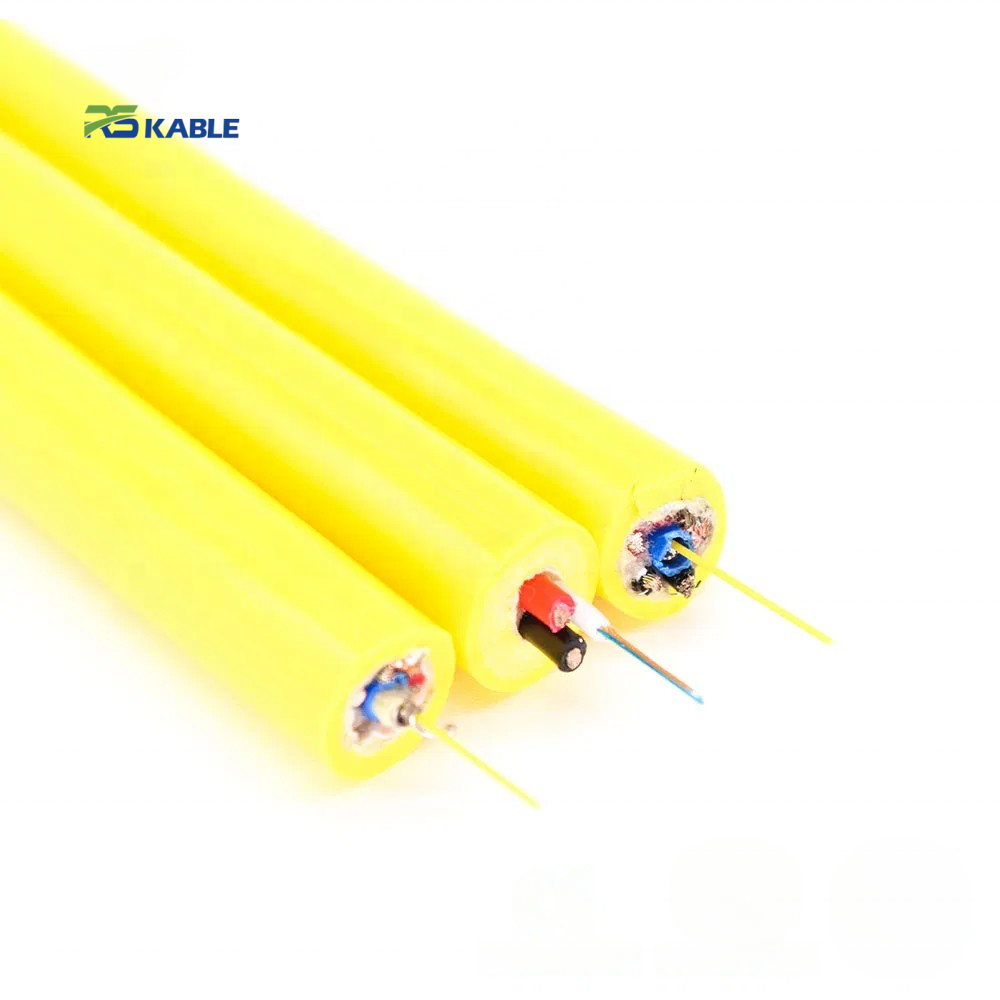

- Polyurethane (PUR) Outer Jacket: Unlike PVC, which can become brittle or permeable over time, PUR provides exceptional resistance to hydrolysis (water breakdown) and microbial attack. It is mechanically tough, offering superior defense against abrasion from rocks, coral, or ship decks, while maintaining flexibility even in near-freezing deep-water temperatures.

- Polyethylene (PE) Insulation: For the signal cores, we use high-grade Polyethylene. PE has a lower dielectric constant compared to other insulation materials, which minimizes signal loss and capacitance. This ensures that video feeds and telemetry data from your ROV reach the surface without distortion.

Key Features & Benefits

- High-Flex Design: Engineered to withstand constant twisting, bending, and tension associated with ROV movement and tether management systems (TMS).

- Zero Halogen & Low Smoke: While built for water, safety remains a priority during storage and transport.

- Corrosion Resistance: Tinned copper conductors prevent oxidation, a common failure point in marine humid environments.

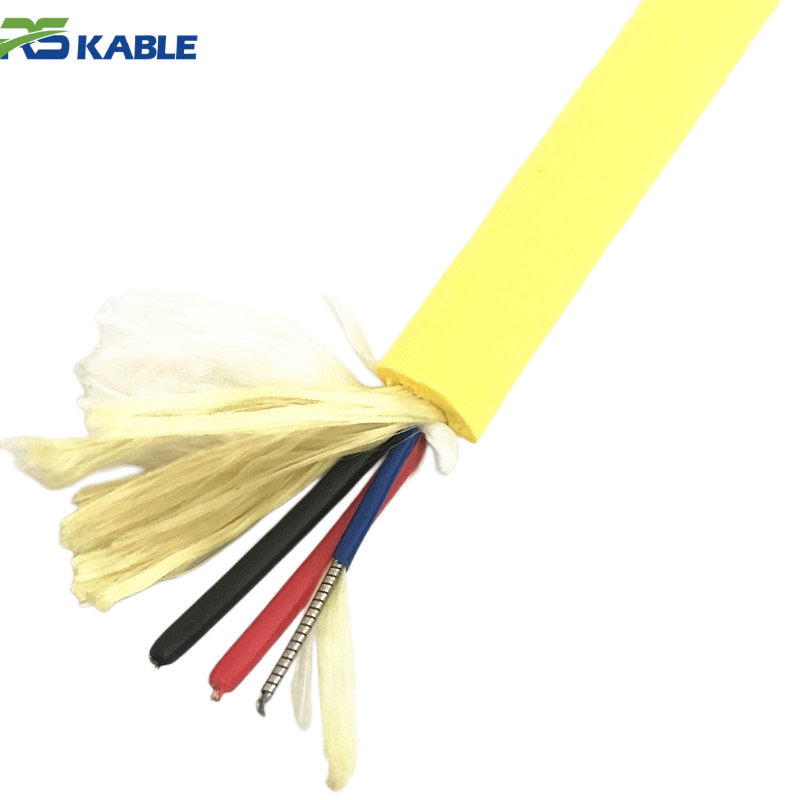

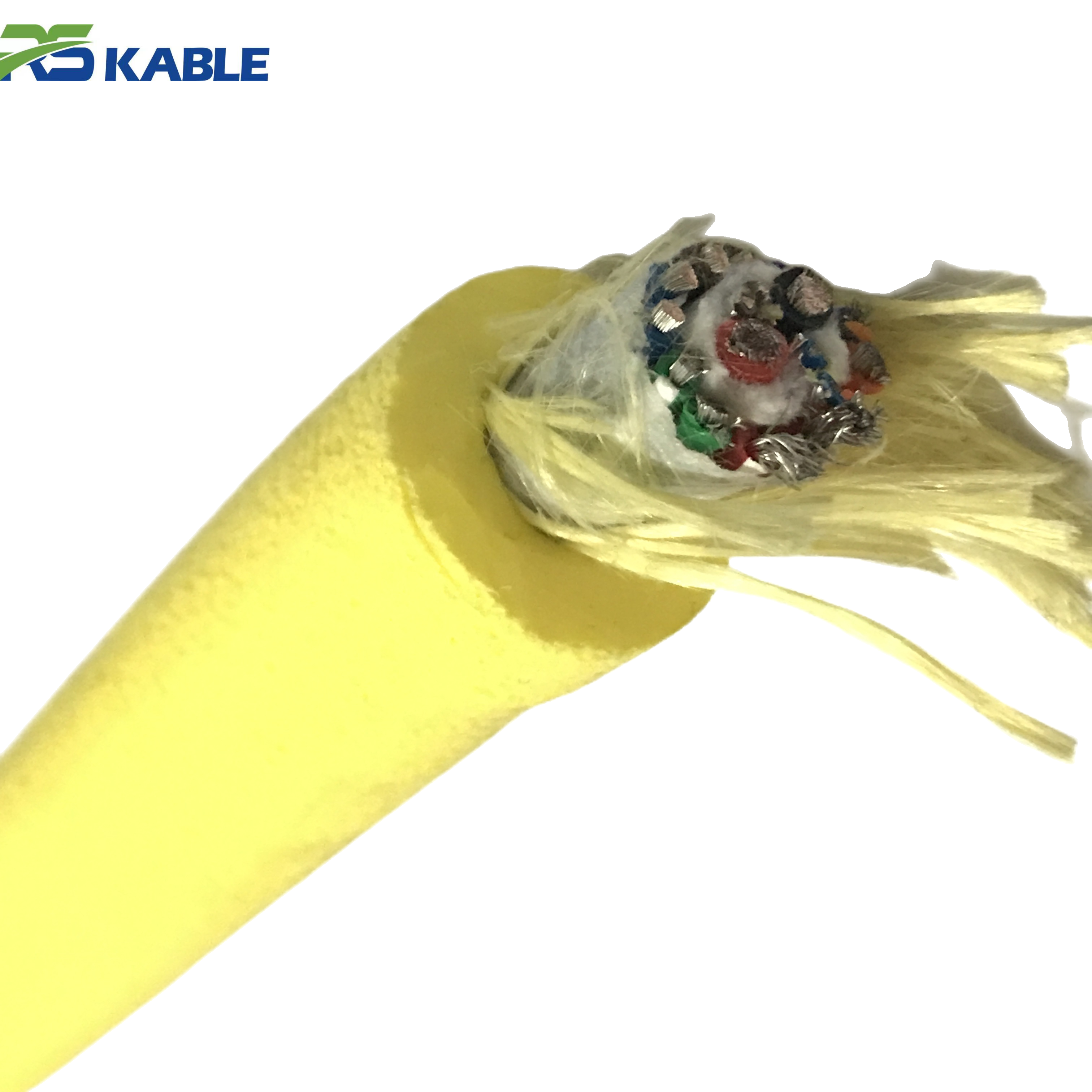

- Tensile Strength: Optional Kevlar (Aramid) fiber braiding reinforcement is available to bear the mechanical load of the ROV, relieving stress on the copper conductors.

- High Visibility: Available in high-contrast colors (Orange/Yellow) to ensure visibility in murky waters and prevent accidental snagging.

Technical Specifications

This cable is customizable to specific depth ratings and power requirements. Below are the standard specifications for our ROV series.

|

Feature |

Specification |

|---|---|

|

Conductor Material |

Finely stranded Tinned Copper (Class 6 flexibility) |

|

Insulation Material |

Special Polyethylene (PE) for data pairs; PP/TPE for power cores |

|

Outer Sheath |

Hydrolysis-resistant Polyurethane (PUR) |

|

Temperature Range (Moving) |

-30°C to +80°C |

|

Temperature Range (Fixed) |

-40°C to +90°C |

|

Nominal Voltage |

300/500V (Control/Signal), 600/1000V (Power) |

|

Bending Radius |

Mobile use: 7.5x cable diameter |

|

Water Depth Rating |

Standard up to 300m (Customizable for deeper applications) |

|

Shielding |

Tinned copper braid or Aluminum foil for EMI protection |

Common Applications

- Observation Class ROVs: Inspection of hulls, dams, and offshore wind farms.

- Work Class ROVs: Heavier subsea construction and manipulation tasks.

- Oceanographic Instrumentation: Tow cables for sonar and sensors.

- Pipe Inspection Robots: Crawlers used in wet, corrosive sewage or chemical pipelines.

Frequently Asked Questions (FAQ)

What is the difference between PUR and PVC cables for underwater use?

PVC (Polyvinyl Chloride) allows water permeability over time, which can lead to electrical shorts in deep water. PUR (Polyurethane) is far more resistant to water ingress, hydrolysis, and microbial growth, making it the industry standard for professional subsea equipment longevity.

Can this cable be made neutrally buoyant?

Yes. We can adjust the specific gravity of the cable using specialized foam materials or fillers to achieve neutral buoyancy. This prevents the cable from dragging on the seabed or floating up into propellers, which is essential for stable ROV maneuvering.

Is this cable suitable for continuous motion?

Absolutely. Shanghai Ruosheng specializes in “drag chain” class cables. This ROV cable uses fine-strand conductors and a low-friction internal structure designed specifically for millions of flex cycles without copper fatigue.

Do you offer custom core configurations?

Yes. We regularly manufacture hybrid cables combining power cores (for thrusters/lights) with shielded twisted pairs (for data/video) and even fiber optics in a single jacket.