Underwater Robotics Systems | Neutral Buoyancy Cable | Waterproof & Durable | PE Insulation, Seawater Resistant

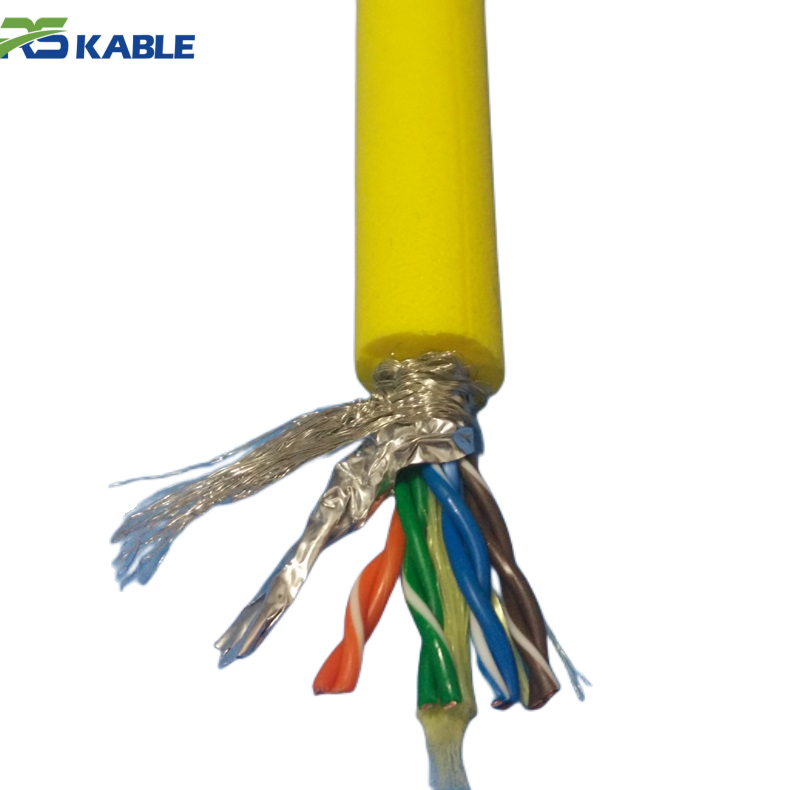

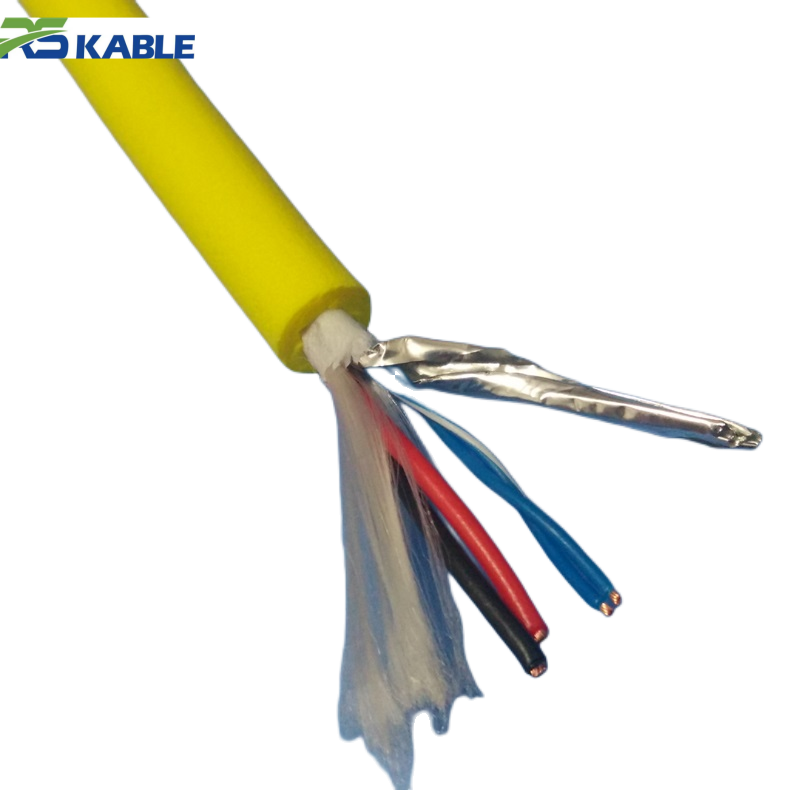

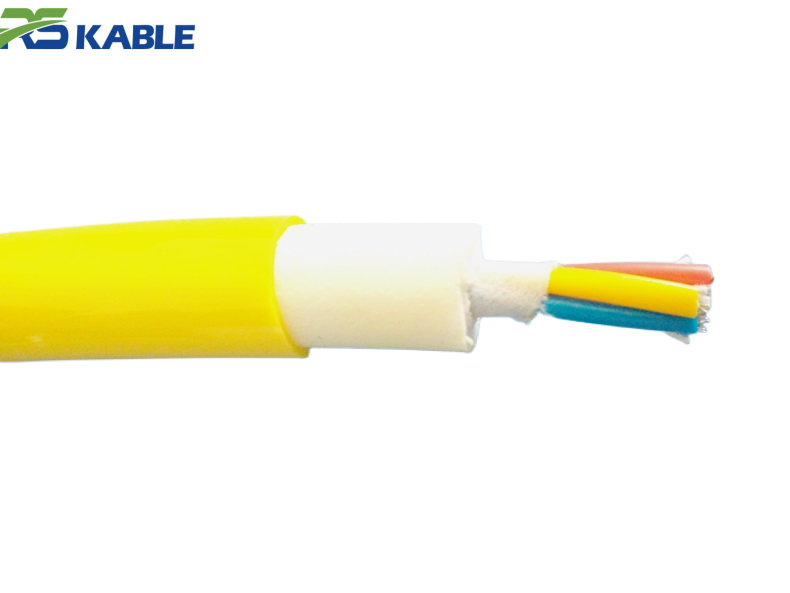

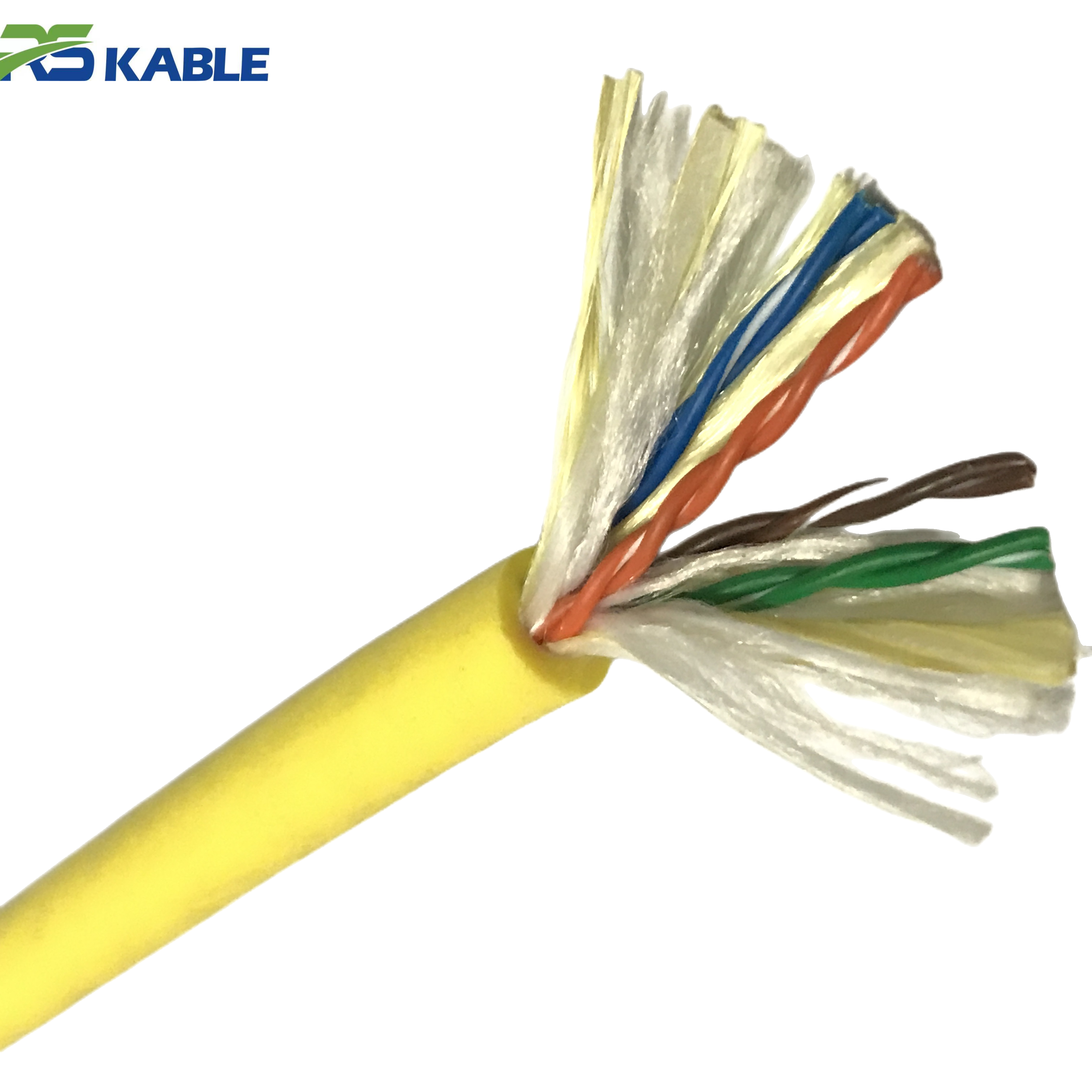

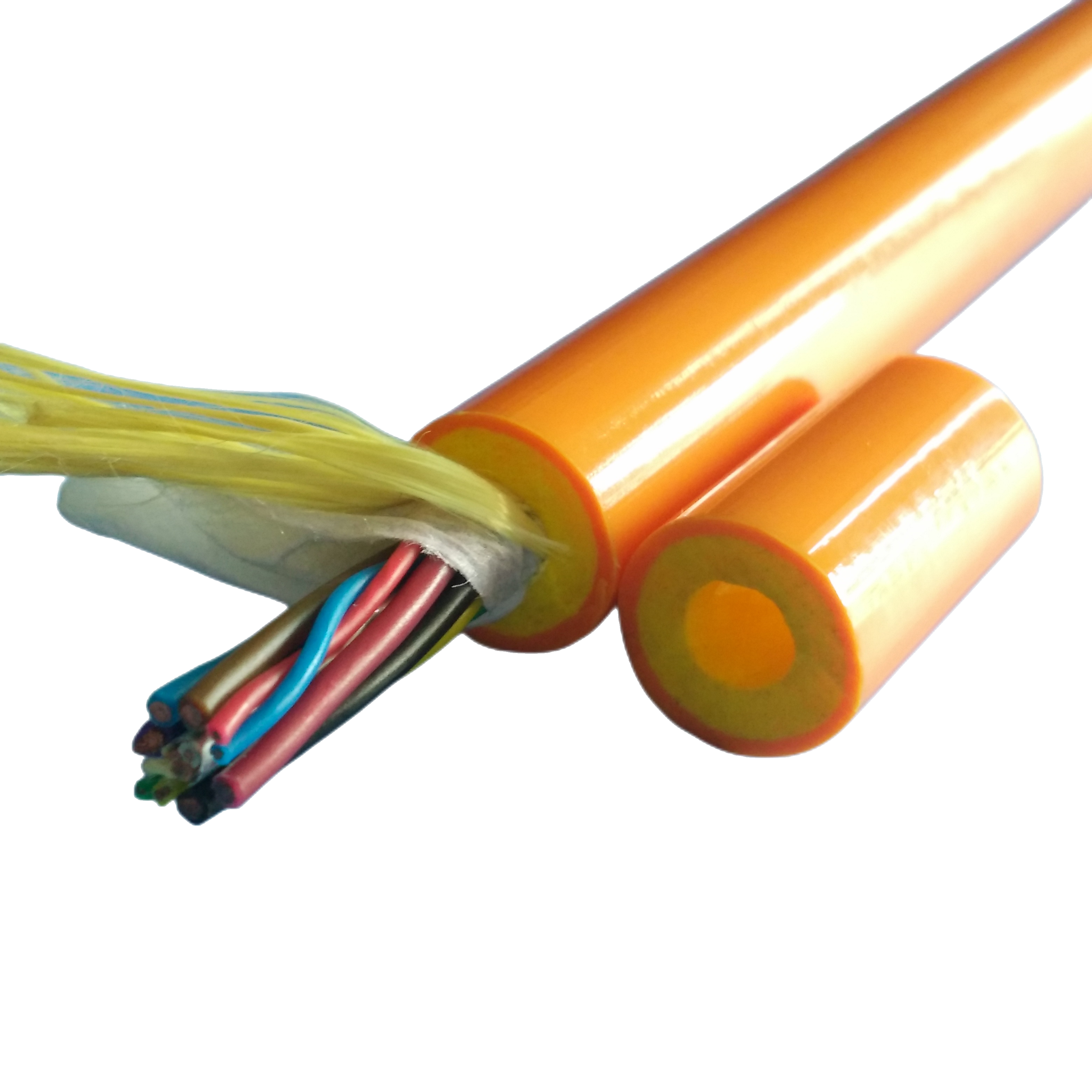

• Conductor: Multi-stranded tinned copper with high-purity construction for excellent signal integrity and corrosion resistance in seawater.

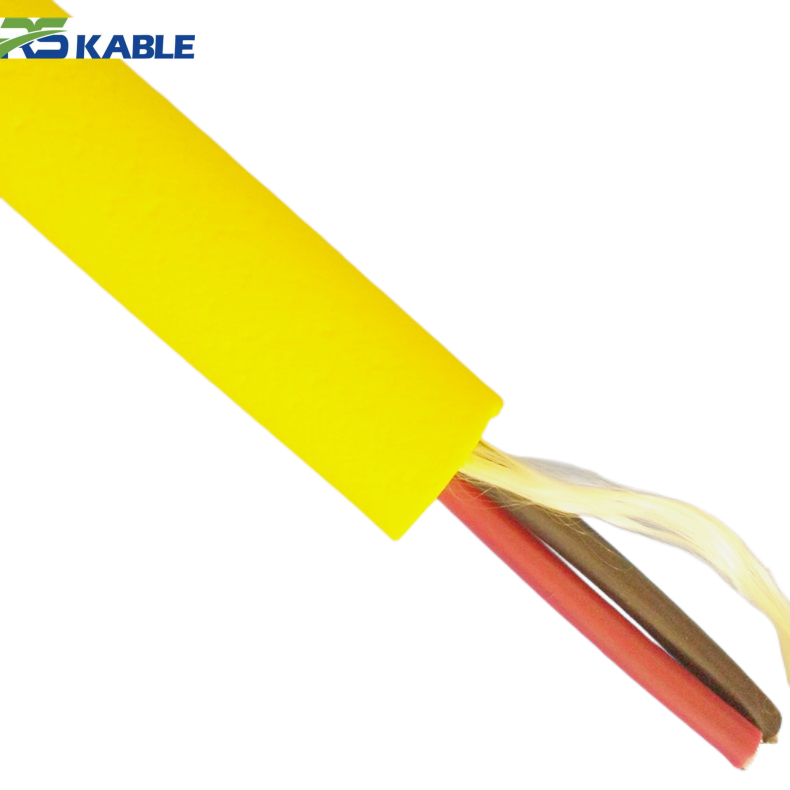

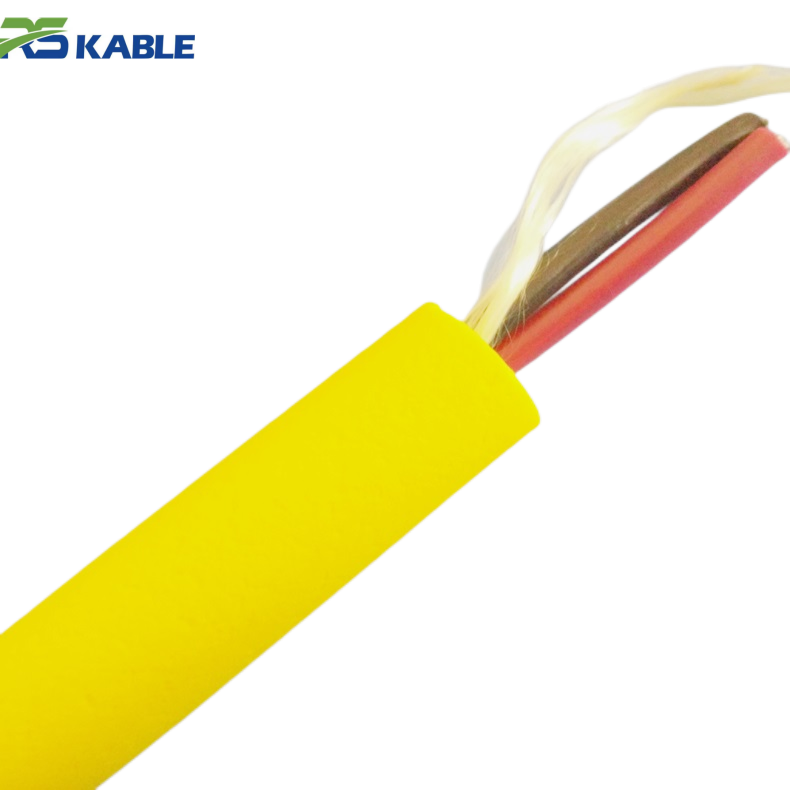

- Jacket: Seawater-resistant polyurethane (PUR) or thermoplastic (TPU) with smooth, low-friction surface for enhanced durability and reduced biofouling.

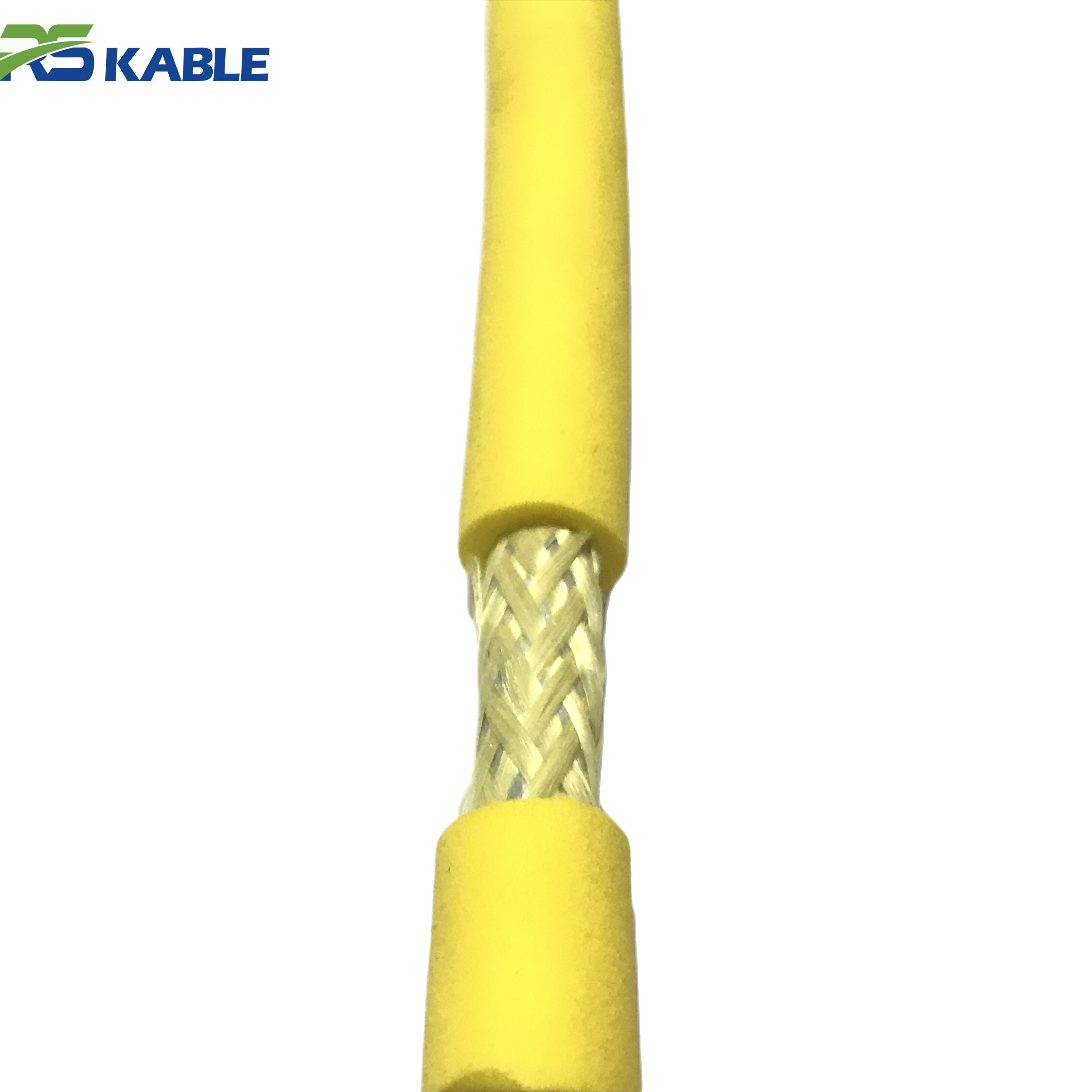

- Structure: Integrated aramid/Kevlar strength members combined with foamed insulation layers for precise neutral buoyancy and superior tensile strength.

- Performance: Engineered for deep-sea flexing with minimum bend radius of 6–8x OD and rated for over 10 million cycles under dynamic loads.

- Environment: Fully waterproof (IP68), hydrolysis-resistant, and optimized for continuous immersion in harsh marine conditions from shallow to 6,000+ meters depth.

Underwater Robotics Systems | Neutral Buoyancy Cable | Waterproof & Durable | PE Insulation, Seawater Resistant

Enhance your underwater robotics systems with our advanced Neutral Buoyancy Cable, engineered for robust, long-term operation in harsh marine environments. Featuring PE insulation and seawater-resistant construction, this durable cable maintains perfect neutral buoyancy while ensuring uninterrupted power, control, and data transmission for AUVs, ROVs, gliders, and other subsea platforms.

With over 18 years of experience in marine cable engineering and thousands of successful deployments worldwide, our solutions are trusted by research institutions, commercial operators, and government agencies. All cables are manufactured under ISO 9001:2015 quality systems and fully compliant with RoHS, REACH, with optional DNV or ABS classification society approvals.

Key Benefits of Our Neutral Buoyancy Cable

In deep-sea missions, cable performance directly impacts vehicle efficiency and reliability. Our Neutral Buoyancy Cable eliminates drag from sinking or floating, allowing underwater vehicles to maintain precise positioning while reducing energy consumption.

-

Precise neutral buoyancy in freshwater and seawater through optimized PE foaming and jacket density

-

Fully waterproof and durable with long-term submersion capability

-

High mechanical strength with abrasion-resistant jacket and aramid reinforcement

-

PE insulation providing stable electrical performance and low water uptake

-

Low-drag design to improve vehicle range and efficiency

-

Ideal for long-term missions with minimal maintenance

Product Models & Specifications

| Model | Core Attributes | Conductor Configuration | Rated Depth | Outer Diameter | Buoyancy in Seawater |

|---|---|---|---|---|---|

| NB-URS-4C | 4-core power, waterproof, PE insulation | 4 × 1.5 mm² tinned copper | 3,000 m | 16.8 mm | Neutral (~0 kg/m) |

| NB-URS-6CS | 6-core power + signal, shielded, seawater-resistant | 4 × 2.0 mm² + 2 × 0.5 mm² pairs | 4,500 m | 19.4 mm | Neutral (~0 kg/m) |

| NB-URS-4FO | 4 power + fiber optic composite, durable jacket | 4 × 1.0 mm² + 2–4 fiber elements | 5,000 m | 20.6 mm | Neutral (~0 kg/m) |

| NB-URS-HD | Heavy-duty armor, enhanced seawater resistance | 6 × 2.5 mm² + twisted shielded pairs | 6,000 m | 24.3 mm | Neutral (~0 kg/m) |

All models use high-grade PE insulation and TPU or equivalent seawater-resistant outer jackets.

Applications & Use Cases

Our Neutral Buoyancy Cable is ideal for diverse underwater robotics systems:

-

Autonomous Underwater Vehicles (AUVs) for ocean mapping and environmental monitoring

-

ROVs for marine research and subsea infrastructure inspection

-

Gliders and hybrid platforms for long-endurance data collection

-

Commercial diving umbilicals requiring life-support links

-

Subsea sensor networks and resident vehicle tethers

-

Offshore renewable energy monitoring systems

Long-tail SEO phrases: neutral buoyancy cable for AUV missions, waterproof PE-insulated ROV tether, durable subsea cable 3000–6000m.

Technical Parameters

| Parameter | Specification | Standard / Notes |

|---|---|---|

| Conductor | Tinned multi-stranded copper (Class 5) | IEC 60228 |

| Insulation | Foamed polyethylene (PE) | Low water uptake, excellent dielectric properties |

| Strength Member | High-tenacity aramid yarns | Break load ≥1,800 kg |

| Shielding | Tinned copper braid + aluminum foil (≥90%) | EMI protection |

| Outer Jacket | TPU or PE compound | UV stabilized, anti-biofouling, seawater resistant |

| Buoyancy Control | Neutral in seawater | Adjustable for freshwater |

| Operating Temperature | –30°C to +70°C | Continuous submersion suitable |

| Voltage Rating | 300/500V standard | Higher ratings available |

| Certifications | ISO 9001, RoHS, REACH, optional DNV/ABS | Third-party verified |

Engineering Credibility & Quality Assurance (E-E-A-T)

-

Developed by engineers with extensive subsea cable and ROV experience

-

Manufactured under ISO 9001:2015 standards

-

Fully tested for long-term immersion, flex, and mechanical loads

-

Optional DNV or ABS approvals ensure global compliance

-

Thousands of successful deployments in commercial, research, and government ocean projects

Customization & Ordering Options

-

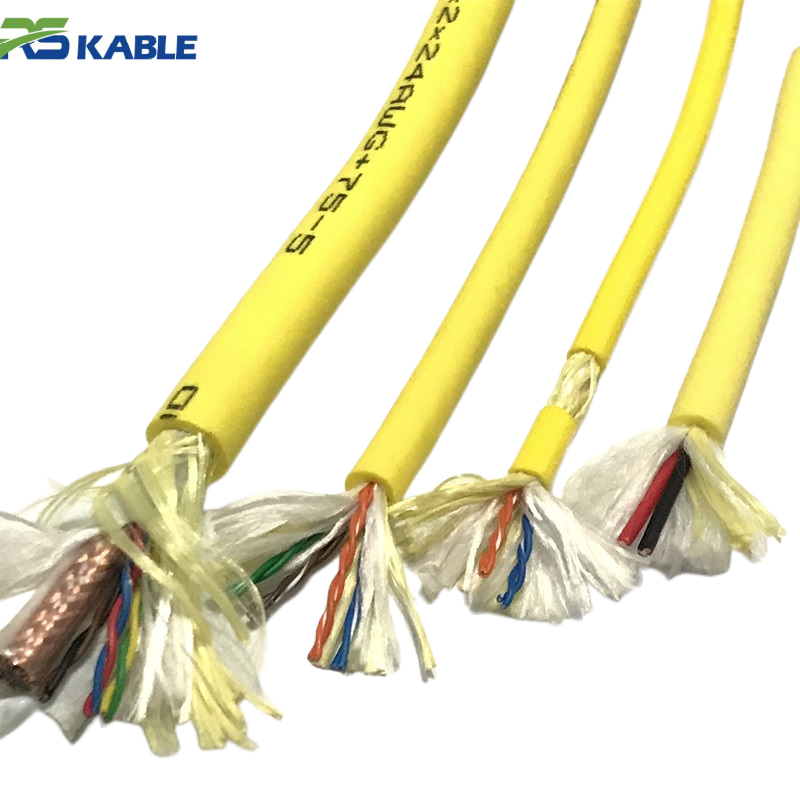

Core count and conductor size adjustments

-

Hybrid power + fiber optic integration

-

Jacket material, armor, and seawater resistance upgrades

-

Buoyancy tuning for specific water types

-

Factory-terminated connectors (SubConn®, SEACON, Burton)

Contact our technical team for a customized recommendation and quotation.

Frequently Asked Questions (FAQ)

Q: How does the PE insulation enhance performance?

A: It provides low water absorption, stable electrical characteristics, and assists in precise neutral buoyancy through controlled foaming.

Q: Is the cable suitable for long-term seawater exposure?

A: Yes. Tinned conductors and seawater-resistant jackets prevent corrosion and degradation.

Q: Can buoyancy be adjusted for freshwater?

A: Yes, factory calibration allows neutral buoyancy for freshwater or specific salinity conditions.

Q: Are pre-terminated assemblies available?

A: Yes. SubConn®, SEACON, and Burton connector options are available with full testing.

Q: What warranty and support are provided?

A: Standard 2-year warranty, extendable to 5 years, with global technical support and replacement spools.