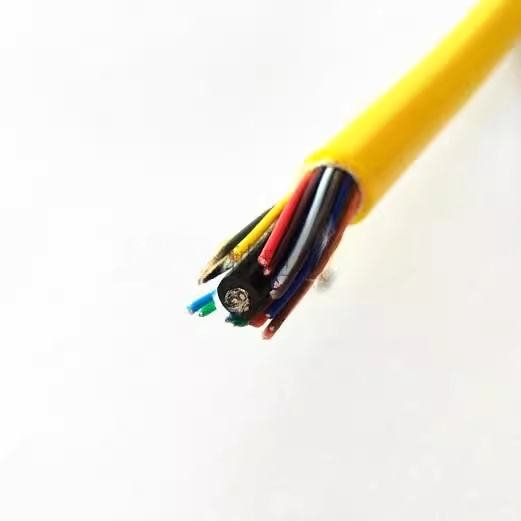

Ultra-Soft Flexible Stranded Copper CCTV Pipeline Robot Cable/Pipeline Inspection Robot Cable/Cleaning Robot Cable

Ultra-Soft Flexible Stranded Copper CCTV Pipeline Robot Cable

.Conductor: Fine Stranded Oxygen-Free Copper

.Insulation: Special Polyurethane (PUR) Compound

.Reinforcement: Kevlar Fiber for High Tensile Strength

.Application: Pipeline Inspection, CCTV Crawlers, Cleaning Robots

.Compliance: CE, RoHS, ISO Standards

Ultra-Soft Flexible Stranded Copper CCTV Pipeline Robot Cable: High-Tensile Polyurethane Solutions for Inspection Crawlers

In the world of trenchless pipe repair and municipal inspection, equipment failure is not an option. The environment inside a sewage or industrial pipeline is chemically aggressive, wet, and physically demanding. The weakest link in any pipeline inspection system (CCTV crawlers) is often the tether connecting the robot to the control unit. Standard PVC cables stiffen in cold water, snap under tension, or corrode when exposed to acidic waste.

Shanghai Rousheng Wire and Cable Co., Ltd. addresses these specific pain points with our specialized Ultra-Soft Flexible Stranded Copper CCTV Pipeline Robot Cable. Engineered specifically for the rigorous demands of sewer crawlers, cleaning robots, and endoscopes, this cable combines high-tensile strength with superior signal integrity.

This technical guide details the engineering behind our polyurethane (PUR) robot cables, exploring why they are the preferred choice for operators in over 100 countries requiring robust, compliant, and customizable infrastructure solutions.

The Engineering Challenge: Why Standard Cables Fail in Pipelines

To understand the value of a specialized robot cable, one must first look at the environment it serves. Pipeline inspection robots operate in “hostile” zones.

- Chemical Exposure: Sewage contains hydrogen sulfide, varying pH levels, and industrial run-off that dissolves standard cable jackets.

- Mechanical Stress: The cable is constantly dragged over concrete lips, rusty metal edges, and debris. It endures high tensile loads when pulling the robot back.

- Dynamic Motion: The cable is wound and unwound from a reel thousands of times. This repetitive bending radius can cause internal copper fatigue (wire breakage) in generic cables.

Shanghai Rousheng’s solution utilizes a composite design philosophy that prioritizes abrasion resistance, flexibility, and tensile strength.

Material Composition and Construction

The performance of our Ultra-Soft Flexible Cable is derived from premium raw materials and precise manufacturing techniques.

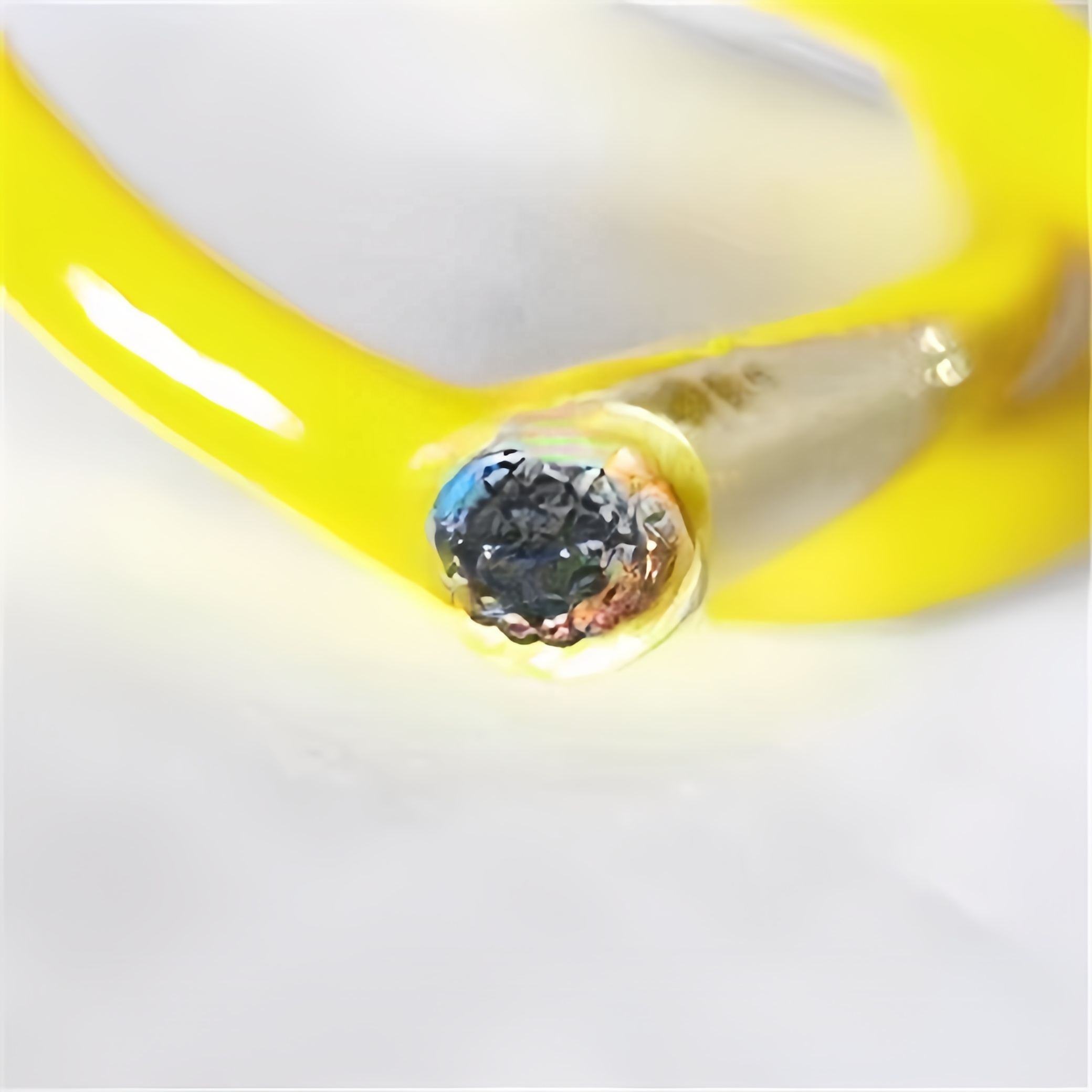

1. The Jacket: High-Grade Imported Polyurethane (PUR/TPU)

Unlike PVC (Polyvinyl Chloride), which is prone to cracking and hardening, we utilize imported Polyurethane (PUR/TPU) for the outer sheath.

- Wear Resistance: PUR offers mechanical wear resistance 3-5 times higher than rubber. This effectively prevents the “skinning” of the cable as it drags against rough concrete pipes.

- Hydrolysis and Microbe Resistance: Essential for sewer environments, our jacket resists breakdown from constant moisture and bacterial activity.

- Low-Temperature Flexibility: The cable maintains its “ultra-soft” flexibility even in freezing temperatures (storage down to -20°C), ensuring the robot moves smoothly without the cable acting as a stiff brake.

2. The Conductor: Ultra-Fine Stranded Oxygen-Free Copper

Flexibility comes from the core. We use high-purity, oxygen-free copper (OFC) stranded into ultra-fine bundles.

- Anti-Fatigue: Fine stranding allows the cable to bend repeatedly without work-hardening and snapping.

- Signal Clarity: High conductivity ensures that high-definition video signals from the CCTV crawler reach the control monitor without interference or graininess, even over long distances (100m+).

3. Tensile Reinforcement: Kevlar (Aramid Fiber) Braiding

A common point of failure is cable stretching, which thins the copper conductors and breaks the signal.

- Bulletproof Strength: We integrate Kevlar fiber—the same material used in body armor—into the cable structure.

- Load Bearing: This allows the cable to act as a lifeline. If the robot loses traction or power, the operator can manually pull the unit out using the cable alone, with tensile loads often exceeding 100kg depending on the specification.

Key Performance Advantages for Industrial Operators

When you choose Shanghai Rousheng’s specialized cabling for your fleet of crawlers or cleaning robots, you secure several operational advantages.

Signal Integrity for HD Diagnostics

Modern inspections require clarity. Whether detecting hairline cracks or verifying CIPP lining curing, the video feed must be crisp. Our cables often integrate coaxial lines with optimized shielding to block electromagnetic interference (EMI) from the robot’s motors, ensuring stable video and data transmission.

Optimized for Cable Drums and Drag Chains

The “Ultra-Soft” designation isn’t just about feel; it’s about physics. A softer, more pliable cable spools tighter and more evenly on automatic cable drums. It resists “corkscrewing” or tangling, which significantly reduces the wear and tear on the automatic payout systems of expensive crawler vans.

Global Compliance and Safety

In line with the requirements of major markets in Europe and North America, our manufacturing processes adhere to strict quality controls.

- RoHS Compliant: Free from hazardous substances like lead and mercury.

- Environmental Stability: Designed to withstand oil, acid, alkali, and UV exposure.

Customizable Configurations for Diverse Robots

Pipeline robots vary significantly—from small push-rod cameras for residential plumbing to heavy-duty municipal main line crawlers. We do not believe in a “one size fits all” approach.

Shanghai Rousheng offers extensive customization with low Minimum Order Quantities (MOQ usually starting at 100 meters):

Customization Options:

- Core Structure: We can combine power lines (for the motors/lights) and signal lines (for video/sensors) into a single jacket. Common setups include 2-core, 4-core, or hybrid coaxial+power designs.

- Floating vs. Sinking: Depending on the application, we can adjust the specific gravity of the cable to be neutrally buoyant (for underwater ROVs) or heavy (for sewer crawlers).

- Length: Custom cutting for 100m, 200m, 300m, or 500m reels.

- Branding: OEM services allow for your company logo and part numbers to be printed directly on the cable jacket.

Technical Specifications

To assist engineers and procurement officers in validating compatibility, the following table outlines standard specifications for our Pipeline Robot series.

|

Parameter |

Specification Details |

|---|---|

|

Product Name |

Ultra-Soft Flexible Stranded Copper CCTV Pipeline Robot Cable |

|

Jacket Material |

Special Matte/Glossy Polyurethane (PUR/TPU) |

|

Conductor Material |

High-Purity Stranded Oxygen-Free Copper |

|

Insulation |

Special formulated PVC or PE (Polyethylene) |

|

Reinforcement |

Kevlar / Aramid Fiber Braiding (Customizable Tensile Strength) |

|

Rated Voltage |

300/300V or 300/500V |

|

Temperature Range |

Mobile installation: -20°C to +80°C |

|

Bending Radius |

Mobile use: 7.5 x Cable Diameter (High Flexibility) |

|

Shielding |

Tinned copper braid shielding (density ≥ 85%) for anti-interference |

|

Oil Resistance |

Excellent (Suitable for industrial machinery) |

|

Acid/Alkali Resistance |

High (Suitable for sewage environments) |

|

Standard Lengths |

100m, 200m, 500m drums (Customizable) |

Application Scenarios

Our cables are currently deployed in infrastructure projects globally, serving three primary sectors:

1. Municipal Sewer Inspection (CCTV Crawlers)

This is the primary use case. The cable powers the crawler unit and transmits HD video back to the truck. The Kevlar reinforcement ensures the crawler can be retrieved if it becomes stuck in debris.

2. Pipeline Cleaning and Rehabilitation

Robots equipped with high-pressure water jets or cutting heads require cables that can withstand the vibration and splash-back of industrial cleaning operations. Our PUR jacket sheds water and grime, making post-job cleaning easier for the crew.

3. Industrial Endoscopy and Push Rods

For smaller diameter pipes (DN50-DN150), stiffness is required to push the camera, yet flexibility is needed to navigate 90-degree bends. We engineer specialized semi-rigid push cables using fiberglass reinforced cores mixed with copper for these applications.

Frequently Asked Questions (FAQ)

Q: Can this cable withstand continuous immersion in water?

A: Yes. The Polyurethane (PUR) jacket is hydrolysis-resistant and impermeable, making it suitable for wet sewer lines and underwater applications up to moderate depths (IP68 equivalent protection when properly terminated).

Q: What is the tensile strength of the cable?

A: This depends on the specific customization. Standard models include Kevlar braiding that can withstand pull forces ranging from 50kg to over 200kg, preventing copper breakage during retrieval.

Q: How does this cable compare to standard rubber cables?

A: PUR cables are significantly lighter and thinner than rubber cables of the same rating, allowing for longer lengths to fit on smaller reels. They also possess far superior resistance to cutting and abrasion.

Q: Is the signal transmission compatible with 4K or 1080p cameras?

A: Absolutely. We can manufacture the signal components of the cable using coaxial structures or twisted pairs with high shielding rates to support high-bandwidth digital video transmission without signal loss.

Q: What is the lead time for a custom order?

A: For standard specifications under 1000 meters, lead time is typically around 15 days. Larger custom orders or complex hybrid structures are negotiated based on production slots, ensuring efficient delivery for your project schedules.

Why Partner with Shanghai Rousheng?

Sourcing specialized cable is not just about the product; it is about the reliability of the supply chain. Shanghai Rousheng Wire and Cable Co., Ltd. has established itself as a leader in the special cable sector by focusing on “Value Engineering.”

We do not simply extrude plastic over wire. We analyze the stress points of robotic applications and engineer cables that extend the service life of your expensive machinery. With ISO-certified manufacturing and a global footprint, we provide the documentation, testing reports, and consistent quality required by major European and American distributors.

From the first meter to the last, our cables are built to ensure that your inspection data flows uninterrupted, regardless of the conditions underground.