Subsea Sensor Networks | Neutral Buoyancy Cable | Anti-Corrosion | Shielded Structure, Long Service Life

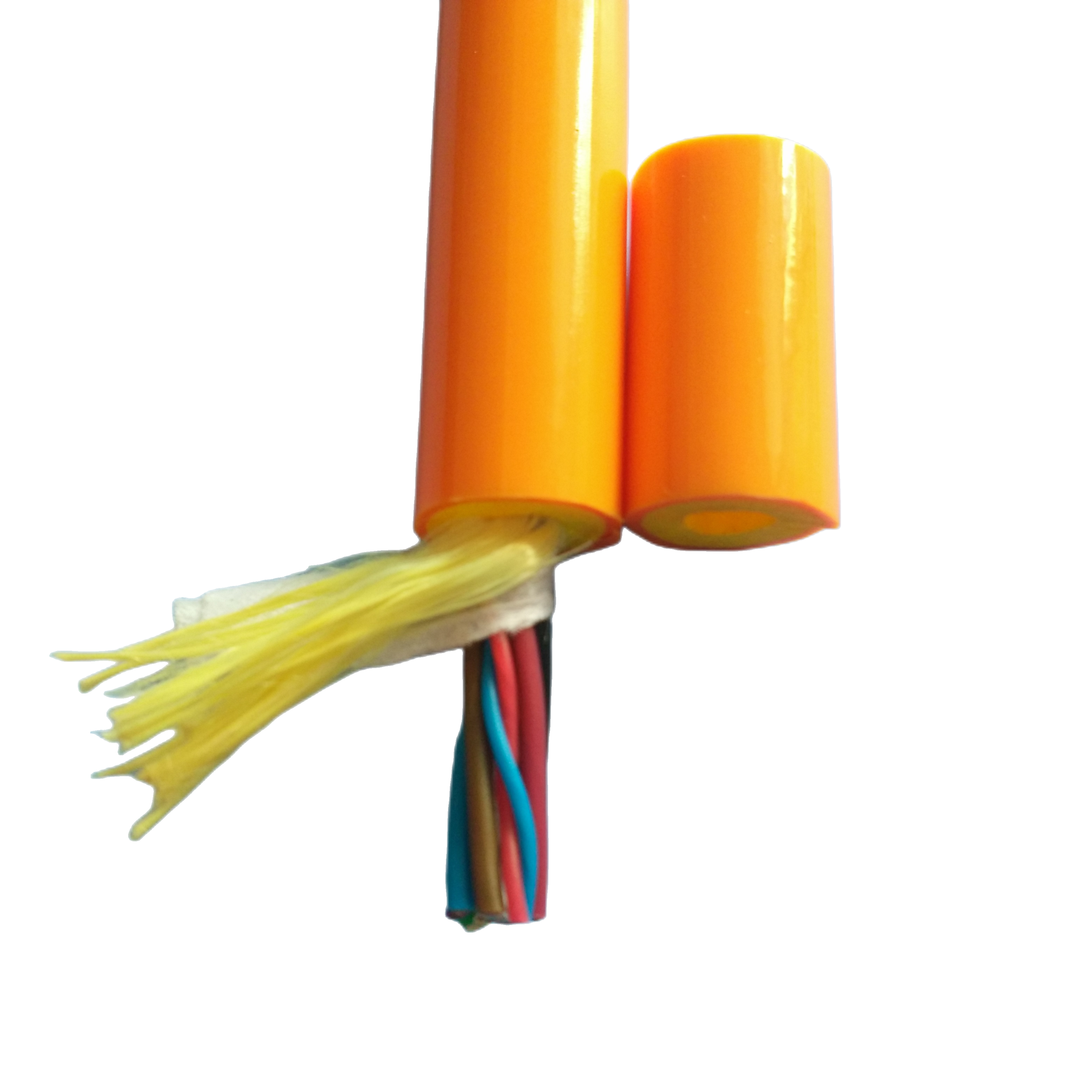

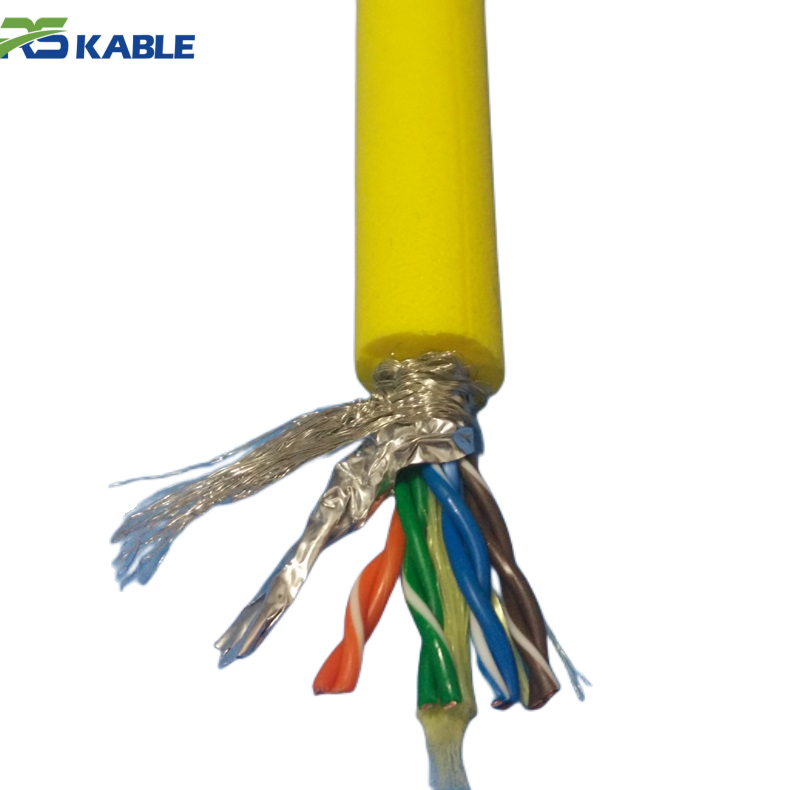

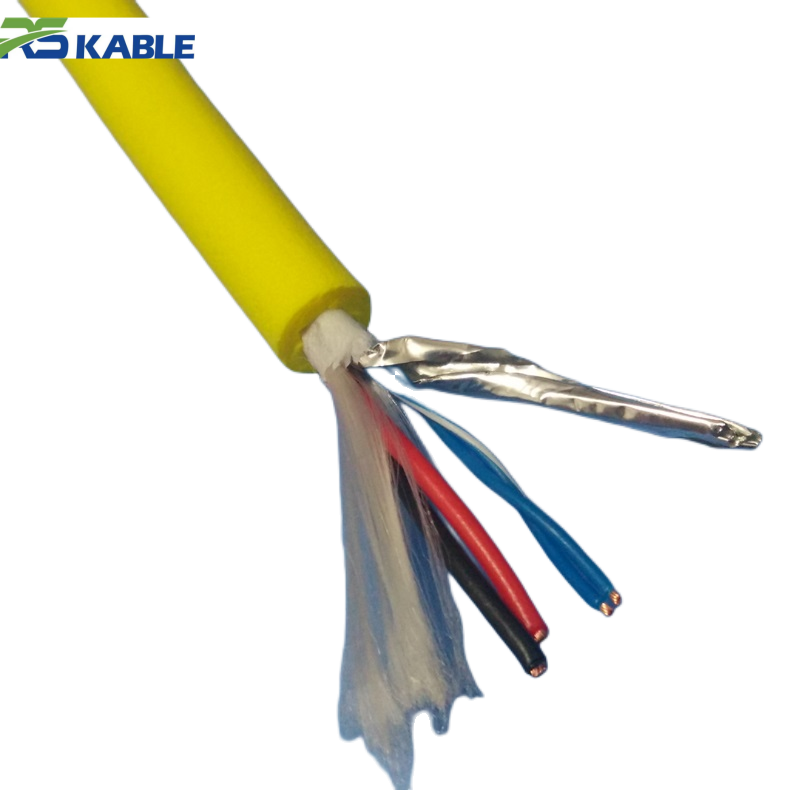

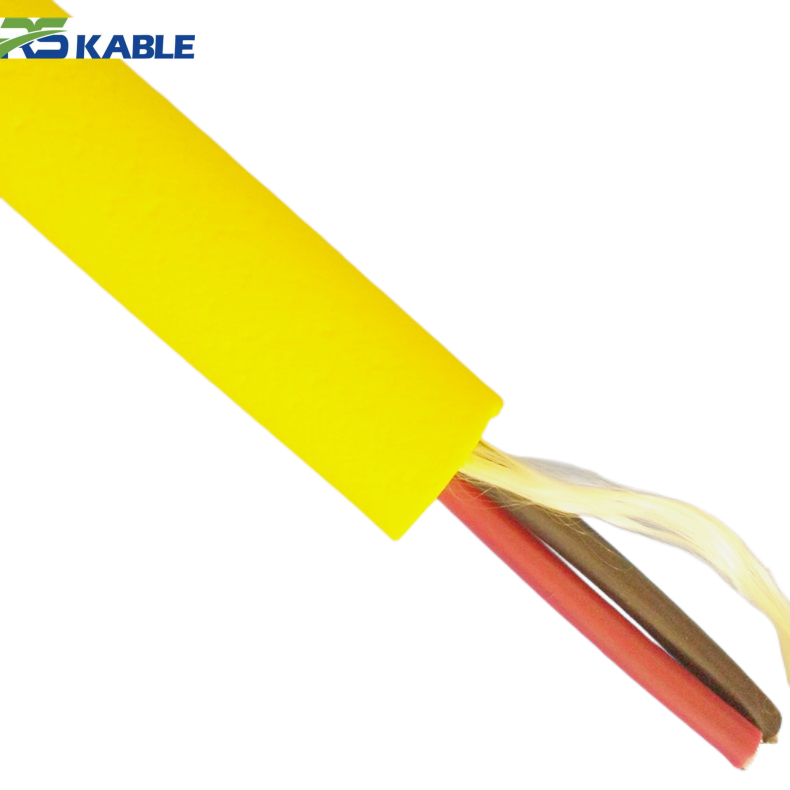

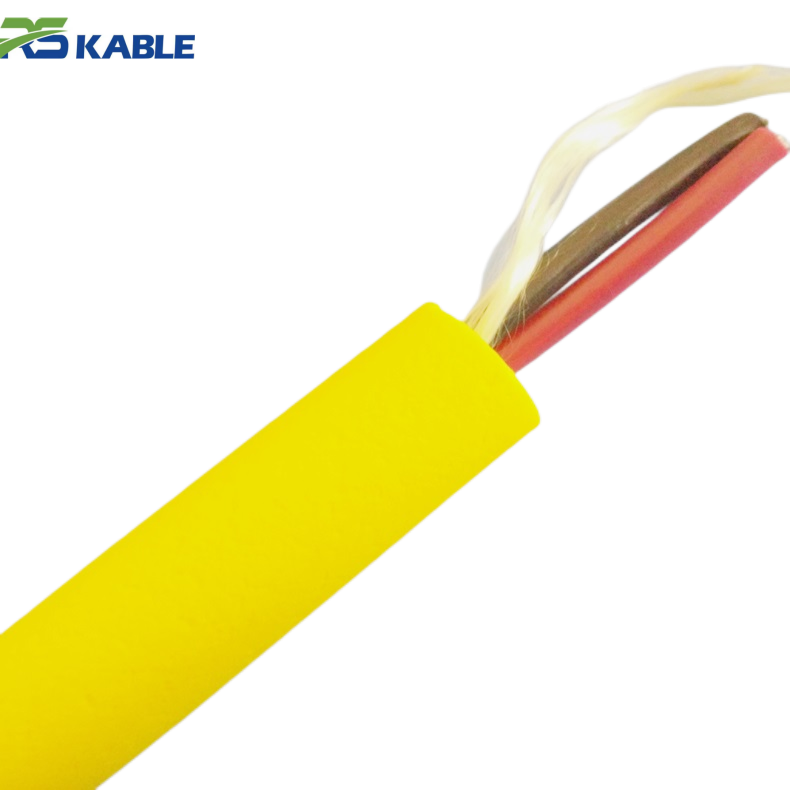

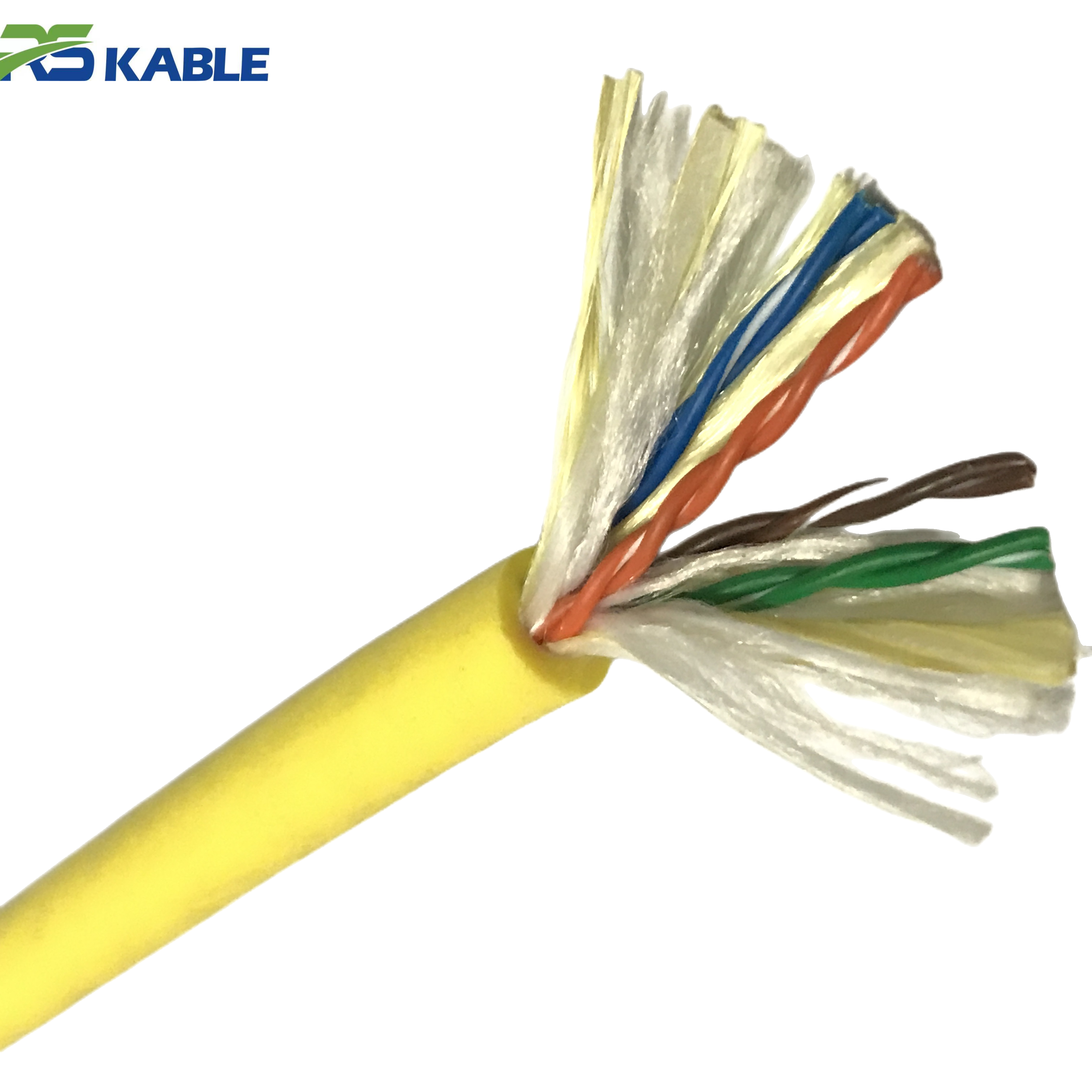

• Conductor: High-conductivity tinned multi-stranded copper, ensuring long-term corrosion resistance and stable sensor data transmission.

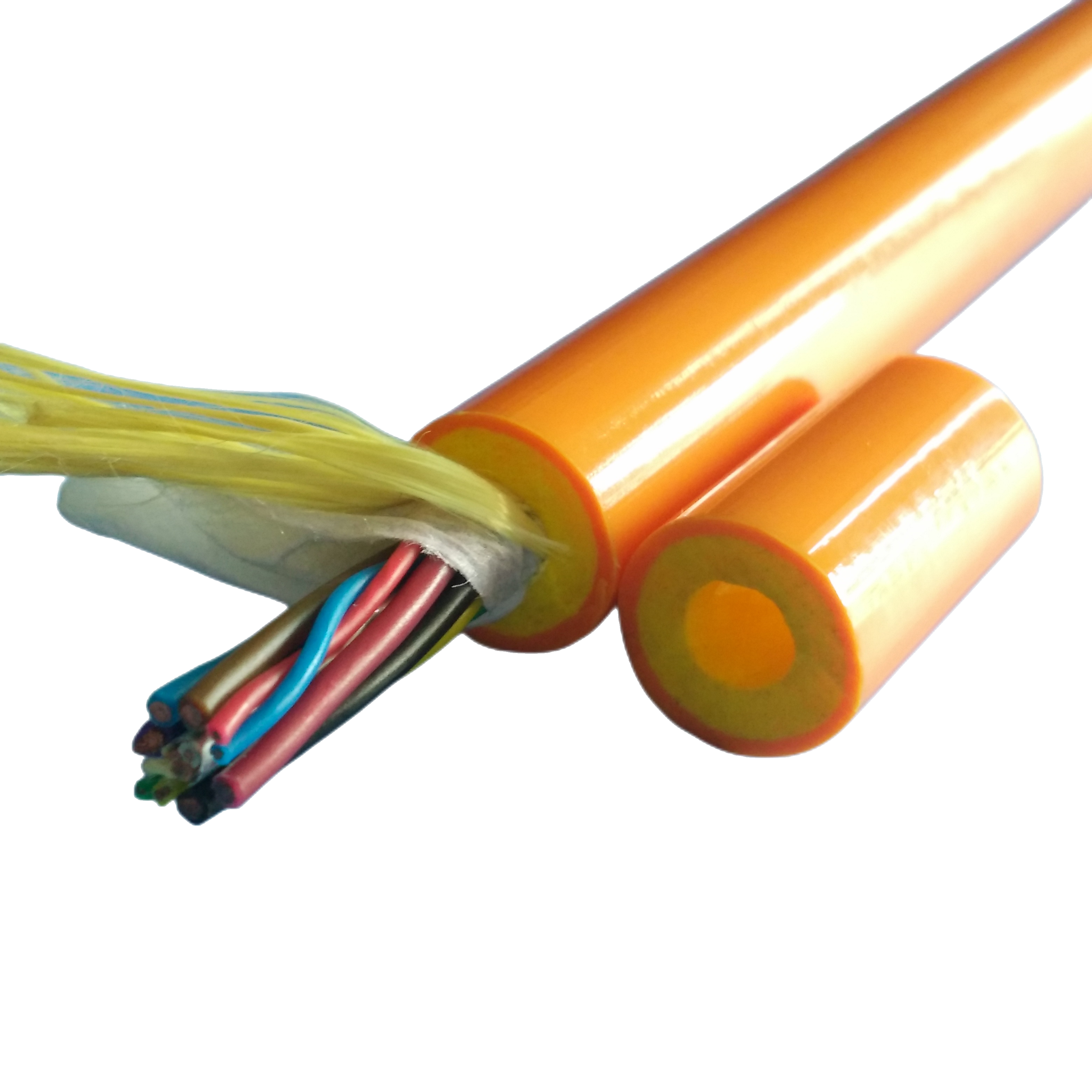

- Jacket: Specialized anti-corrosion thermoplastic compound with anti-biofouling properties, suitable for years of continuous subsea immersion.

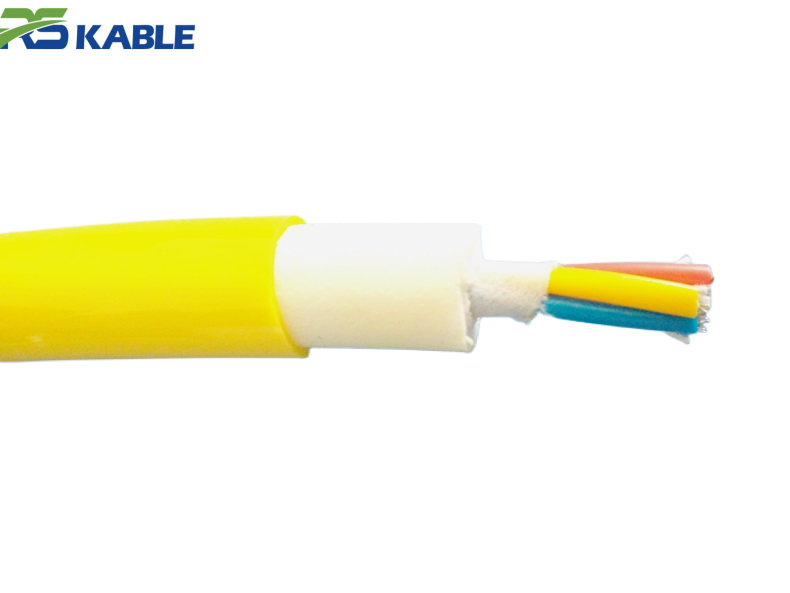

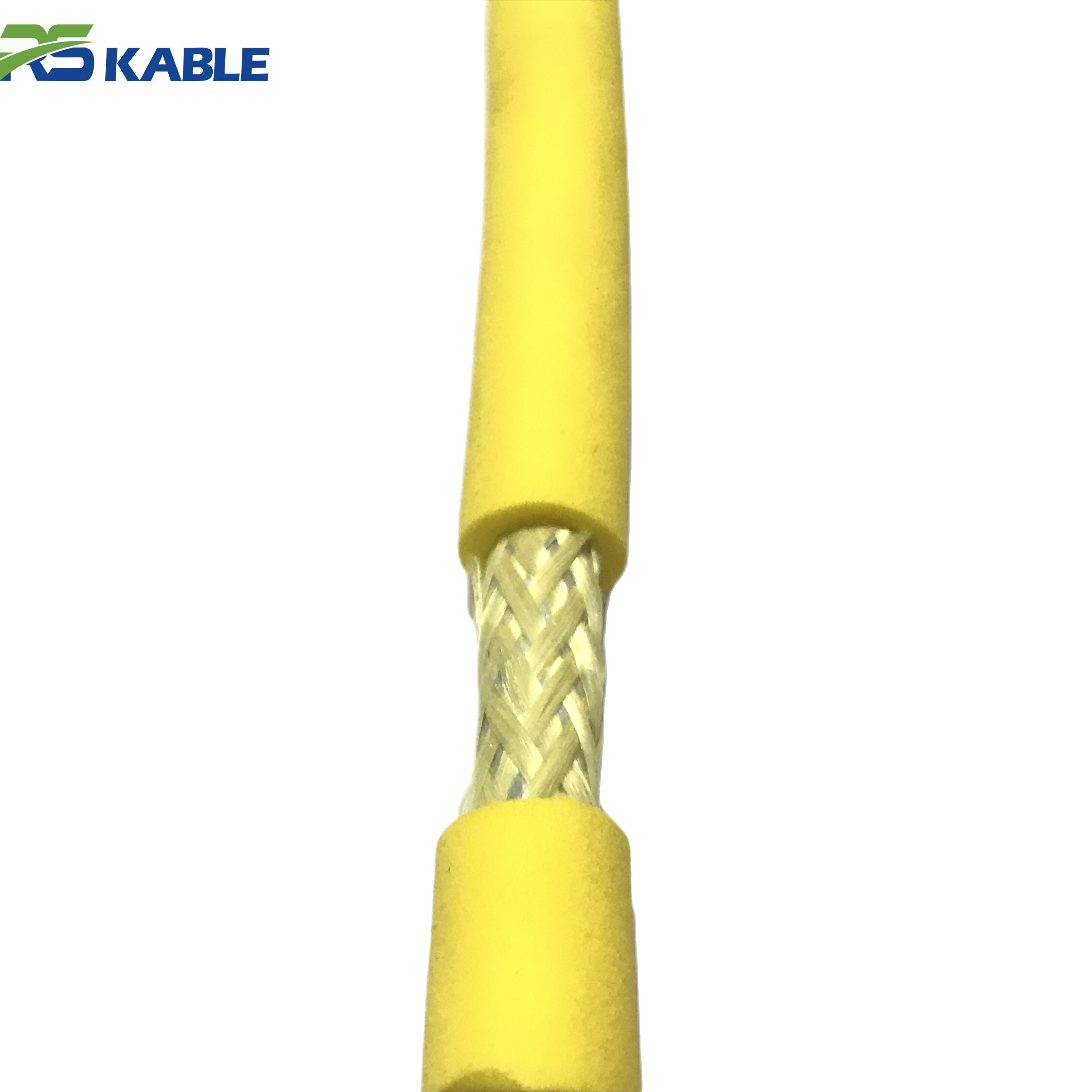

- Structure: Multi-layer shielding design combined with high-modulus synthetic fiber strength members, providing superior EMI protection and mechanical integrity.

- Performance: Rated service life of 20+ years, ideal for fixed seafloor installations with minimal maintenance required.

- Environment: Precise neutral buoyancy, resistant to deep-sea high pressure and chemical erosion, optimized for harsh ocean observation network environments.

Subsea Sensor Networks | Neutral Buoyancy Cable | Anti-Corrosion | Shielded Structure, Long Service Life

Enhance the reliability of your subsea sensor networks with our advanced Neutral Buoyancy Cable—designed for permanent or semi-permanent underwater deployments. Featuring anti-corrosion materials, multi-layer shielding, and precisely calibrated buoyancy, this cable ensures stable power and data transmission for seafloor sensor arrays, ROVs, and long-term ocean monitoring systems.

With over 20 years of subsea cable expertise and successful deployments across global observatories, our solutions are manufactured under ISO 9001:2015 standards, comply with RoHS and REACH, and offer optional third-party approvals from DNV, ABS, and Lloyd’s Register.

Why Our Neutral Buoyancy Cable Excels in Subsea Sensor Networks

For long-term ocean monitoring, cable integrity is critical. Our Neutral Buoyancy Cable combines anti-corrosion protection, robust shielding, and precise neutral buoyancy to prevent vertical stress on sensors and moorings.

Key benefits include:

-

Advanced anti-corrosion barriers: specialized polymers and sacrificial layers for saltwater and microbial protection

-

Multi-layer shielded structure: blocks EMI/RFI from nearby power lines or environmental sources

-

Extended service life: typically 15–25 years in continuous submersion

-

Precise neutral buoyancy: eliminates vertical tension/compression on seafloor installations

-

Low-maintenance design: resistant to biofouling and chemical degradation

-

High signal integrity: ideal for acoustic, seismic, and environmental sensor arrays

Product Models & Core Attributes

| Model | Core Attributes | Conductor & Signal Configuration | Rated Depth | Outer Diameter | Expected Service Life |

|---|---|---|---|---|---|

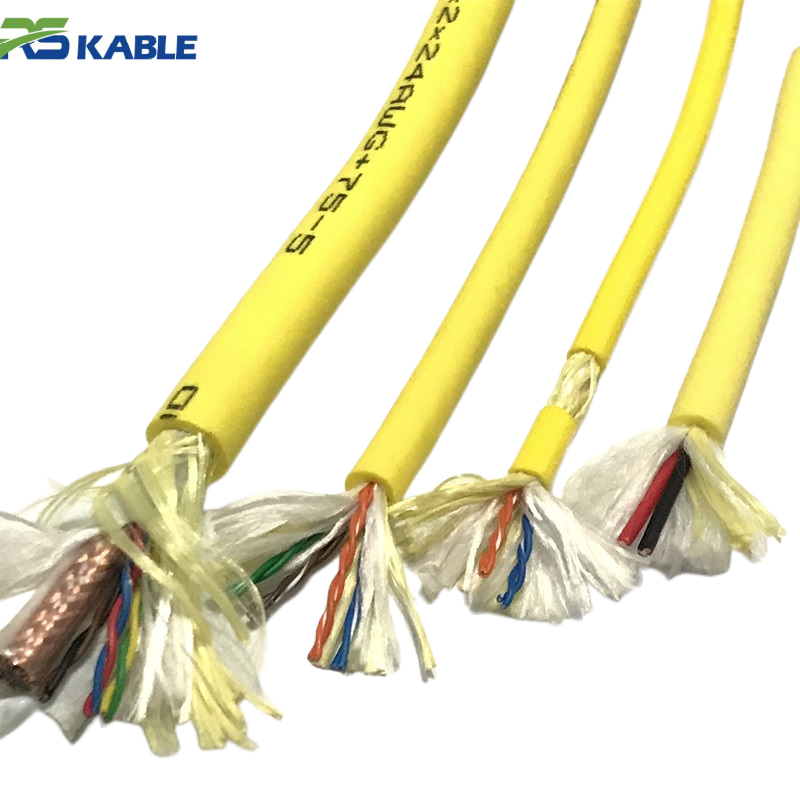

| NB-SSN-8S | 8 signal cores, heavy shielding, anti-corrosion | 8 × 0.75 mm² twisted shielded pairs | 4,000 m | 20.1 mm | 20+ years |

| NB-SSN-12M | 12 mixed cores, multi-layer shield, long-life jacket | 6 × 1.0 mm² power + 6 × 0.5 mm² signal | 5,000 m | 23.7 mm | 20+ years |

| NB-SSN-FO | Fiber optic hybrid, enhanced anti-corrosion | 4 × 1.5 mm² + 4–12 fiber elements | 6,000 m | 22.4 mm | 25+ years |

| NB-SSN-XHD | Extra heavy-duty, triple shield, maximum longevity | 8 × 2.0 mm² + multi-pair shielded | 6,000 m | 27.8 mm | 25+ years |

All models incorporate specialized seawater-resistant jackets and multi-layer shielding for superior EMI rejection and corrosion protection.

Applications & Deployment Scenarios

Our Neutral Buoyancy Cable is ideal for subsea sensor networks and long-term ocean monitoring systems:

-

Cabled ocean observatories (e.g., NEPTUNE, OOI, EMSO networks)

-

Seismic and tsunami early-warning arrays

-

Environmental monitoring for climate research and carbon sequestration

-

Distributed temperature and pressure sensing along subsea pipelines

-

Acoustic sensor networks for marine mammal tracking and naval applications

-

Permanent underwater IoT and data collection platforms

Long-tail SEO phrases: neutral buoyancy cable for subsea sensor networks anti-corrosion, long-life shielded tether for ocean observatories, anti-corrosion neutral buoyancy cable for 6000m seafloor installations.

Technical Specifications

| Parameter | Specification | Standard / Notes |

|---|---|---|

| Conductor | Tinned high-conductivity copper strands | IEC 60228, Class 5/6 |

| Insulation | Cross-linked polyethylene (XLPE) or equivalent | Low water permeation, stable over decades |

| Shielding | Triple-layer: foil + braid + conductive polymer | >95% coverage, EMI/RFI rejection |

| Strength Member | High-modulus synthetic fibers (aramid or similar) | Load bearing ≥2,500 kg |

| Outer Jacket | Specialized anti-corrosion thermoplastic compound | Resistant to hydrolysis, biofouling, chemicals |

| Buoyancy | Precisely neutral in seawater (customizable) | Density 1.01 ± 0.01 g/cm³ |

| Operating Temperature | –20°C to +70°C | Suitable for deep-ocean deployment |

| Voltage Rating | 300/600V (higher available on request) | Safe for sensor power and data |

| Certifications | ISO 9001, RoHS, REACH, optional DNV/ABS/LR | Independently verified performance |

Engineering Credibility & Quality Assurance (E-E-A-T)

-

Developed by subsea cable engineers with decades of experience

-

Manufactured under ISO 9001:2015 certified quality systems

-

Fully tested for long-term immersion, flex, and mechanical loads

-

Optional DNV, ABS, Lloyd’s Register approvals for global compliance

-

Proven performance in ocean observatories and commercial subsea projects

Customization & Ordering Options

-

Conductor count and fiber integration adjustments

-

Jacket, armor, and anti-corrosion enhancements

-

Buoyancy calibration for specific water types

-

Factory-terminated connectors (SubConn®, SEACON, Burton)

Contact our engineering team for tailored project solutions and quotations.

Frequently Asked Questions (FAQ)

Q: How is long service life achieved in corrosive seawater?

A: Through multi-layer anti-corrosion barriers, non-metallic strength members, and advanced polymer jackets tested for accelerated aging equivalent to 25+ years.

Q: What level of EMI shielding does the cable provide?

A: Multi-layer shielding provides >95% coverage, ideal for noise-sensitive sensor networks.

Q: Can the cable be customized for specific sensor protocols?

A: Yes. We can tailor conductor count, fiber integration, breakout configurations, and terminations.

Q: Is independent verification available?

A: Yes. Third-party reports and classification society approvals (DNV, ABS, LR) can be provided.

Q: How is neutral buoyancy maintained over long deployments?

A: Materials are selected and calibrated for minimal density change over time, ensuring consistent performance.