Subsea Robotic Platforms | Neutral Buoyancy Cable | Mechanical Stability | Reinforced Jacket Design

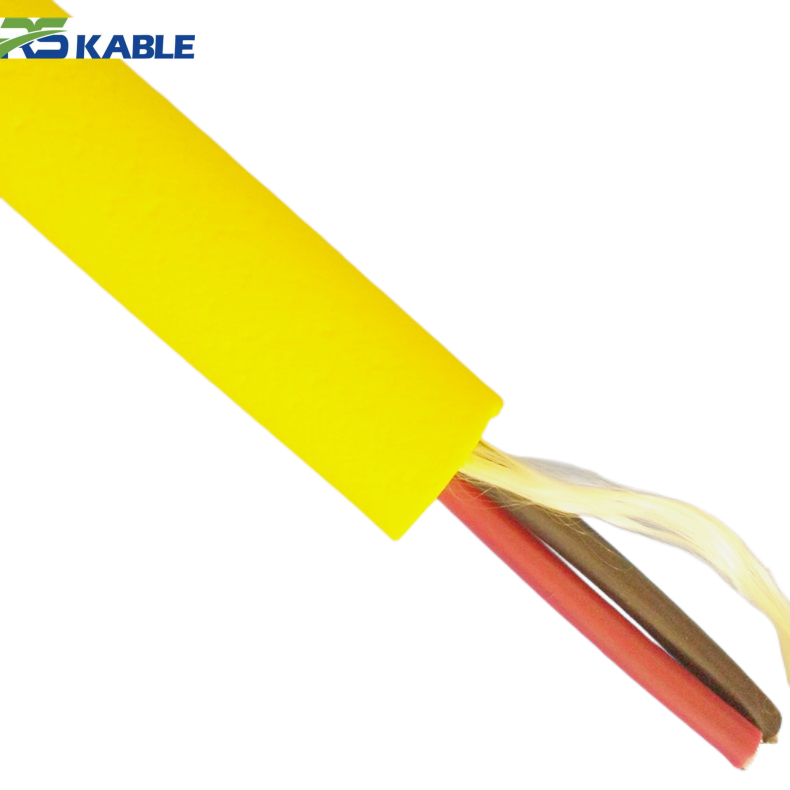

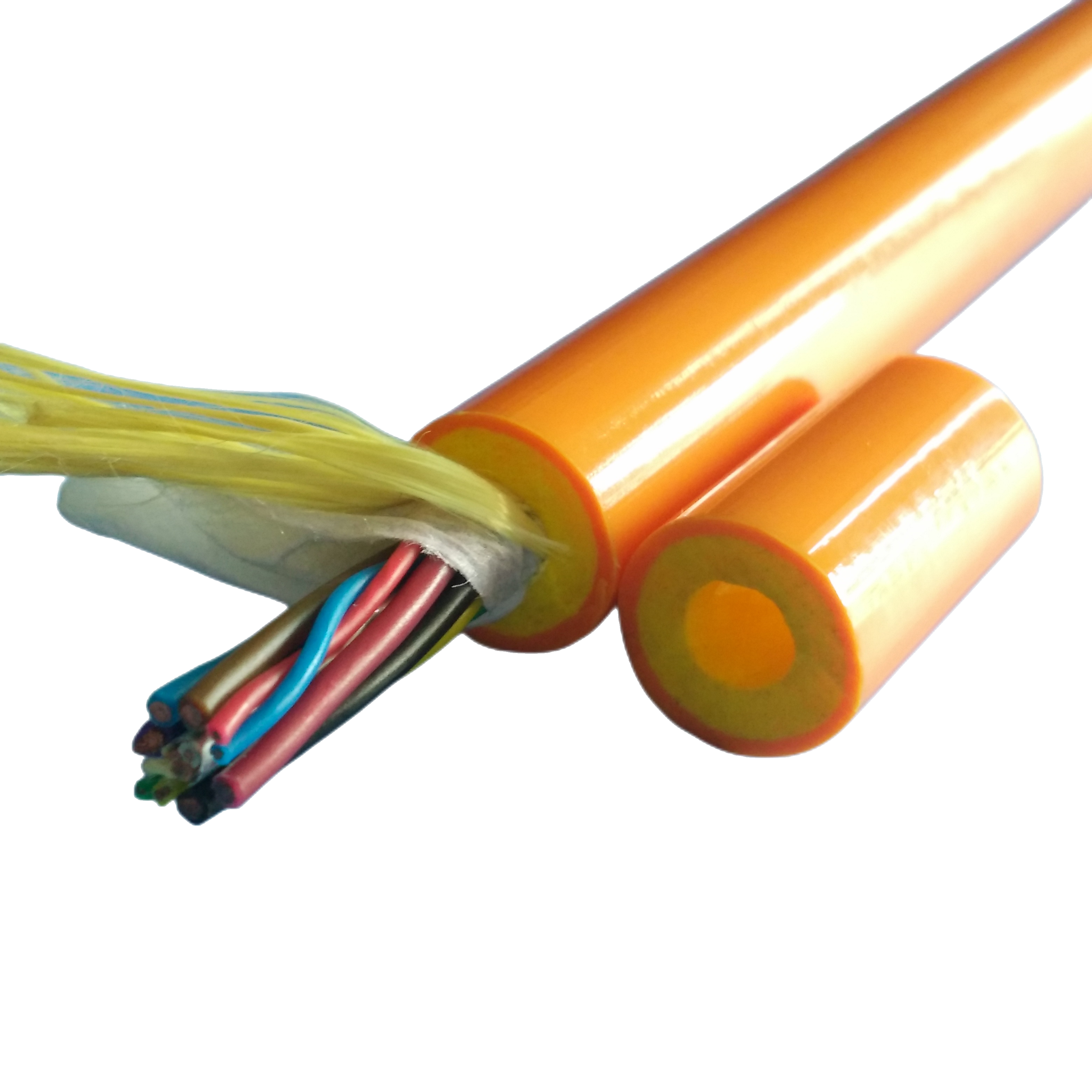

This Neutral Buoyancy Cable is designed for subsea robotic platforms requiring mechanical stability and enhanced physical protection. Featuring a reinforced jacket and balanced buoyancy, it reduces drag and stress during robotic movement while ensuring reliable power and signal transmission in demanding underwater environments.

Subsea Robotic Platforms | Neutral Buoyancy Cable | Mechanical Stability | Reinforced Jacket Design

Subsea robotic platforms operate in environments where cable-induced forces directly affect system stability and control accuracy. This Neutral Buoyancy Cable is engineered to provide balanced underwater suspension and enhanced mechanical protection, reducing drag, vibration, and structural stress during robotic operation.

With a reinforced jacket design and controlled buoyancy, it supports reliable power and signal transmission while maintaining mechanical integrity in demanding subsea robotic applications.

Mechanical Stability as a System Requirement

Unlike fixed subsea installations, robotic platforms involve continuous movement, articulation, and interaction with surrounding structures. In such systems, cable instability can lead to:

-

Unwanted torque affecting robotic positioning

-

Increased load on joints, frames, and connectors

-

Accelerated wear due to abrasion and bending

-

Reduced operational precision in confined environments

A properly engineered Neutral Buoyancy Cable helps stabilize cable behavior, becoming an integral part of the robotic system rather than a limiting factor.

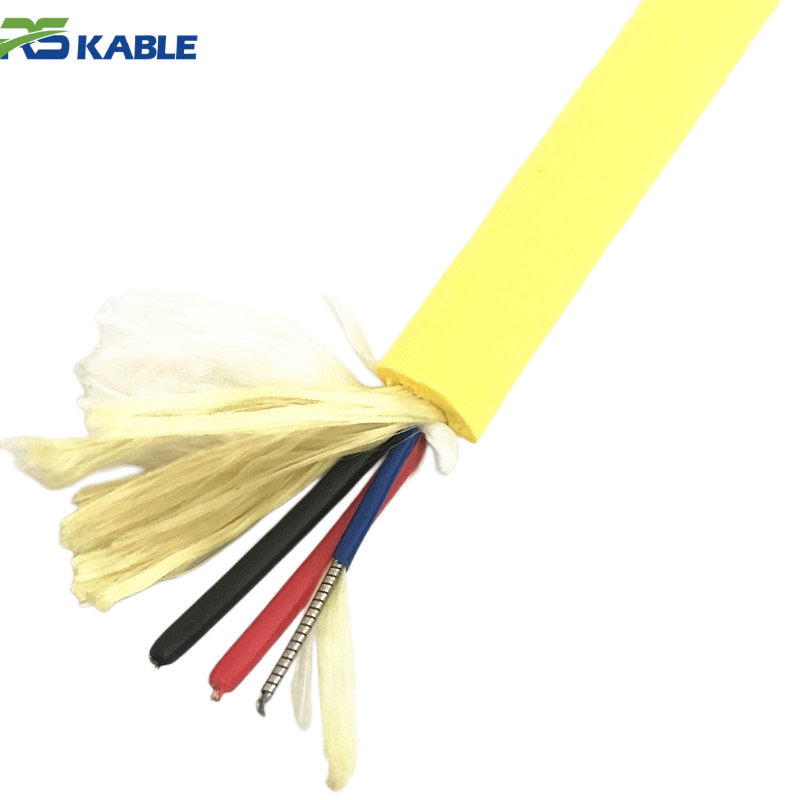

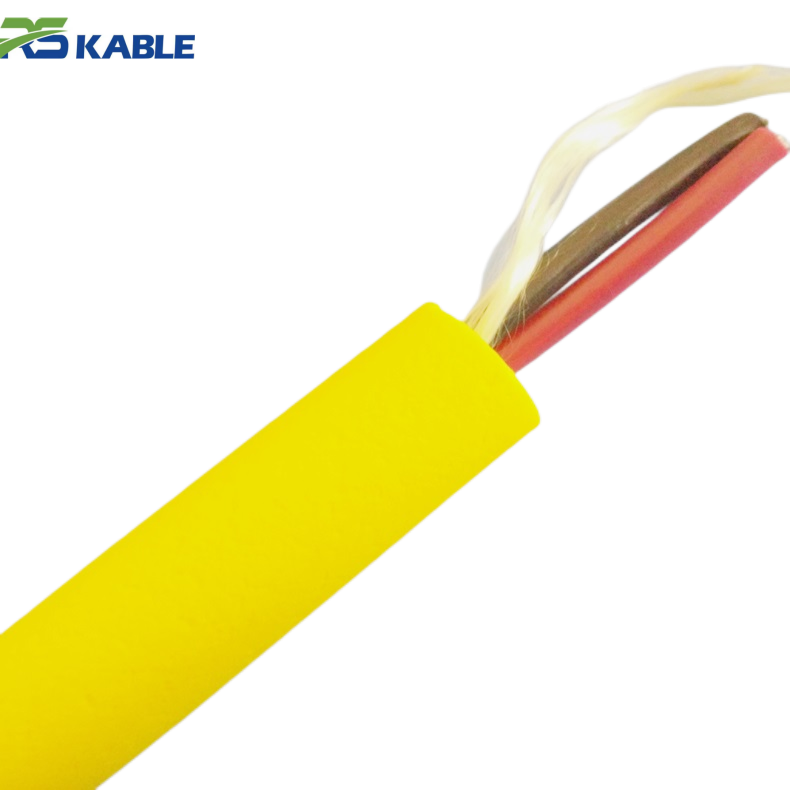

Reinforced Jacket Design for Robotic Operations

Subsea robotic platforms frequently operate near structures, seabeds, and equipment where physical contact is unavoidable. This cable incorporates a reinforced outer jacket to address these risks:

-

Abrasion-resistant marine-grade compounds

-

Enhanced cut and tear resistance

-

Structural reinforcement for load distribution

-

Protection against impact and localized compression

These features allow the cable to withstand repeated mechanical interaction without compromising performance.

Typical Applications & Robotic Platforms

This cable solution is widely used across various subsea robotic systems, including:

-

Work-class and inspection-class ROV platforms

-

Autonomous subsea robotic systems

-

Intervention and maintenance robots

-

Subsea construction and tooling platforms

-

Research and industrial robotic manipulators

Its stable behavior makes it suitable for both dynamic operation and semi-static robotic positioning.

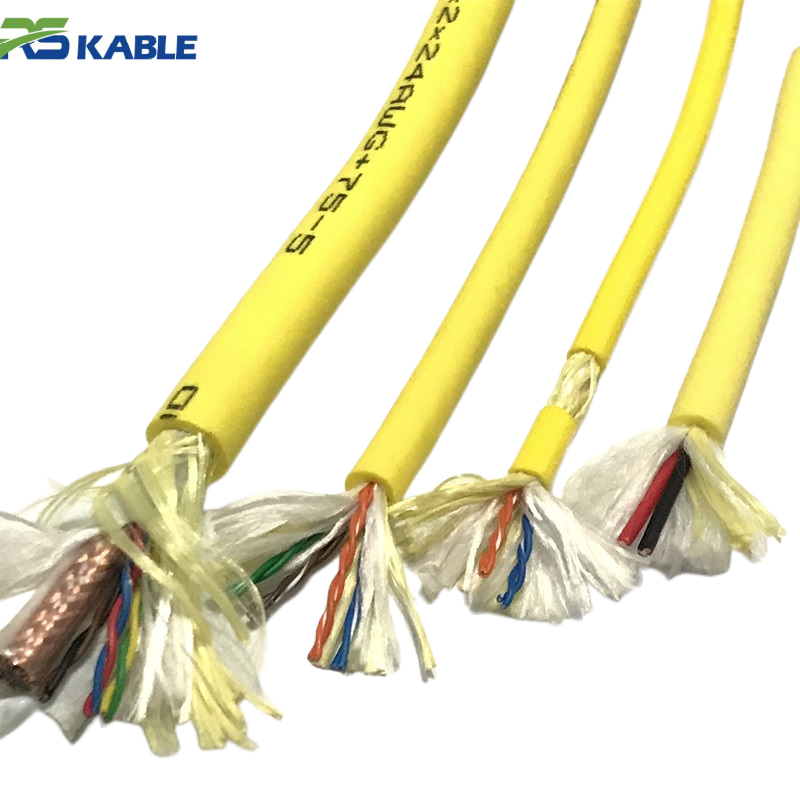

Product Configuration Overview

| Product Name / Model | Core Attributes |

|---|---|

| NB-RP Series Neutral Buoyancy Cable | Reinforced jacket, mechanical stability, robotic-platform optimized |

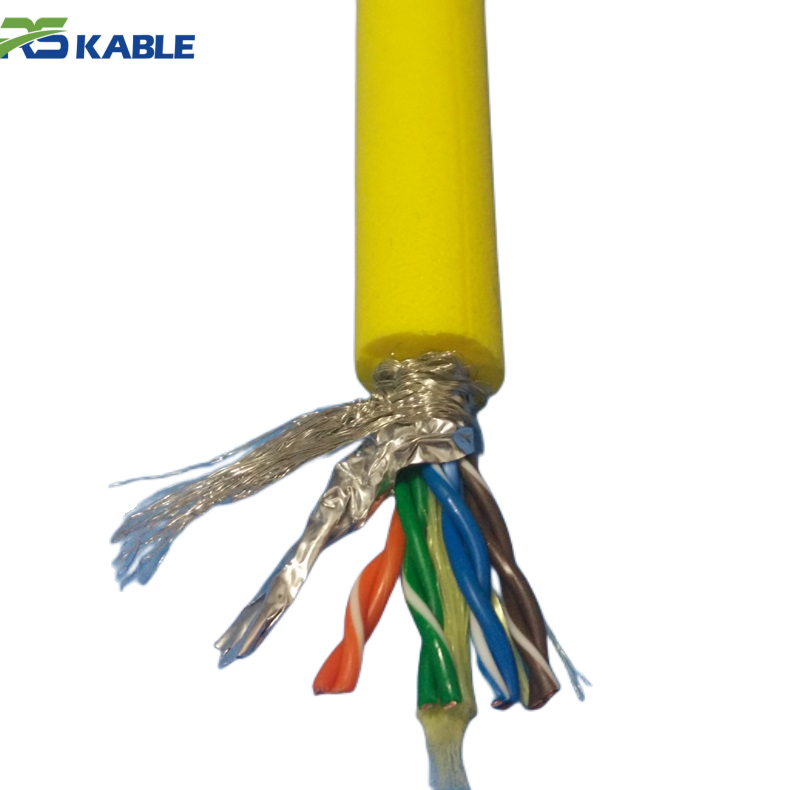

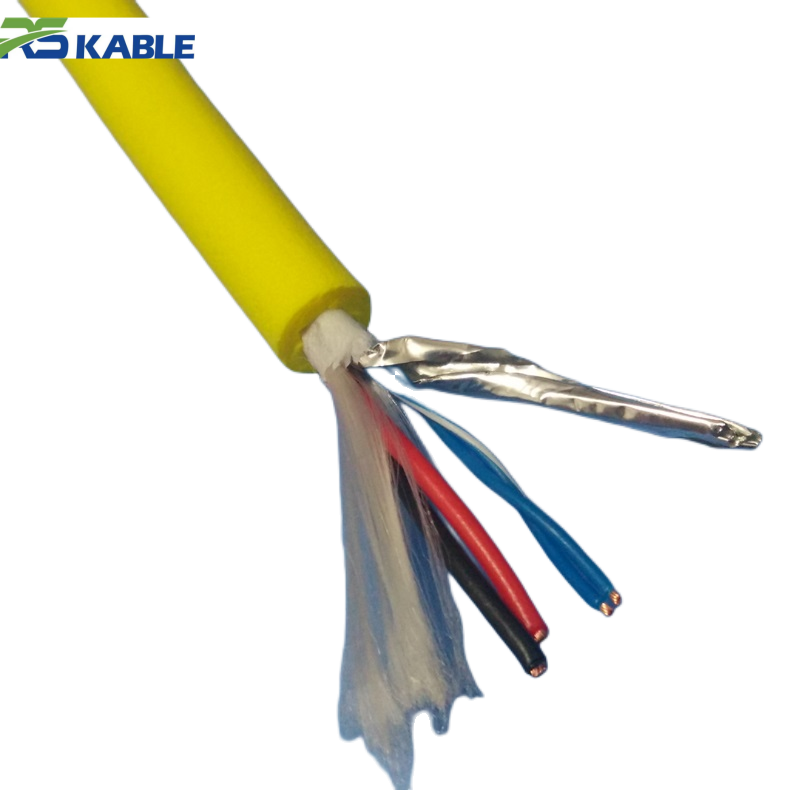

Key Technical Parameters

| Parameter | Specification Options |

|---|---|

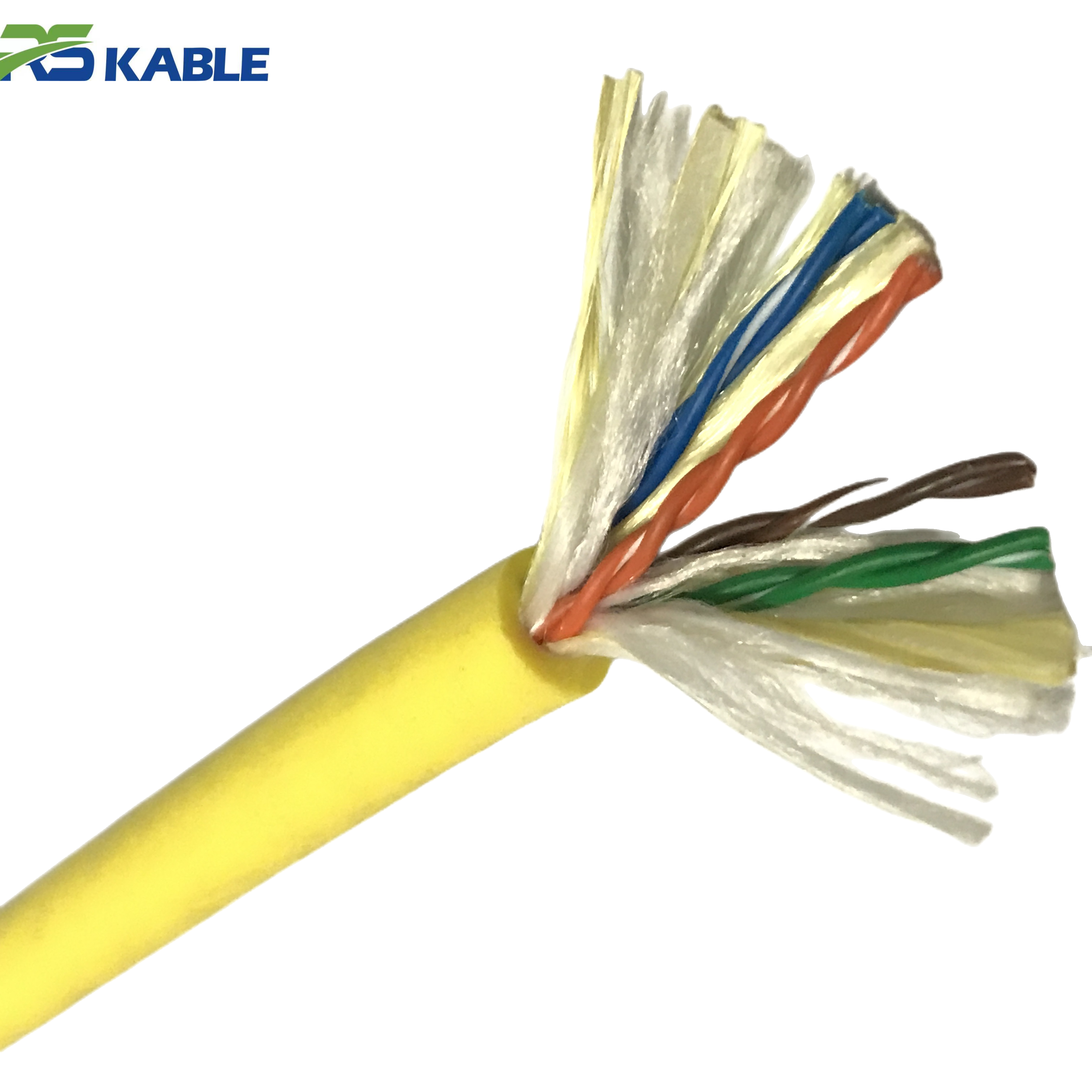

| Core Configuration | Power, signal, or hybrid power & signal |

| Conductor Material | Fine-stranded tinned copper |

| Insulation | PE / XLPE / TPU |

| Buoyancy Control | Precision-balanced fillers for neutral density |

| Outer Jacket | Reinforced marine-grade polyurethane |

| Mechanical Protection | Abrasion- and impact-resistant structure |

| Operating Environment | Continuous freshwater or seawater immersion |

| Bending Radius | Designed for dynamic robotic motion |

| Temperature Range | -40°C to +90°C |

Core count, jacket thickness, and buoyancy balance can be customized to match robotic platform design requirements.

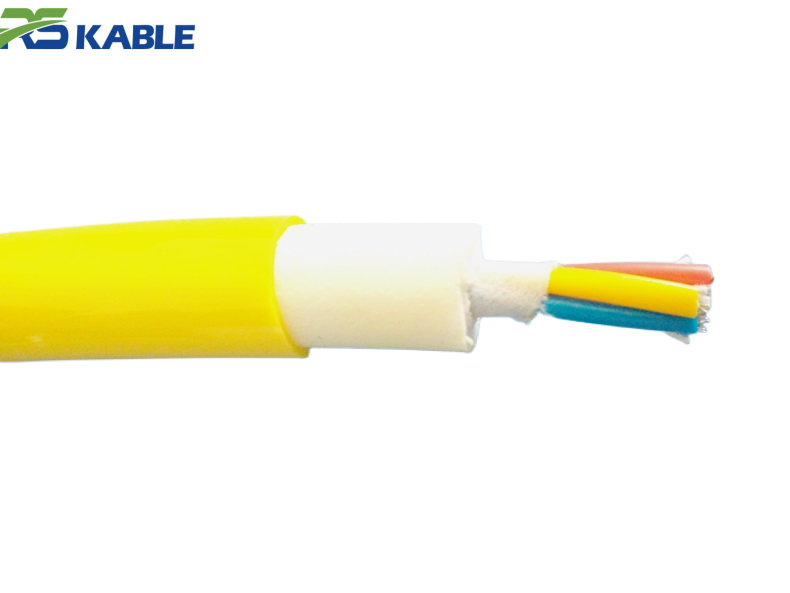

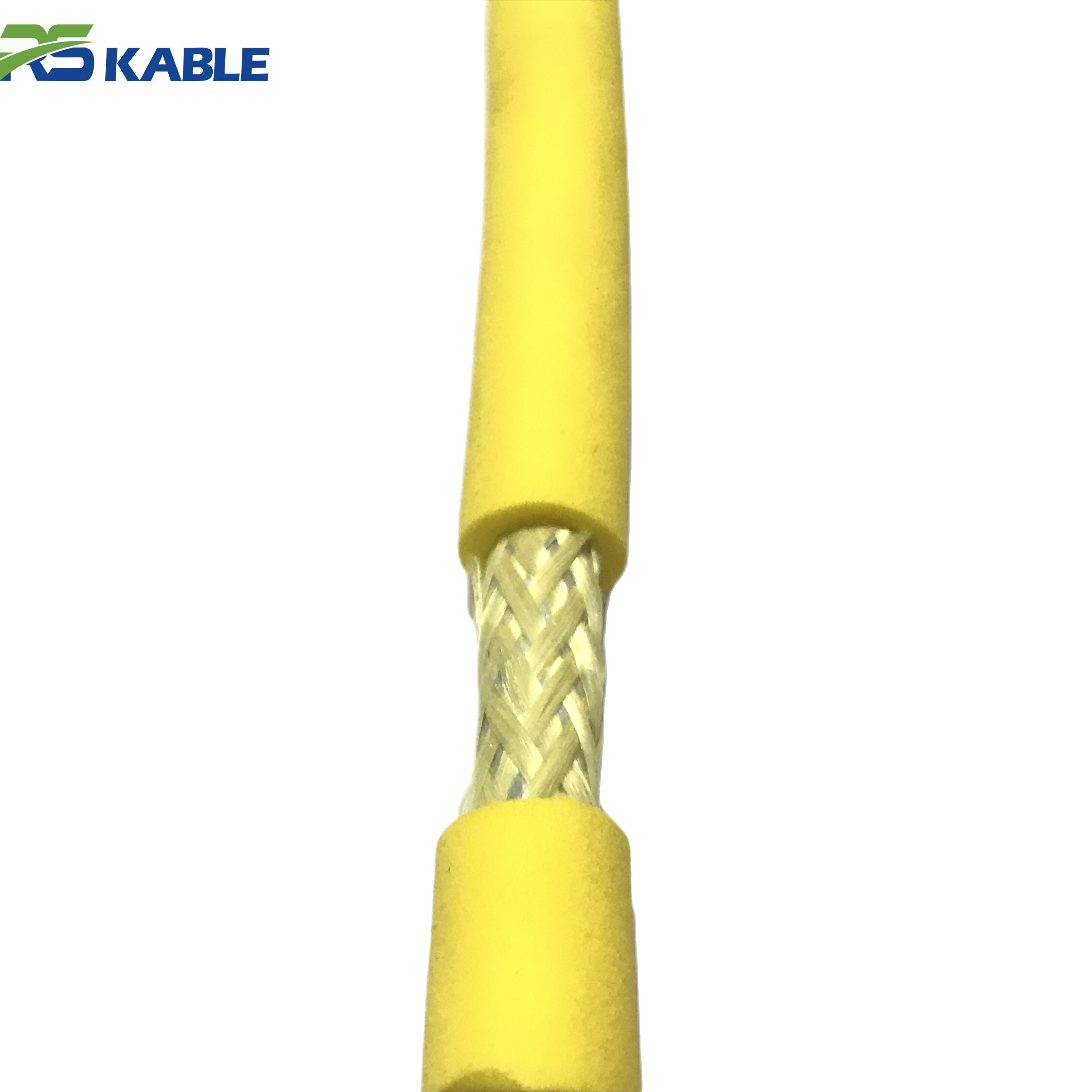

Structural Design for Dynamic Robotic Movement

To support robotic platforms with complex motion profiles, this Neutral Buoyancy Cable integrates:

-

Low-stress internal core layout to reduce fatigue

-

Anti-twist reinforcement for directional stability

-

Multi-layer sealing to prevent water ingress

-

Load-sharing structure to protect internal conductors

These design elements help ensure consistent performance under repeated movement cycles.

Operational Benefits for Subsea Robotics

When deployed on subsea robotic platforms, this Neutral Buoyancy Cable provides:

-

Improved mechanical stability during maneuvering

-

Reduced drag and resistance in confined spaces

-

Lower stress on robotic joints and connectors

-

Enhanced durability in contact-prone environments

This directly contributes to safer operation and longer system service life.

Engineering Quality & Compliance (E-E-A-T)

-

Designed by engineers experienced in subsea robotic cable systems

-

Manufactured under ISO-certified quality management systems

-

Tested for mechanical endurance, buoyancy balance, and sealing integrity

-

Materials selected for long-term subsea robotic deployment

Each configuration is reviewed to ensure alignment with real-world robotic operating conditions.

Customization & Technical Support

We support subsea robotics manufacturers and operators with:

-

Platform-specific cable design and optimization

-

Jacket reinforcement selection based on operating risk

-

Hybrid configurations for integrated robotic systems

-

Technical drawings, testing data, and validation samples

👉 Request a technical consultation or custom quotation today.

FAQ

Is this cable suitable for highly dynamic robotic platforms?

Yes. The structure and bending radius are designed for repeated robotic motion.

How does the reinforced jacket improve reliability?

It protects against abrasion, impact, and compression common in robotic operations.

Can power and signal be combined in one cable?

Yes. Hybrid power and signal configurations are available.

Is buoyancy adjustable for different robotic systems?

Yes. Buoyancy can be tuned to match system weight and deployment conditions.