Subsea Engineering Projects | Neutral Buoyancy Cable | Structural Durability | Heavy-Duty Outer Sheath

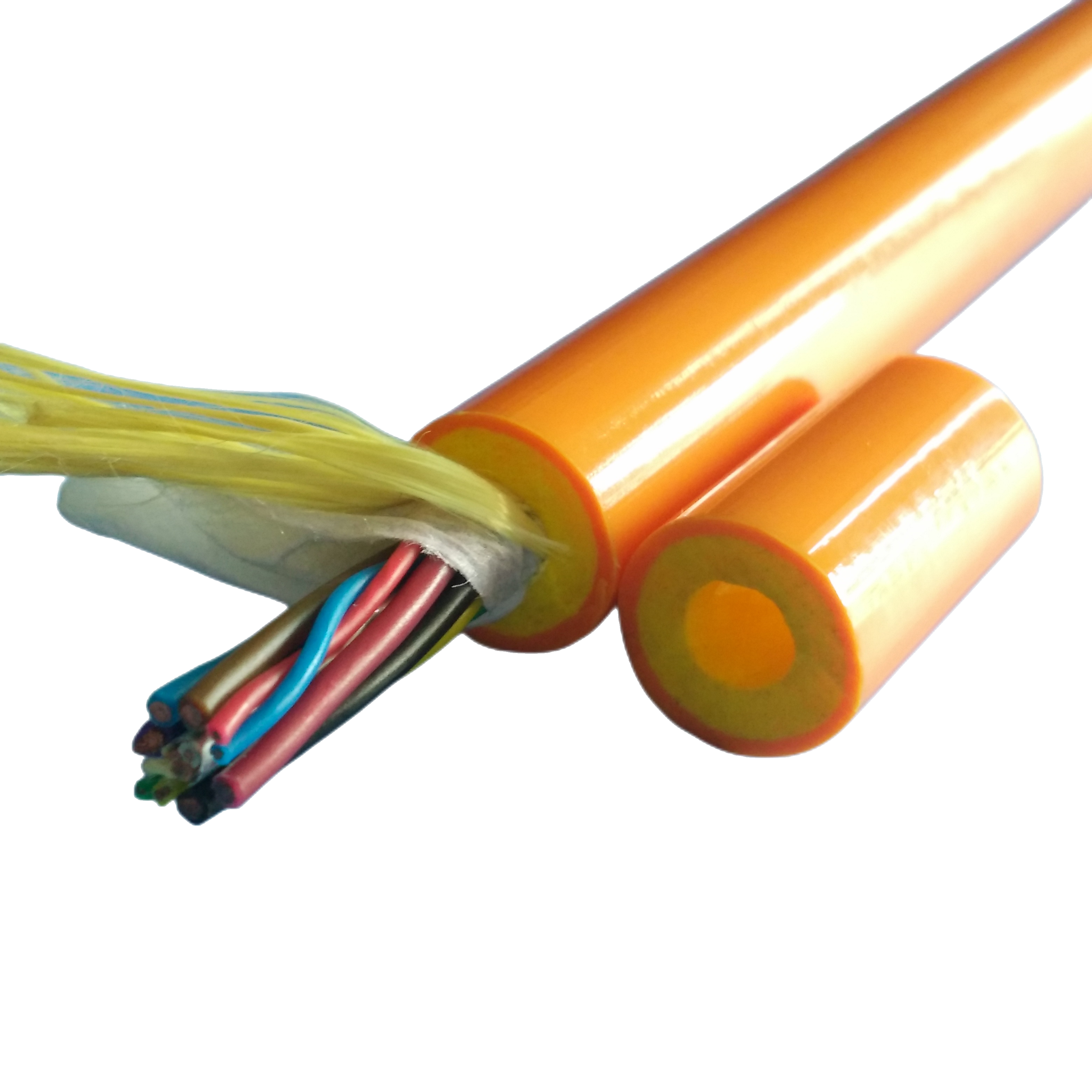

This Neutral Buoyancy Cable is designed for subsea engineering projects requiring structural durability and heavy-duty protection. Featuring a reinforced outer sheath and balanced buoyancy, it supports reliable power and signal transmission in demanding underwater construction and engineering environments.

Subsea Engineering Projects | Neutral Buoyancy Cable | Structural Durability | Heavy-Duty Outer Sheath

Subsea engineering projects demand cable systems capable of withstanding high mechanical loads, harsh seabed contact, and long-term underwater exposure. This Neutral Buoyancy Cable is designed with a heavy-duty outer sheath and reinforced internal structure to deliver structural durability and stable performance in complex subsea engineering environments.

By maintaining balanced buoyancy while providing enhanced mechanical protection, it supports reliable power and signal transmission throughout demanding underwater construction and engineering operations.

Engineering-Grade Requirements in Subsea Projects

Unlike inspection or research tasks, subsea engineering projects involve direct interaction with the seabed, structures, and tools. Cable systems in these environments are commonly exposed to:

-

Continuous abrasion against hard surfaces

-

Localized compression and impact loads

-

Extended static and semi-static deployment

-

High mechanical stress during installation and recovery

A robust Neutral Buoyancy Cable is essential to maintain system integrity under these conditions.

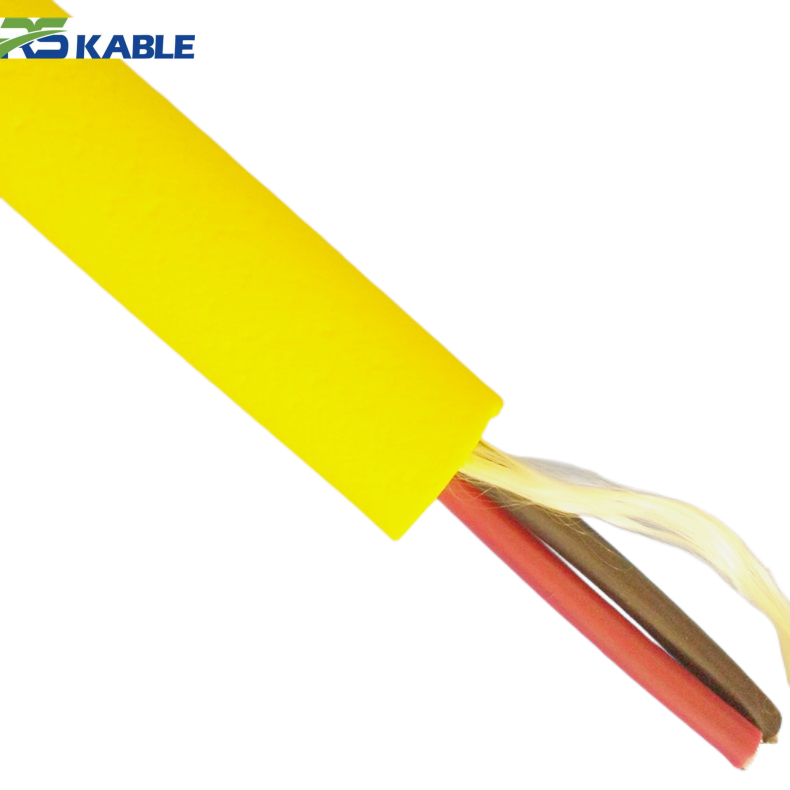

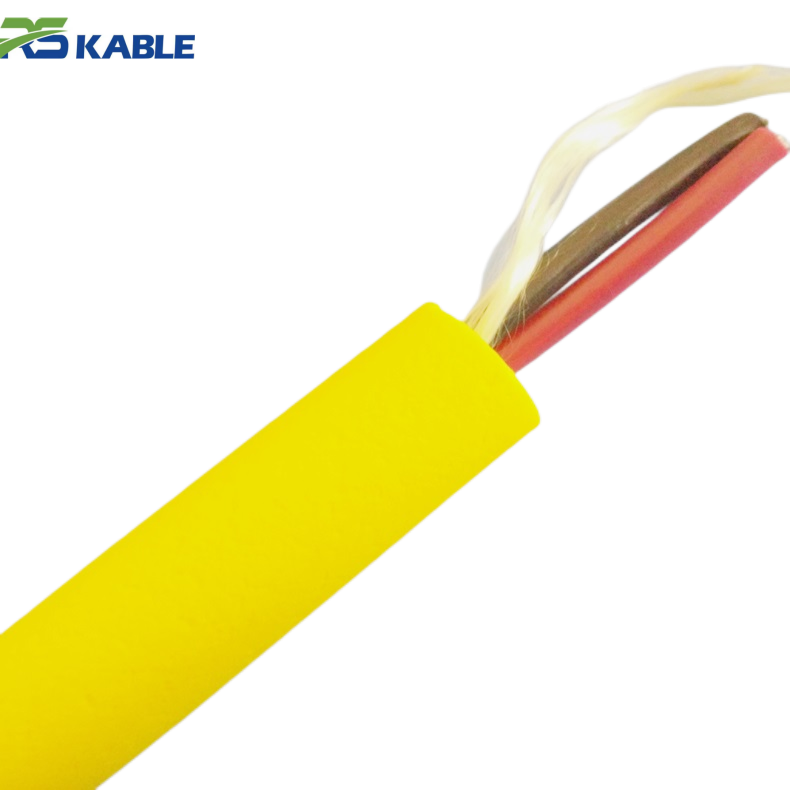

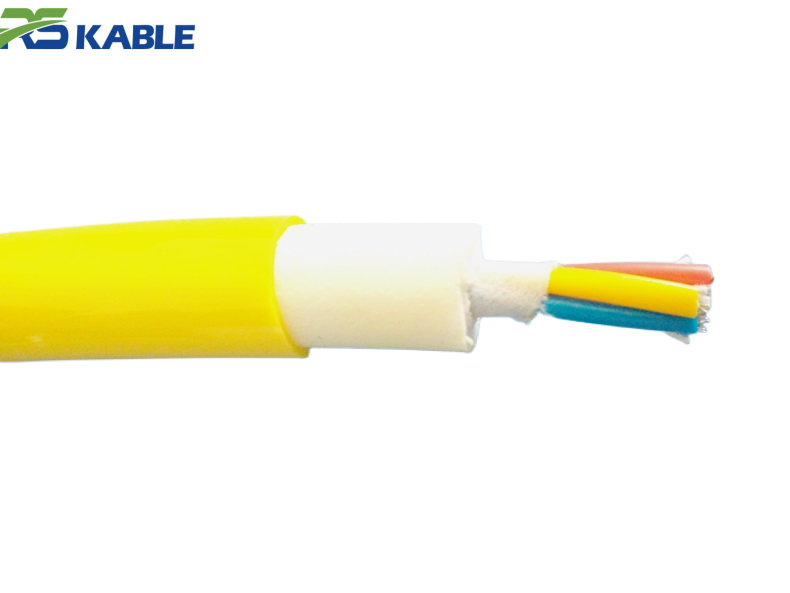

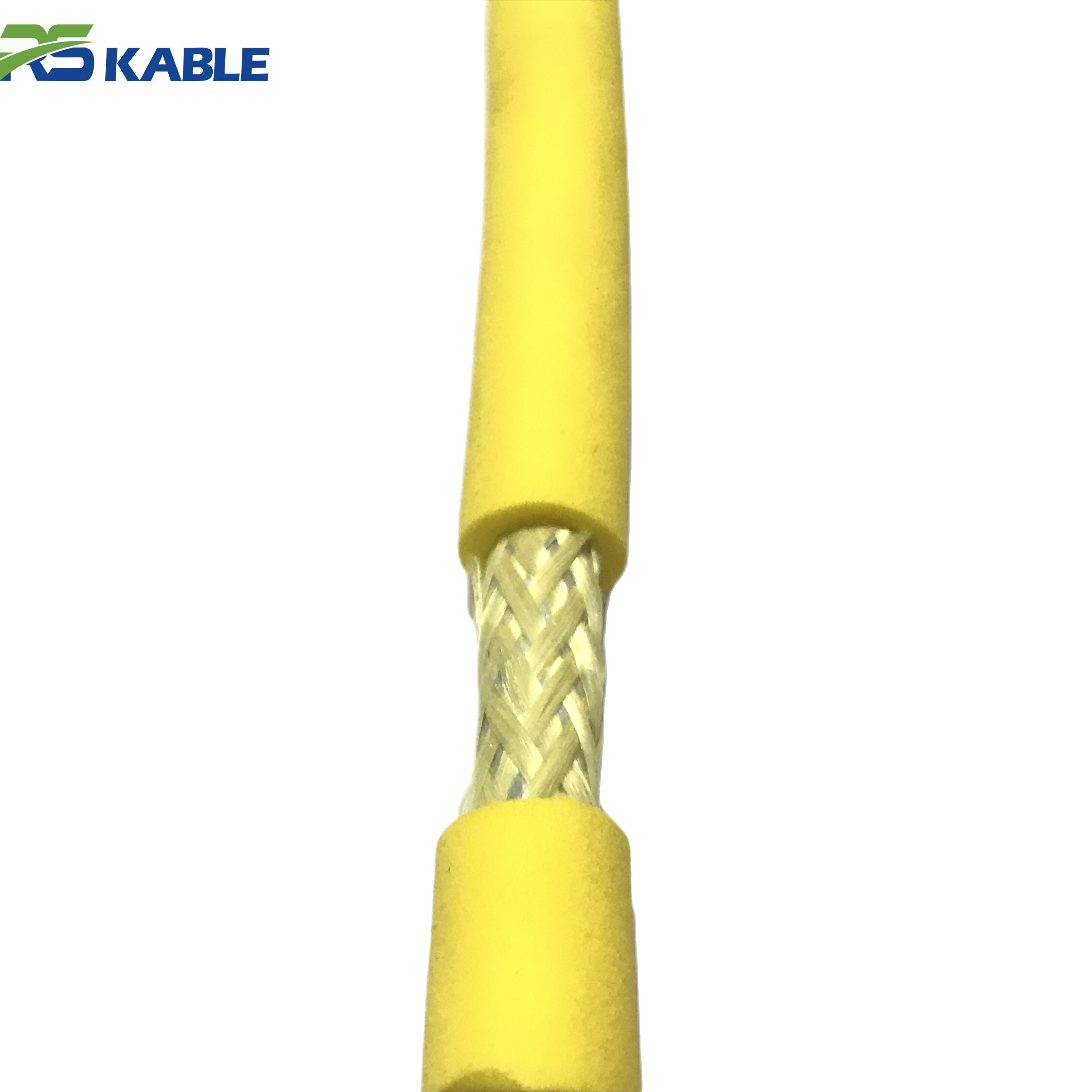

Heavy-Duty Outer Sheath for Structural Protection

To meet engineering-grade durability requirements, this cable incorporates a heavy-duty outer sheath designed to provide:

-

Enhanced abrasion resistance for seabed contact

-

Increased resistance to cuts and localized damage

-

Structural reinforcement to distribute mechanical loads

-

Long-term material stability in marine environments

This outer protection allows the Neutral Buoyancy Cable to perform reliably in heavy-duty subsea engineering applications.

Application Scenarios & Engineering Use Cases

This cable solution is widely used across subsea engineering and construction projects, including:

-

Subsea infrastructure installation and maintenance

-

Offshore oil & gas engineering operations

-

Underwater construction and repair activities

-

Subsea tooling and intervention systems

-

Engineering support for marine structures

It is commonly specified as a heavy-duty subsea cable, underwater engineering cable, and neutral buoyancy power and signal cable.

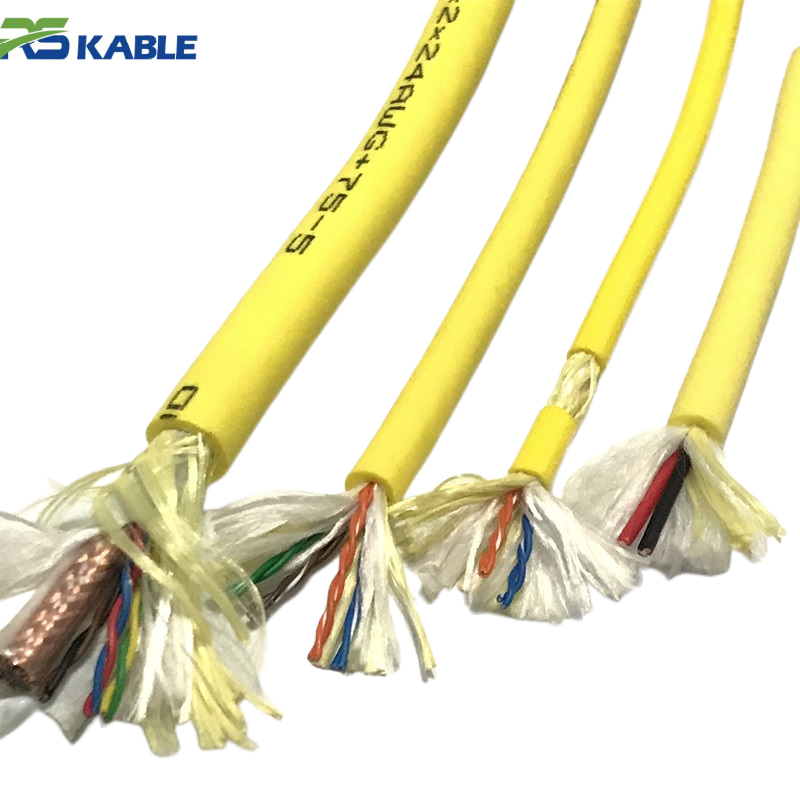

Product Configuration Overview

| Product Name / Model | Core Attributes |

|---|---|

| NB-SE Series Neutral Buoyancy Cable | Heavy-duty outer sheath, structural durability, engineering-grade design |

Key Technical Parameters

| Parameter | Specification Options |

|---|---|

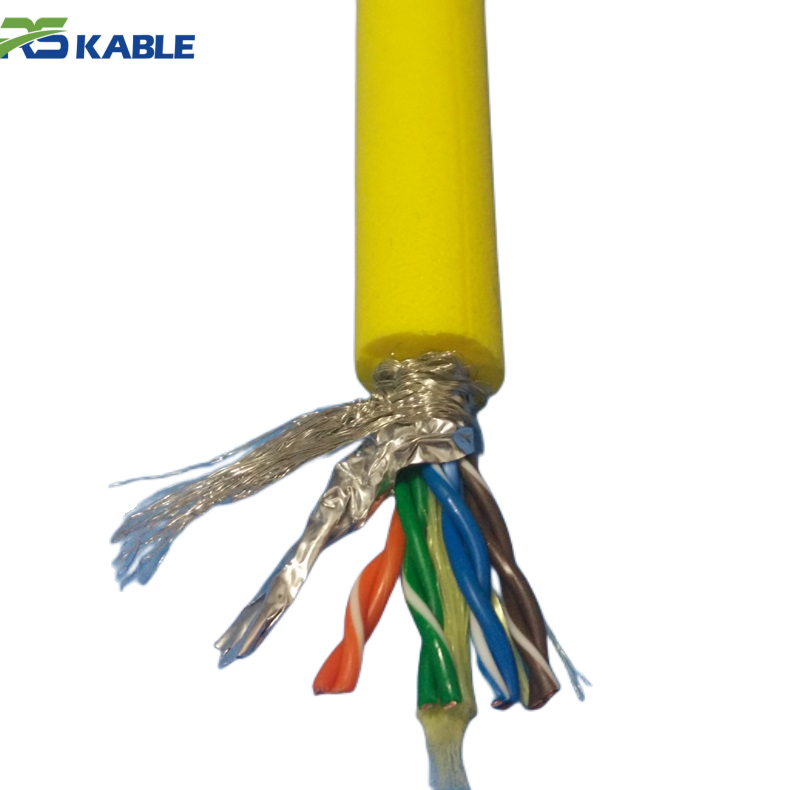

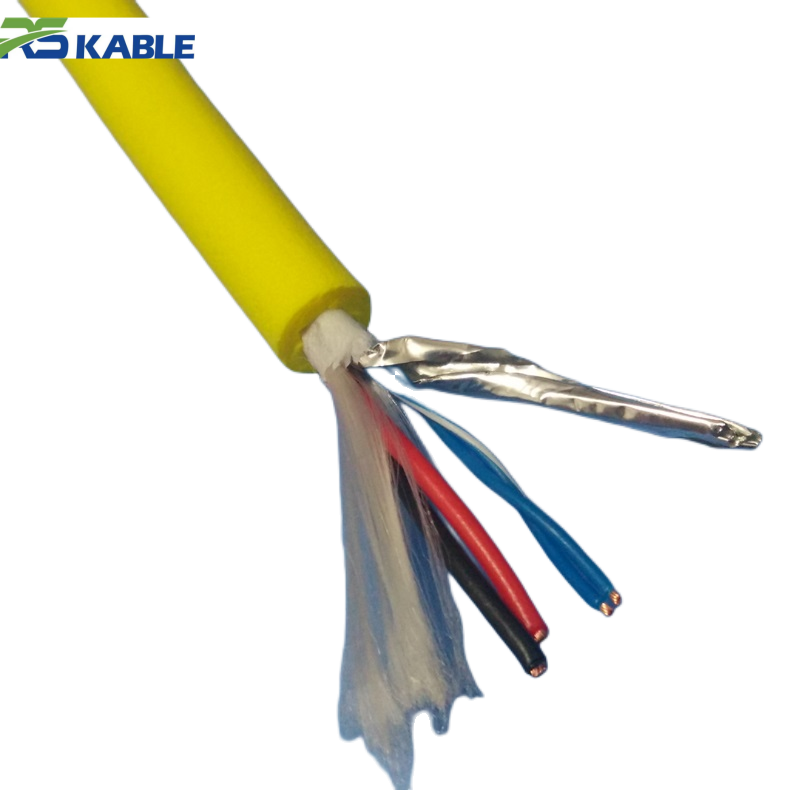

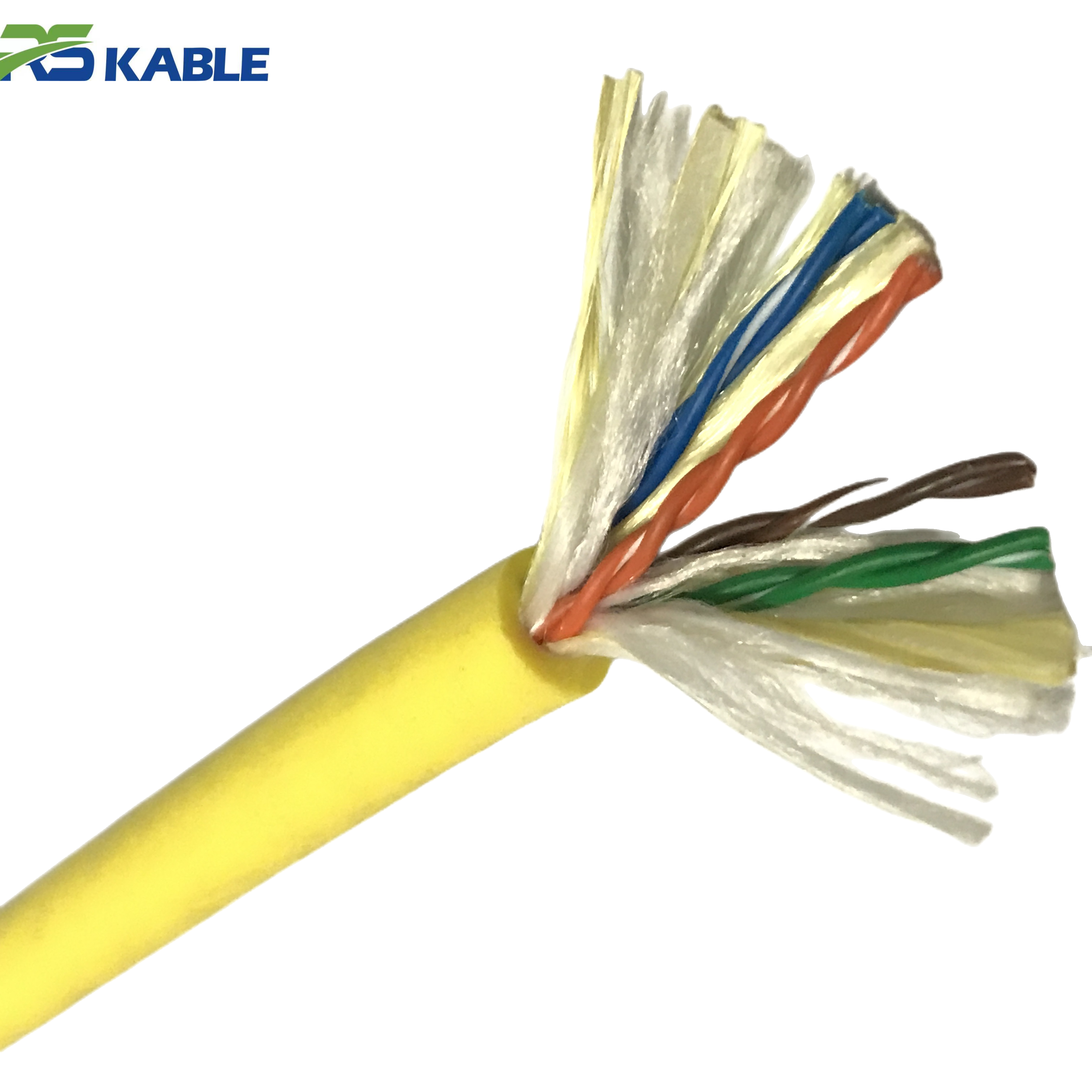

| Core Configuration | Power cores, signal cores, or hybrid power & signal |

| Conductor Material | Tinned copper |

| Insulation | PE / XLPE |

| Buoyancy Control | Precision-balanced fillers for neutral buoyancy |

| Outer Sheath | Heavy-duty marine-grade polyurethane |

| Mechanical Protection | Abrasion- and impact-resistant structure |

| Operating Environment | Continuous subsea and seabed-contact environments |

| Temperature Range | Suitable for offshore and subsea engineering operations |

Cable diameter, sheath thickness, and reinforcement level can be customized based on project load and deployment depth.

Structural Design for Heavy-Duty Subsea Operations

This Neutral Buoyancy Cable is engineered with internal features that support structural durability, including:

-

Reinforced internal geometry to resist deformation

-

Load-sharing layers to protect conductors and insulation

-

Multi-layer sealing to prevent water ingress

-

Stable buoyancy to reduce excess downward force

These design elements help maintain performance during extended engineering campaigns.

Operational Advantages for Engineering Projects

When deployed in subsea engineering environments, this Neutral Buoyancy Cable delivers:

-

Improved resistance to abrasion and mechanical damage

-

Reduced maintenance and replacement frequency

-

Stable handling during installation and recovery

-

Enhanced system reliability in heavy-duty applications

This makes it a dependable solution for critical underwater engineering work.

Engineering Authority & Quality Assurance (E-E-A-T)

-

Designed by engineers with experience in subsea engineering cable systems

-

Manufactured under ISO-certified quality management standards

-

Tested for mechanical endurance, sheath integrity, and buoyancy balance

-

Materials selected for long-term subsea engineering reliability

Each design is evaluated to ensure suitability for real-world subsea construction and engineering conditions.

Customization & Technical Support

We support subsea engineering contractors and system integrators with:

-

Project-specific cable design and reinforcement options

-

Hybrid configurations for power and signal transmission

-

Technical documentation and mechanical performance data

-

Engineering consultation for complex subsea projects

👉 Contact our engineering team to discuss your subsea engineering cable requirements.

FAQ

Is this cable suitable for seabed-contact applications?

Yes. The heavy-duty outer sheath is designed for abrasion and impact resistance.

Can it handle high mechanical loads during installation?

Yes. The reinforced structure supports demanding engineering operations.

Is buoyancy adjustable for different project conditions?

Yes. Buoyancy can be customized based on deployment depth and load.

Can power and signal be combined in one cable?

Yes. Hybrid power and signal configurations are available.