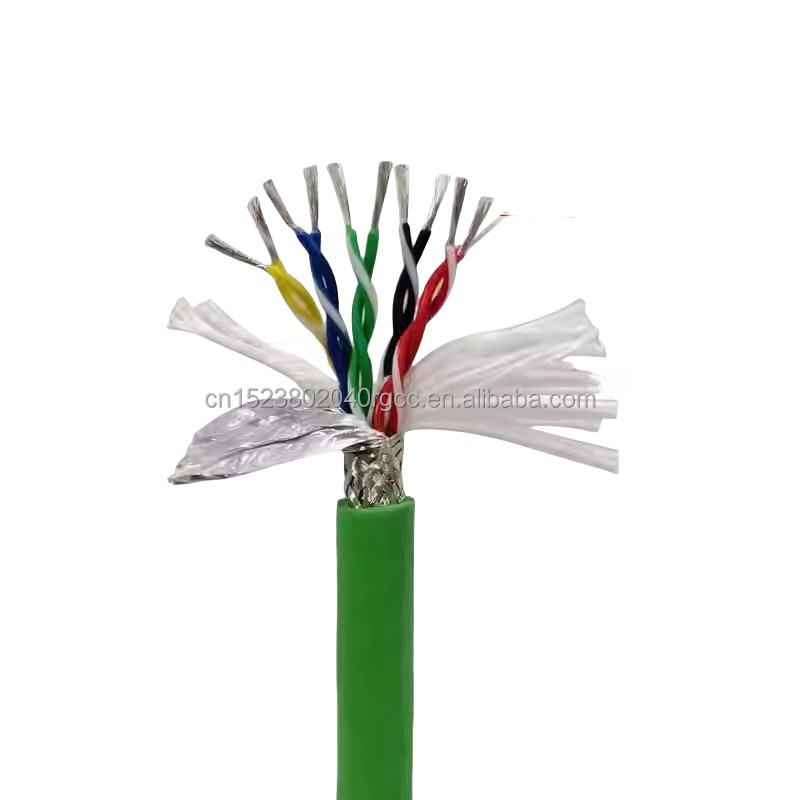

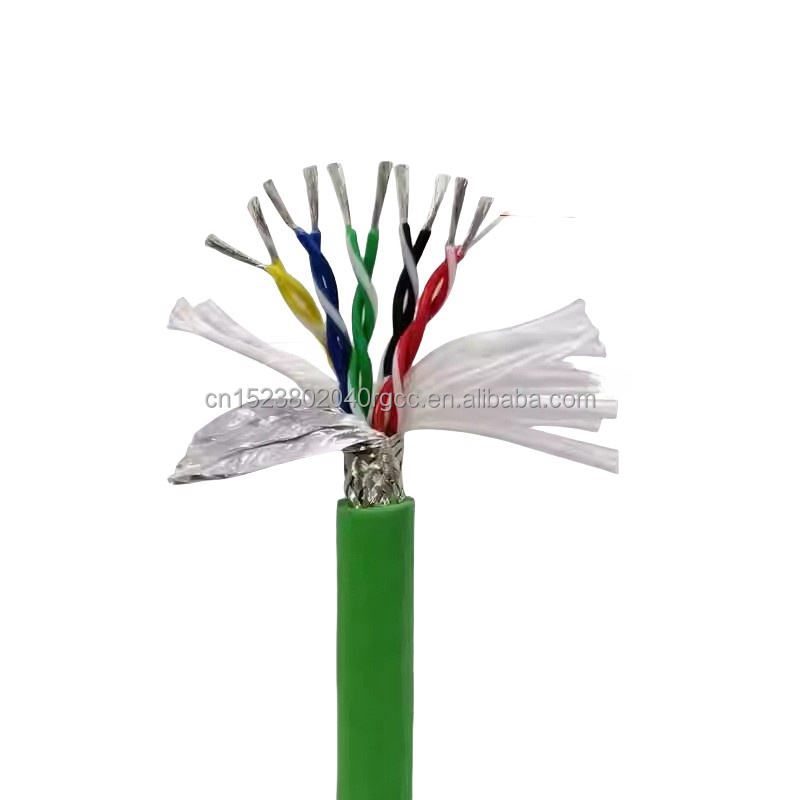

Servo Signal Cable, Green Shielded 14 × 0.2 Encoder Cable with 7 Twisted Pairs for Electrical Equipmen

This servo signal cable is designed for stable and accurate signal transmission in industrial automation systems. With a shielded twisted-pair structure and optimized conductor layout, it effectively reduces electromagnetic interference, ensuring reliable encoder feedback and servo control performance in electrically noisy environments.

Key Features:

-

14 × 0.2 mm stranded copper conductors arranged in 7 twisted pairs

-

Shielded structure to minimize EMI and signal crosstalk

-

Green outer jacket for easy identification and industrial use

-

Stable signal transmission for servo motors and encoder systems

-

Suitable for CNC machines, automation equipment, and control systems

Product Overview

The Servo Signal Cable is engineered for reliable signal transmission in industrial automation systems where accuracy, stability, and durability are critical. Manufactured by Shanghai Rosheng Cable Co., Ltd., this cable is designed to meet the demanding requirements of servo drives, encoders, and precision electrical equipment operating in dynamic and noise-sensitive environments.

Featuring a green outer jacket, shielded structure, and 14 × 0.2 mm conductors arranged into 7 twisted pairs, this cable ensures stable signal integrity while supporting flexible installation and long service life.

Shanghai Rosheng Cable Co., Ltd. is a professional manufacturer specializing in high-flex drag chain cables and specialty industrial cables, offering more than 100 cable types with integrated R&D, production, sales, and technical service capabilities.

Why This Servo Signal Cable Matters in Real Applications

Designed for Signal Accuracy and System Stability

In servo control systems, even minor signal interference can lead to positioning errors, speed instability, or system alarms. This Servo Signal Cable adopts a twisted-pair structure combined with aluminum foil and braided shielding to effectively suppress electromagnetic interference (EMI), ensuring clean and accurate signal transmission between controllers, encoders, and servo motors.

Built for Industrial Environments

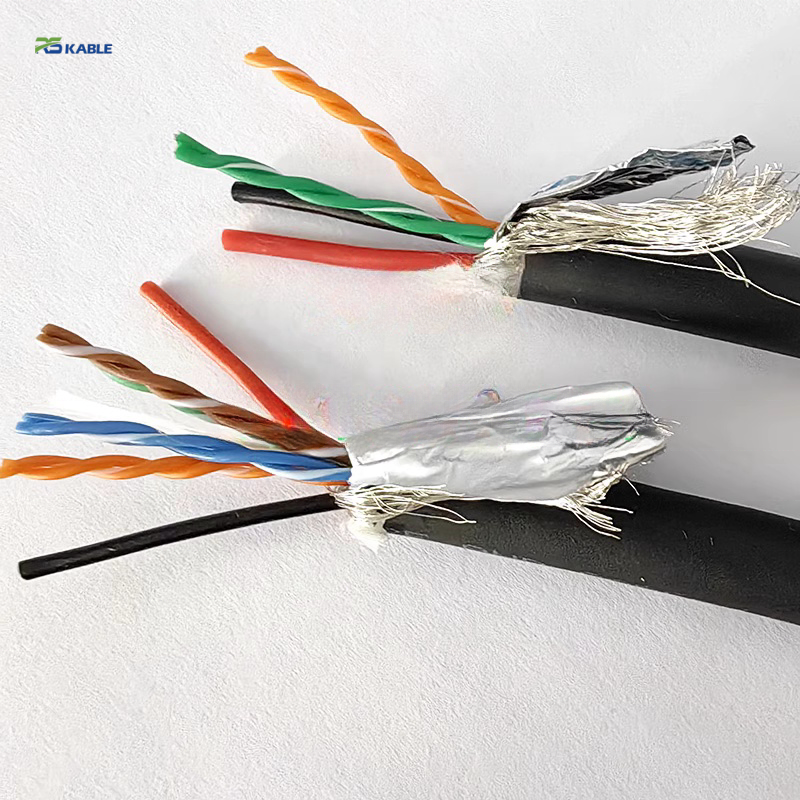

The durable green outer jacket provides strong resistance to abrasion, oil, and common industrial chemicals. Based on the internal structure visible in the product images, each twisted pair is individually insulated and clearly color-coded, improving installation efficiency and reducing wiring errors during maintenance or system upgrades.

Structural Design Highlights

Multi-Layer Shielding for Noise Protection

-

Inner aluminum foil shielding for each signal group

-

Overall braided copper shield for enhanced EMI suppression

-

Optimized shielding overlap to maintain performance under movement

Optimized Conductor Configuration

-

14 × 0.2 mm stranded copper conductors

-

7 precisely matched twisted pairs to minimize crosstalk

-

Fine stranding improves flexibility and fatigue resistance

Practical Jacket Design

-

High-visibility green jacket for easy identification

-

Smooth surface reduces friction in cable trays and control cabinets

Typical Applications

This Servo Signal Cable is widely used in:

-

Servo motor feedback and control systems

-

Encoder signal transmission

-

CNC machines and automated production lines

-

Industrial robots and motion platforms

-

Electrical equipment requiring multi-pair signal integrity

Key Features at a Glance

-

Cable Type: Servo signal & encoder cable

-

Conductor Structure: 14 × 0.2 mm stranded copper

-

Pairing: 7 twisted pairs

-

Shielding: Foil + braided copper shield

-

Jacket Color: Green

-

Signal Performance: Low noise, high stability

-

Installation: Suitable for fixed and semi-flex applications

Technical Specifications

| Specification | Description |

|---|---|

| Cable Type | Shielded Servo Signal Cable |

| Conductor Size | 14 × 0.2 mm |

| Conductor Material | Stranded Copper |

| Pair Structure | 7 Twisted Pairs |

| Shielding | Aluminum Foil + Braided Shield |

| Outer Jacket | Industrial-grade Polymer (Green) |

| Signal Protection | EMI & Crosstalk Reduction |

| Application | Servo systems, encoders, electrical equipment |

Custom conductor configurations, jacket materials, and shielding options are available upon request.

Installation and Use Recommendations

-

Maintain proper grounding of the braided shield to maximize EMI protection

-

Avoid excessive tension during installation to preserve conductor alignment

-

Use appropriate strain relief at termination points

-

Separate signal cables from high-power lines where possible

Frequently Asked Questions (FAQ)

Q1: What makes this Servo Signal Cable suitable for encoder systems?

A: The twisted-pair design combined with dual-layer shielding significantly reduces noise and crosstalk, which is essential for accurate encoder signal transmission.

Q2: Is this cable suitable for moving applications?

A: It is suitable for fixed and moderate-movement applications. For continuous drag chain motion, a high-flex version can be customized.

Q3: Why use 7 twisted pairs instead of parallel conductors?

A: Twisted pairs help cancel electromagnetic interference and maintain consistent signal quality across multiple channels.

Q4: Can the jacket material be customized?

A: Yes. Jacket materials and colors can be customized based on environmental or branding requirements.

Q5: Which industries commonly use this type of Servo Signal Cable?

A: Automation, robotics, CNC machining, packaging equipment, and industrial control systems.