ROV Power & Signal Systems | Neutral Buoyancy Cable | Integrated Design | Power + Signal Combination

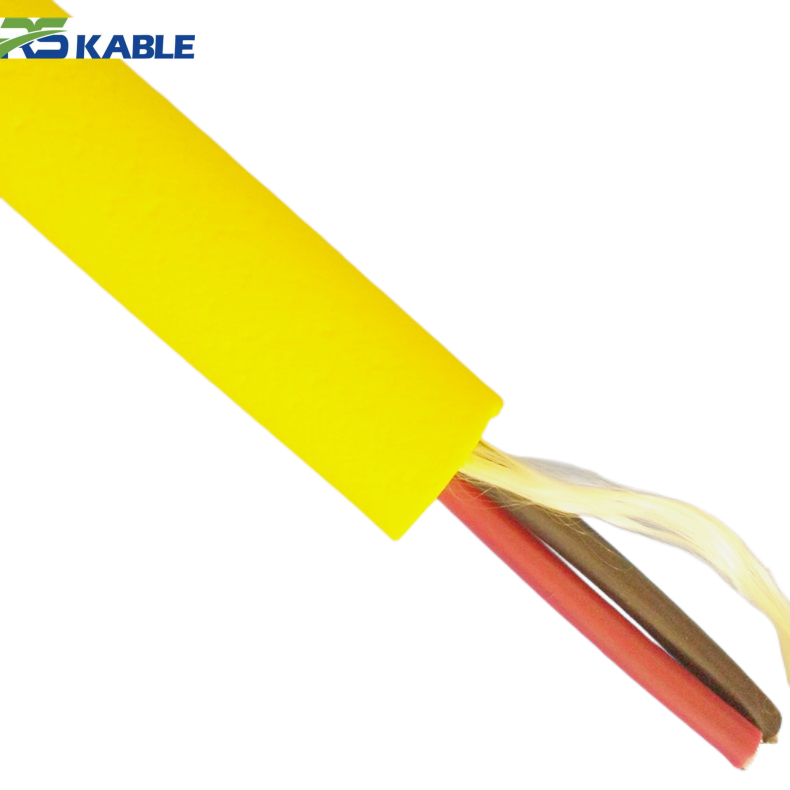

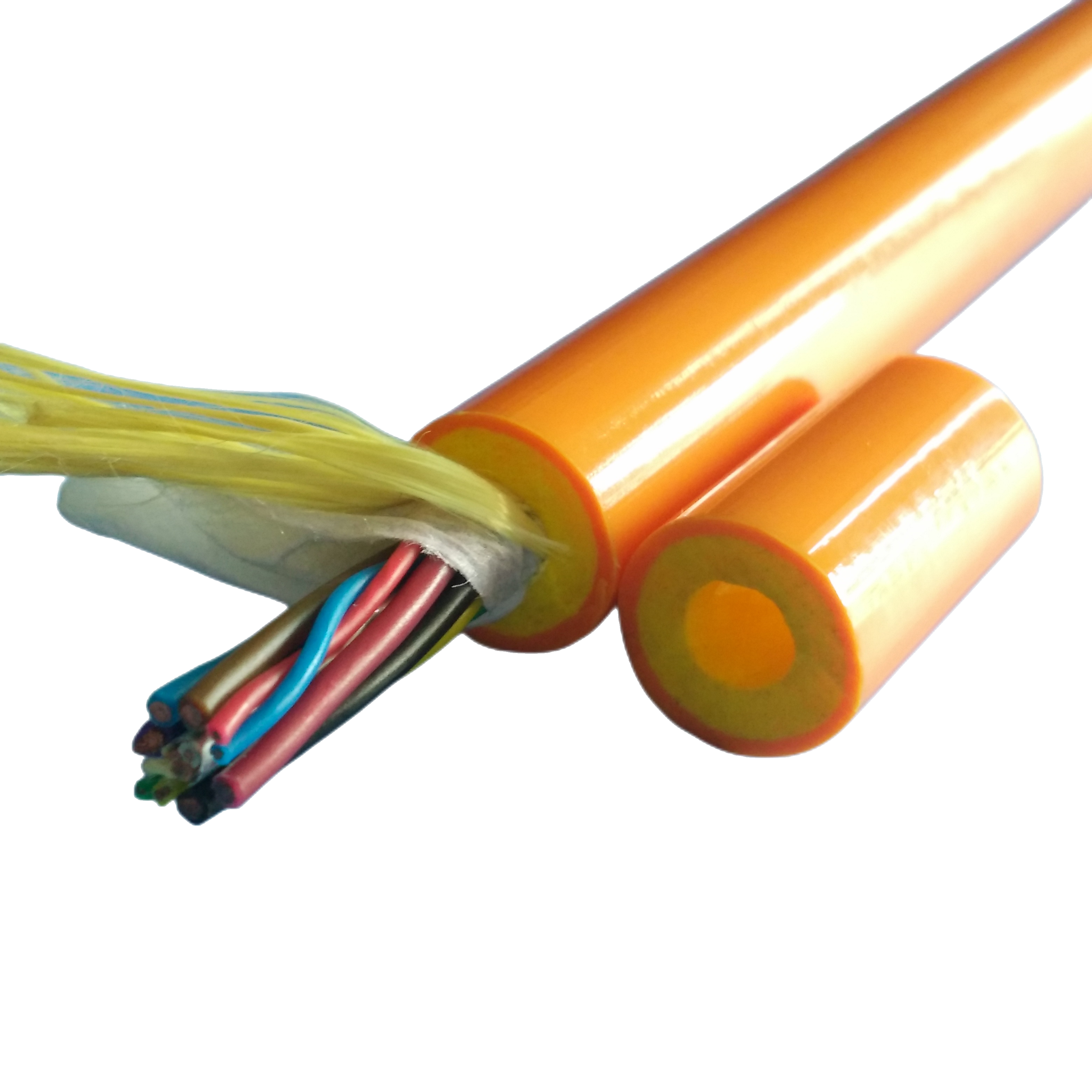

This Neutral Buoyancy Cable is designed for ROV power and signal systems requiring integrated transmission in a single, balanced structure. By combining power and signal elements, it simplifies ROV tether design while improving underwater stability and system reliability.

ROV Power & Signal Systems | Neutral Buoyancy Cable | Integrated Design | Power + Signal Combination

Modern ROV systems demand compact, reliable solutions capable of transmitting both power and signals without compromising underwater stability. This Neutral Buoyancy Cable is designed for integrated power and signal transmission, combining multiple functions into a single, load-balanced cable to simplify system architecture and improve operational reliability.

By integrating power conductors and signal elements within one unified structure, it supports efficient ROV deployment while maintaining stable underwater behavior.

Why Integrated Power + Signal Matters in ROV Systems

Traditional ROV setups often rely on separate power and signal cables, which can introduce:

-

Increased system complexity and routing difficulty

-

Higher drag and uneven load distribution underwater

-

Additional connection points and failure risks

-

More complicated maintenance and troubleshooting

An integrated Neutral Buoyancy Cable reduces these challenges by consolidating power and signal transmission into a single, well-balanced tether solution.

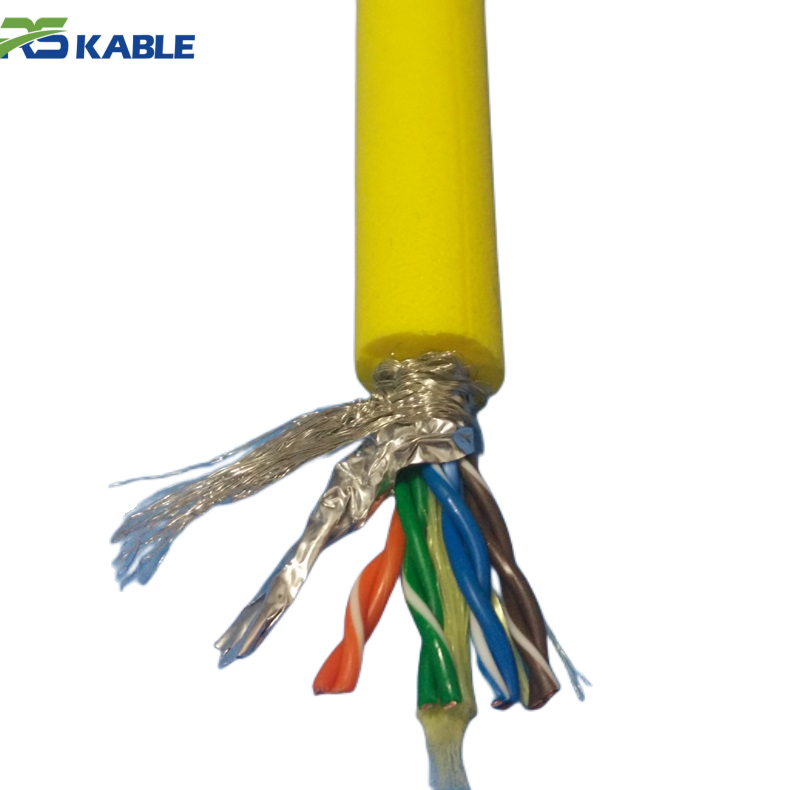

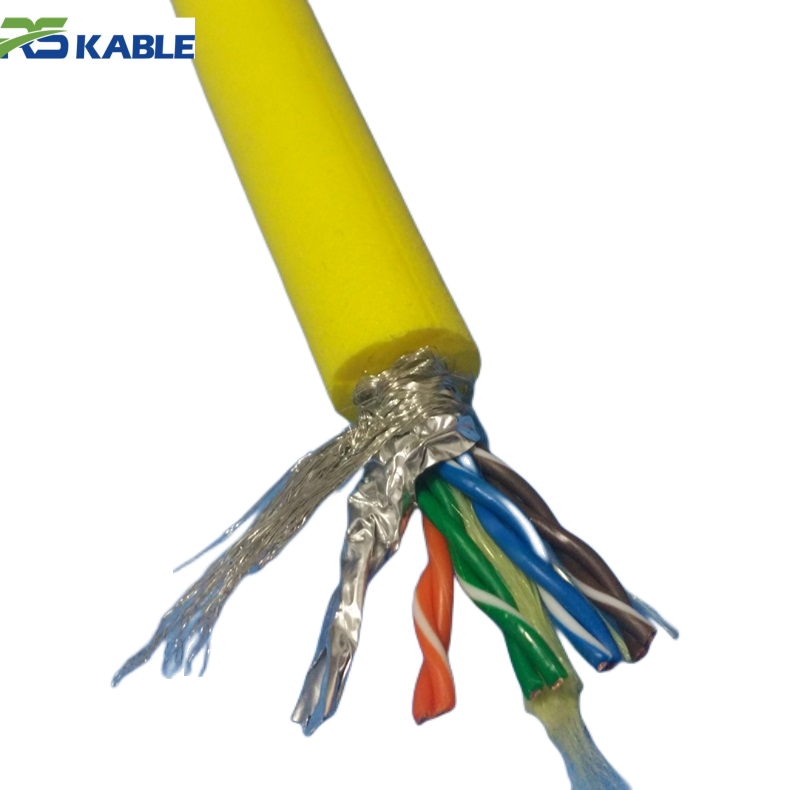

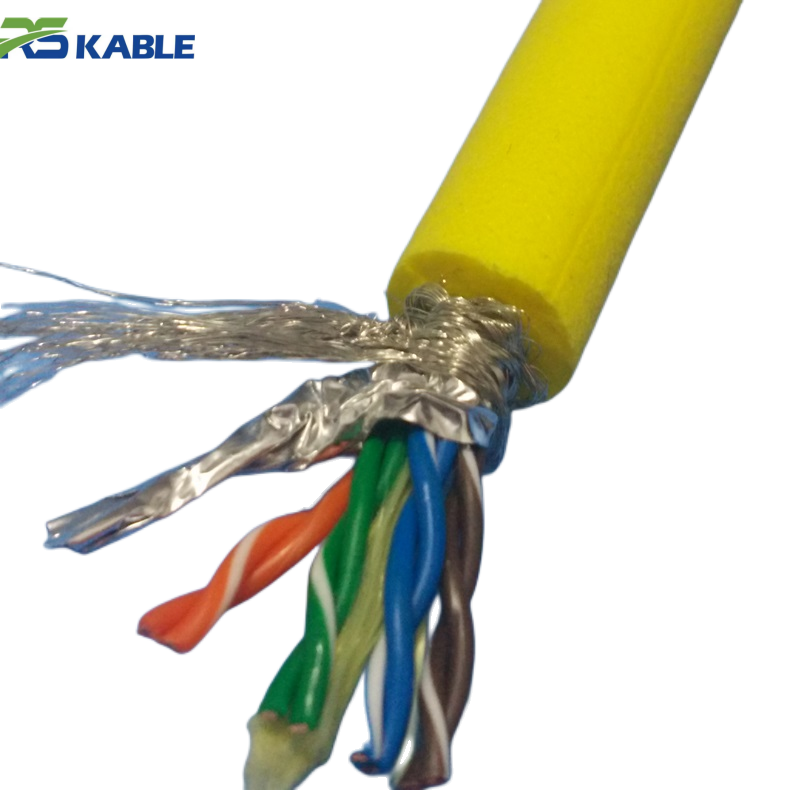

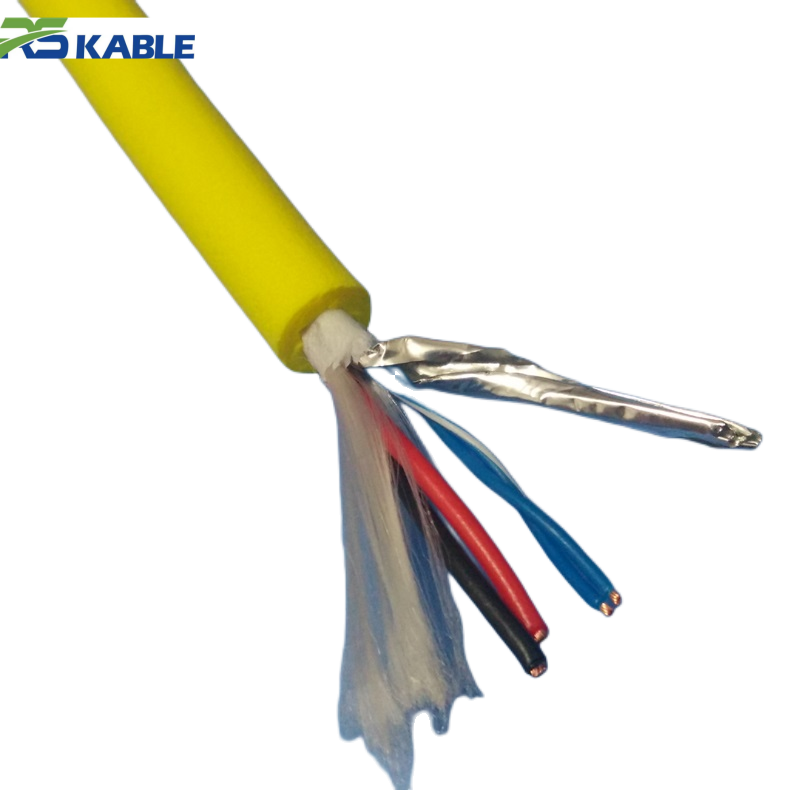

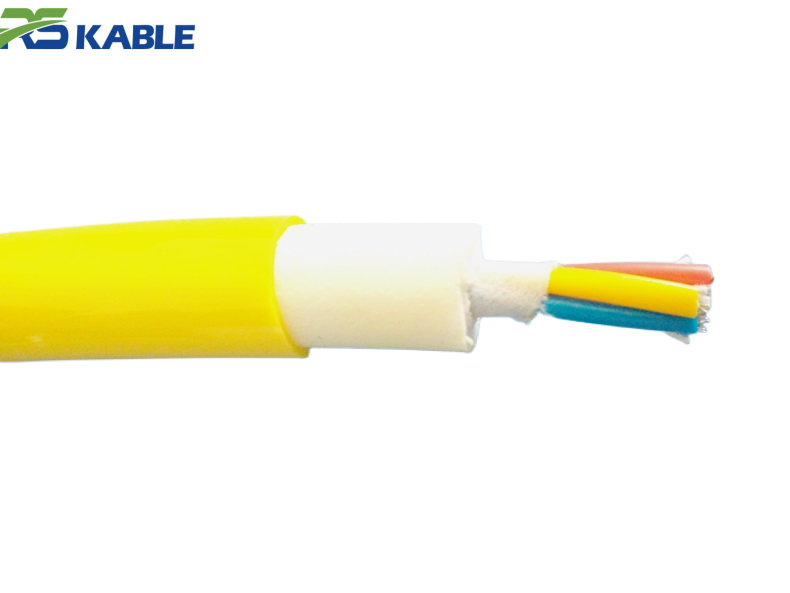

Integrated Cable Architecture: Designed at System Level

Rather than simply combining conductors, this cable is engineered as a system-level component:

-

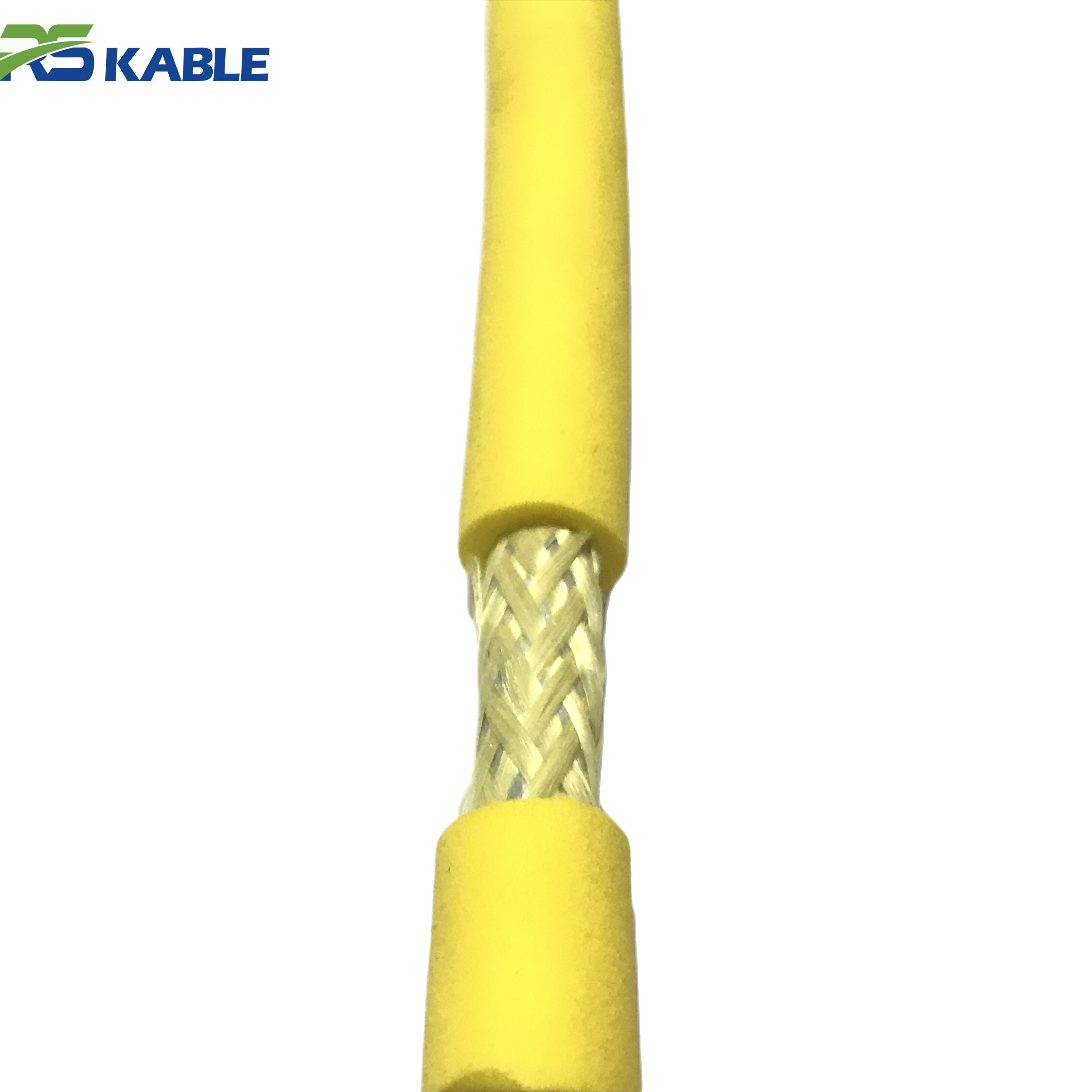

Dedicated power cores and signal cores arranged to minimize interference

-

Physical separation and shielding to protect signal quality

-

Controlled buoyancy fillers to offset combined cable weight

-

Unified jacket design to protect all elements simultaneously

This architecture allows power delivery and data transmission to coexist reliably in demanding ROV environments.

Typical ROV Applications & Deployment Scenarios

This cable is widely used in ROV systems where compact integration and reliability are critical, including:

-

Observation and work-class ROV power & control systems

-

ROV tether management systems (TMS)

-

Integrated propulsion, lighting, and sensor power supply

-

Control, telemetry, and feedback signal transmission

-

Offshore inspection, survey, and intervention ROVs

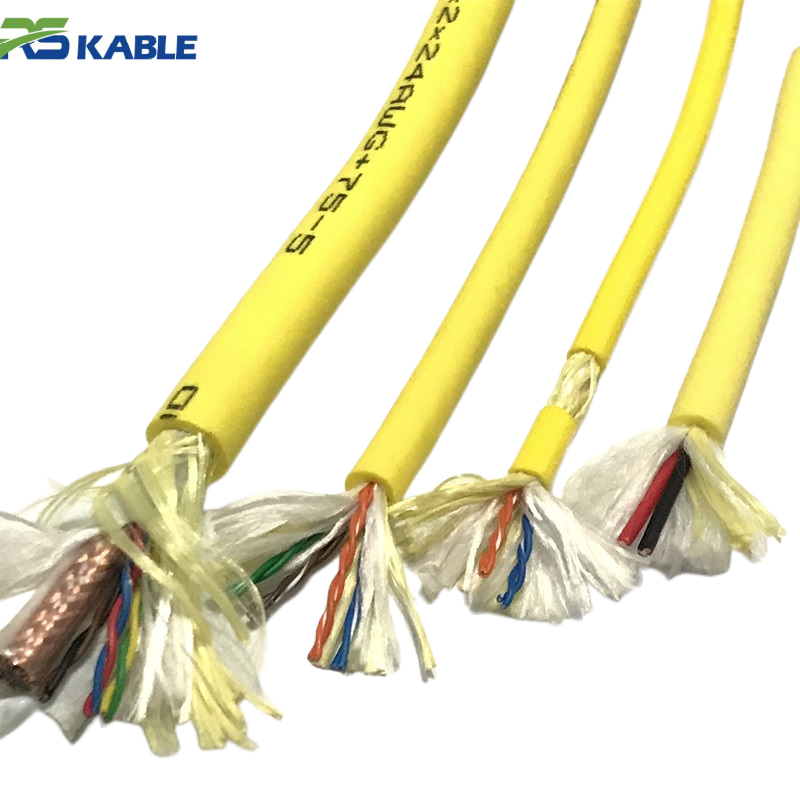

It is commonly specified as a ROV hybrid power and signal cable, integrated ROV tether, or neutral buoyancy ROV umbilical.

Product Configuration Overview

| Product Name / Model | Core Attributes |

|---|---|

| NB-RPS Series Neutral Buoyancy Cable | Integrated power + signal, system-level design, balanced buoyancy |

Key Technical Parameters

| Parameter | Specification Details |

|---|---|

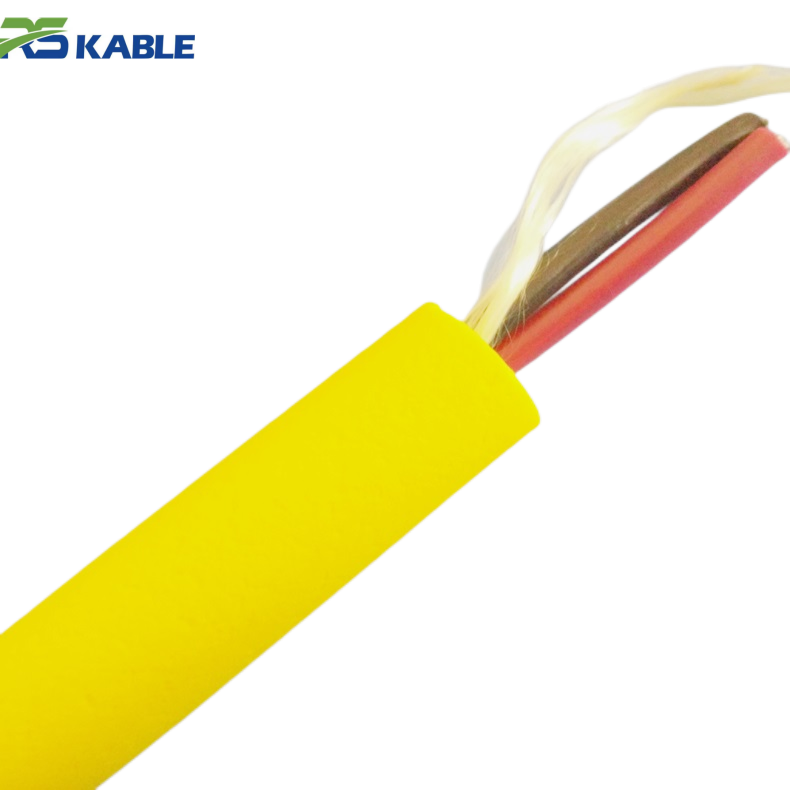

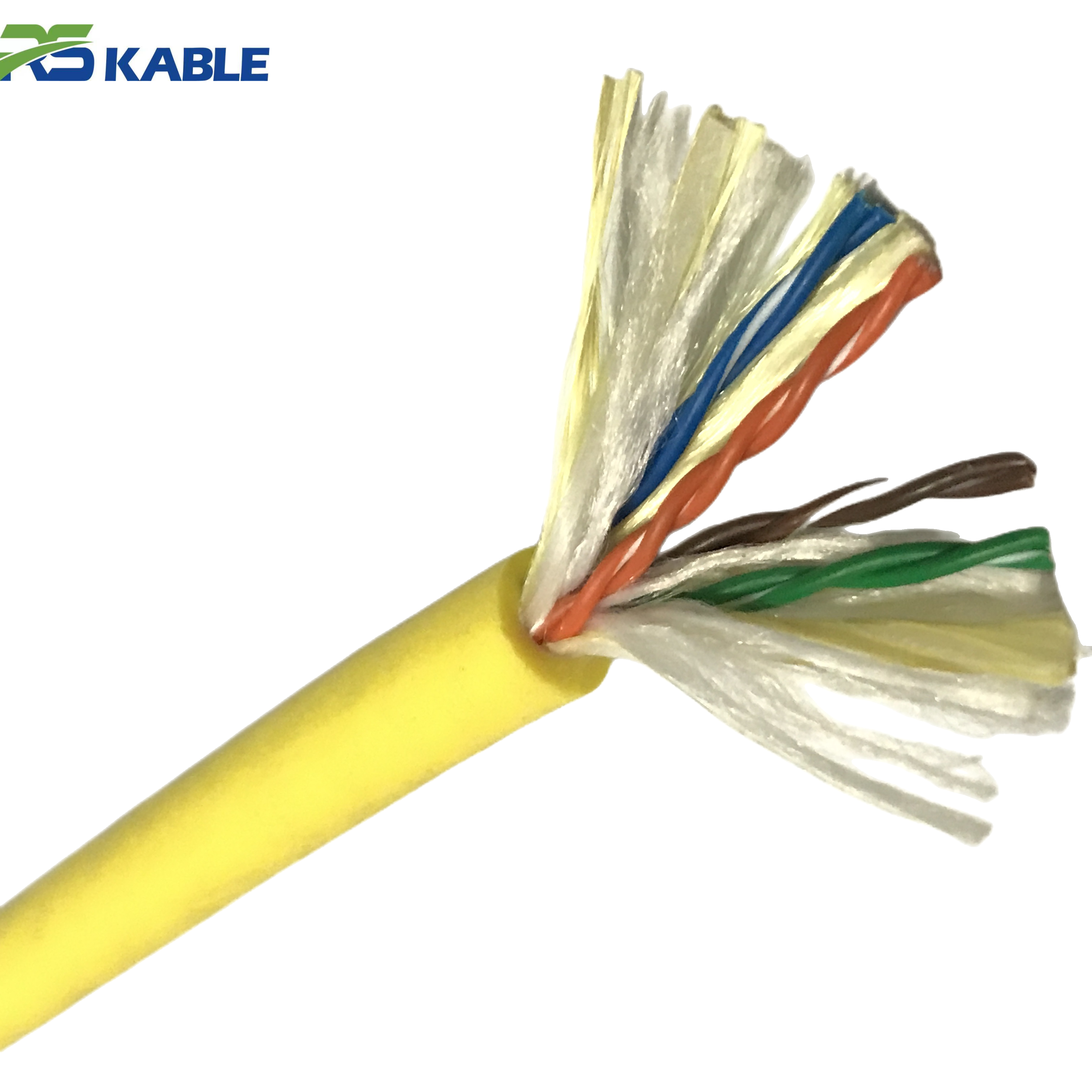

| Core Configuration | Power cores + signal cores (hybrid design) |

| Conductor Material | Tinned copper |

| Signal Protection | Shielded signal elements to reduce interference |

| Insulation | PE / XLPE compounds for power and signal stability |

| Buoyancy Structure | Integrated fillers for near-neutral buoyancy |

| Outer Jacket | Marine-grade polyurethane |

| Application Orientation | ROV power supply and control signal transmission |

Power rating, signal type, shielding level, and buoyancy balance can be customized based on ROV size and mission profile.

Simplified Deployment, Improved Reliability

Using a single integrated Neutral Buoyancy Cable enables ROV operators to achieve:

-

Cleaner and more manageable tether routing

-

Reduced mechanical interaction between multiple cables

-

Lower hydrodynamic drag during operation

-

Fewer connectors and reduced failure points

These advantages translate directly into higher mission uptime and easier system integration.

Performance Benefits for ROV Manufacturers & Operators

This integrated cable approach delivers measurable system-level value:

-

Improved overall ROV maneuverability

-

Stable power delivery and signal transmission

-

Reduced installation and maintenance complexity

-

Enhanced long-term operational reliability

It is especially beneficial for compact ROV platforms and systems with limited tether capacity.

Engineering Expertise & Quality Assurance (E-E-A-T)

-

Designed by engineers specializing in ROV power and control systems

-

Manufactured under ISO-certified quality management processes

-

Evaluated for electrical separation, buoyancy balance, and subsea reliability

-

Materials selected based on real ROV operational conditions

Design validation focuses on system integration rather than standalone cable metrics.

Custom Integration & Technical Support

We support ROV system builders and integrators with:

-

Power and signal layout optimization

-

Hybrid cable electrical and mechanical design

-

Buoyancy and load analysis for ROV tethers

-

Technical documentation for system integration

👉 Contact our engineering team to specify an integrated cable for your ROV power and signal system.

FAQ

Can power and signal really be combined without interference?

Yes. Proper conductor separation and shielding are used to protect signal integrity.

Does integration increase cable weight?

The design compensates through buoyancy control to maintain near-neutral underwater behavior.

Is this suitable for different ROV sizes?

Yes. The configuration can be scaled for small observation ROVs or larger work-class systems.

Can it replace existing separate power and signal cables?

In many systems, yes—after proper specification and integration review.