ROV Deep Sea Operations | Neutral Buoyancy Cable | High Flexibility | IP68, Multi-Stranded Copper

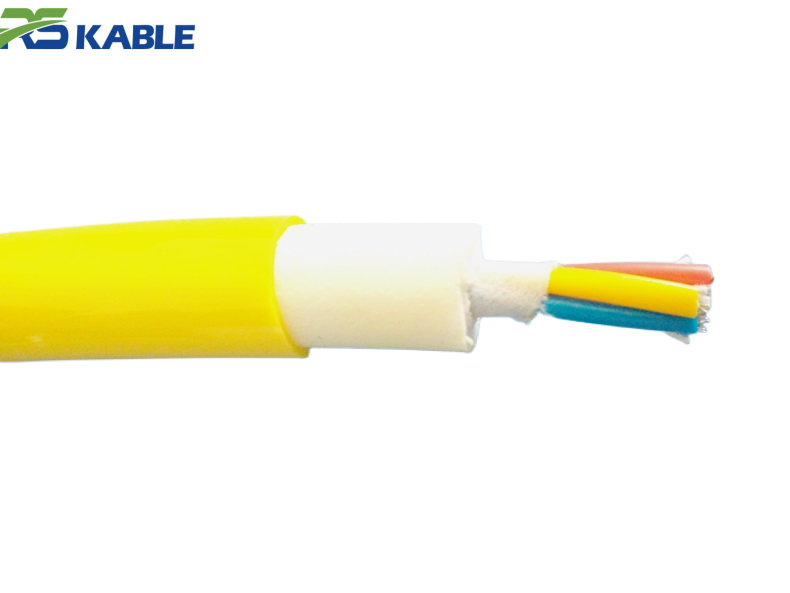

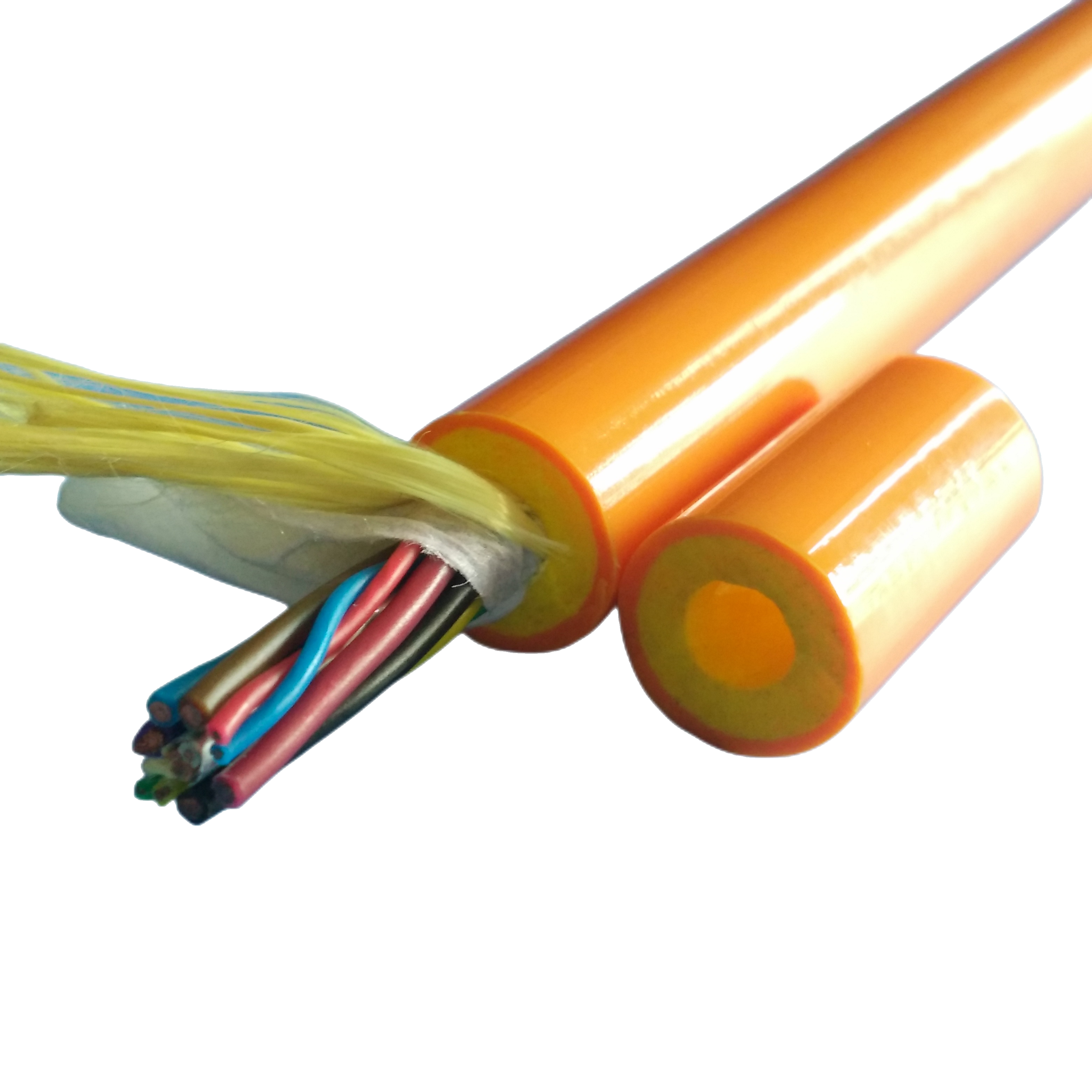

Our Neutral Buoyancy Cable is engineered for deep-sea ROV operations, combining precise buoyancy balance, high flexibility, and IP68 waterproof protection. Designed with multi-stranded copper conductors and durable PUR/TPU jackets, it ensures reliable power and signal transmission while minimizing drag and mechanical stress in harsh underwater environments. Ideal for offshore inspection, subsea research, and subsea infrastructure projects.

ROV Deep Sea Operations | Neutral Buoyancy Cable | High Flexibility | IP68, Multi-Stranded Copper

ROV deep sea missions place extreme demands on tether performance, where buoyancy balance, flexibility, and electrical reliability directly affect vehicle stability and operational efficiency. This Neutral Buoyancy Cable is purpose-built for professional subsea robotics, delivering true zero-buoyancy behavior in seawater alongside high mechanical endurance and stable power and signal transmission.

Backed by over 15 years of specialized underwater cable engineering experience, our solutions are trusted by offshore operators, research institutes, and subsea contractors worldwide for operations exceeding 6,000 meters in depth.

Product Overview

Engineered for dynamic underwater environments, this cable maintains equilibrium in the water column, eliminating drag caused by sinking or floating. The optimized structure reduces stress on ROV thrusters and tether management systems while enabling smooth maneuverability during inspection, intervention, and survey tasks.

Compared with conventional underwater tethers, a properly designed Neutral Buoyancy Cable significantly improves handling precision, energy efficiency, and long-term system reliability in deep-sea conditions.

Why This Cable Performs in Deep-Sea ROV Operations

Deep-water performance depends on more than waterproofing alone. This design integrates mechanical, electrical, and buoyancy control into a single optimized system.

Key performance advantages include:

-

Precisely controlled neutral buoyancy in seawater (density 1.00–1.03 g/cm³)

-

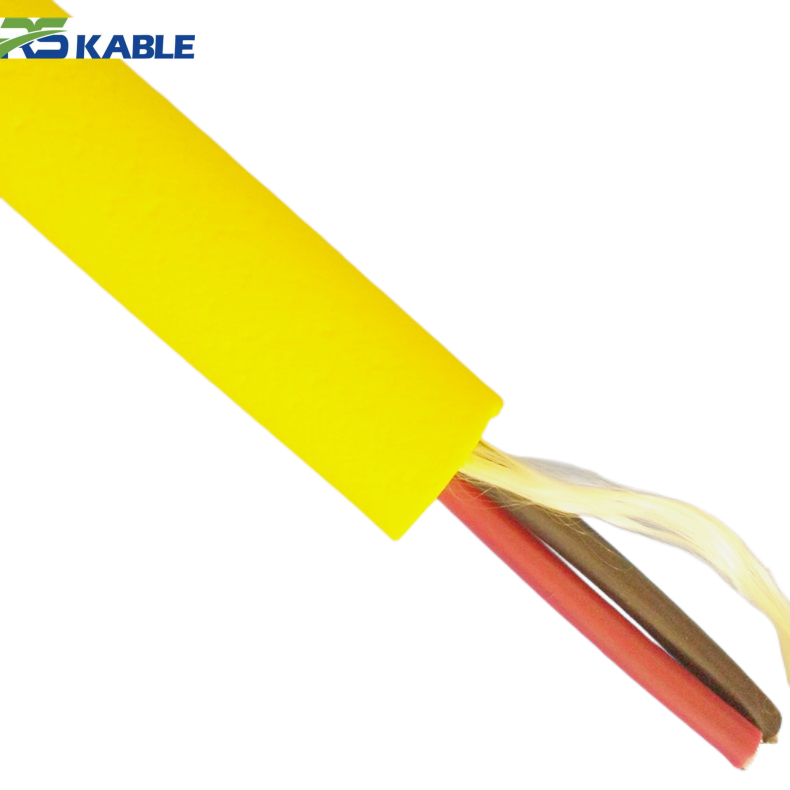

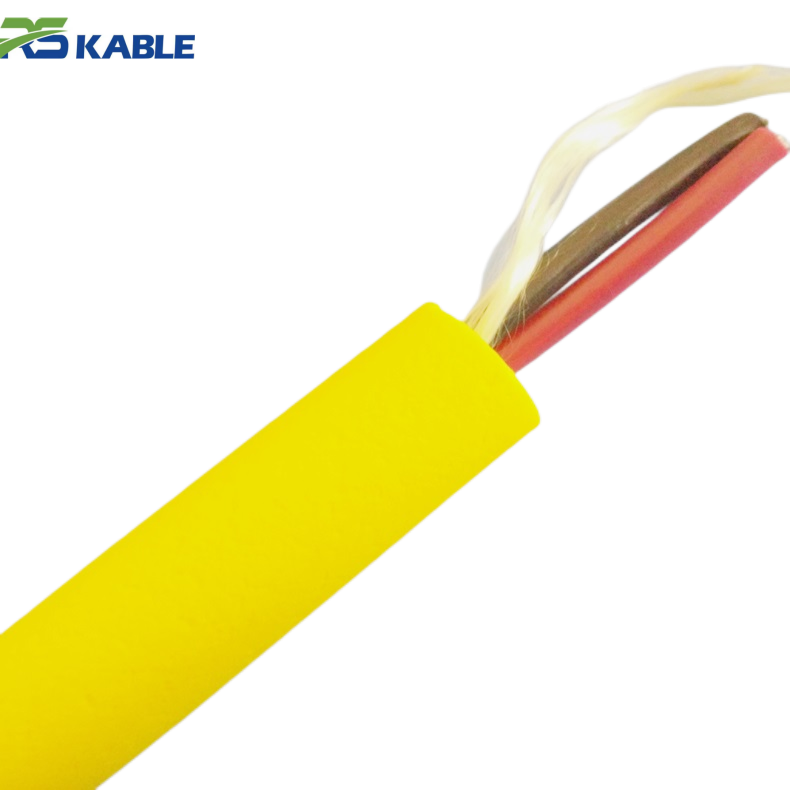

High-flex construction with minimum bend radius of 6×OD

-

IP68-rated sealing for continuous long-term immersion

-

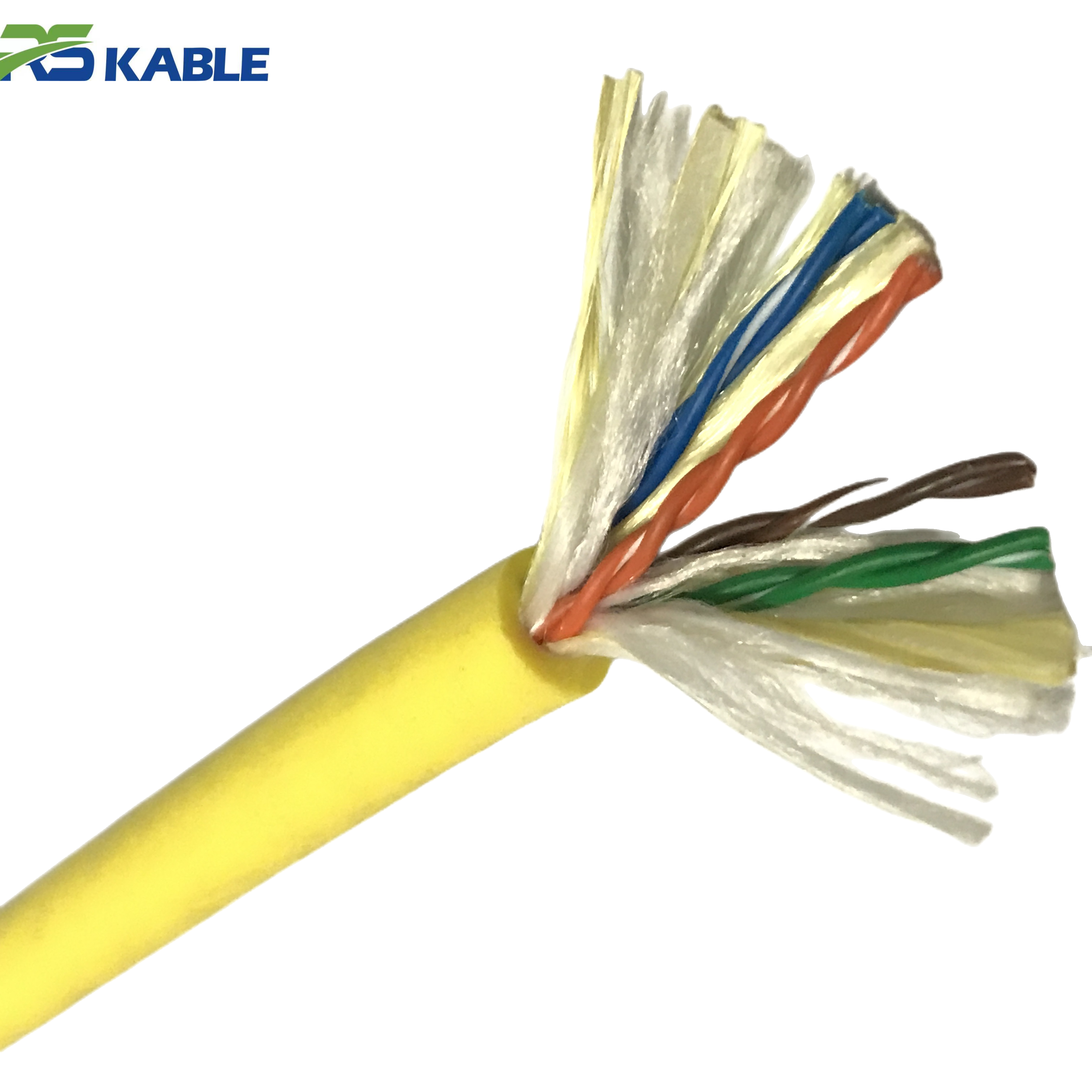

Multi-stranded tinned copper conductors for low resistance and corrosion resistance

-

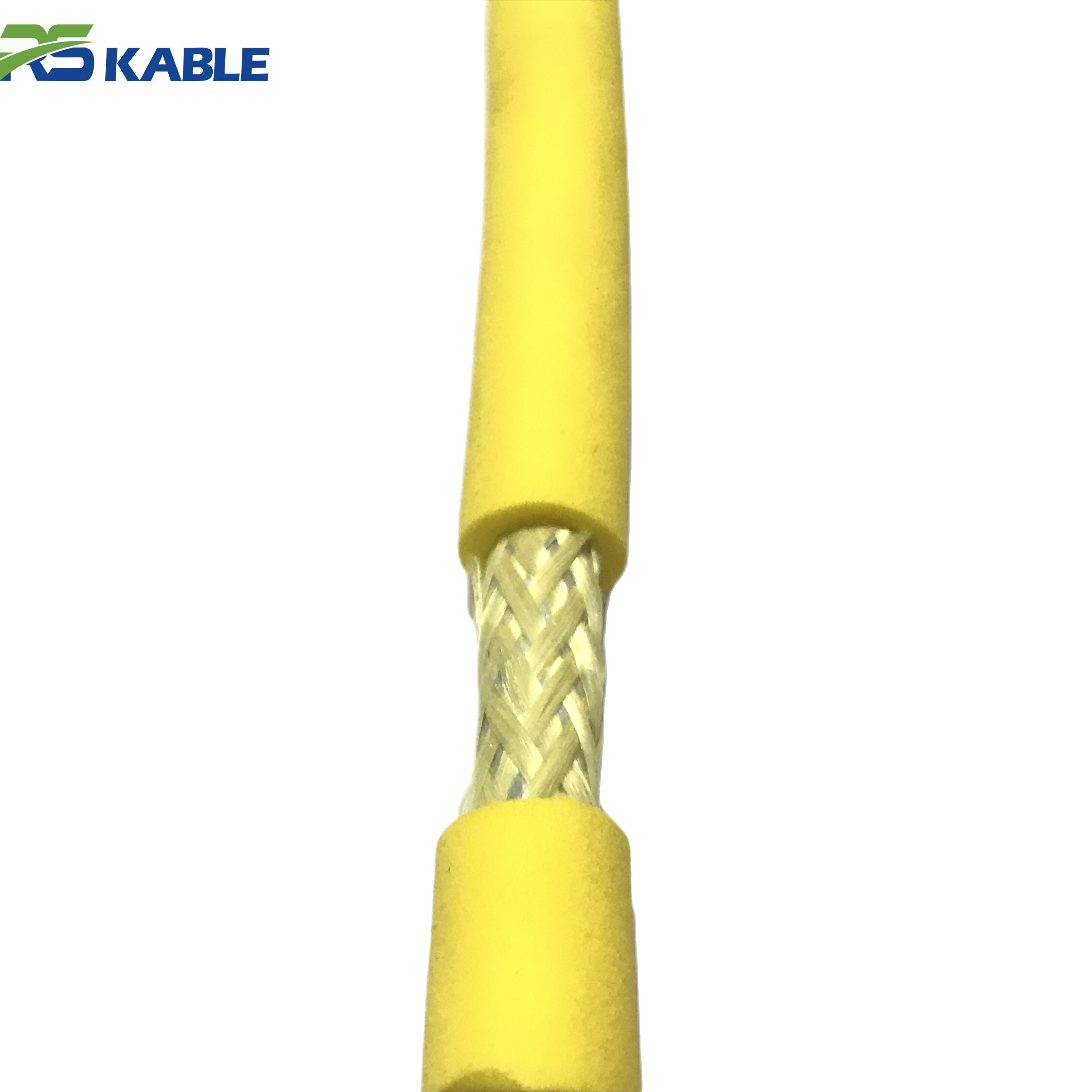

Optional Kevlar or aramid strength members supporting high tensile loads

-

EMI-shielded structure for clean video, control, and data transmission

These characteristics make the cable suitable for demanding ROV operations where reliability is non-negotiable.

Product Models & Core Attributes

| Model | Core Attributes | Conductor Configuration | Rated Depth | Outer Diameter | Buoyancy |

|---|---|---|---|---|---|

| NB-ROV-4P | High-flex power cable, IP68 | 4 × 2.5 mm² multi-stranded Cu | 6,000 m | 18.5 mm | Neutral |

| NB-ROV-8PS | Power + signal, shielded | 4 × 1.5 mm² + 4 × 0.75 mm² | 6,000 m | 21.2 mm | Neutral |

| NB-ROV-4F | Power + fiber composite | 4 × 2.0 mm² + fiber elements | 8,000 m | 22.8 mm | Neutral |

| NB-ROV-PRO | Heavy-duty, enhanced armor | 6 × 4.0 mm² + twisted pairs | 10,000 m | 26.5 mm | Neutral |

All models feature PUR or TPU outer jackets selected for abrasion resistance, hydrolysis stability, and long-term seawater exposure.

Typical Applications & Use Scenarios

This Neutral Buoyancy Cable is widely deployed in professional subsea environments, including:

-

Offshore oil & gas pipeline inspection and IRM operations

-

Deep-sea scientific research and seabed sampling

-

Subsea infrastructure installation and maintenance

-

Marine renewable energy surveys and cable routing

-

Search, recovery, and salvage missions

-

Defense and military underwater vehicle systems

Common long-tail search terms include:

neutral buoyancy cable for 6000m ROV, IP68 high-flex deep sea tether, zero buoyancy ROV power and signal cable.

Technical Specifications

| Parameter | Specification |

|---|---|

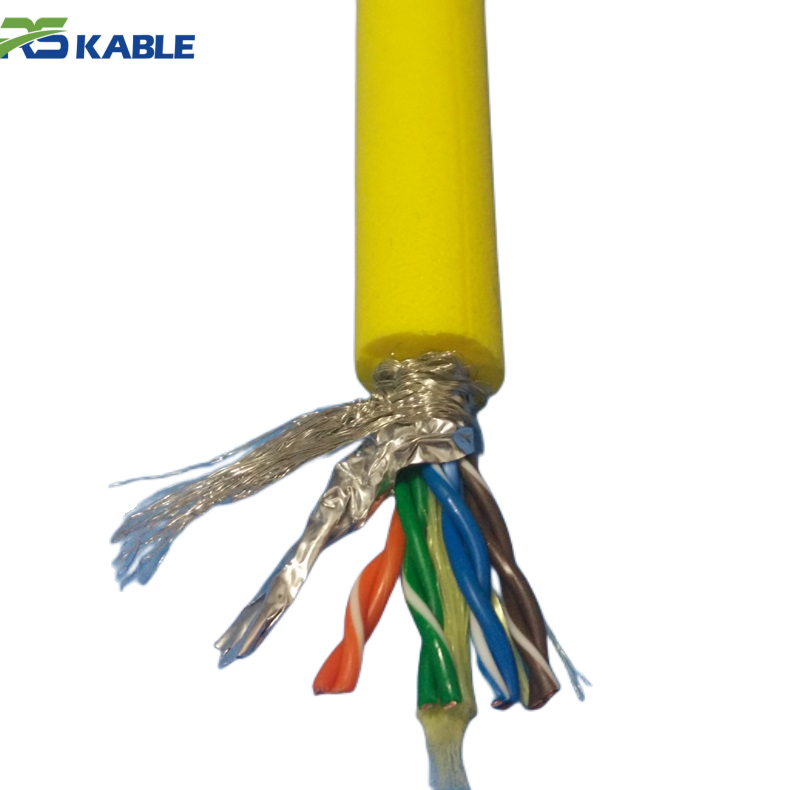

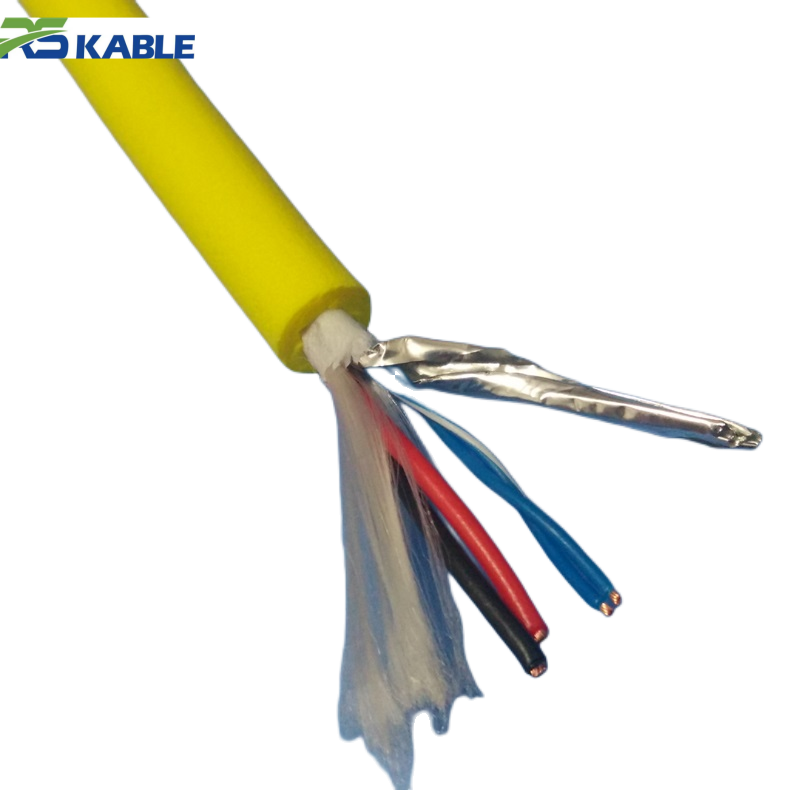

| Conductor | Tinned multi-stranded copper (IEC 60228 Class 5 / 6) |

| Insulation | Foamed PE or XLPE for buoyancy control |

| Strength Member | Kevlar or aramid braid |

| Shielding | Aluminum foil + copper braid (≥85% coverage) |

| Outer Jacket | PUR / TPU, high-visibility colors available |

| Buoyancy | Neutral in seawater (customizable) |

| Operating Temperature | –40°C to +80°C |

| Voltage Rating | 300/500V or 600/1000V |

| Certifications | ISO 9001, RoHS, CE; ABS available |

Engineering Credibility & Quality Assurance

-

Designed by engineers with extensive subsea cable project experience

-

Materials validated through pressure, flex, and immersion testing

-

Manufacturing aligned with ISO-certified quality management systems

-

Each cable electrically and mechanically tested prior to delivery

Our expertise spans ROV tethers, subsea power cables, hybrid fiber solutions, and other mission-critical underwater cable systems.

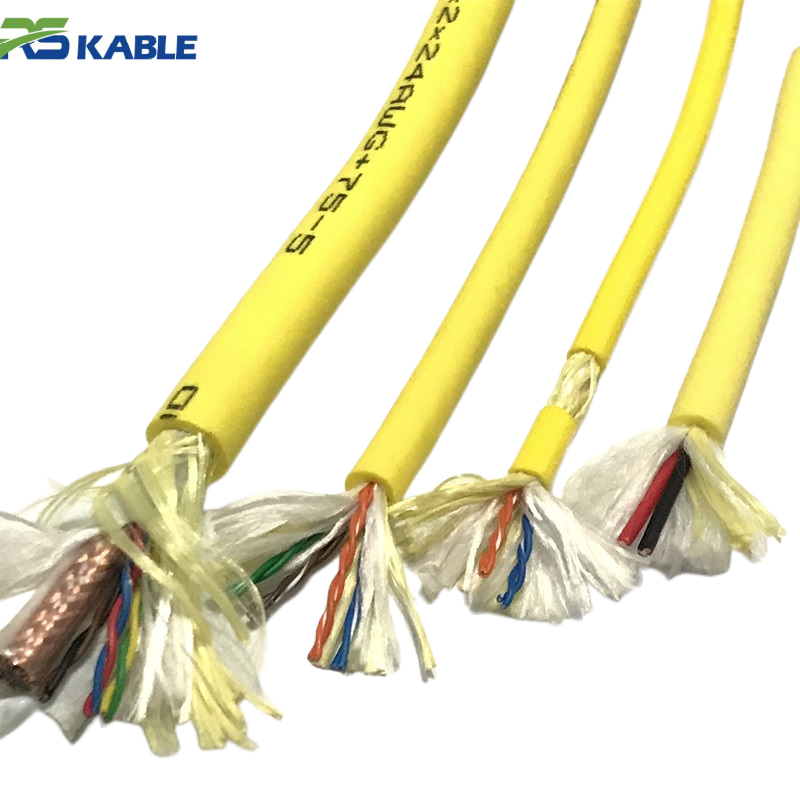

Customization & Integration Options

We support project-specific configurations, including:

-

Core count and conductor cross-section

-

Hybrid power, signal, and fiber optic integration

-

Buoyancy tuning for seawater or freshwater

-

Jacket material, color, and armor reinforcement

-

Factory termination with subsea connectors

👉 Contact our technical team to discuss system requirements and receive a tailored recommendation.

Frequently Asked Questions

How is neutral buoyancy achieved?

Through density-matched insulation and jacket materials, calibrated during production to achieve near-zero buoyancy in seawater.

Can the cable be adapted to specific ROV platforms?

Yes. Full customization is available, including mechanical structure, electrical layout, and connector integration.

What service life can be expected?

Typical service life ranges from 10–15 years under normal operational conditions, based on accelerated testing.

Is fiber optic integration supported?

Yes. Single-mode and multi-mode fiber elements can be incorporated for high-bandwidth data transmission.