PVC Insulated Flexible Flat Cable | Transformer & Elevator Overhead Power & Control Cable

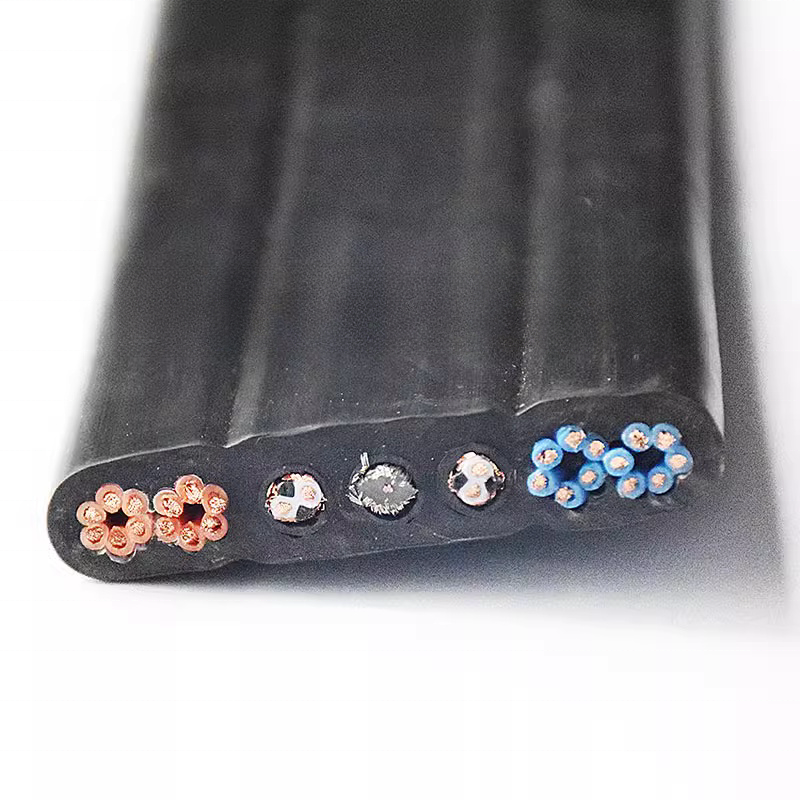

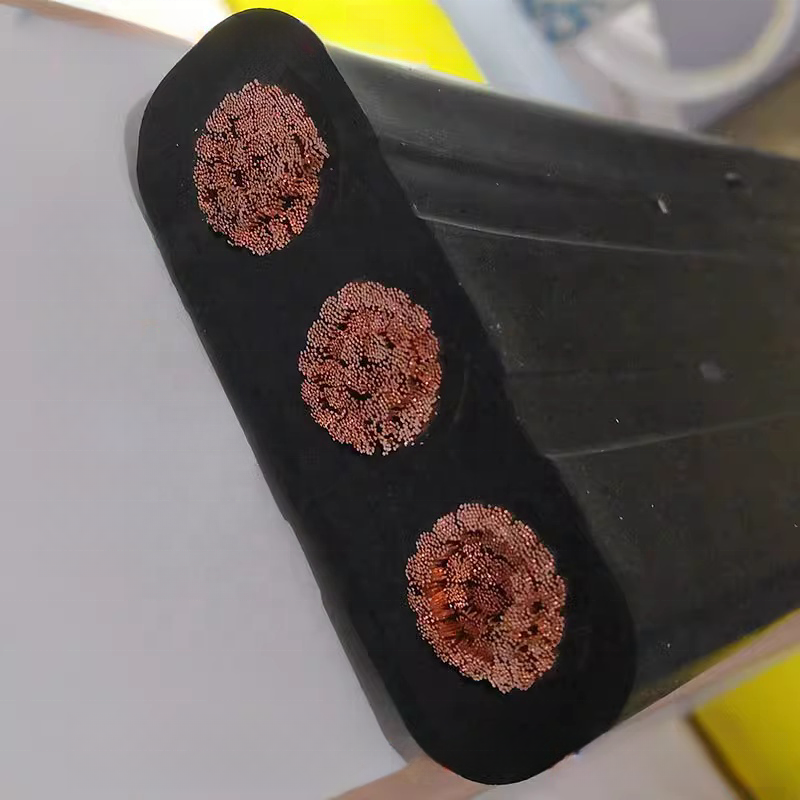

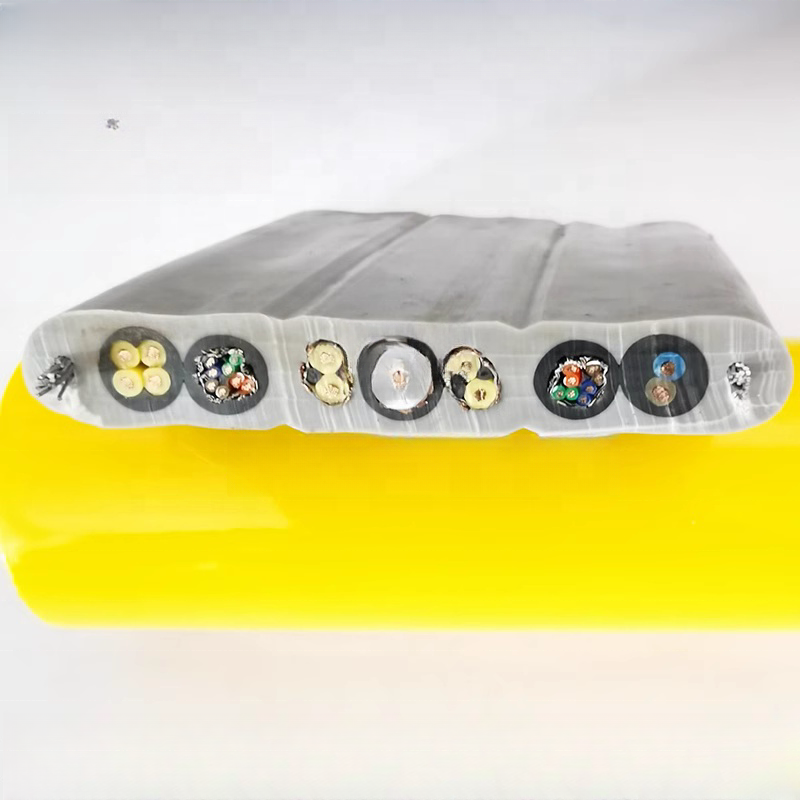

High-performance TVVB flexible flat cable featuring stranded copper conductors and durable PVC insulation. Designed for elevators, cranes, and transformers, it offers superior flexibility, oil resistance, and a tight bending radius for reliable vertical transmission.

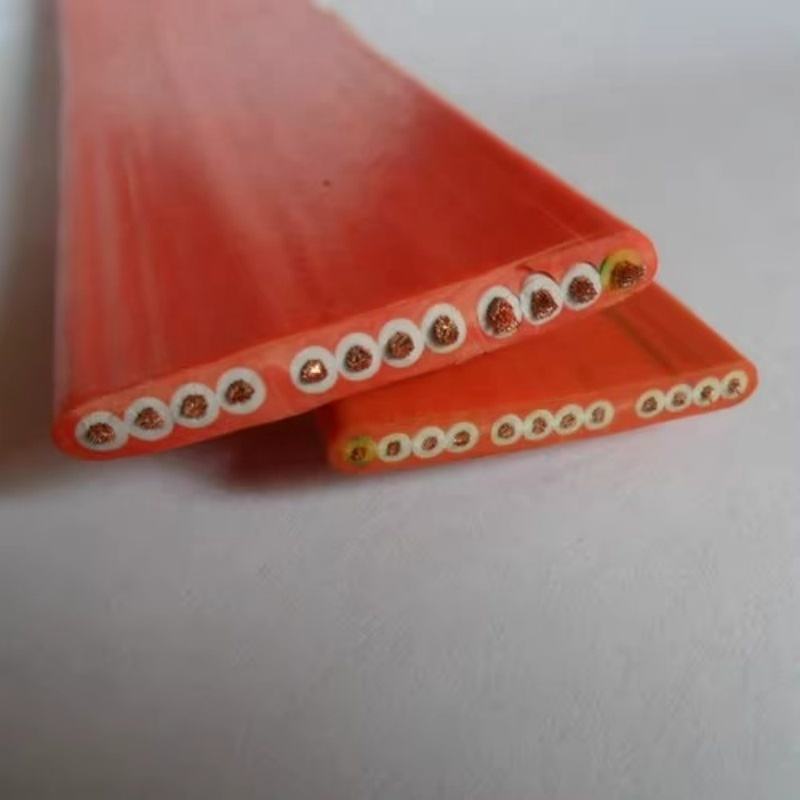

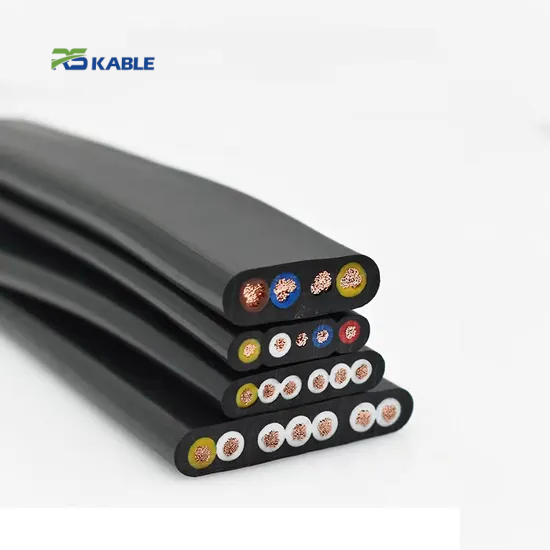

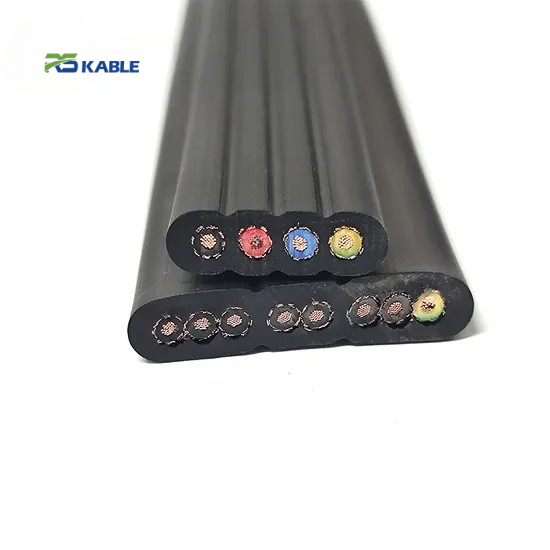

Designed for flexibility and durability, the TVVB series flat cable is the industry standard for vertical suspension systems. Unlike round cables, its flat structure allows for smaller bending radii and tighter packing, making it ideal for the space-constrained, high-movement environments found in elevator shafts and automated overhead machinery.

Manufactured by Shanghai Ruosheng Wire and Cable Co., Ltd.—specialists with over 100 varieties of high-flexibility drag chain and special cables—this product ensures consistent performance in dynamic motion applications.

Key Features & Benefits

- Optimized for Vertical Motion: The flat configuration reduces internal stress during bending and flexing, significantly extending the cable’s service life in traveling applications.

- High Flexibility: Specially formulated soft PVC insulation and sheathing allow for a bending radius as small as 0.3m, preventing cracking under continuous movement.

- Robust Construction: Resistant to oil, acid, moisture, and aging, ensuring reliability in harsh industrial environments (-15°C to +70°C).

- Space-Saving Design: The flat profile stacks neatly, maximizing space efficiency in cable tracks and elevator shafts.

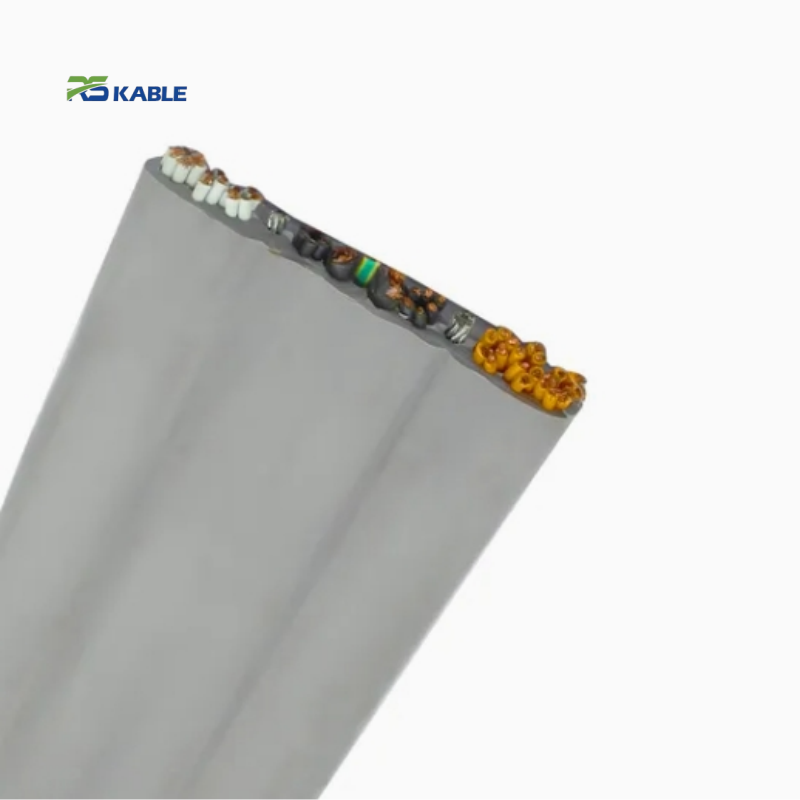

- Customizable Configurations: Available in various core counts (up to 60+ cores) and cross-sections to meet specific power and signal transmission needs.

Technical Specifications

|

Feature |

Specification |

|---|---|

|

Model Number |

TVVB (Flat Elevator/Travelling Cable) |

|

Conductor Material |

High-Purity Flexible Stranded Copper |

|

Insulation Material |

Special Soft PVC (Polyvinyl Chloride) |

|

Sheath Material |

Cold & Oil Resistant Flexible PVC |

|

Rated Voltage |

300/500V (≤1.5mm²); 450/750V (>1.5mm²) |

|

Temperature Range |

-15°C to +70°C (Static/Flexing) |

|

Standard Compliance |

IEC 60227-6, GB/T 5023.6 |

|

Bending Radius |

Approx. 10x Cable Thickness (Min 0.3m recommended) |

|

Available Sizes |

0.75mm² – 2.5mm² (Custom sizes available) |

|

Core Identification |

Color-coded or Number-coded cores |

|

Suspension Length |

Recommended free suspension length ≤35m (Standard) or ≤80m (Reinforced) |

Applications

This versatile flat cable is specifically engineered for:

- Elevator Systems: Main traveling cable for internal and panoramic elevators, carrying power and control signals.

- Material Handling: Overhead cranes, hoists, and gantry systems requiring vertical cable management.

- Transformer Connections: Flexible power leads for transformers where space and routing flexibility are critical.

- Automated Machinery: Moving machine parts and conveyors requiring reciprocating motion.

Frequently Asked Questions (FAQ)

Q: What is the difference between TVVB and round elevator cables?

A: TVVB flat cables are designed to flex in one plane, which reduces twisting and internal stress during vertical travel. This makes them more durable and space-efficient for elevators compared to round cables, which require larger bending radii.

Q: Can this cable be used for high-rise buildings (over 80m)?

A: Standard TVVB cables are recommended for suspension lengths up to 80m. For higher-rise applications exceeding this length, we recommend our reinforced versions with integrated steel wire ropes for added tensile strength. Please contact us for custom solutions.

Q: What is the Minimum Order Quantity (MOQ)?

A: We offer flexible ordering options. For standard stock items, we can accommodate smaller orders (1-100 pieces). For custom lengths or specific core counts, the MOQ may vary. Please submit an inquiry for a precise quote.

Q: Is the cable resistant to oil and cold environments?

A: Yes, the outer PVC sheath is specially formulated to resist oil, abrasion, and cold temperatures down to -15°C, making it suitable for industrial environments.

Q: How do you package the cable for shipping?

A: Cables are typically packaged in wooden drums or coils, wrapped in protective plastic to ensure they arrive in perfect condition. We ship globally via ocean freight (e.g., Maersk) or air freight depending on urgency.