PVC Insulated Flat Polyurethane Oil‑Resistant Anti‑Drag Coaxial CCTV Video + Power Cable for Pipeline Inspection Robots

.Rugged PVC insulated flat hybrid cable with oil‑resistant polyurethane jacket for CCTV pipeline robot systems.

.Integrates coaxial video signal, power and signal cores in one robust assembly.

.Designed for underground, sewer and pipeline inspection robots with drag and abrasion resistance.

.High flexibility and extended cable life under repeated motion and tension.

.Customizable options available from Shanghai Rousheng Wire & Cable Co., Ltd.

This PVC insulated, oil‑resistant, flat hybrid cable is engineered specifically for pipeline inspection robots with CCTV, providing a rugged and integrated solution for real‑time video transmission and power delivery in challenging underground and sewer environments.

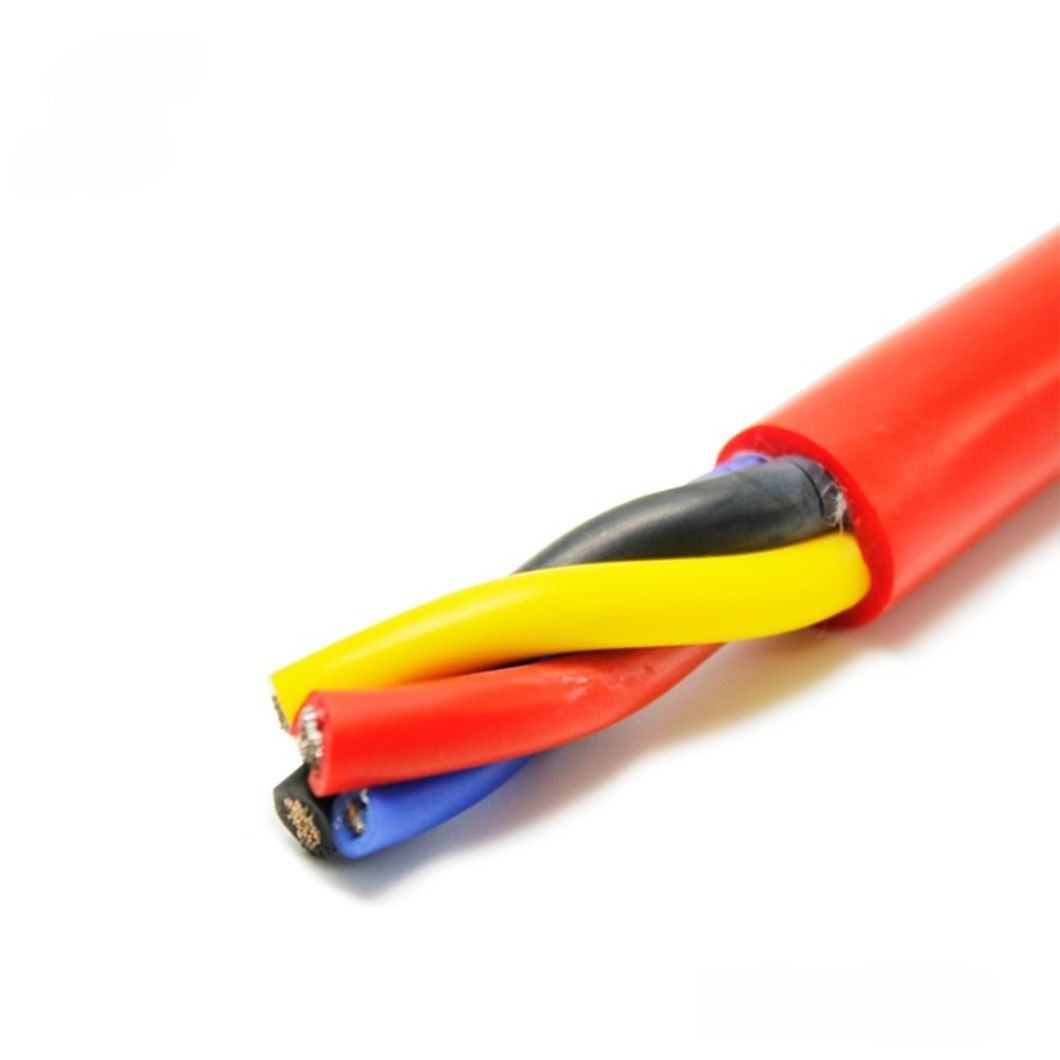

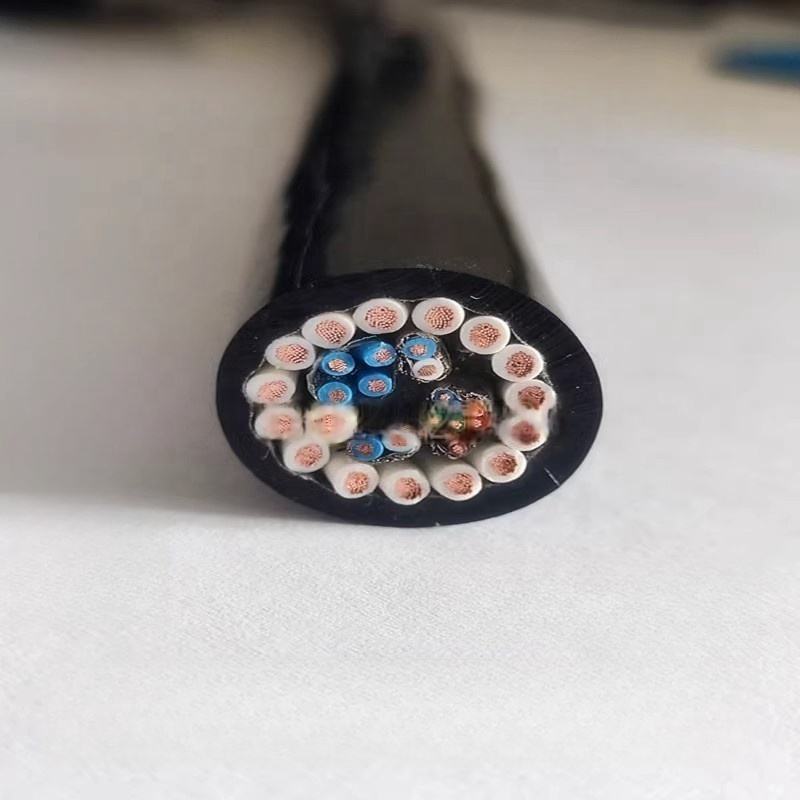

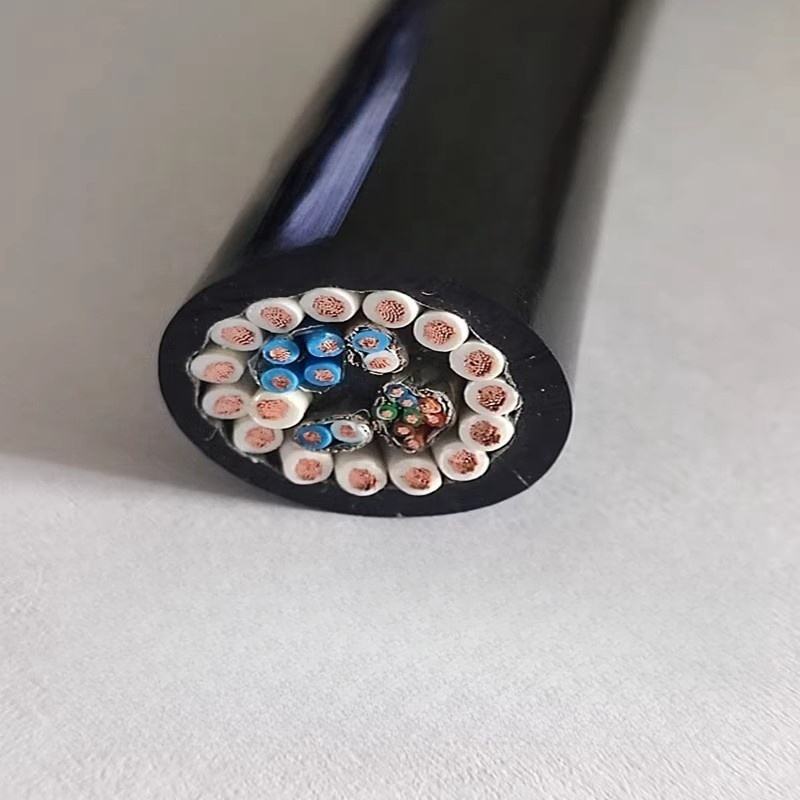

Unlike standard coaxial video cables, this hybrid design combines coaxial video signal cores, power conductors and multiple communication pathways inside a flat, abrasion‑resistant polyurethane jacket — ideal for rotating, pulling and bending movements during robot deployment.

Shanghai Rousheng Wire & Cable Co., Ltd. is a trusted specialist in high‑flex drag chain cables and custom industrial cabling solutions with over 100 product types developed for industrial automation, robotics and inspection equipment.

Key Product Benefits

📍 Designed for Robot CCTV Inspection Systems

Pipeline inspection robots rely on stable video feeds and dependable power to operate camera systems, lights, sensors and movement actuators. This hybrid cable solves both needs in one robust assembly, minimizing cable changeover and failure points.

Real‑time video and data transmission is critical to accurate pipeline diagnostics and thorough inspection reporting. This cable delivers that capability with consistent signal integrity during motion.

📍 Flat Polyurethane Jacket with PVC Insulation

-

Flat profile: improves feeding and tracking along robot guides and confined conduit spaces.

-

Polyurethane outer jacket: excellent resistance to oils, abrasion, chemical exposure and temperature changes — key for underground or industrial environments.

-

PVC insulation: stable dielectric properties for both video and power cores.

📍 Anti‑Drag Strength & Long Life

The cable is built to resist repeated tension and drag when deployed inside pipelines. Its structure absorbs mechanical stress, reducing fatigue and extending service life even with frequent pulling and repositioning.

📍 Integrated Multi‑Core Design

This hybrid cable integrates:

✔ Coaxial video core for CCTV imaging transmission

✔ Power conductors to energize robot components

✔ Additional signal or communication cores for control or telemetry

This combination simplifies installation and reduces maintenance effort.

Typical Applications

-

Underground pipeline CCTV inspection & sewer network mapping.

-

Drainage, stormwater and sewer system maintenance drones/robots.

-

Endoscope detection systems for municipal infrastructure.

-

Automation systems where video and power need to run in one cable.

-

Safe, robust cable solution for confined, wet or contaminated work environments where cable drag is expected.

Technical Specifications

| Attribute | Specification |

|---|---|

| Conductor Material | Stranded Copper |

| Insulation Material | PVC |

| Outer Jacket Material | Polyurethane (PUR) |

| Cable Shape | Flat hybrid construction |

| Rated Voltage | 220 V |

| Operating Temperature | -20 °C to +70 °C |

| Cable Diameter / Width | Approx. 2.5 mm (core wires) |

| Core Type | Coaxial video + power + multi‑signal |

| Application Environment | Underground / Sewer / Pipeline inspection |

| Color Options | Black / Orange / Custom |

Product Highlights

✔ Coaxial Video Signal Support: Enables high‑quality CCTV feed transmission for real‑time inspection.

✔ Power & Signal in One Assembly: Reduces complexity and improves reliability.

✔ Resistance to Oil and Abrasion: Suited for harsh environments and heavy mechanical demands.

✔ Flat & Flexible Design: Improves cable management on robot reels and guide systems.

Frequently Asked Questions (FAQ)

Q1: Why combine video and power conductors in one cable?

A: Pipeline robots require both continuous power and stable video transmission. An integrated cable reduces installation complexity, failure points and space requirements.

Q2: What is the advantage of a flat cable profile?

A: Flat design improves feeding into tight spaces and reduces twisting during robot motion, enhancing durability and handling.

Q3: Can this cable withstand oil and mechanical wear?

A: Yes. The polyurethane outer jacket and PVC insulation provide strong resistance to oils, abrasion, chemical exposure and mechanical stresses typical in underground inspection environments.

Q4: What temperature range can this cable support?

A: Standard operating range is ‑20 °C to +70 °C, appropriate for most underground and industrial installation scenarios.

Q5: Is customization available?

A: Yes — core configuration, conductor materials, jacket colors and lengths can be tailored to project specifications.