PUR Stranded Polyethylene Insulated Sea Water Resistant Cable | Abrasion-Resistant, Cold-Resistant, Corrosion-Resistant for Underwater Robots | OEM

The PUR Stranded Polyethylene Insulated Sea Water Resistant Cable combines the best in cable technology for underwater robots. With its exceptional abrasion resistance, corrosion protection, and cold resistance, it is an essential component for any subsea application. Whether you need reliable signal transmission in harsh underwater conditions or durable cable protection, this cable provides the ideal solution.

The PUR Stranded Polyethylene Insulated Sea Water Resistant Cable is specifically designed for high-performance underwater applications. Ideal for ROVs (Remotely Operated Vehicles) and other underwater robotics, this cable ensures uninterrupted signal transmission even under extreme conditions. Offering abrasion resistance, cold resistance, and corrosion resistance, it is an excellent choice for long-lasting underwater operations.

Key Features & Benefits

1. Premium Material

-

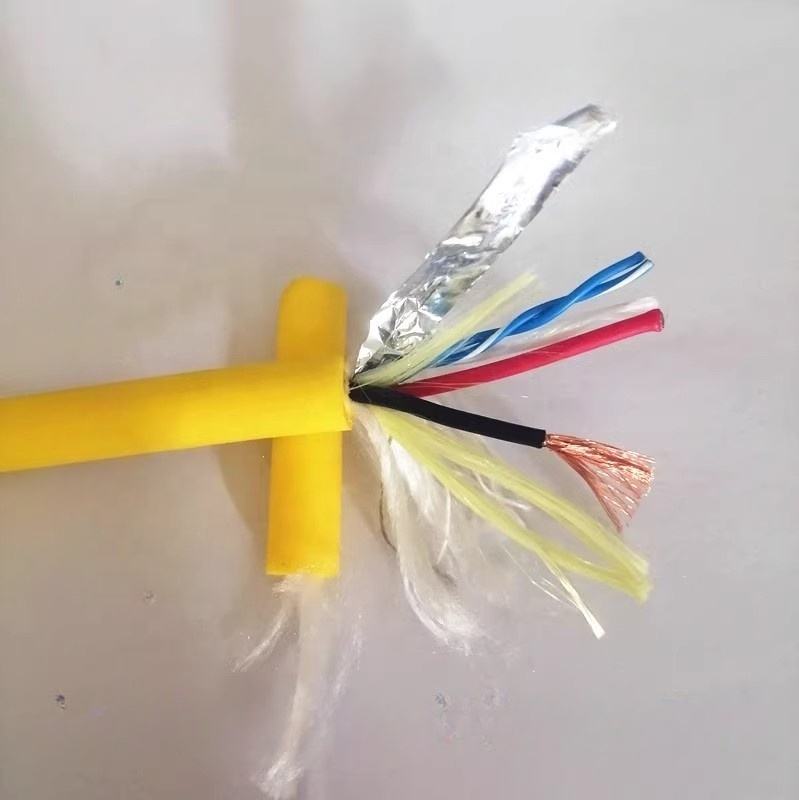

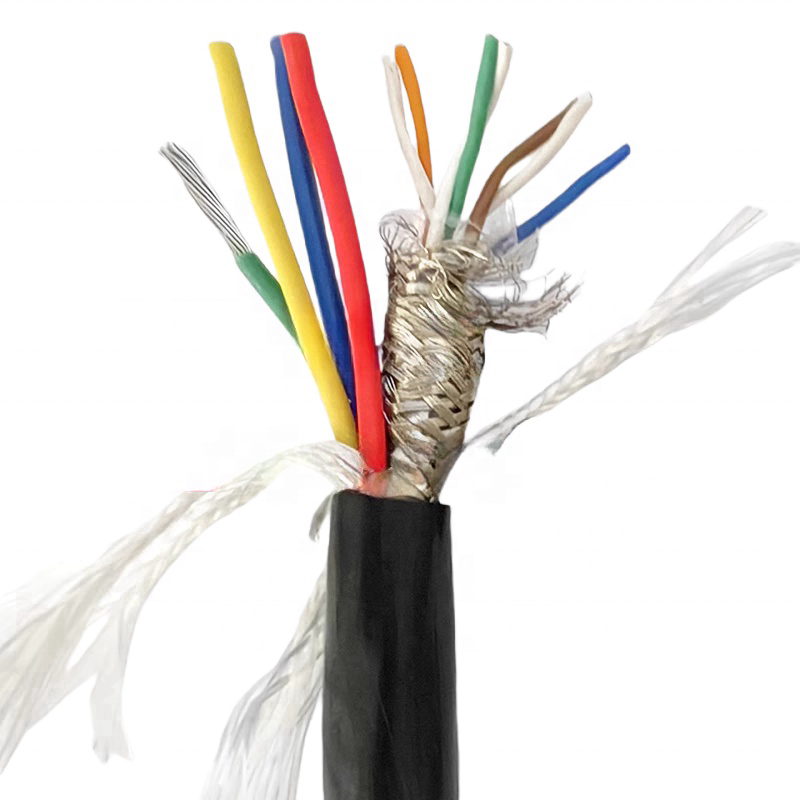

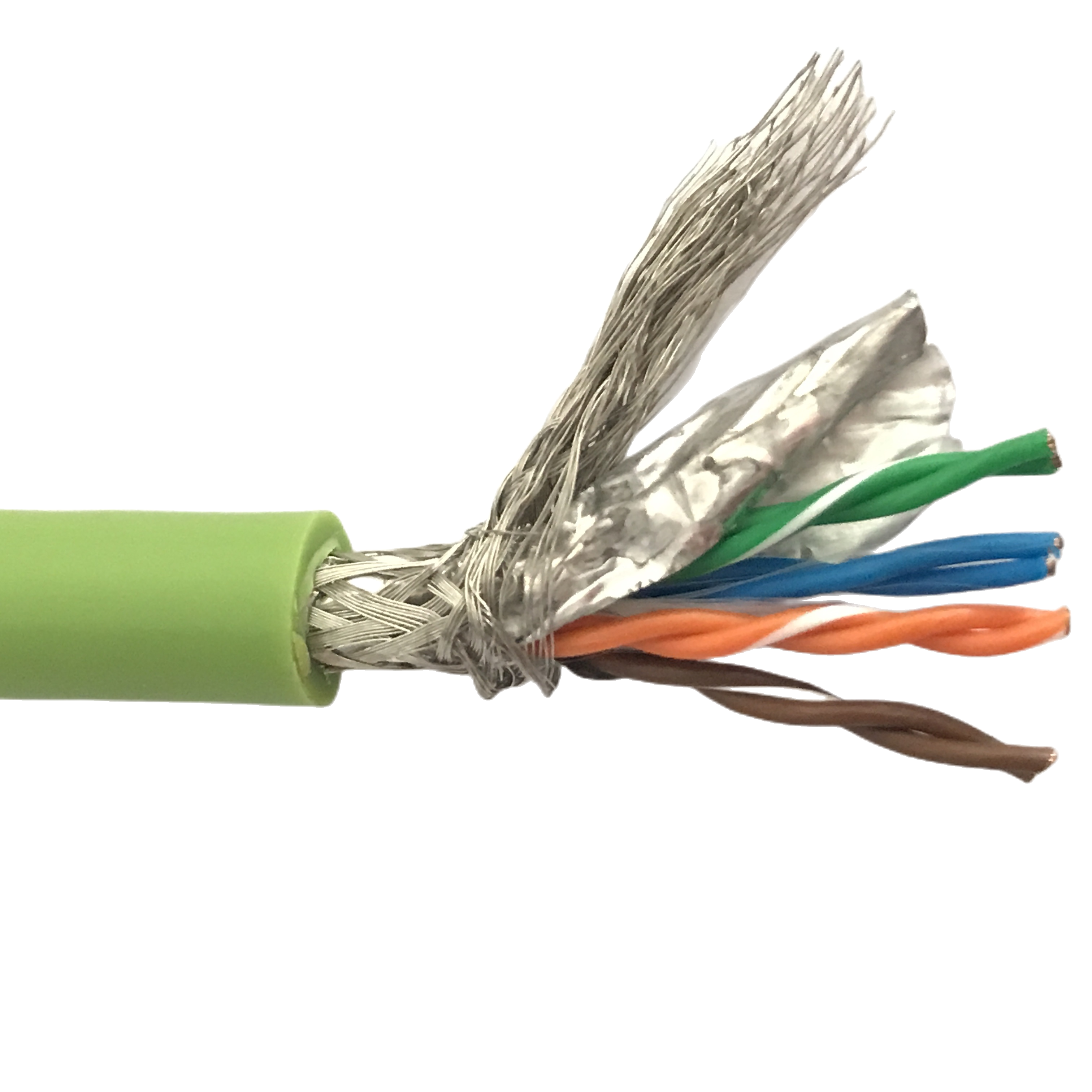

The cable features polyurethane (PUR) insulation, known for its high abrasion resistance and durability in harsh environments.

-

Polyethylene (PE) ensures superior protection against water, enhancing performance in saline water conditions.

2. Superior Performance in Water

-

Designed with a sea-water resistant sheath, this cable is engineered to handle long durations in aquatic environments, ensuring minimal degradation even when submerged for extended periods.

3. Excellent Durability

-

Abrasion-resistant: The cable can withstand physical wear and tear, making it ideal for applications involving constant movement.

-

Cold-resistant: Remains flexible and reliable even at low temperatures, ensuring the cable performs optimally in cold underwater environments.

-

Corrosion-resistant: Perfect for underwater robots, as it prevents damage caused by exposure to saltwater and other corrosive elements.

4. Customizable

-

Available in multiple configurations: 2/4/6/8-core designs, with zero buoyancy features for flexible, reliable operation in submerged conditions.

-

Tailored OEM solutions are offered to meet specific project needs and scale.

5. Signal Integrity

-

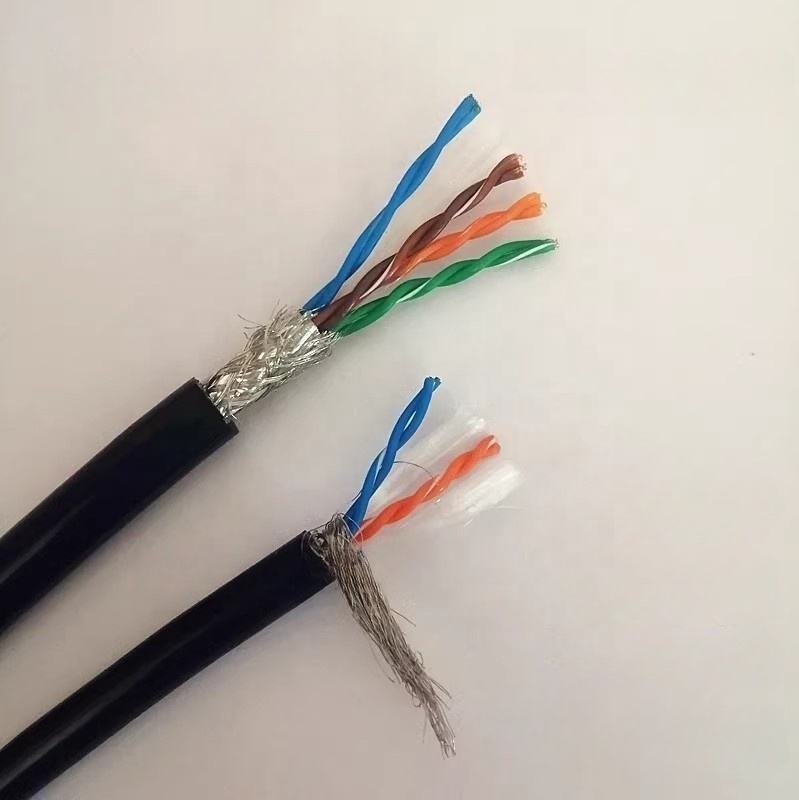

Designed to carry strong network signals without degradation, this cable ensures optimal data transmission in underwater communication systems. It supports a twisted pair configuration, providing enhanced noise immunity.

Applications

-

Underwater Robots (ROVs): Ensures reliable signal transmission for underwater operations.

-

Marine Engineering: Used for various oceanic and marine-based engineering projects, such as cable laying, underwater maintenance, and research.

-

Subsea Communication Systems: Optimized for communication in submerged conditions, including offshore structures.

Technical Specifications

| Attribute | Details |

|---|---|

| Material | Polyurethane (PUR), Polyethylene (PE) |

| Insulation | Sea Water Resistant, Abrasion Resistant, Cold-Resistant, Corrosion-Resistant |

| Wire Gauge | 24AWG |

| Core | 2, 4, 6, 8 cores |

| Twisted Pair | Yes |

| Buoyancy | Zero Buoyancy |

| Customization | OEM Solutions Available |

FAQ

Q1: Is this cable suitable for long-term underwater use?

Yes, the PUR Stranded Polyethylene Insulated Sea Water Resistant Cable is designed to perform in extreme underwater environments. It provides high durability and resistance to saltwater corrosion, making it ideal for long-term underwater operations.

Q2: Can I use this cable in cold environments?

Absolutely. This cable is engineered with cold-resistant properties, maintaining its flexibility and functionality even in low temperatures.

Q3: What types of underwater robots is this cable compatible with?

This cable is perfect for ROVs (Remotely Operated Vehicles) and other underwater robots that require durable, long-lasting cables for reliable data transmission in marine environments.

Q4: Is it customizable for different project needs?

Yes, this cable is available in various configurations, including 2, 4, 6, or 8-core designs. OEM customization options are available to meet specific requirements.