Custom 2/4/6/8‑Core ROV Cable with 0.2–1.5″ Power Conductors | Neutral Buoyancy Underwater Robotics Cable

-

Custom 2/4/6/8‑Core Zero Buoyancy ROV Tether with Kevlar Reinforcement

-

Jacket Material: Hydrolysis‑resistant Polyurethane (PUR/TPU)

-

Tensile Strength: Reinforced with Kevlar fiber for high load‑bearing capacity

-

Features: Neutral buoyancy, water‑blocking, oil/abrasion resistance, -30°C to +90°C temperature range

-

Application: Power and data transmission for underwater robots and inspection systems

Your underwater vehicle’s reliability depends on its tether connection to the surface. For operators who require precise control and uninterrupted power delivery in harsh marine environments, the tether’s integrity is non‑negotiable.

This professional‑grade ROV umbilical cable is engineered to solve the two greatest challenges in underwater robotics: drag and durability. Whether you are conducting deep‑sea exploration, pipeline inspection, or aquaculture monitoring, this cable acts as a neutral‑buoyancy lifeline, allowing your vehicle to maneuver freely without fighting the weight of its tether.

Manufactured by Shanghai Rousheng Wire & Cable Co., Ltd., a leader in high‑flexibility and specialty cable R&D and production, this series offers fully customizable core configurations to match your specific power and data requirements.

Why Choose Rousheng Custom ROV Cables?

True Neutral Buoyancy

Standard cables sink and create drag that drains your ROV’s battery and hampers movement. We use specialized foamed Polyurethane (PUR) or other low‑density materials to achieve near‑zero buoyancy. This allows the robot to hover and move naturally in the water column.

Military‑Grade Tensile Strength

The ocean environment is unpredictable. To prevent catastrophic equipment loss, our cables are reinforced with braided Kevlar (Aramid) fibers. This reinforcement provides exceptional tensile strength (up to 1000 kgf depending on diameter) without adding significant weight, ensuring the copper conductors resist breakage under tension.

Water‑Blocking Technology

A small nick in the outer jacket shouldn’t spell disaster. Our cables incorporate water‑blocking fillers and compounds. If the outer sheath is compromised, these materials prevent water from traveling down the cable and shorting electronic components or reaching the surface control system.

Extreme Environment Durability

The outer jacket is crafted from marine‑grade PUR (Polyurethane). Unlike standard PVC, PUR is resistant to:

-

Seawater corrosion and hydrolysis

-

Microbial attack (common with prolonged immersion)

-

Abrasion from rocks, barnacles, and ship decks

-

Oil contamination and UV radiation

Technical Specifications

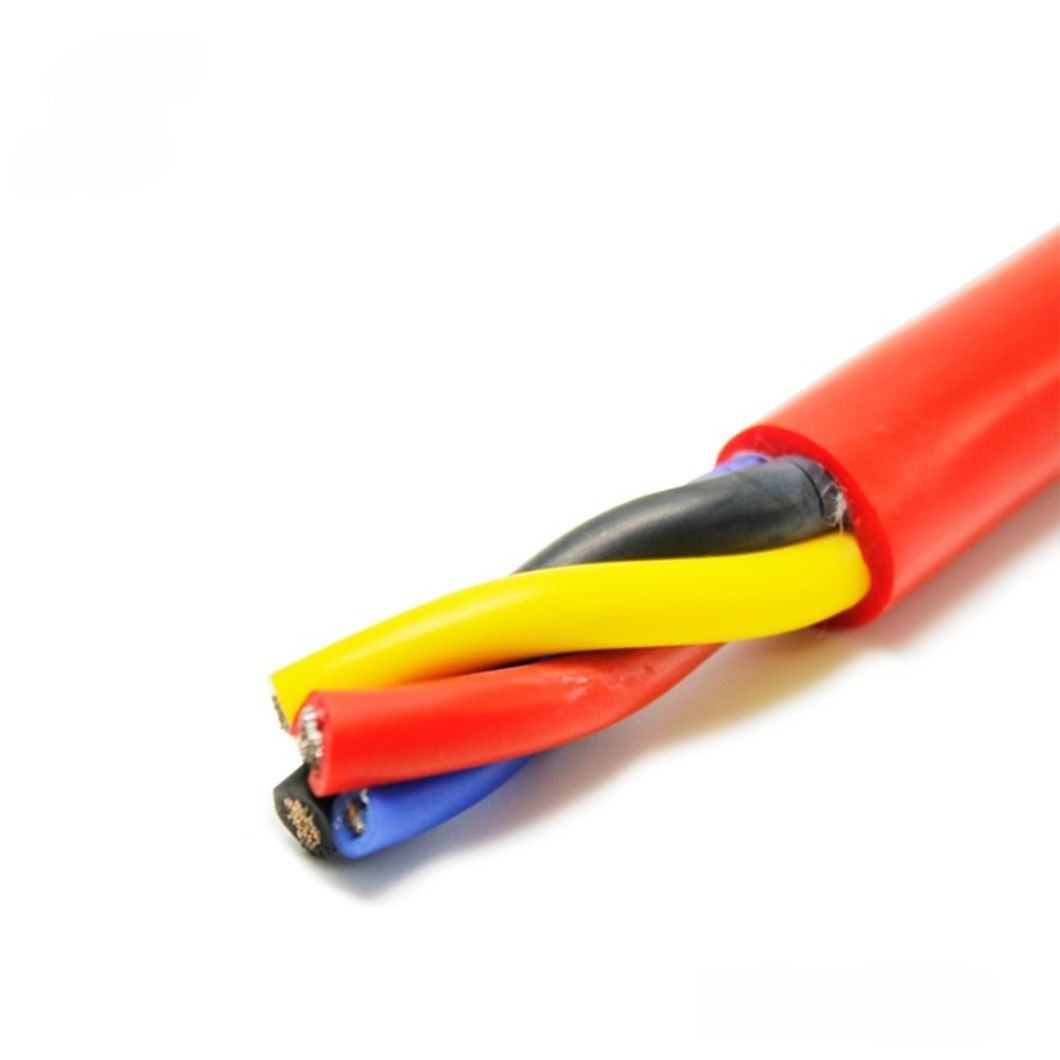

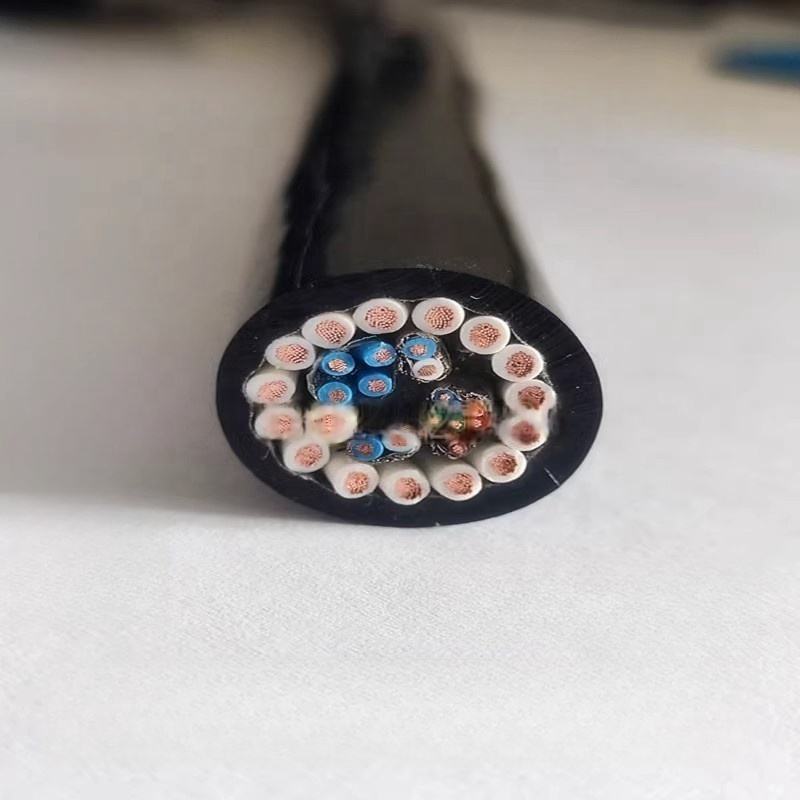

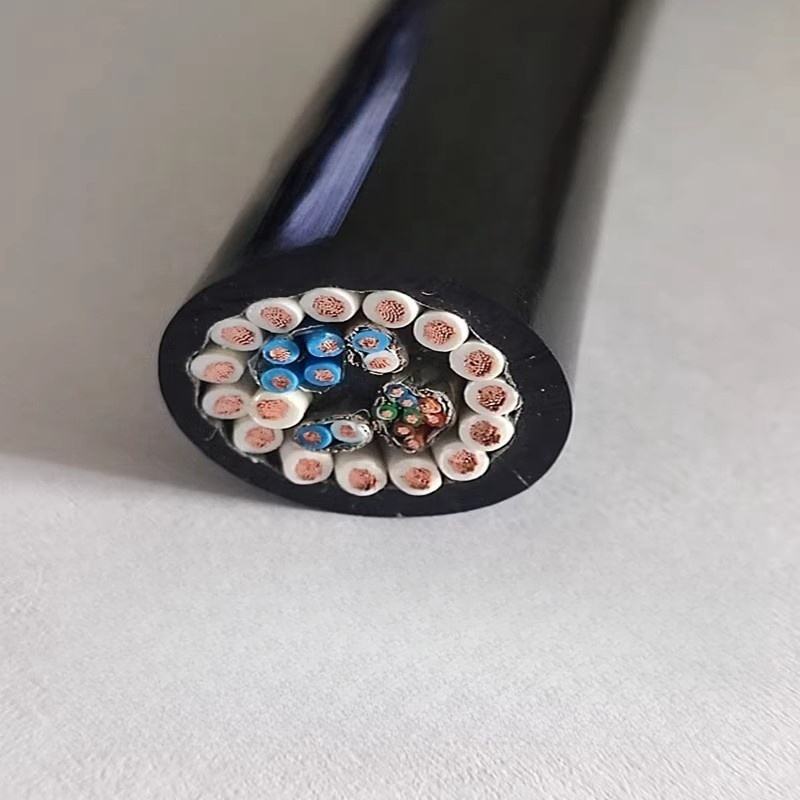

We offer customization for 2, 4, 6, and 8‑core configurations, mixing power and signal pairs as needed for your specific thrusters and sensors.

| Feature | Specification |

|---|---|

| Core Configuration | 2 / 4 / 6 / 8 Cores (custom twisted pairs available) |

| Conductor Material | Multi‑strand, ultra‑fine oxygen‑free tinned copper (Class 6 flexibility) |

| Power Conductor Size | Custom sizing from 0.2″ up to 1.5″ equivalent (standard 26AWG to 16AWG) |

| Insulation | High‑density TPE / PE / Foam PE (for data pairs) |

| Tensile Member | Kevlar® Aramid Fiber Braid (bulletproof grade) |

| Outer Jacket | Marine‑grade Polyurethane (PUR) / Foam PUR |

| Jacket Color | High‑visibility Yellow or Orange (matte finish) |

| Voltage Rating | 300/500V (customizable up to 1000V) |

| Temperature Range | Fixed: -40°C to +90°C |

| Depth Rating | Designed for depths up to 300m (standard) or deeper upon request |

| Min. Bending Radius | 7.5 × Cable Diameter (mobile use) |

Applications

This cable series is specifically optimized for:

-

Observation Class ROVs: BlueROV, Chasing, and custom commercial builds

-

Underwater Inspection: Pipe crawlers and down‑looking cameras

-

Marine Research: Tow cables for sonar and oceanographic sensors

-

Aquaculture: Net cleaners and feeding monitoring systems

Manufacturer Expertise: Shanghai Rousheng

With over 100 varieties of specialty cables in our portfolio, Shanghai Rousheng Wire & Cable Co., Ltd. goes beyond “off‑the‑shelf” limitations. We focus on research and development for high‑flexility drag chain and underwater applications. Our production process ensures that every meter of cable is tested for concentricity, abrasion resistance, and signal integrity before leaving the factory.

Frequently Asked Questions (FAQ)

Q: Can you customize the combination of power and data wires?

A: Yes. A common configuration is a hybrid cable containing 2 thicker cores for power (thrusters/lights) and 2 twisted pairs for data (Ethernet/video). We can adjust the conductor size (0.2″ to 1.5″) based on your load requirements.

Q: What is the difference between foam PUR and standard PUR jackets?

A: Standard PUR is extremely tough and sinks slowly due to its density. Foam PUR contains air bubbles within the material structure, lowering its density so the cable floats or remains neutral in freshwater and seawater. Foam PUR is recommended for smaller ROVs where weight is critical.

Q: Is this cable compatible with standard watertight connectors?

A: Yes. The jacket is designed to bond well with potting compounds and fits standard gland sizes (e.g., PG7, M10) and connectors (such as SubConn or Blue Robotics penetrators).

Q: What is the lead time for a custom specification?

A: While we stock common sizes (like 2×26AWG + 2×18AWG), fully custom runs typically require 7–15 days for production depending on complexity and quantity.