Precision Underwater Maneuvering | ROV Cable | Neutral Buoyancy Balance | Enhanced Stability

This precision-engineered ROV Cable is designed to achieve neutral buoyancy balance for enhanced underwater stability. By integrating density-controlled materials and reinforced structural layers, it minimizes hydrodynamic drag while maintaining consistent power and signal transmission. Suitable for inspection-class and light work-class ROV platforms, it improves maneuverability, reduces propulsion strain, and enhances video stability during sensitive operations. Available in power-only, power-and-signal, or electro-optical hybrid configurations, it provides reliable performance for offshore, scientific, and industrial underwater applications.

Precision Underwater Maneuvering | ROV Cable | Neutral Buoyancy Balance | Enhanced Stability

The ROV Cable in this neutral buoyancy series is specifically engineered for precision underwater maneuvering where stability, balance, and drag control are critical. By achieving near-neutral buoyancy in water, this tether minimizes vertical pull and lateral resistance, allowing ROV systems to maintain accurate positioning and smoother directional control in dynamic subsea environments.

Designed for inspection-class and light work-class vehicles, this ROV Cable enhances operational stability without compromising electrical performance or mechanical strength.

Engineered for Neutral Buoyancy Performance

Unlike standard subsea tethers, this design integrates density-controlled materials to achieve balanced buoyancy characteristics.

Key Design Objectives:

-

Neutral or micro-positive buoyancy in seawater

-

Reduced hydrodynamic drag

-

Improved vehicle maneuverability

-

Lower thruster energy consumption

-

Stable suspension in mid-water operations

The result is more precise movement during delicate tasks such as structural inspection, marine research sampling, and subsea asset surveys.

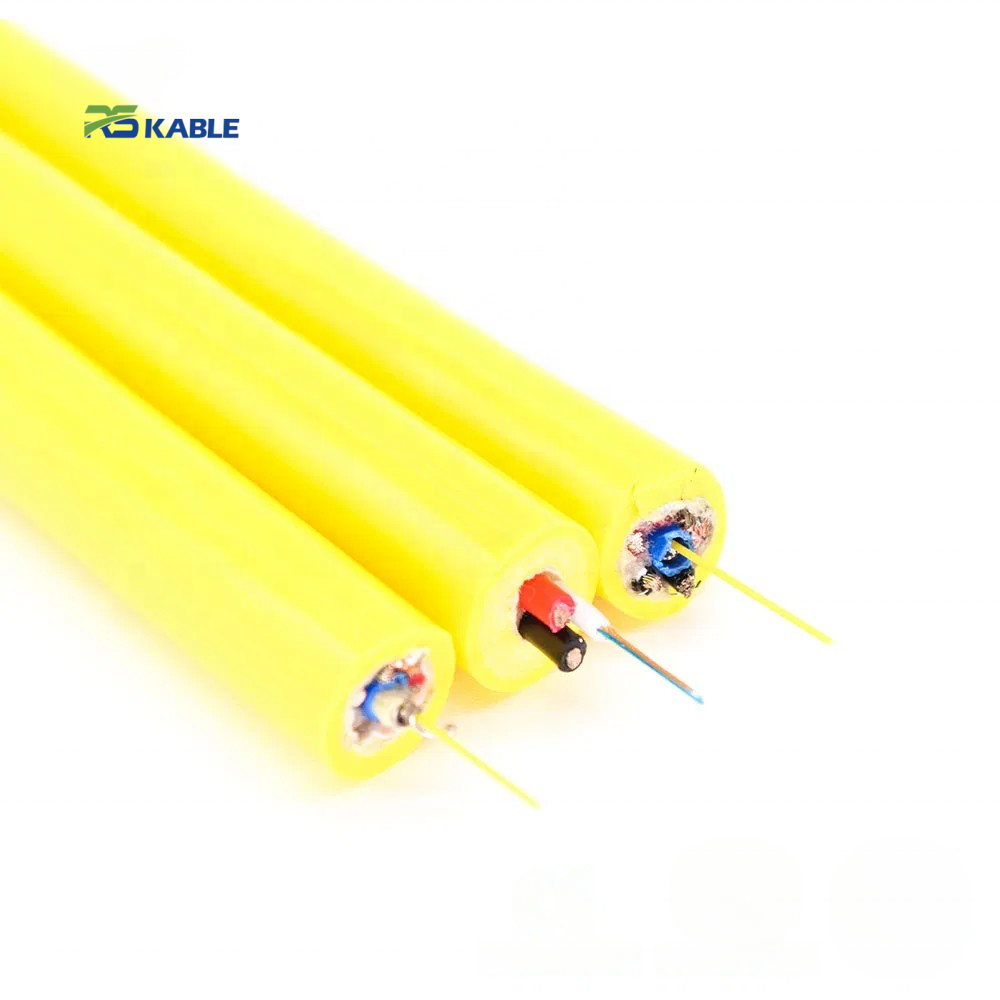

Product Models & Configuration Options

| Model Code | Product Name (Model + Core Attribute) | Application Scenario | Core Technical Structure |

|---|---|---|---|

| NB-ROV-4P | 4-Core Neutral Buoyancy Power Cable | Pipeline & hull inspection | 4 × 2.5 mm² tinned copper + buoyant filler |

| NB-ROV-6PS | Power + Signal Balanced Tether | Offshore structure monitoring | 4 × 2.5 mm² + 2 shielded twisted pairs |

| NB-ROV-HF | Hybrid Electro-Optical Neutral Cable | HD camera & data systems | 2 power cores + 2–4 fiber optics |

| NB-ROV-ST | Stabilized Reinforced ROV Cable | Precision intervention tasks | Multi-core + aramid tensile layer |

All models support customized lengths, voltage ratings, and buoyancy calibration.

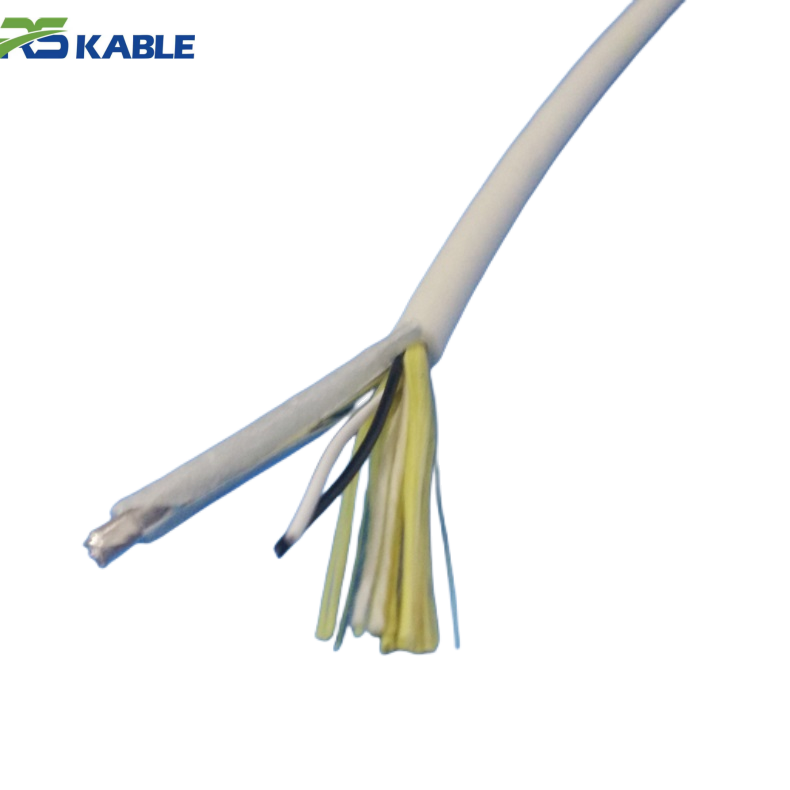

Structural Composition & Materials

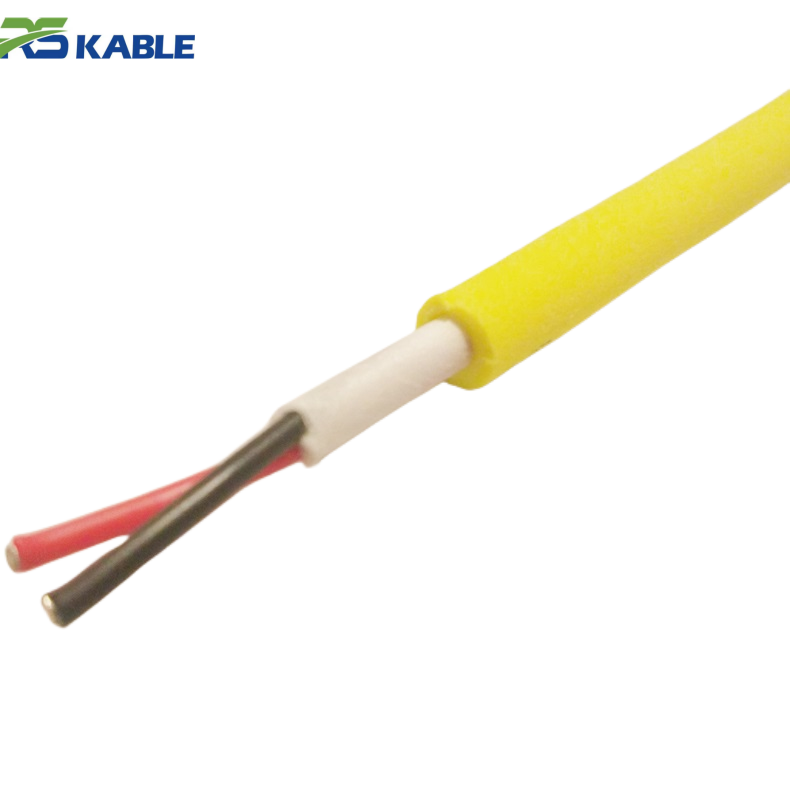

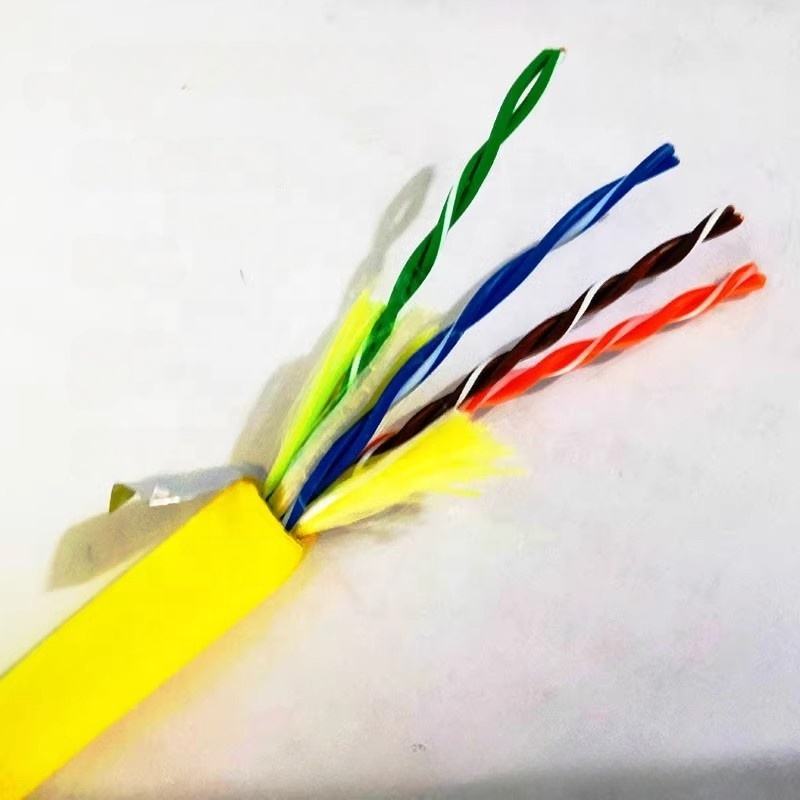

Conductor

-

Fine-stranded tinned copper

-

Low-resistance design for consistent voltage delivery

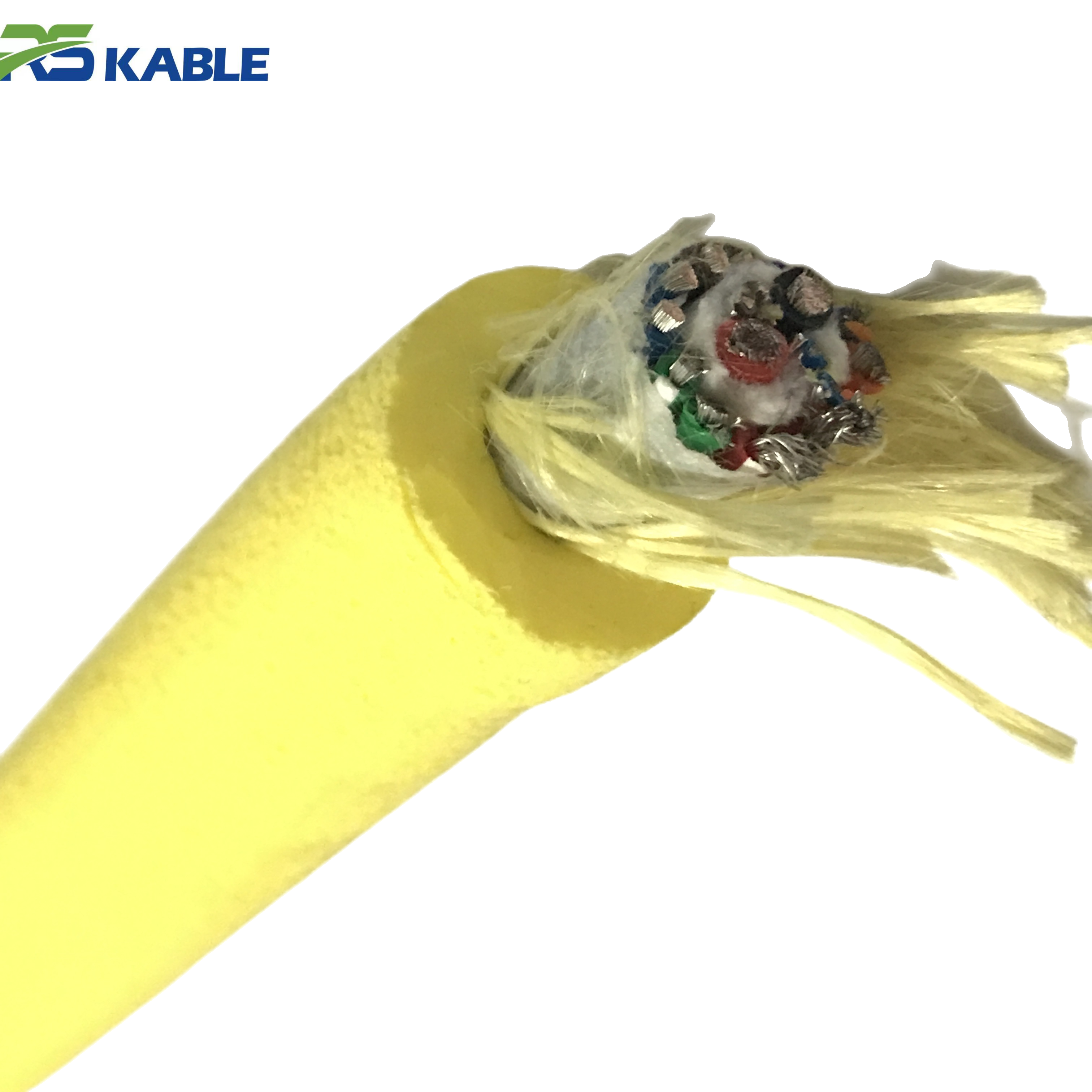

Signal & Data

-

Shielded twisted pairs for low-noise communication

-

Optional single-mode or multi-mode fiber optics

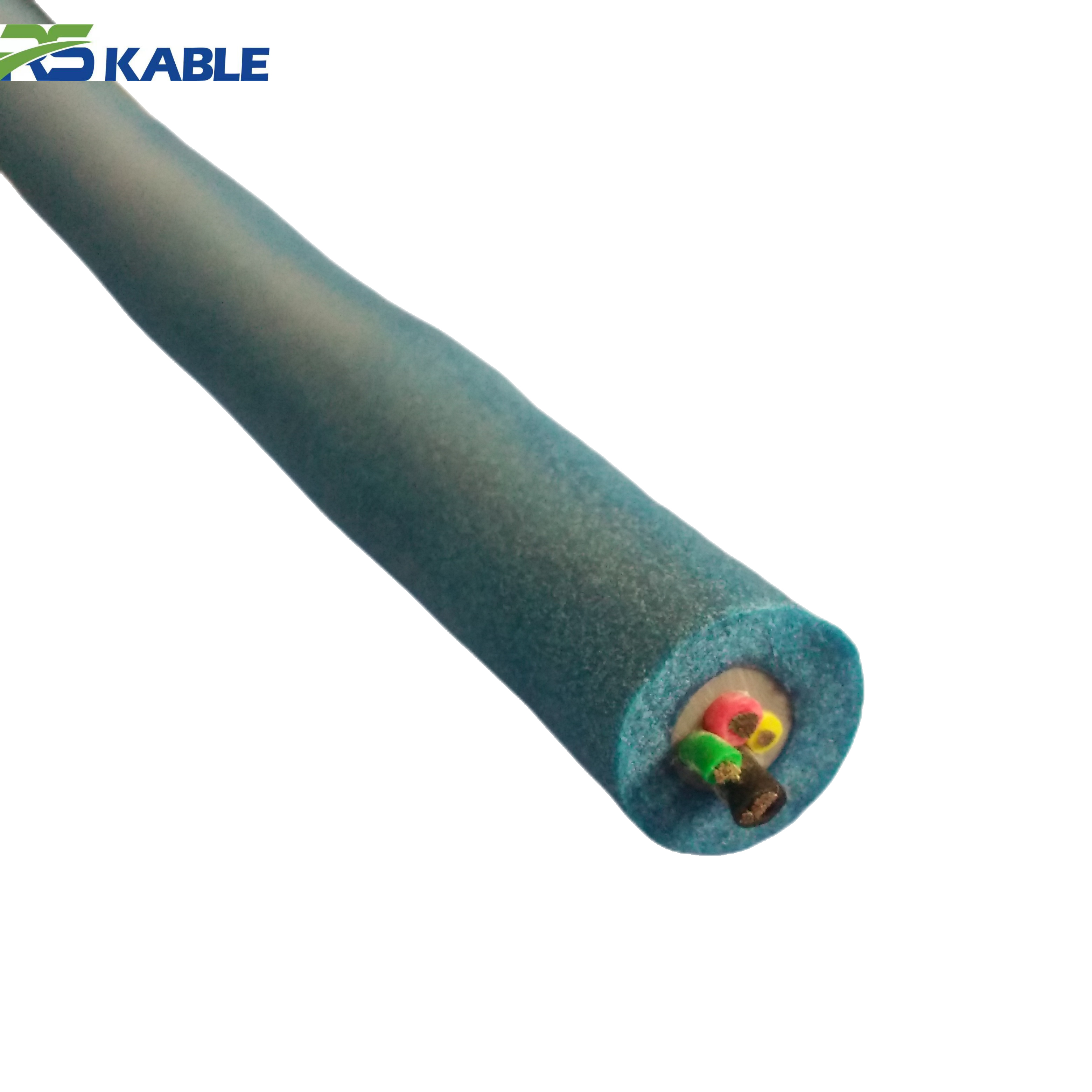

Buoyancy Control Layer

-

Lightweight filler compounds

-

Density-adjusted insulation materials

-

Controlled specific gravity close to seawater (≈1.02–1.05 g/cm³)

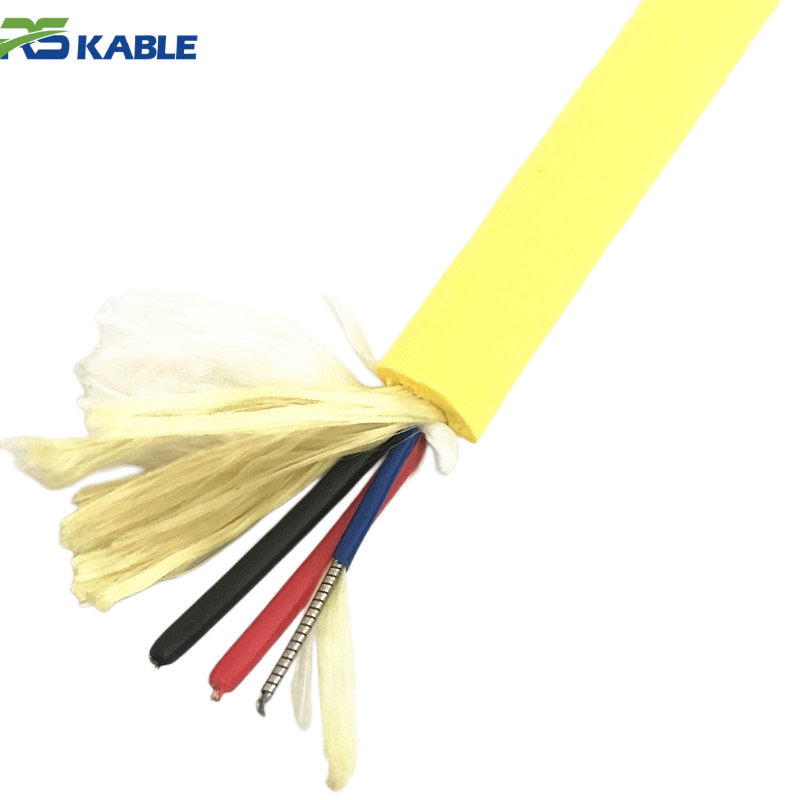

Reinforcement

-

Aramid fiber strength member

-

Central tensile core for load distribution

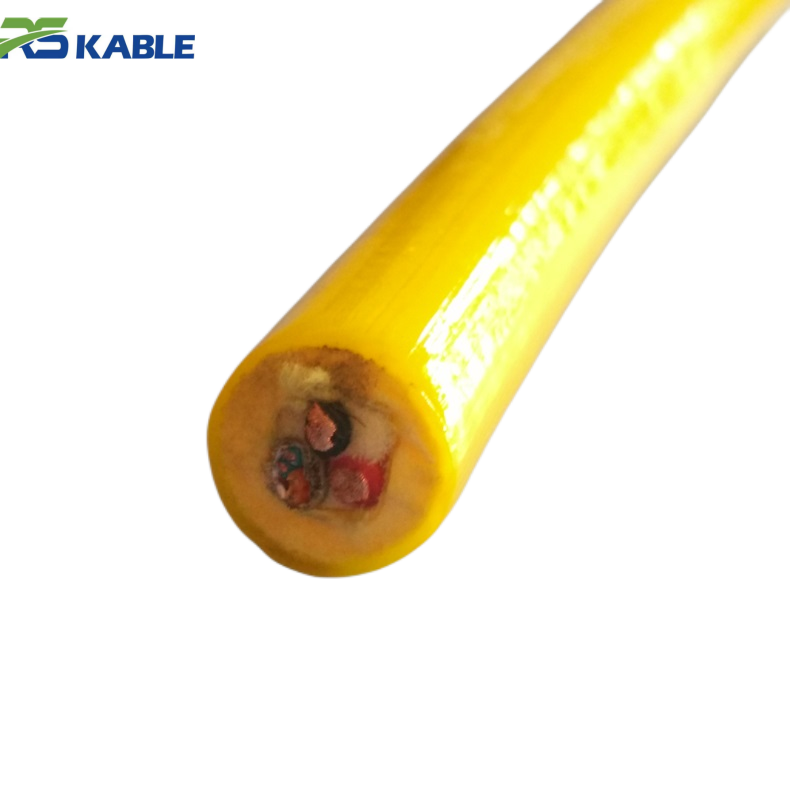

Outer Jacket

-

High-performance TPU or PUR

-

Abrasion-resistant and hydrolysis-resistant

This ROV Cable construction ensures balanced flotation while maintaining tensile reliability and long-term durability.

Technical Parameters Overview

| Parameter | Specification |

|---|---|

| Depth Rating | Up to 2,000 m (customizable) |

| Voltage Rating | 300/500V – 0.6/1kV |

| Tensile Strength | Up to 2,500 kg (model dependent) |

| Operating Temperature | –30°C to +80°C |

| Buoyancy | Neutral / Slight positive |

| Compliance | ISO 9001, RoHS |

Application Scenarios

Neutral buoyancy tethers are critical in:

-

Subsea infrastructure inspection

-

Offshore wind foundation surveys

-

Marine scientific research missions

-

Underwater archaeological exploration

-

Ship hull and propeller examination

-

Dam and reservoir inspections

Long-tail keyword optimization focus:

-

“neutral buoyancy ROV cable for offshore inspection”

-

“balanced subsea tether for precision maneuvering”

-

“low-drag ROV cable for underwater survey systems”

Performance Benefits in Dynamic Environments

✔ Improved mid-water stability

✔ Reduced operator correction input

✔ Lower propulsion power consumption

✔ Enhanced video stability during inspection

✔ Minimized entanglement risk

By reducing vertical tension and drag, the ROV Cable contributes directly to smoother navigation and more accurate inspection results.

Quality Assurance & Engineering Expertise

-

Manufactured under ISO-certified quality systems

-

Density testing for buoyancy accuracy

-

Tensile load validation per production batch

-

Electrical continuity & insulation resistance testing

-

Custom engineering support for system integration

Our subsea cable engineering team provides buoyancy calculation support based on water salinity, operating depth, and ROV weight.

Optimize Your Underwater Control System

Enhance maneuverability and operational stability with a neutral buoyancy ROV Cable tailored to your mission profile.

📩 Contact our engineering team for customized specifications, technical drawings, and performance consultation.

Frequently Asked Questions (FAQ)

Q1: What is neutral buoyancy in ROV cables?

It means the cable’s density closely matches seawater, minimizing vertical pull and drag.

Q2: Can buoyancy be precisely calibrated?

Yes, material density can be adjusted to match specific salinity and operational conditions.

Q3: Is this cable suitable for deep-sea missions?

Yes, depth ratings up to 2,000 m are available depending on model configuration.

Q4: Does neutral buoyancy affect tensile strength?

No. Reinforced aramid members ensure mechanical reliability.

Q5: Can fiber optics be integrated?

Yes, hybrid electro-optical versions support high-bandwidth data transmission.