Servo Motor Power Cable Orange Double Jacket 4 x 2.5mm² Cable

.High-flexibility Class 5/6 stranded copper conductors for dynamic drag chain applications.

.Double-jacket construction (Inner/Outer) provides superior mechanical stability and lifespan.

.Industry-standard RAL 2003 Orange sheath for easy identification and safety compliance.

.High-density tinned copper braid shielding available for maximum EMC protection.

.Oil and abrasion-resistant outer sheath suitable for harsh industrial environments.

Servo Motor Power Cable Orange Double Jacket Cable

If there is one component in your automation system that you cannot afford to overlook, it is the cabling. Your servo motors are the muscle of your machinery, but the cables are the nerves and blood vessels. A failure here doesn’t just mean a stopped machine; it means lost revenue, frustrated maintenance teams, and expensive downtime.

At Shanghai Rousheng Wire and Cable Co., Ltd., we understand that the modern factory floor is a hostile environment for electronics. Oil, constant motion, electromagnetic interference, and physical abrasion are constant threats. That is why we have engineered our Servo Motor Power Cable (Orange Double Jacket, 4 x 2.5mm²) to withstand the toughest conditions while delivering reliable power transmission. This page details everything you need to know about choosing the right connection for your high-performance drives.

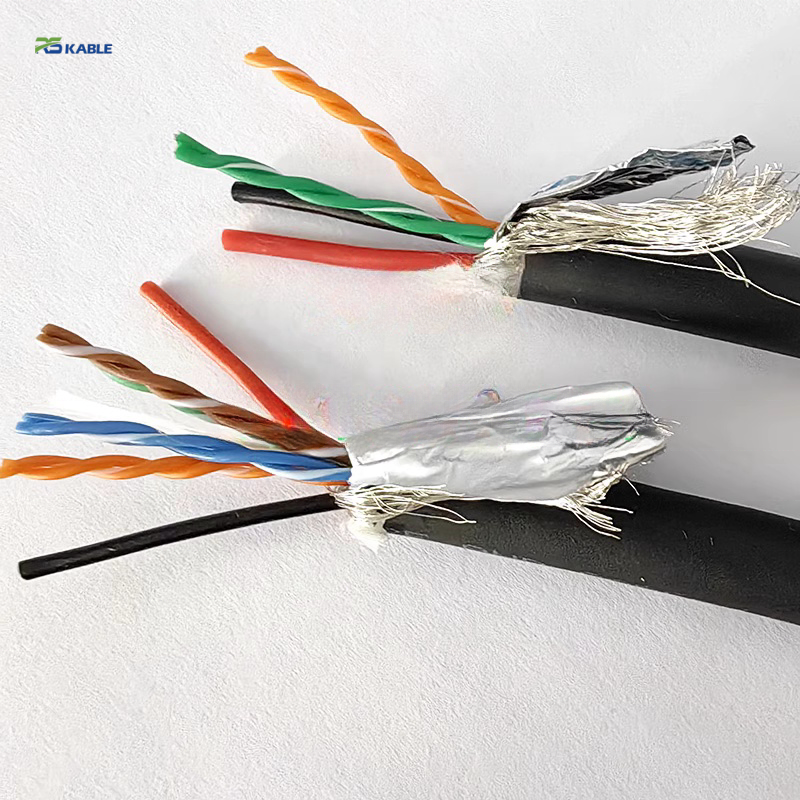

Why “Double Jacket” Matters for Industrial Durability

You might see generic cables on the market with a single layer of insulation. For static installations, those might suffice. But for dynamic, high-speed automation, a single layer is a risk you shouldn’t take.

Our servo cables feature a double jacket construction. This isn’t just about adding thickness; it’s about engineering resilience.

- Inner Jacket: Acts as a mechanical buffer, stabilizing the cores and ensuring they remain in the correct lay length even during rapid twisting and bending. It prevents the conductors from “corkscrewing” inside the cable.

- Outer Jacket: Made from specialized high-grade PVC (or optional PUR for extreme environments), this layer is the first line of defense against cutting fluids, hydraulic oils, and abrasive dust.

The result? A cable that lasts significantly longer in drag chains and cable carriers than standard alternatives.

Precision Power Delivery: The 4 x 2.5mm² Configuration

The 4 x 2.5mm² specification is one of the most versatile standards for industrial servo motors. It strikes the perfect balance between current carrying capacity and flexibility.

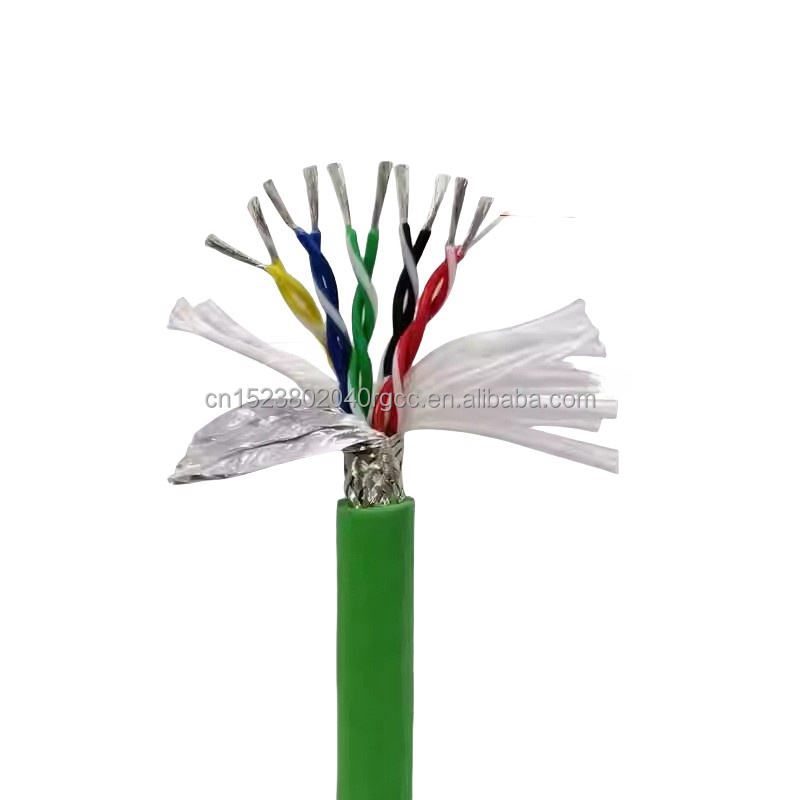

Optimized Core Structure

Inside the orange sheath, you will find four cores constructed from Class 5 or Class 6 finely stranded bare copper. Unlike solid cores which snap under repeated stress, our fine stranding allows the cable to flex millions of times without work-hardening or breaking.

Voltage Handling and Safety

Rated for 600/1000V, this cable handles the power spikes typical of servo motor acceleration and deceleration with ease. The 2.5mm² cross-section ensures voltage drop is minimized over longer runs, keeping your motor torque consistent and your system efficient.

Defeating Signal Noise with Superior EMC Shielding

In a cabinet full of VFDs (Variable Frequency Drives) and PLCs, electrical noise is the enemy. “Ghost” errors and erratic motor behavior are often traced back to poor Electromagnetic Compatibility (EMC).

While power delivery is the primary job, our servo cables can be equipped with a high-density tinned copper braid shield.

- Coverage: We aim for high optical coverage (typically >85%) to create a Faraday cage around the power conductors.

- Function: This prevents the high-frequency noise generated by the VFD switching from escaping the cable and interfering with sensitive sensor data nearby. It also protects the power feed from external interference.

Engineered for Motion: Drag Chain Performance

Static cables belong in the walls. Our Orange Double Jacket cables belong in motion.

We test our cables rigorously for drag chain suitability.

- Bending Radius: Capable of tight bend radii (typically 7.5x to 10x diameter for dynamic use), allowing for compact machine designs.

- Speed and Acceleration: Designed to handle the rapid acceleration forces found in pick-and-place robots and CNC machining centers.

- Cycle Life: Engineered for millions of bending cycles without degradation of the insulation or conductor breakage.

Technical Specifications

Below is the detailed data sheet for the Shanghai Rousheng Servo Motor Power Cable.

|

Feature |

Specification |

|---|---|

|

Product Name |

Servo Motor Power Cable Orange Double Jacket |

|

Configuration |

4 Cores x 2.5mm² |

|

Conductor Material |

Finely Stranded Oxygen-Free Copper (Class 5/6) |

|

Insulation Material |

Special PVC / TPE (Customizable) |

|

Inner Jacket |

PVC (Mechanical Buffer) |

|

Outer Jacket Color |

Orange (RAL 2003 Standard) |

|

Outer Jacket Material |

Oil-Resistant PVC (Standard) or PUR (Optional) |

|

Voltage Rating |

0.6 / 1 kV (600/1000V) |

|

Test Voltage |

4000V |

|

Temperature Range (Fixed) |

-30°C to +80°C |

|

Temperature Range (Moving) |

-5°C to +70°C |

|

Min. Bending Radius (Fixed) |

4 x Cable Diameter |

|

Min. Bending Radius (Moving) |

7.5x – 10x Cable Diameter |

|

Shielding |

Tinned Copper Braid (Optional but Recommended) |

|

Compliance |

RoHS, REACH, CE |

|

Flame Retardancy |

IEC 60332-1-2 |

Application Scenarios

Where should you use the Shanghai Rousheng 4×2.5mm² Servo Cable?

- CNC Machine Tools: Spindle drives and axis motors requiring constant back-and-forth motion.

- Robotics: Power supply to 6-axis robot bases and auxiliary axes.

- Automated Packaging Lines: High-speed conveyors and sorting systems.

- Textile Machinery: Complex weaving and spinning machines where space is tight and movement is constant.

- Woodworking & Glass Processing: Environments with high dust and debris where the durable orange jacket provides essential protection.

Frequently Asked Questions (FAQ)

What is the difference between PVC and PUR jackets for servo cables?

PVC (Polyvinyl Chloride) is excellent for general-purpose automation. It is cost-effective, flame retardant, and has good oil resistance. PUR (Polyurethane) is a premium material that offers superior resistance to cutting fluids, coolants, and extreme abrasion. If your machine cuts metal and is flooded with coolant, ask us about upgrading to a PUR jacket.

Can this cable replace Siemens or Lenze servo cables?

Yes. Our cables are manufactured to meet or exceed the electrical and mechanical specifications of major drive manufacturers. The orange RAL 2003 color is the industry standard for servo power, making it a visual match as well. We can offer compatible solutions for 6FX systems and others.

Why is the jacket color Orange (RAL 2003)?

In the international standard (DESINA), orange indicates a power cable with shielding. This allows maintenance technicians to instantly distinguish high-voltage motor cables from green data cables or grey control cables, improving safety and speed of repair.

Does this cable support a brake pair?

The standard 4×2.5mm² configuration carries the three power phases plus earth (ground). If your servo motor requires an integrated brake, we offer hybrid configurations (e.g., 4×2.5 + 2×1.0mm²) where the brake pair is included inside the same sheath, often with its own individual shield to prevent interference.

How do I install this cable in a drag chain correctly?

To maximize lifespan:

- Ensure the cable is not twisted when laying it into the chain.

- Leave enough slack at the ends (do not pull it tight).

- Ideally, cables should be separated by dividers in the chain to prevent friction against other cables.

- Maintain the minimum bending radius specified in our datasheet.

What is the lead time for orders?

Shanghai Rousheng maintains a robust stock of common sizes like the 4×2.5mm². For stock items, we often ship within 48-72 hours. For custom lengths or specialized jacket materials, typical production times range from 7 to 14 days depending on volume.

Choose Shanghai Rousheng for Your Cabling Needs

Sourcing cables from Shanghai Rousheng Wire and Cable Co., Ltd. means partnering with a manufacturer dedicated to “High Flexibility” and “Special Cable” solutions. We don’t just extrude copper; we engineer reliability. With customers in over 100 countries and a defect rate near zero, our cables are tested to ensure your machines keep running.

Don’t let a $50 cable ruin a $50,000 machine. Upgrade to our Orange Double Jacket Servo Cables today and experience the difference in durability and performance.