Port & Bridge Inspection | ROV Cable | Flexible Structure | Easy Deployment Solution

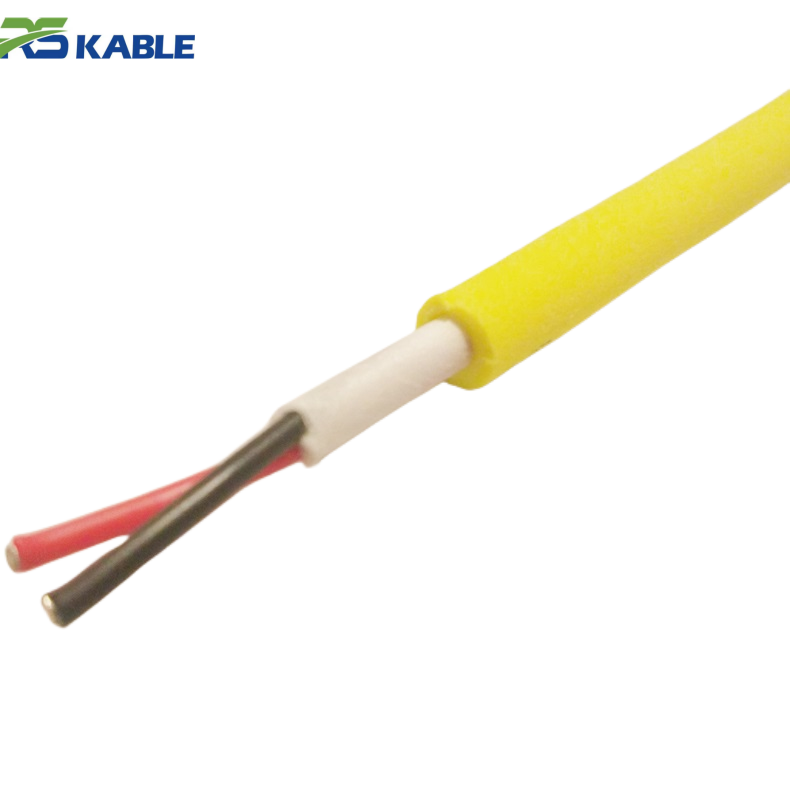

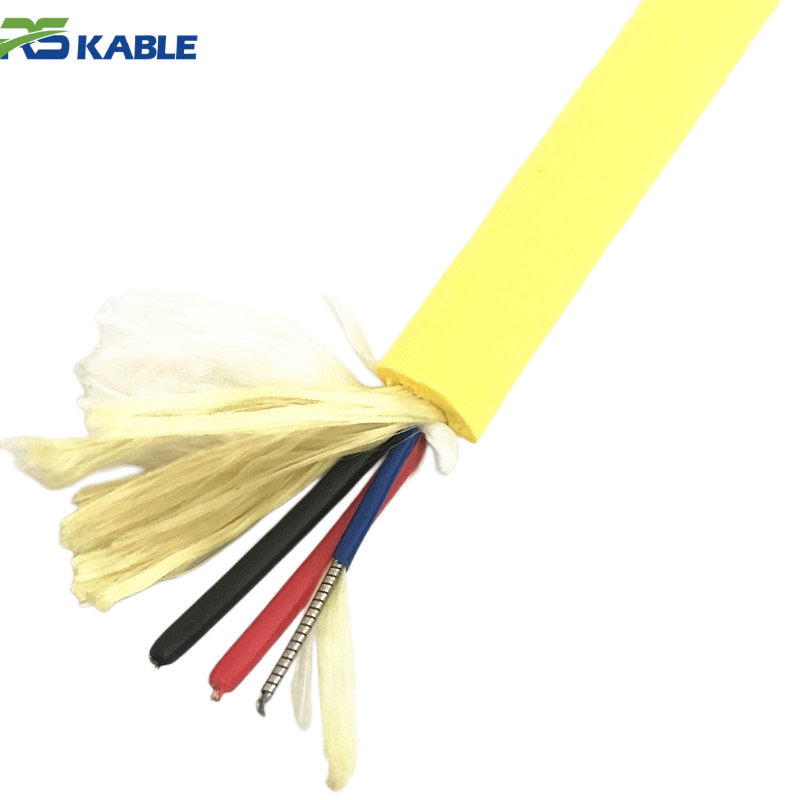

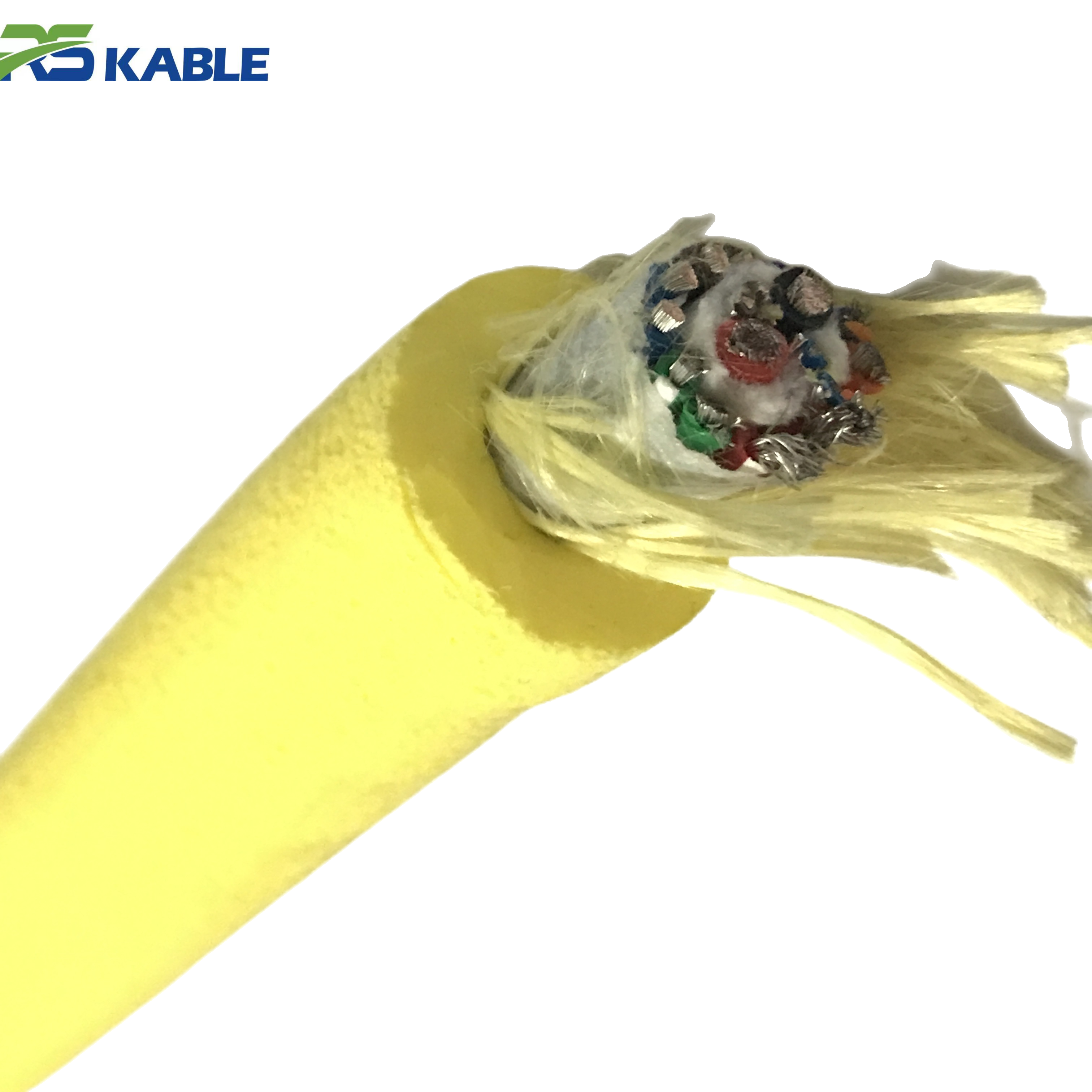

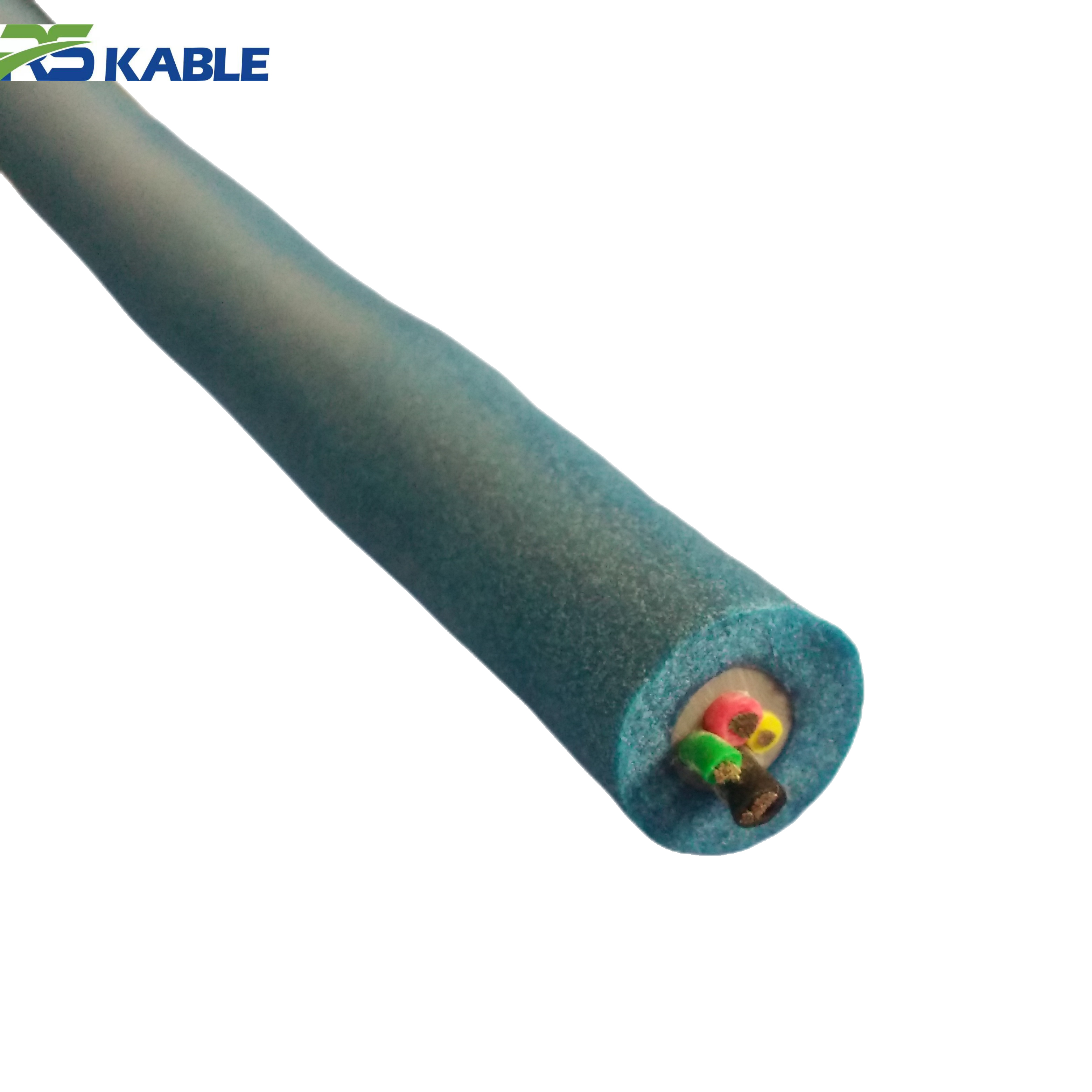

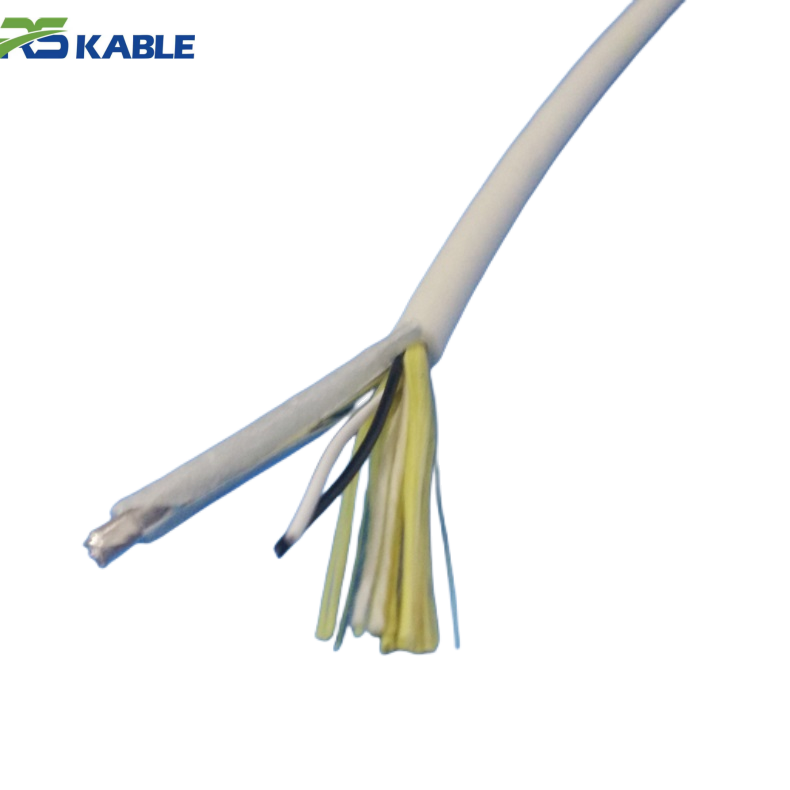

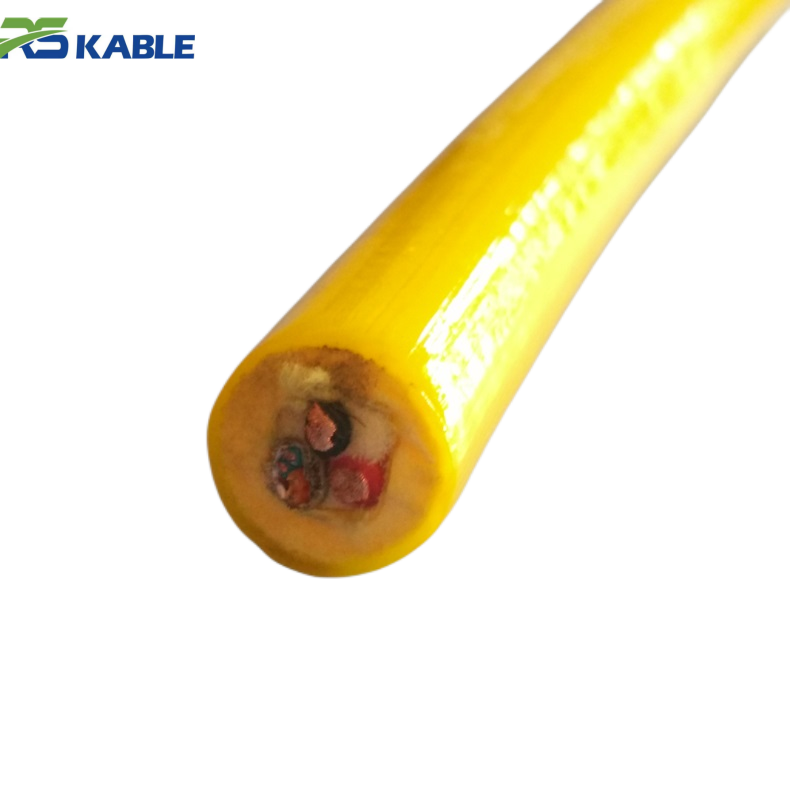

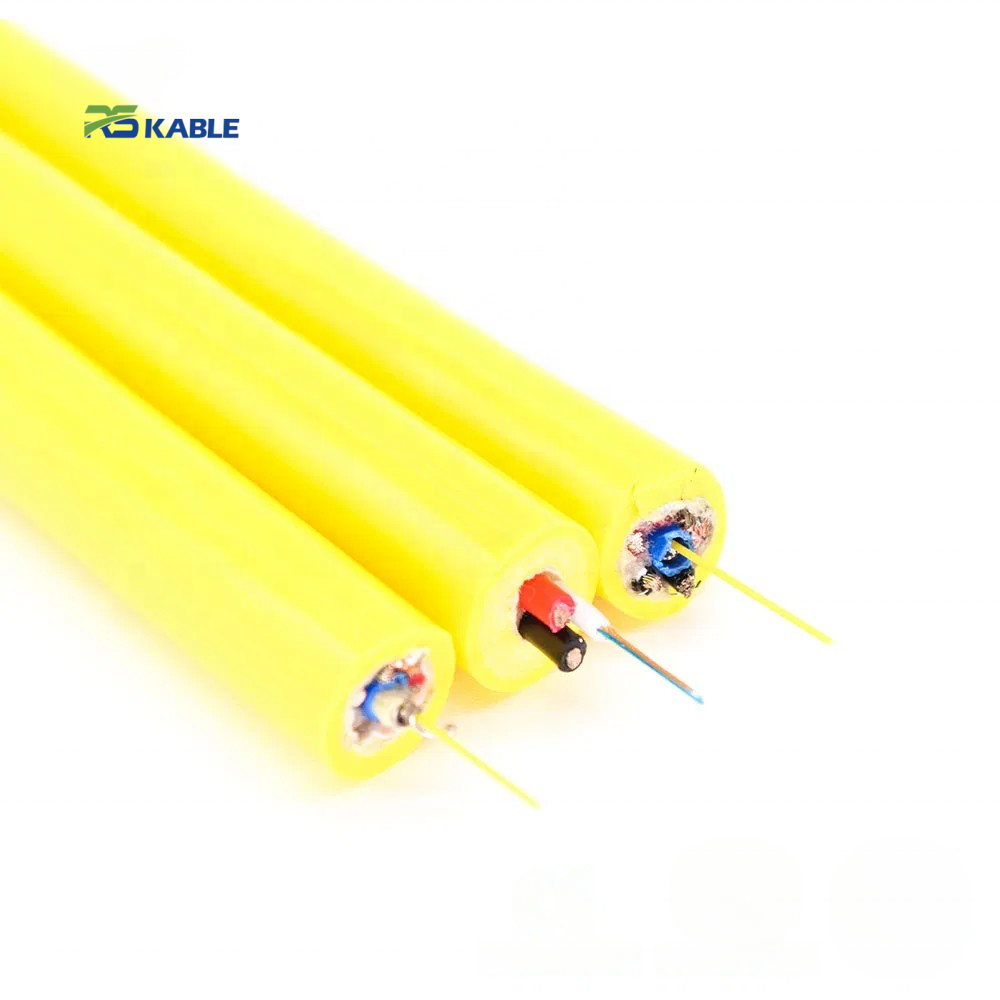

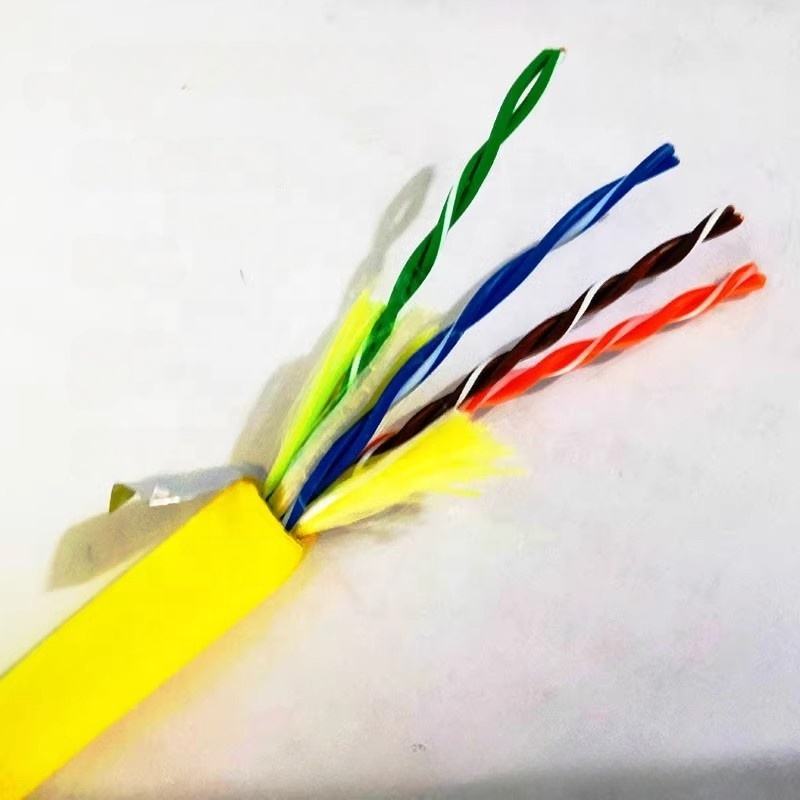

Our ROV Cable is engineered for offshore and nearshore inspection projects, providing a combination of flexibility, abrasion resistance, and long-term reliability. Its reinforced yet lightweight construction allows smooth navigation around pilings, piers, and confined underwater structures. Available in multiple core configurations, including power-only, hybrid signal, and fiber-optic variants, this cable supports high-current operations, real-time video, and sensor telemetry. With neutral buoyancy or slightly negative profiles, it minimizes drag and ensures stable deployment for multi-day inspection missions.

Port & Bridge Inspection | ROV Cable | Flexible Structure | Easy Deployment Solution

Enhance your port and bridge inspection operations with our ROV Cable, designed for flexible deployment and reliable subsea performance. This durable tether delivers stable power and signal transmission while simplifying handling and installation for inspection ROVs in confined or complex underwater environments. Built with abrasion-resistant materials and engineered flexibility, it ensures smooth operation in tight spaces and supports repeated mission cycles with minimal maintenance.

Key Features & Benefits

-

Flexible structure for maneuvering through tight underwater spaces

-

Abrasion-resistant outer layer for long-term durability

-

Reliable power and signal transmission over extended distances

-

Lightweight yet strong design reduces handling complexity

-

Compatible with a variety of inspection-class ROVs

-

Easy deployment and recovery for fast operational turnaround

Product Models and Core Attributes

| Model | Core Attributes | Conductor / Signal Configuration | Rated Depth | Outer Diameter | Weight per Meter |

|---|---|---|---|---|---|

| NB-PORT-4F | 4-core flexible power cable, low drag | 4 × 1.5 mm² tinned copper | 3,000 m | 15.2 mm | ≤ 200 g |

| NB-PORT-6S | 6-core signal + power, reinforced jacket | 4 × 2.0 mm² + 2 × twisted pair | 4,500 m | 18.0 mm | ≤ 250 g |

| NB-PORT-4FO | Fiber optic hybrid, lightweight jacket | 2 × 1.5 mm² + 4–8 fiber elements | 5,000 m | 19.2 mm | ≤ 280 g |

| NB-PORT-HD | Heavy-duty flexible cable, enhanced shielding | 6 × 2.5 mm² + shielded pairs | 6,000 m | 22.5 mm | ≤ 320 g |

All models utilize high-grade PVC/PE or TPU outer jackets optimized for subsea wear, UV resistance, and low-maintenance operations.

Applications

Our ROV Cable is tailored for:

-

Underwater structural inspection of ports, bridges, and piers

-

Confined-space ROV missions in harbors and locks

-

Subsea survey and monitoring of marine infrastructure

-

Pipeline crossings and shallow-water inspection

-

Temporary or permanent mooring inspections

-

Multi-day inspection missions requiring flexible, reliable tethers

Long-tail keywords: “flexible ROV cable for port inspection,” “easy deployment subsea cable for bridge ROVs,” “abrasion-resistant tether for underwater inspection.”

Technical Specifications

| Parameter | Specification | Standard / Notes |

|---|---|---|

| Conductor | Fine-stranded tinned copper | IEC 60228, Class 5 |

| Insulation | PVC or PE with foamed layer for buoyancy | Low water absorption, flexible |

| Shielding | Tinned copper braid or foil | EMI/RFI protection |

| Strength Member | High-modulus aramid fibers | Load bearing ≥1,800 kg |

| Outer Jacket | TPU, PVC, or PE abrasion-resistant coating | UV and seawater resistant |

| Buoyancy Control | Neutral or slightly negative | Customizable for freshwater/seawater |

| Temperature Range | –20°C to +70°C | Operational in various climates |

| Voltage Rating | 300/500V standard | Safe power delivery |

| Certifications | ISO 9001, RoHS, REACH, optional DNV/ABS | Third-party verified |

Ready to Equip Your ROV?

Optimize your port and bridge inspection capabilities with a flexible, reliable ROV Cable. Designed for rapid deployment, smooth handling, and long-term subsea operation, it ensures safe and efficient underwater inspection missions.

Frequently Asked Questions (FAQ)

Q: Can this cable withstand repeated deployments in confined areas?

A: Yes. The reinforced, abrasion-resistant outer jacket and flexible design allow repeated maneuvering through tight underwater spaces without compromising signal or power integrity.

Q: Is the cable suitable for both shallow and mid-depth inspections?

A: Absolutely. Rated for depths up to 6,000 m depending on model, with options for neutral or slightly negative buoyancy for different mission needs.

Q: Can I integrate fiber optics for high-speed data?

A: Yes. Our hybrid models allow seamless integration of fiber cores alongside power and signal pairs for video and telemetry transmission.

Q: What makes this cable easy to deploy?

A: Lightweight design, flexible structure, and low-drag jacket material reduce handling effort and operational setup time, especially in port and bridge environments.