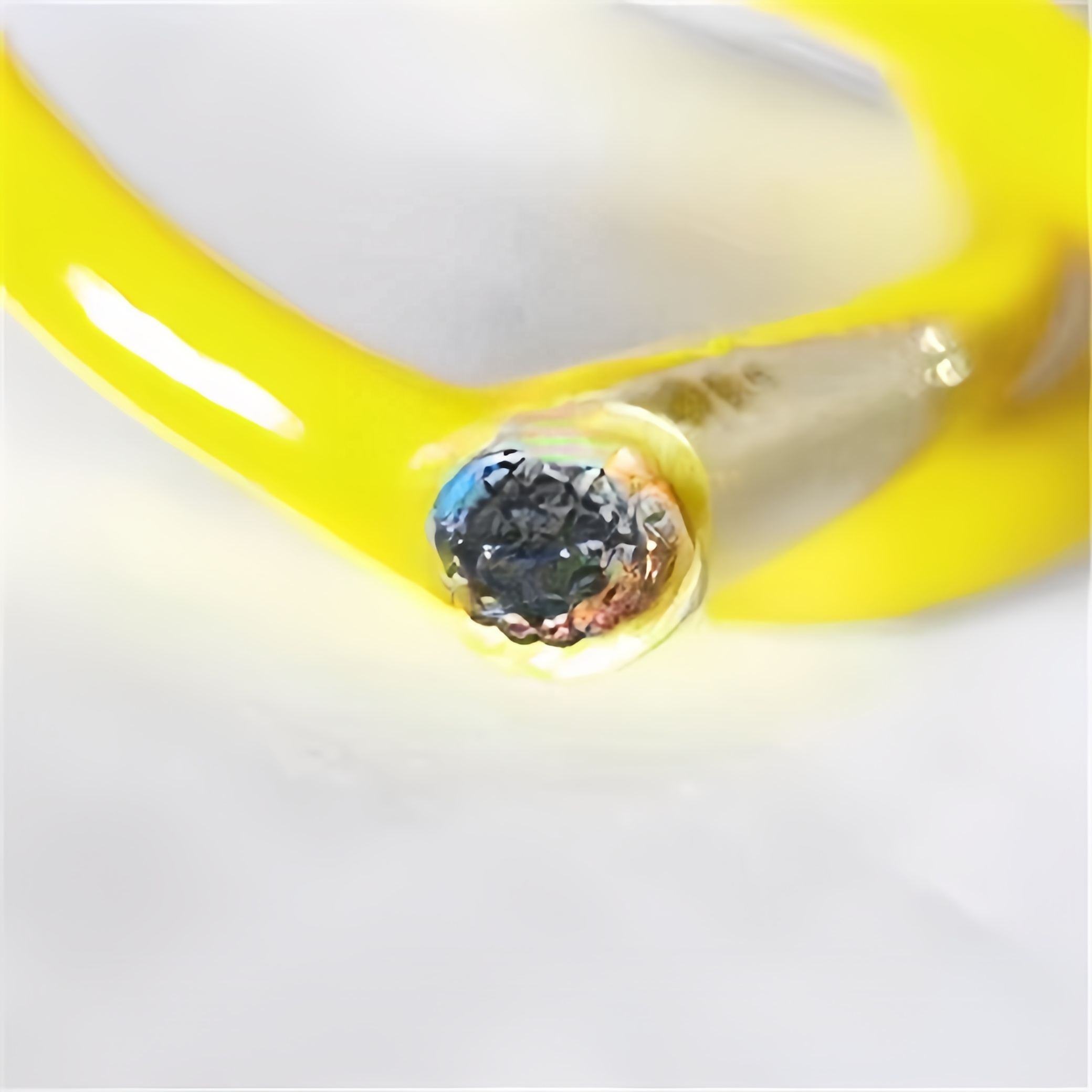

Polyurethane Double-Sheath Multi-Strand Pure Copper Single-Core Cable

- Conductor: 99.99% Oxygen-Free Copper (OFC) for superior conductivity and fatigue resistance.

- Jacket: Oil-resistant, halogen-free Polyurethane (PUR) with matte finish to reduce friction.

- Structure: Double-sheath technology reinforces the cable against torsion and mechanical stress.

- Performance: Rated for millions of flex cycles with a bending radius as low as 7.5x OD.

- Environment: UV and weather-resistant, suitable for harsh indoor and outdoor industrial zones.

Maximize Durability: Polyurethane Double-Sheath Multi-Strand Pure Copper Single-Core Cable (TRVSP)

Cable failure isn’t just an annoyance; it’s a production stop. In automated manufacturing, steel mills, and robotic assembly lines, a snapped wire or a cracked jacket means downtime that costs thousands per hour.

If you are an engineer or procurement manager sourcing for high-stress environments, standard PVC cables often don’t cut it. You need a solution designed to survive millions of flex cycles, resist aggressive coolants, and maintain conductivity under duress.

Enter the Polyurethane Double-Sheath Multi-Strand Pure Copper Single-Core Cable (TRVSP).

Manufactured by Shanghai Ruosheng Wire and Cable Co., Ltd., this cable represents the pinnacle of high-flex, drag-chain technology. This guide analyzes exactly why this specific cable configuration is the preferred choice for industrial clients across Europe and over 100 countries globally.

The “Double-Sheath” Advantage: Why Two Layers Matter

Most standard drag chain cables rely on a single outer jacket to protect the copper core. While cost-effective, this design creates a single point of failure. Once the outer jacket is compromised by abrasion or a sharp cut, the insulation and conductor are immediately exposed to oil and moisture.

The Ruosheng TRVSP model utilizes a double-sheath design.

Layer 1: The Inner Mechanical Buffer

The inner sheath acts as a mechanical stabilizer. In dynamic applications like drag chains, the internal copper strands move and shift. The inner sheath holds the stranded structure tight, preventing “corkscrewing”—a common failure where the internal wires twist out of shape and eventually snap.

Layer 2: The PUR Armor

The outer jacket is made from high-grade Polyurethane (PUR). Unlike PVC, PUR creates a “hard skin” that is exceptionally resistant to:

- Mineral oils and cutting fluids (essential for CNC machines).

- Mechanical abrasion (vital for cables dragging over concrete or steel).

- Notch sensitivity (it resists tearing even if nicked).

By combining these two layers, we create a redundancy system. Even if the outer environment is harsh enough to wear the surface, the core remains protected, extending the Mean Time Between Failures (MTBF) significantly.

Material Science: Inside the Cable

A cable is only as good as the sum of its parts. We break down the material composition of this high-performance single-core cable.

The Conductor: Oxygen-Free Copper (OFC)

We don’t use recycled copper. We use multi-strand, ultra-fine oxygen-free copper.

- Conductivity: Oxygen-free copper offers superior electrical conductivity compared to standard tough-pitch copper.

- Flexibility: The “Multi-Strand” aspect is crucial. Instead of one thick wire which breaks easily when bent, we use hundreds of microscopic strands twisted together. This allows the cable to bend efficiently at tight radii without metal fatigue.

The Insulation: Specialized TPE/FEP/PE Options

Depending on your specific temperature requirements, the core insulation protects the current. We utilize materials with low dielectric constants to ensure signal integrity, even over long distances.

The Jacket: Matte PUR (Polyurethane)

The outer surface uses a matte-finish PUR. This isn’t just for looks. A matte finish reduces the “stick-slip” effect. When cables engage in drag chains, they rub against each other. A glossy surface creates friction (sticking), causing the jacket to wear out. A matte surface glides smoothly, reducing friction heat and wear.

Technical Specifications (TRVSP Series)

Engineers need numbers, not just adjectives. Below are the standard technical parameters for our Polyurethane Double-Sheath Single-Core Cable.

|

Technical Parameter |

Specification |

|---|---|

|

Model Number |

TRVSP (High-Flex Drag Chain Series) |

|

Rated Voltage |

300/300V (for <0.5mm²); 300/500V (for ≥0.5mm²) |

|

Test Voltage |

2000V / 5min |

|

Conductor Material |

Ultra-fine stranded Oxygen-Free Copper (Class 6 VDE 0295) |

|

Insulation Material |

Special TPE / PE / FEP mixtures |

|

Sheath Material |

High-performance Polyurethane (PUR) |

|

Bending Radius (Moving) |

7.5x to 10x Cable Diameter |

|

Bending Radius (Fixed) |

4x Cable Diameter |

|

Temperature Range (Moving) |

-30°C to +90°C |

|

Temperature Range (Fixed) |

-50°C to +100°C |

|

Oil Resistance |

Extremely High (Standard: VDE 0472 part 803/B) |

|

Flame Retardancy |

IEC 60332-1-2 |

|

Weather Resistance |

UV Resistant, suitable for outdoor use |

Application Scenarios

This cable is not designed for static wiring behind a wall. It is built for motion.

1. Industrial Automation & Robotics

Robotic arms require cables that can twist (torsion) and bend simultaneously. The TRVSP single-core cable handles high-speed acceleration and deceleration found in pick-and-place robots.

2. CNC Machinery

CNC environments are notoriously difficult for cabling due to the presence of aggressive coolants and metal shavings. The PUR sheath prevents chemical breakdown, while the double-layer protection stops sharp metal chips from puncturing the core.

3. Steel and Glass Production

With a temperature tolerance reaching +90°C (and higher for short bursts) and low-temp flexibility down to -50°C, these cables survive the extreme heat of steel mills and the freezing conditions of industrial freezers or outdoor cranes.

4. High-Speed Drag Chains

For automated storage and retrieval systems (AS/RS) that move at speeds up to 5 meters per second, standard cables add too much weight and friction. Our lightweight, low-friction PUR cable ensures smooth operation and energy efficiency.

Why Source from Shanghai Ruosheng?

In a market flooded with generic cabling, Shanghai Ruosheng Wire and Cable Co., Ltd. stands apart through specialization.

- R&D Focus: We don’t just extrude plastic; we engineer compounds. With over 100 varieties of special cables, our lab constantly tests for flex life and chemical resistance.

- Customization: Need a specific color (Yellow/Orange/Black)? Need a specific cross-section (from 2.5mm² up to 95mm²)? We offer low Minimum Order Quantities (MOQ) for custom runs, allowing you to prototype without overcommitting.

- Quality Control: Every batch undergoes spark testing, resistance testing, and high-voltage testing before leaving the factory.

- Direct Manufacturer: Buying directly from the Shanghai factory removes the middleman, ensuring you get competitive pricing without sacrificing the material quality.

Frequently Asked Questions (FAQ)

What is the difference between PUR and PVC sheathing?

PVC (Polyvinyl Chloride) is a general-purpose material. It is cheap but becomes brittle in cold weather and dissolves when exposed to certain oils. PUR (Polyurethane) is an elastomer. It is mechanically tougher, highly resistant to cutting/abrasion, stays flexible in freezing temperatures, and is chemically inert to most industrial oils. If your cable moves, use PUR.

Can this cable be used outdoors?

Yes. The PUR outer sheath is resistant to UV radiation, oxygen, and hydrolysis. It will not crack or fade when exposed to direct sunlight or rain, making it ideal for outdoor cranes or port machinery.

What is the life expectancy of this drag chain cable?

While life expectancy depends on the installation (bending radius, speed, travel distance), our TRVSP series is designed for 3 to 5 million cycles in standard drag chain applications when installed according to guidelines (bending radius >7.5x OD).

Do you offer tinned copper options?

Yes. While bare oxygen-free copper is standard, we can manufacture tinned copper versions upon request. Tinned copper offers superior corrosion resistance, which is beneficial in marine or high-humidity environments.

What certifications does Ruosheng provide?

We manufacture according to strict international standards. Our products align with CE (European Conformity) requirements for low voltage directive and are RoHS compliant (free of hazardous substances like lead). Specific UL or VDE style certifications can be discussed based on your market requirements.

How do I determine the correct cross-section for my current?

This depends on the amperage load. A single-core cable generally dissipates heat better than a multi-core cable. However, you must apply derating factors based on ambient temperature. Please consult our technical sales team for a precise ampacity chart.