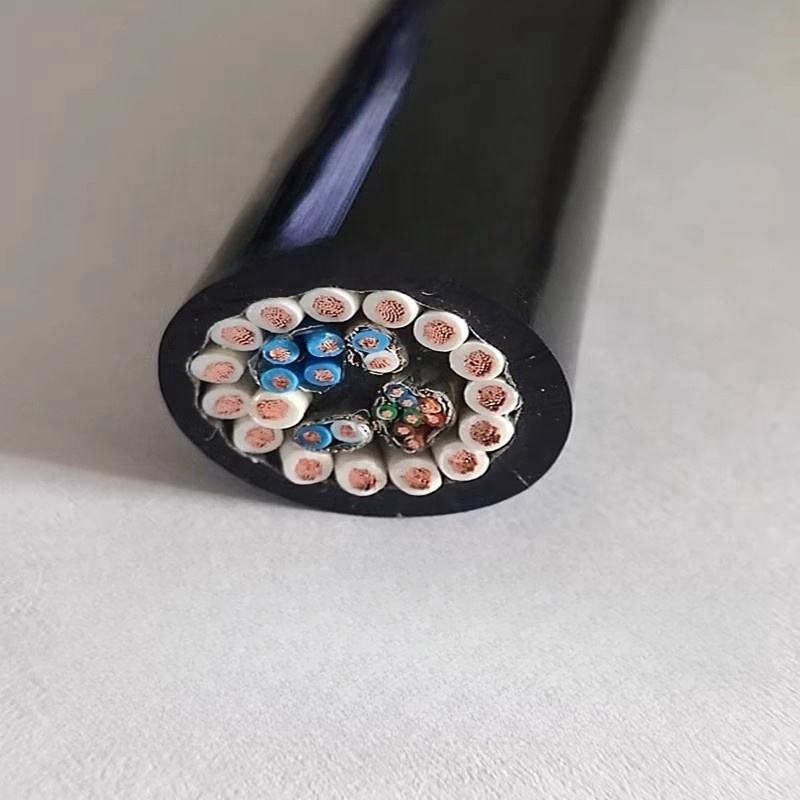

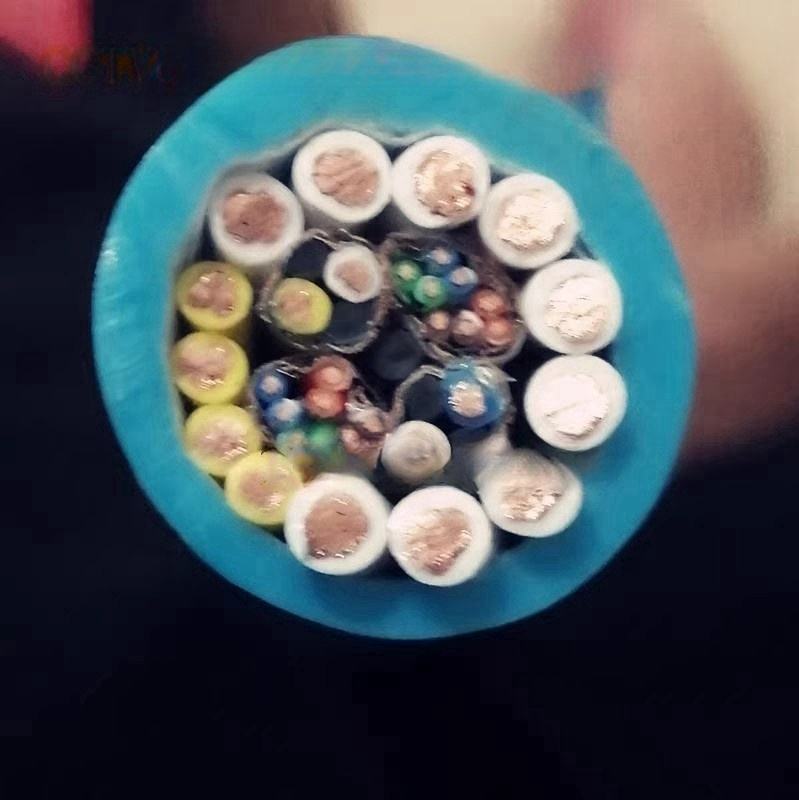

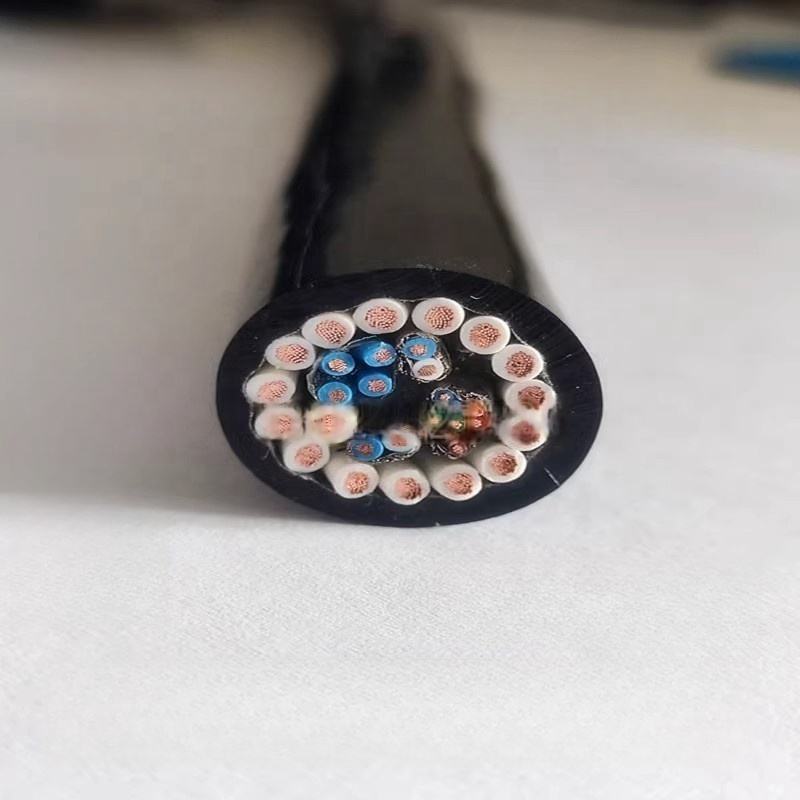

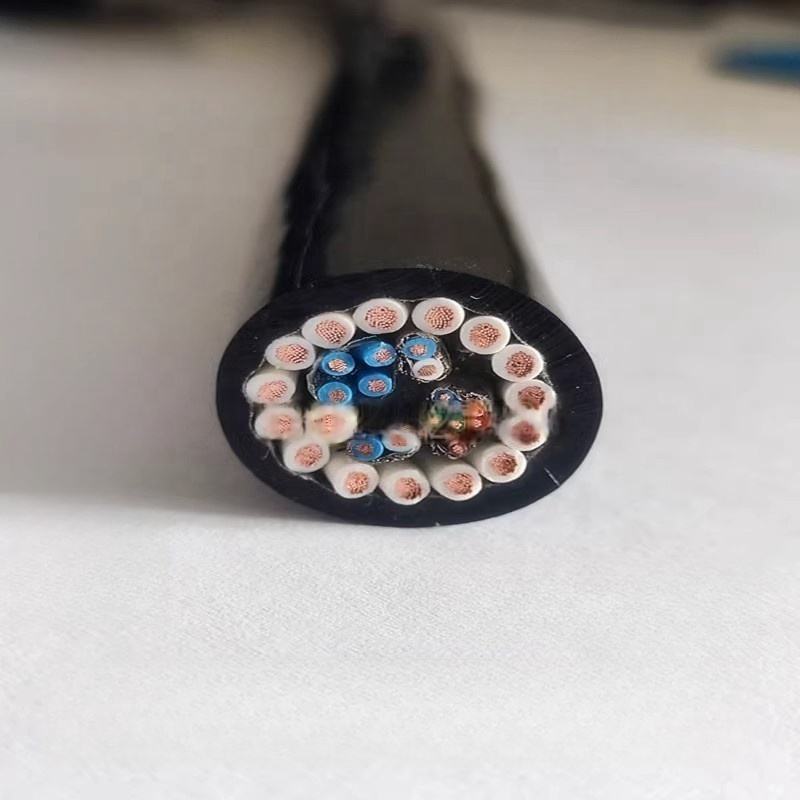

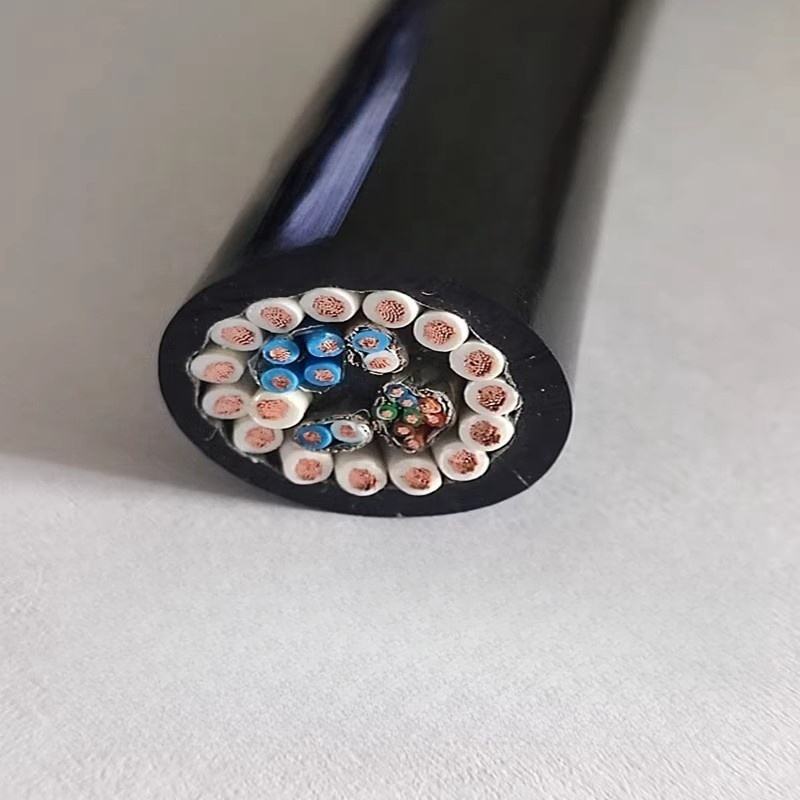

Pipeline Inspection & Maintenance Robot Cable with CCTV Signal and Power Coaxial Video Composite Cable

Industrial‑grade PUR/TPU Inspection Robot Cable with integrated CCTV video coaxial core, high‑flex multi‑core power and signal conductors for pipeline inspection, sewer CCTV systems, and robotic crawler tether applications — engineered for flexibility, durability, and dependable high‑quality transmission.

Shanghai Rousheng Cable Co., Ltd. designs, manufactures and supplies high‑performance, highly flexible cables for specialized industrial applications. Our PUR/TPU Pipeline Inspection & Maintenance Robot Cable integrates power conductors, CCTV video coaxial transmission, and control signal cores in a single composite cable optimized for robotic pipeline inspection and maintenance systems.

This cable is engineered for continuous motion, harsh environments, and real‑time high‑quality video transmission required by pipeline robots and CCTV inspection crawlers. It delivers superior mechanical durability, electrical performance, and dependability for inspection applications across water, sewer, drainage, industrial process, and underground pipelines.

Key Features & Benefits

✅ Hybrid Signal + Power Cable Design

-

Integrated coaxial video cable for CCTV camera signal transmission with minimal interference.

-

Multi‑core power conductors, control pairs, and optional shielded data cores bundled in one outer jacket.

-

Eliminates multiple loose cables; simplifies cable management, reduces connector failure points.

✅ Exceptional Flexibility & Mechanical Durability

-

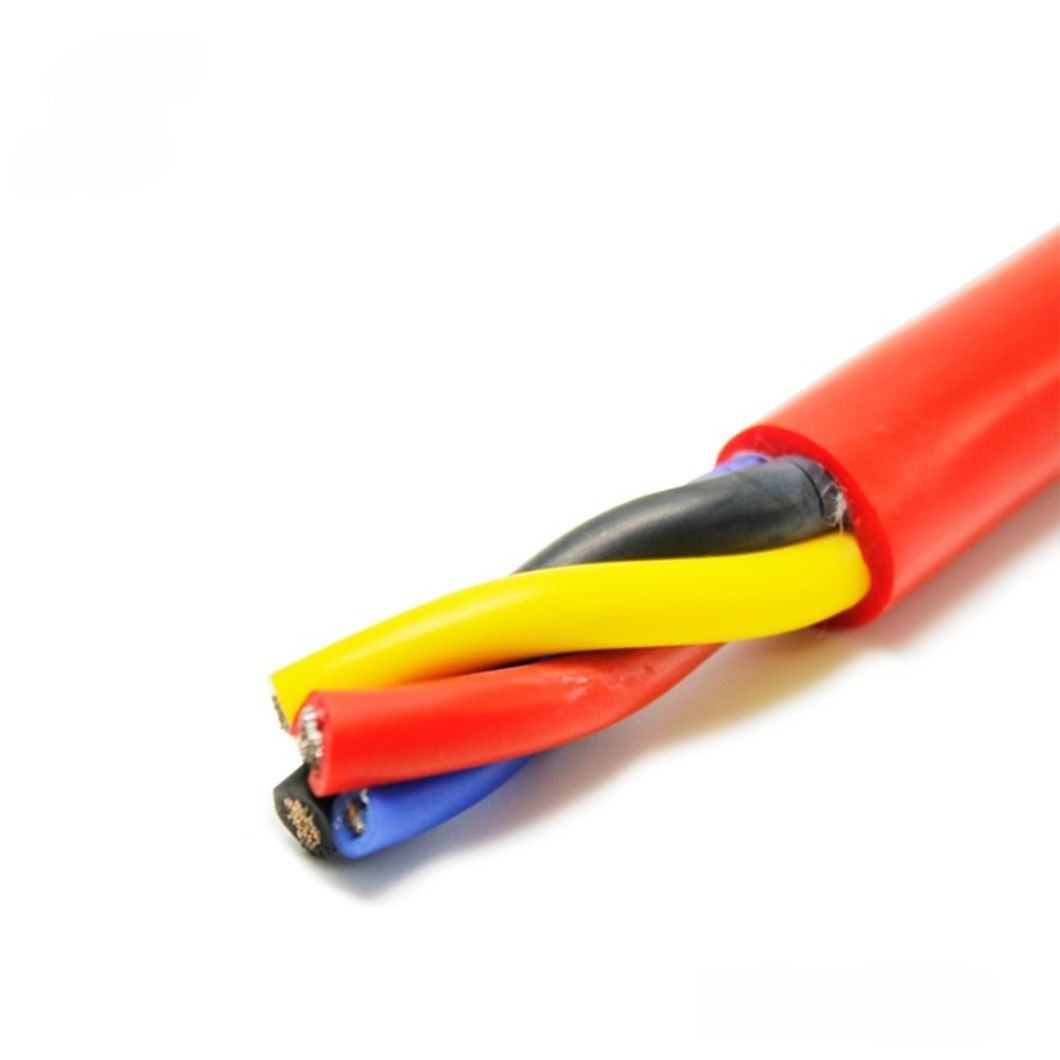

Constructed with fine multi‑strand copper conductors for outstanding flexibility and dynamic bending resistance — critical for pipeline robot tethering.

-

PUR or TPU outer jacket delivers exceptional abrasion, oil, chemical, friction, and wear resistance.

-

Ideal for drag chain systems, cable reels, and repeated motion without fatigue.

✅ High‑Quality Video & Signal Transmission

-

Coaxial core supports reliable live CCTV video feed over long cable runs.

-

Optional shielded pairs and twisted pairs help maintain signal integrity against electrical noise.

✅ Wide Application Scenarios

-

Pipeline inspection robots • Sewer / drainage CCTV systems • Underground and enclosed pipes • Drain line maintenance • Crawler tether cable.

-

Suitable for environments requiring abrasion‑resistant, highly flexible composite cabling.

Technical Specifications

| Attribute | Specification / Option |

|---|---|

| Conductor Material | Fine multi‑strand copper (≥ Class 6 / IEC 60228 equivalent) |

| Coaxial Video Cable | RG59 or equivalent coax core |

| Power Cores | Multiple flexible power cores |

| Control & Data Pairs | Optional shielded twisted pairs |

| Shielding | Foil & braid shield for video/data |

| Jacket Material | PUR or TPU (option) |

| Outer Diameter | Customized per model |

| Temperature Range | Flexible operating range (industrial grade) |

| Motion Type | Dynamic drag / repetitive motion |

| Application | Pipeline robots, CCTV pipeline inspection |

| Certification (possible) | CE / RoHS / VDE / TUV / REACH (based on request) |

Customizable cores, shielding and lengths available upon request.

Why Choose This Cable from Rousheng

✅ Industry‑Proven Design — Designed expressly for robotic inspection applications where flexibility and signal integrity are core requirements.

✅ Durable Build Quality — The combination of multi‑strand conductors and PUR/TPU outer jacket provides long service life even in rough pipe conditions.

✅ Customizable to Your System — Many clients choose bespoke conductor combinations, lengths, and shielding suited to their robot and CCTV system specifications.

✅ Global Deliverability & Support — Shanghai Rousheng Cable Co., Ltd. serves customers across Europe and 100+ countries with consistent quality and technical guidance.

Applications at a Glance

✅ Water & sewer pipeline inspection systems

✅ Drainage and wastewater line CCTV crawler robots

✅ Industrial pipeline visual inspection and maintenance systems

✅ Underground utility inspection equipment

✅ Dynamic robotic crawler tether cable

FAQ – Frequently Asked Questions

Q1: What environments is this cable best suited for?

A: Designed for underground, sewer, drainage, and pipeline robot applications where abrasion, repeated bending, and reliable video transmission are required.

Q2: Can the cable be custom‑manufactured?

A: Yes. We offer customization of conductor count, coaxial cores, shielding, jacket material (PUR or TPU), and length according to your robot system and installation specs.

Q3: How does it handle video signal quality over long distances?

A: The integrated coaxial video core with dedicated shielding ensures low signal loss and strong immunity to interference even when deployed through twist, bends and motion.

Q4: What operating temperatures can this cable tolerate?

A: Industrial grade PUR/TPU jackets and multi‑strand conductor design allow for a wide operating temperature range based on your application requirement (please enquire for exact range per spec).

Q5: Is this cable compatible with standard CCTV inspection units?

A: Yes, the cable can integrate standard RG59‑based coax video for CCTV systems as well as flexible power and data cores as needed by industrial inspection equipment.