Offshore Renewable Energy ROVs | Neutral Buoyancy Cable | Environmental Resistance | UV & Seawater Resistant

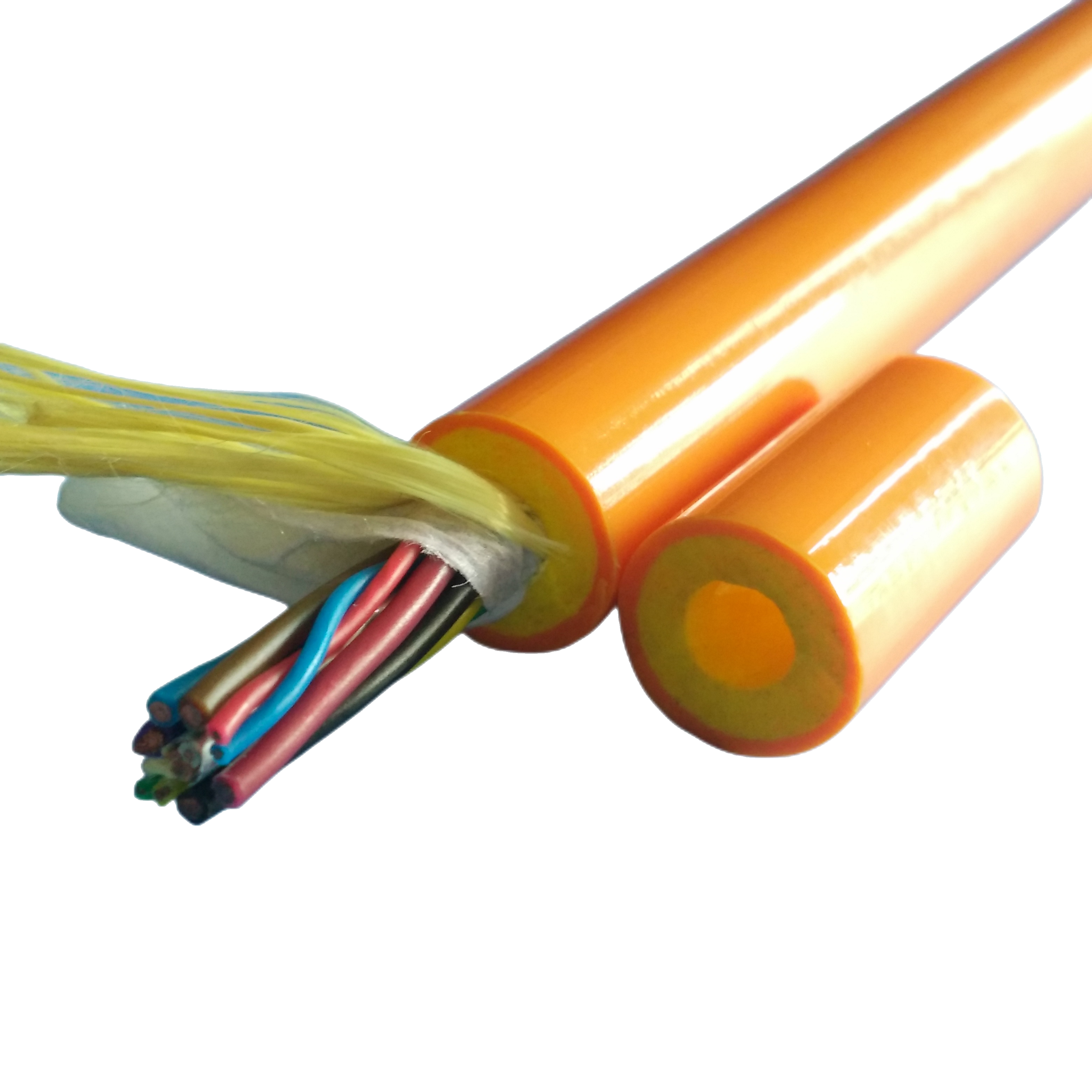

This Neutral Buoyancy Cable is designed for offshore renewable energy ROV operations, offering UV and seawater resistance for harsh marine environments. It provides stable buoyancy, reliable power and signal transmission, and long-term durability for offshore wind, tidal, and marine energy applications.

Offshore Renewable Energy ROVs | Neutral Buoyancy Cable | Environmental Resistance | UV & Seawater Resistant

Offshore renewable energy projects require ROV systems that can operate reliably in harsh marine environments, including constant seawater exposure and prolonged UV radiation. This Neutral Buoyancy Cable is designed to support ROV operations in offshore wind, tidal, and marine energy applications by combining environmental resistance with stable underwater performance.

Engineered for durability and balanced buoyancy, it ensures consistent power and signal transmission while minimizing mechanical stress during offshore renewable energy inspections and maintenance tasks.

Built for Offshore Renewable Energy Environments

ROVs used in renewable energy projects face conditions that differ significantly from deep-sea or laboratory deployments. Typical challenges include:

-

Continuous exposure to seawater and salt spray

-

UV radiation during surface operations and deck handling

-

Variable water depth and near-surface wave motion

-

Long operational hours during inspection and maintenance cycles

This Neutral Buoyancy Cable is optimized to perform reliably under these combined environmental stresses.

Environmental Resistance by Design

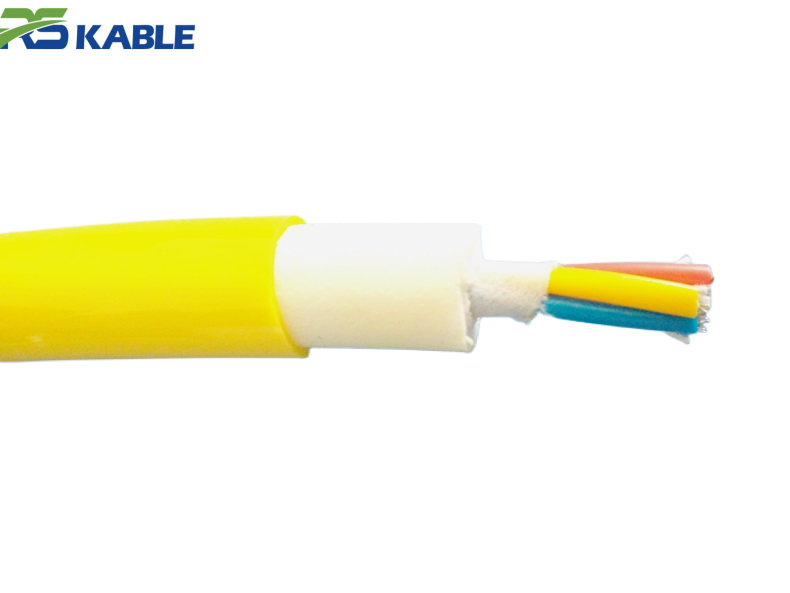

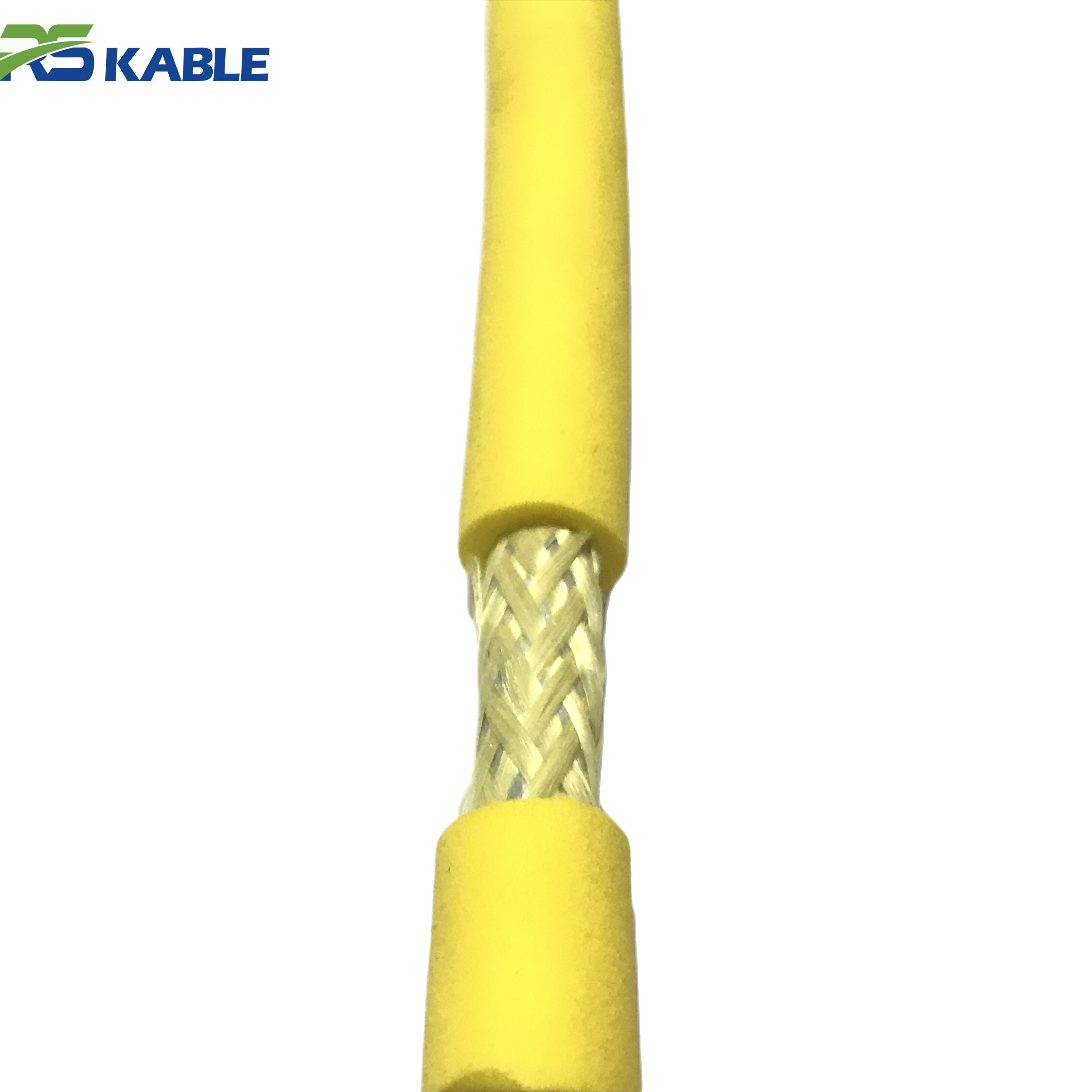

To withstand offshore renewable energy conditions, the cable integrates materials and structural features specifically selected for environmental durability:

-

UV-resistant outer jacket to prevent material degradation

-

Seawater-resistant compounds to reduce corrosion risk

-

Stable buoyancy control to handle near-surface turbulence

-

Flexible structure for repeated deployment and retrieval

These features allow the Neutral Buoyancy Cable to maintain performance in both submerged and partially exposed operating states.

Where This Cable Is Commonly Used

This cable solution is well-suited for ROV systems supporting renewable energy infrastructure, including:

-

Offshore wind farm inspection and maintenance

-

Subsea cable and foundation surveys

-

Tidal and wave energy system monitoring

-

Offshore renewable energy construction support

-

Environmental assessment around energy installations

It is frequently specified for offshore ROV power cables, marine inspection cables, and renewable energy subsea systems.

Product Configuration Snapshot

| Product Name / Model | Core Attributes |

|---|---|

| NB-RE Series Neutral Buoyancy Cable | UV & seawater resistant, environmentally durable, ROV-optimized |

Key Technical Parameters

| Parameter | Specification Options |

|---|---|

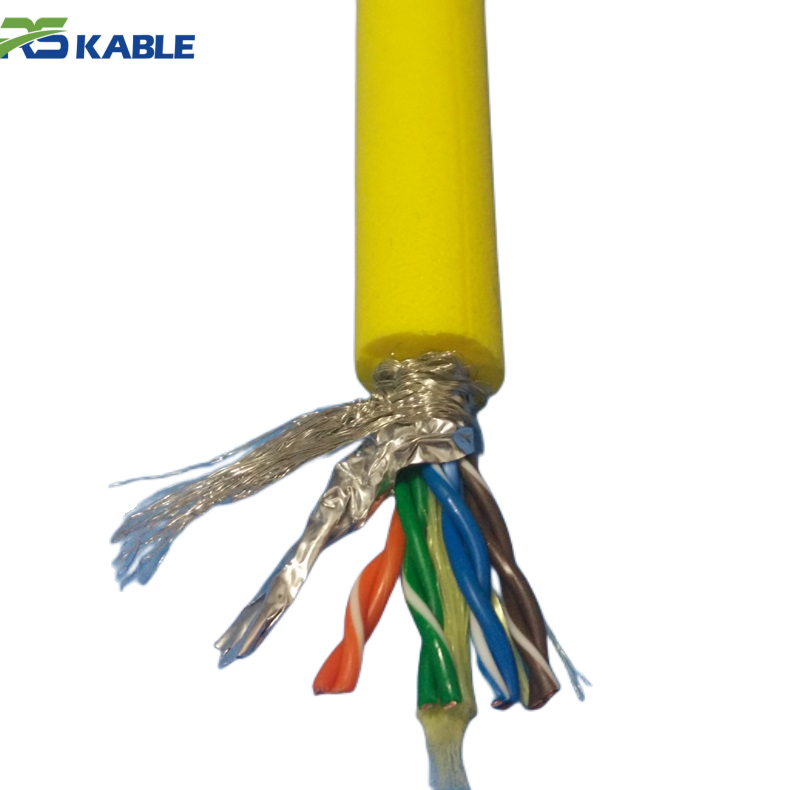

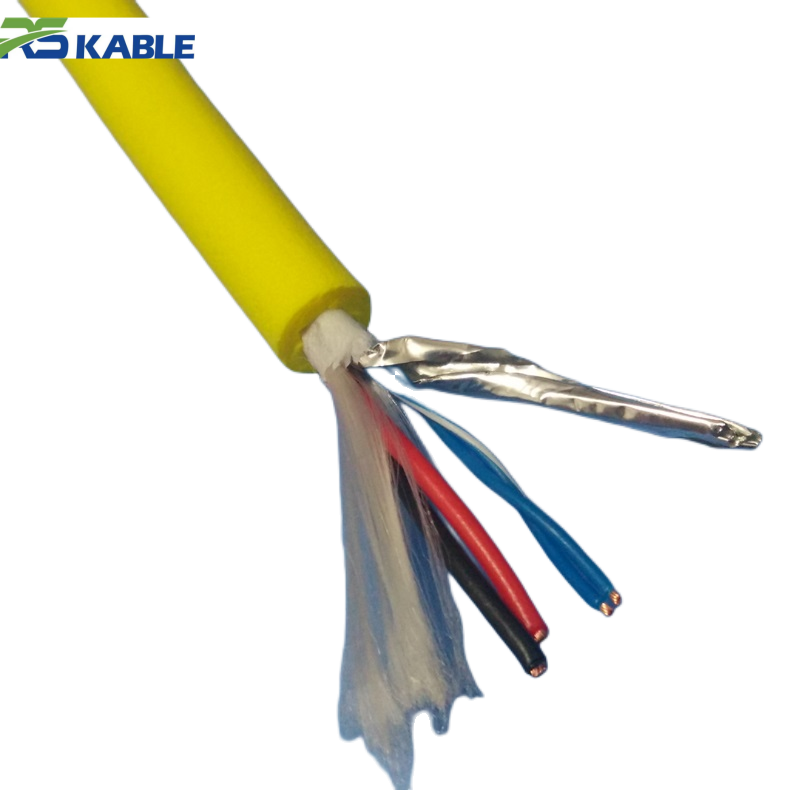

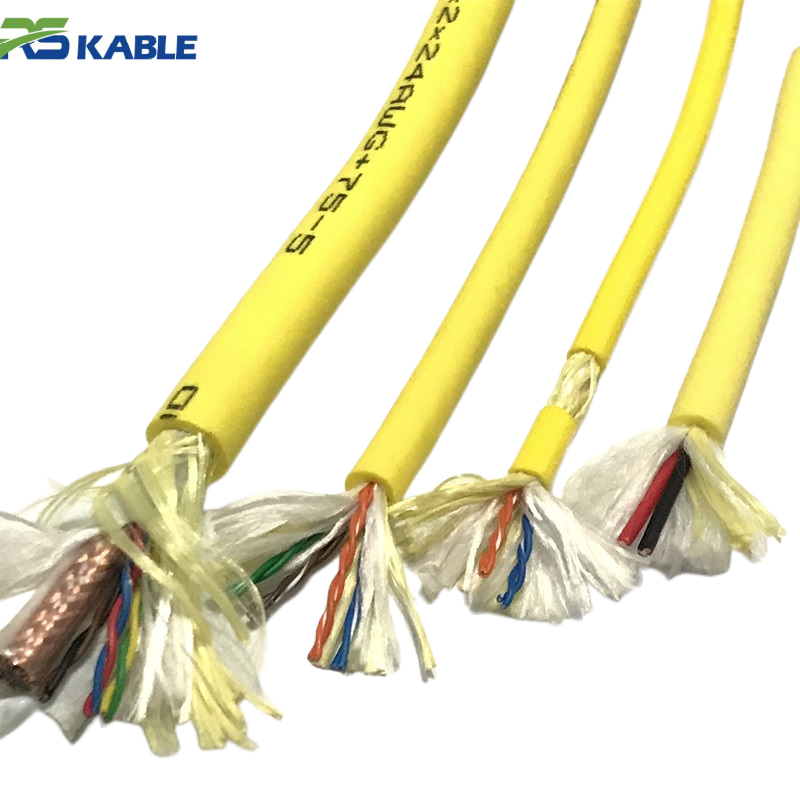

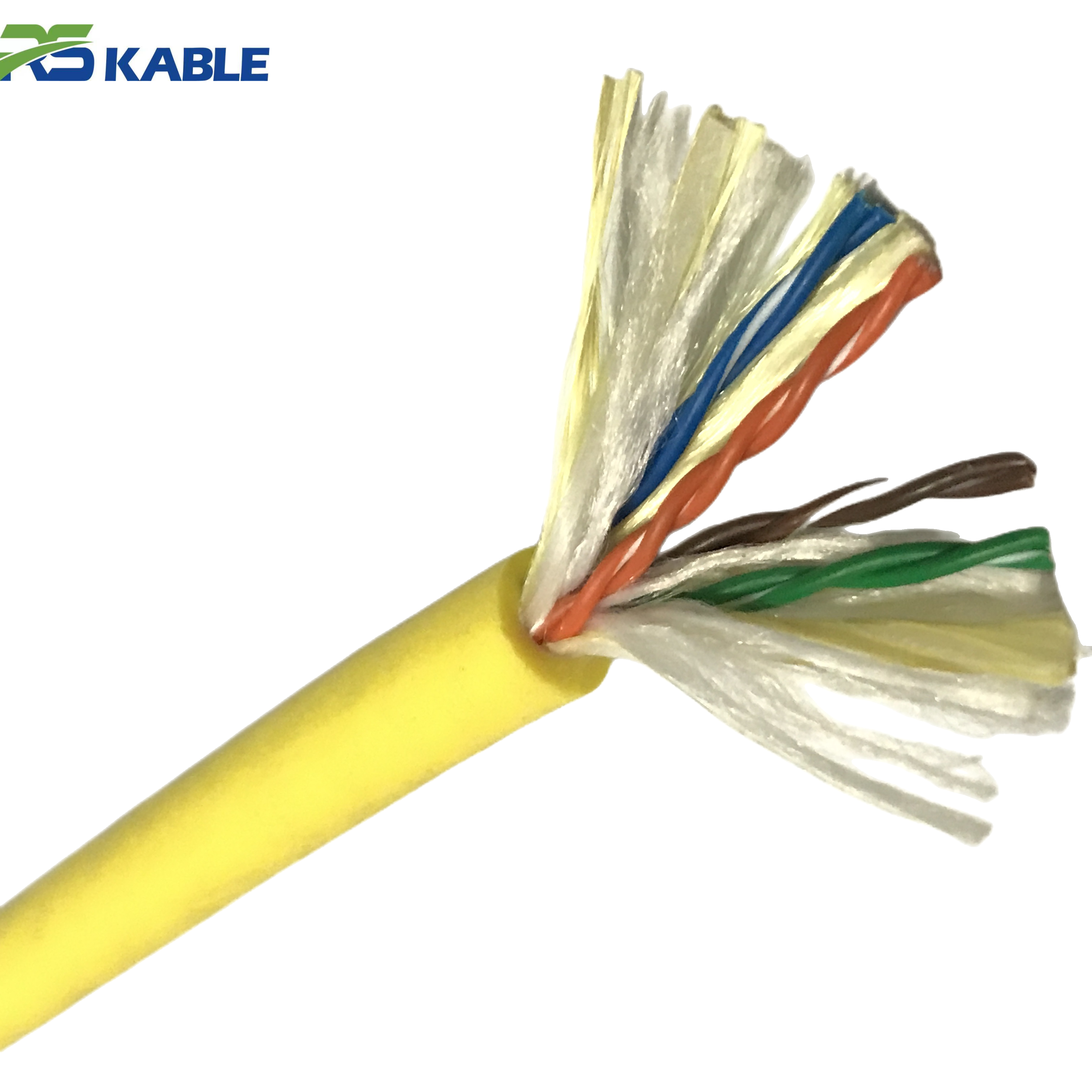

| Core Configuration | Power cores, signal cores, or hybrid power & signal |

| Conductor Material | Tinned copper |

| Insulation | PE / XLPE |

| Buoyancy Control | Precision-balanced fillers for neutral buoyancy |

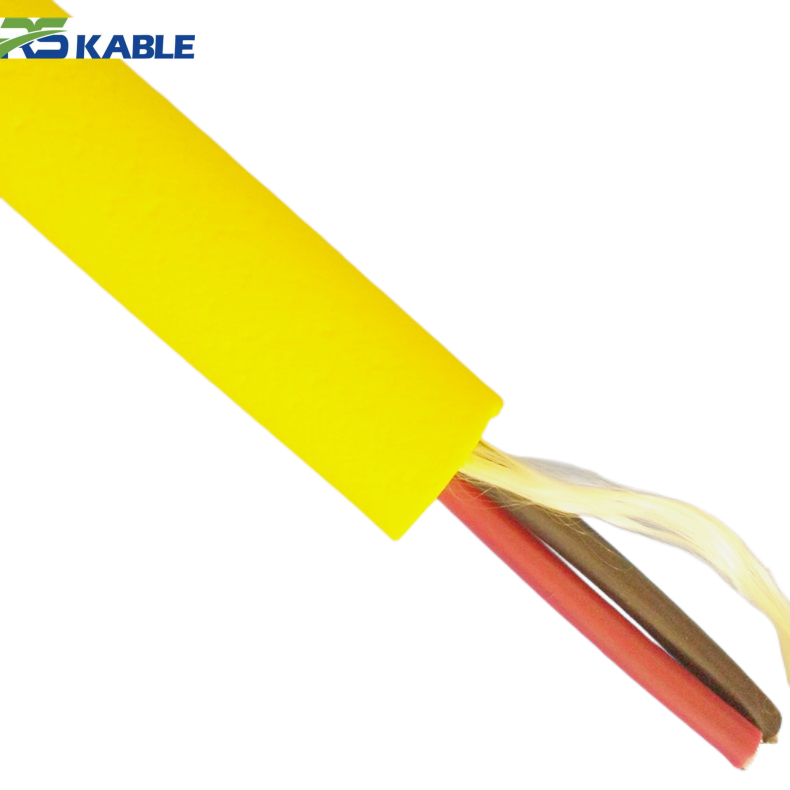

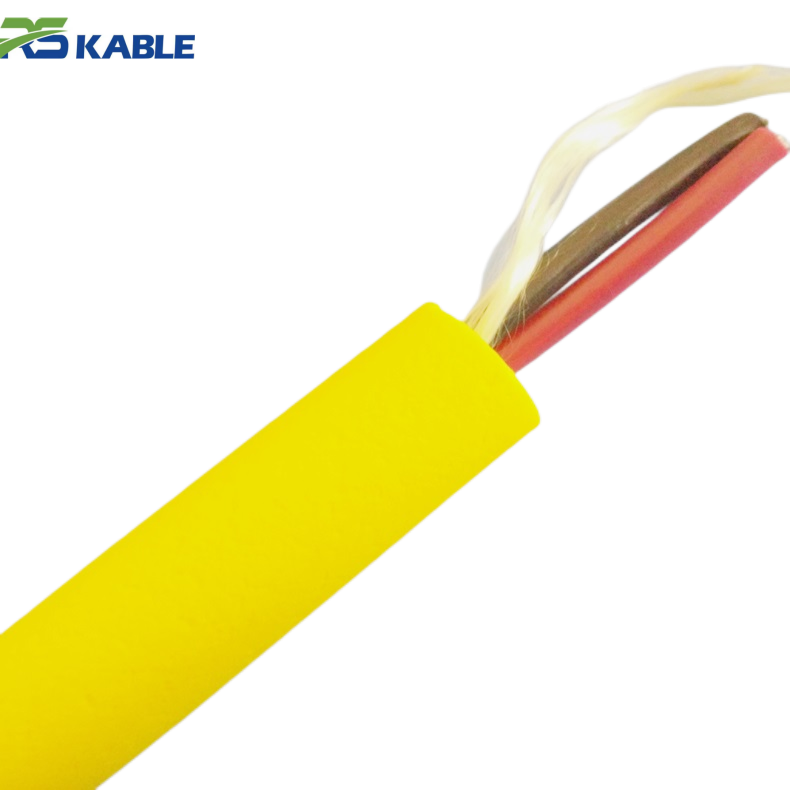

| Outer Jacket | UV-resistant, marine-grade polyurethane |

| Environmental Resistance | UV exposure, seawater corrosion, offshore weather conditions |

| Operating Environment | Near-surface and subsea offshore renewable energy sites |

| Temperature Range | Suitable for offshore and marine operating conditions |

Cable diameter, jacket thickness, and buoyancy balance can be customized based on ROV size and deployment depth.

Operational Advantages for Renewable Energy ROVs

When deployed in offshore renewable energy projects, this Neutral Buoyancy Cable helps operators achieve:

-

Stable ROV maneuverability in dynamic offshore waters

-

Reduced cable wear from UV and seawater exposure

-

Lower mechanical load on ROV frames and winch systems

-

Improved reliability during long inspection campaigns

This directly contributes to safer and more efficient offshore energy operations.

Engineering Credibility & Quality Assurance (E-E-A-T)

-

Designed by engineers with experience in offshore ROV cable systems

-

Manufactured under ISO-certified quality management processes

-

Tested for UV resistance, seawater immersion, and buoyancy stability

-

Materials selected for long-term offshore renewable energy use

Each cable configuration is evaluated to match real-world offshore renewable energy operating conditions.

Customization & Project Support

We support offshore renewable energy operators and ROV manufacturers with:

-

Cable designs tailored to specific offshore energy sites

-

Hybrid power and signal configurations for inspection ROVs

-

Technical documentation and environmental resistance data

-

Engineering consultation for renewable energy projects

👉 Contact our team to discuss your offshore ROV cable requirements.

FAQ

Is this cable suitable for near-surface offshore operations?

Yes. It is designed to handle UV exposure and surface-level marine conditions.

Can it be used for offshore wind farm ROV inspections?

Yes. It is widely applicable to offshore wind and other renewable energy projects.

Does UV resistance affect cable flexibility?

No. The jacket materials balance UV protection with flexibility.

Can buoyancy be adjusted for different ROV systems?

Yes. Buoyancy can be customized based on system weight and operating depth.