Offshore Inspection Robots | Neutral Buoyancy Cable | High Durability | Abrasion Resistant Sheath

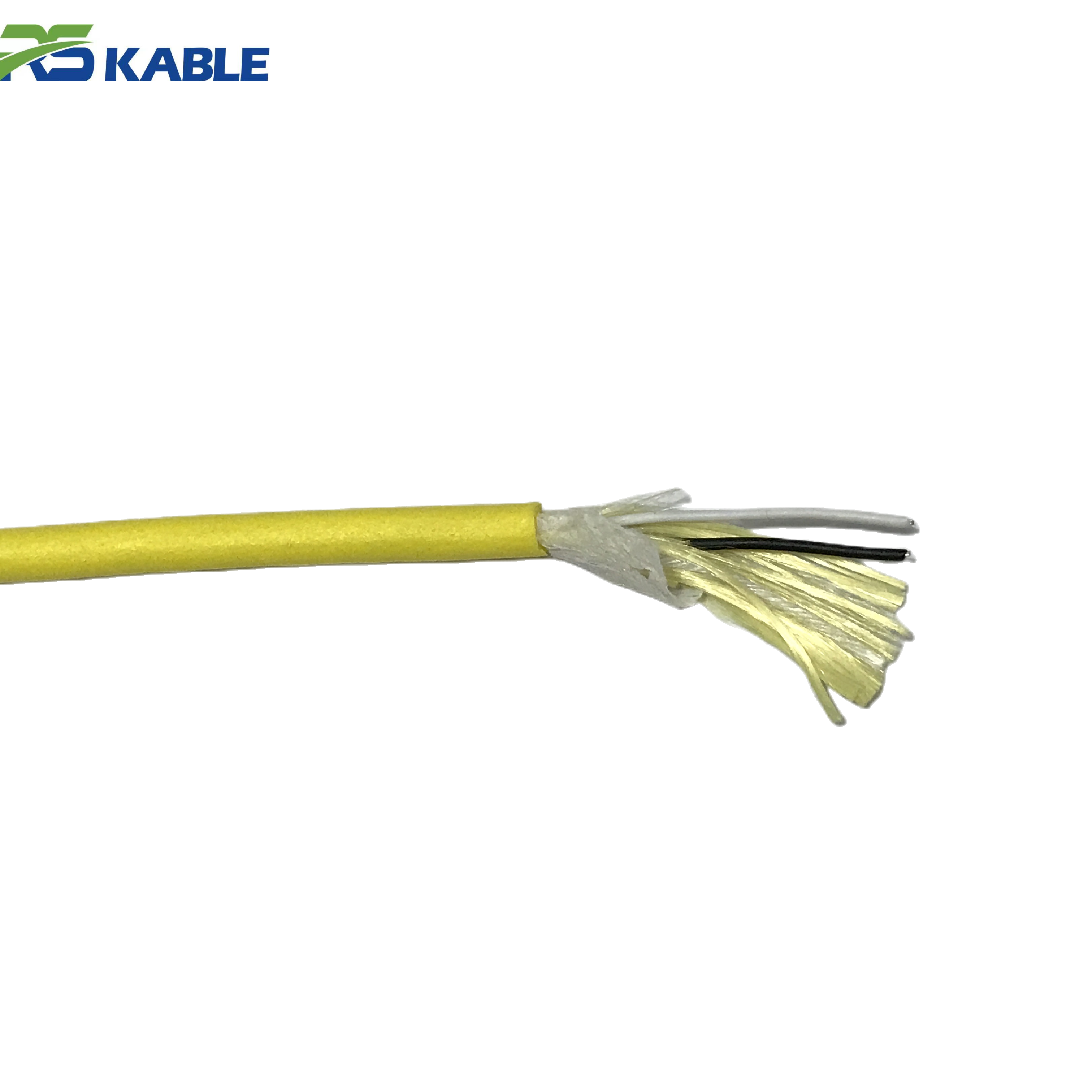

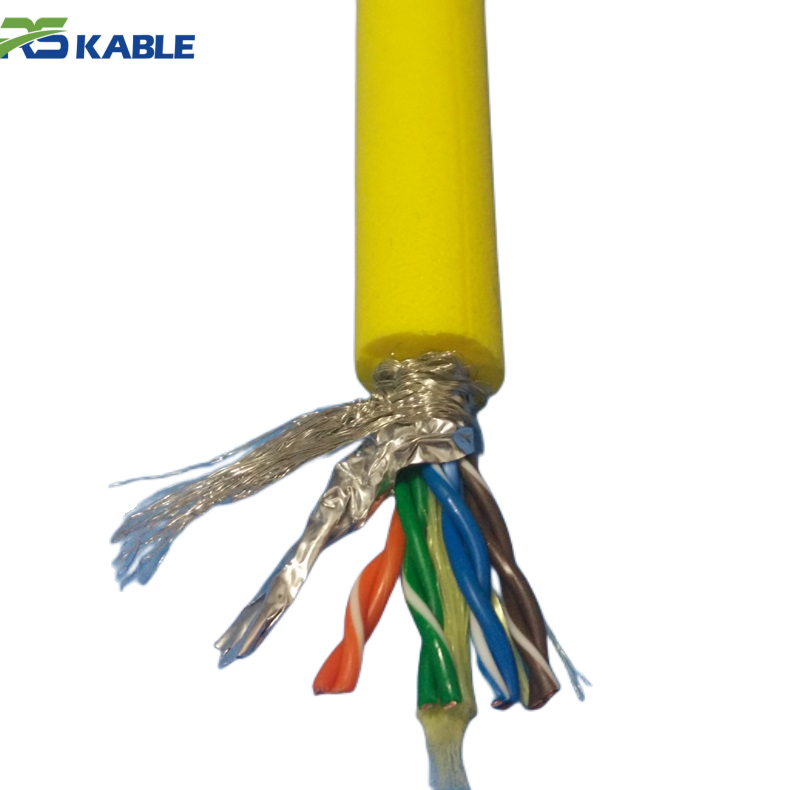

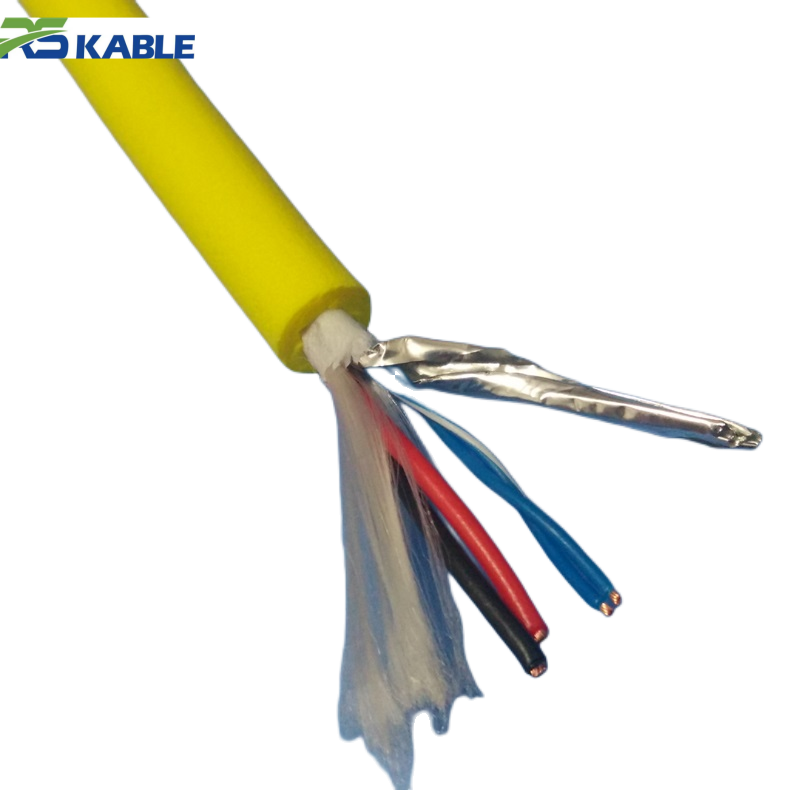

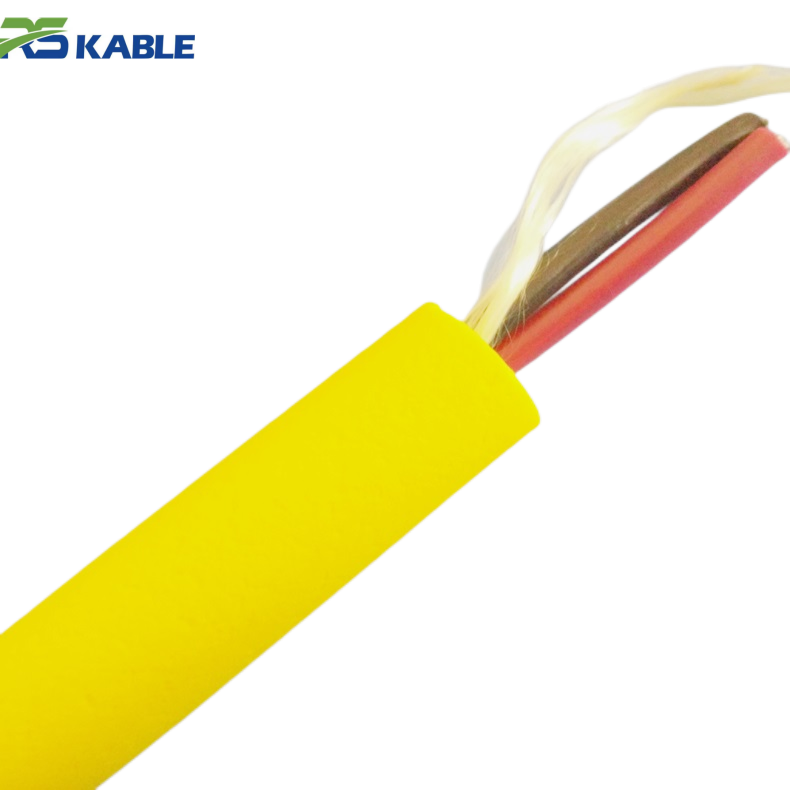

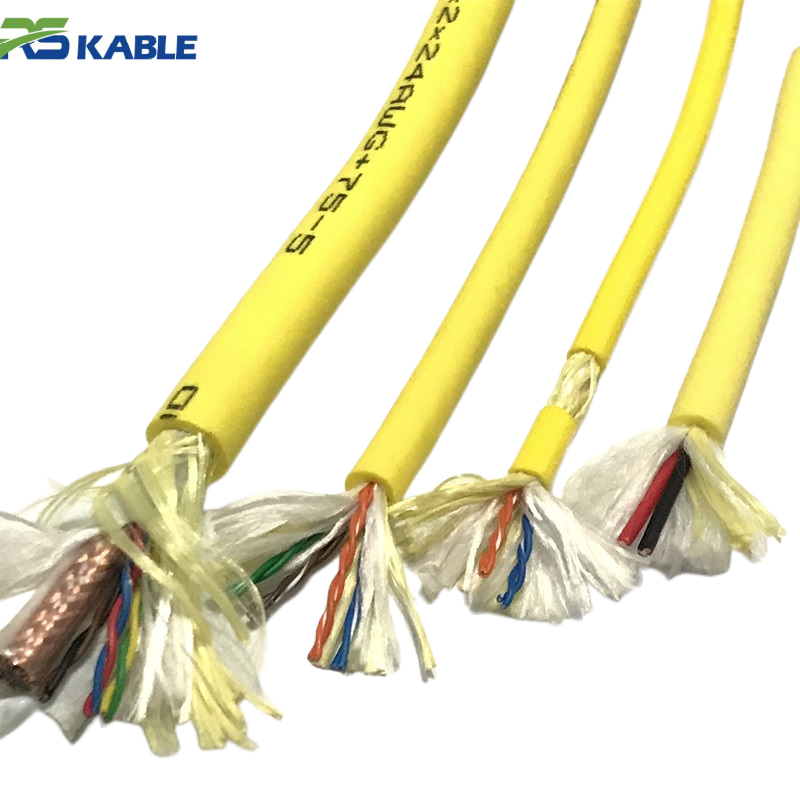

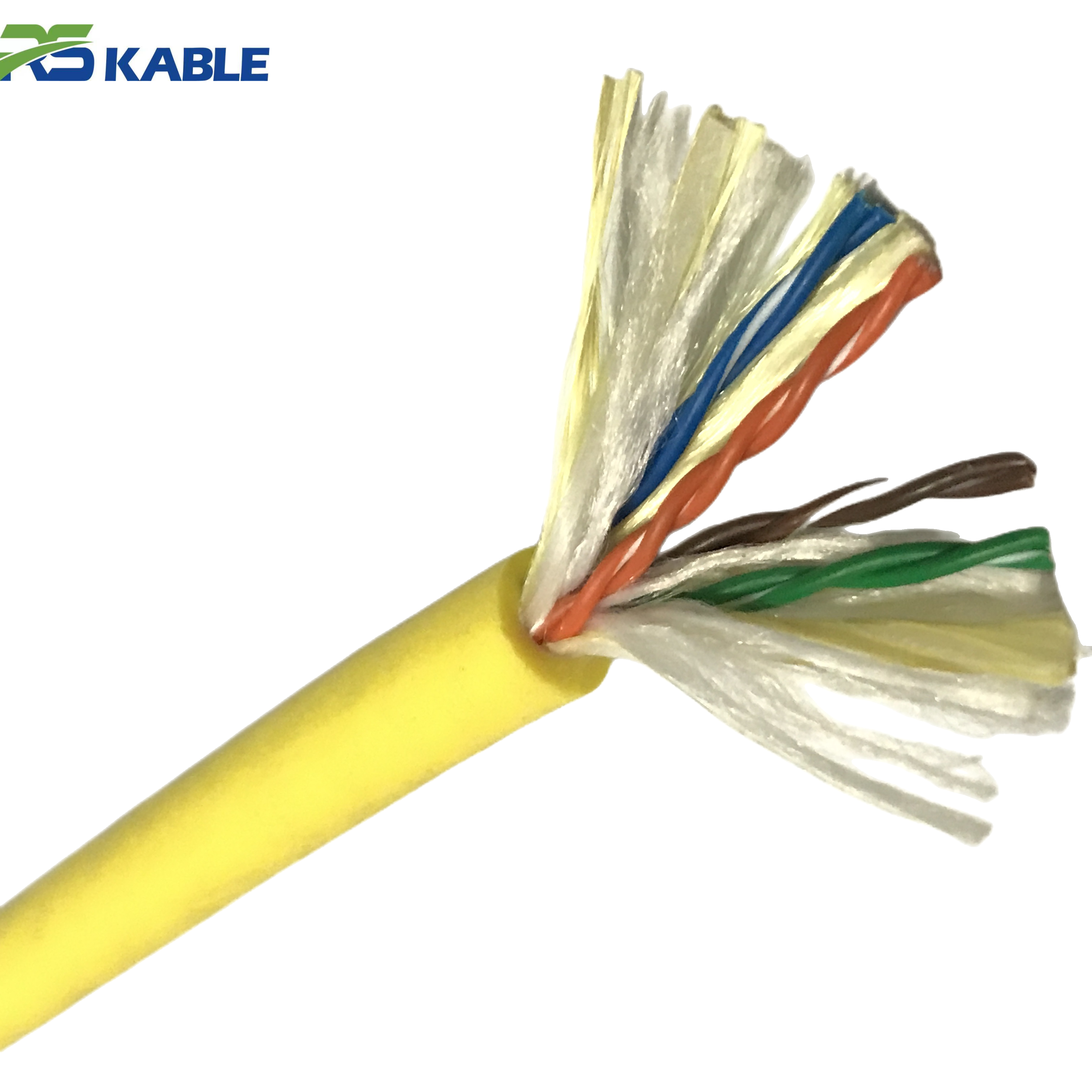

• Conductor: Multi-stranded tinned copper optimized for stable power, control, and optional fiber integration for high-speed data transmission in offshore ROV systems.

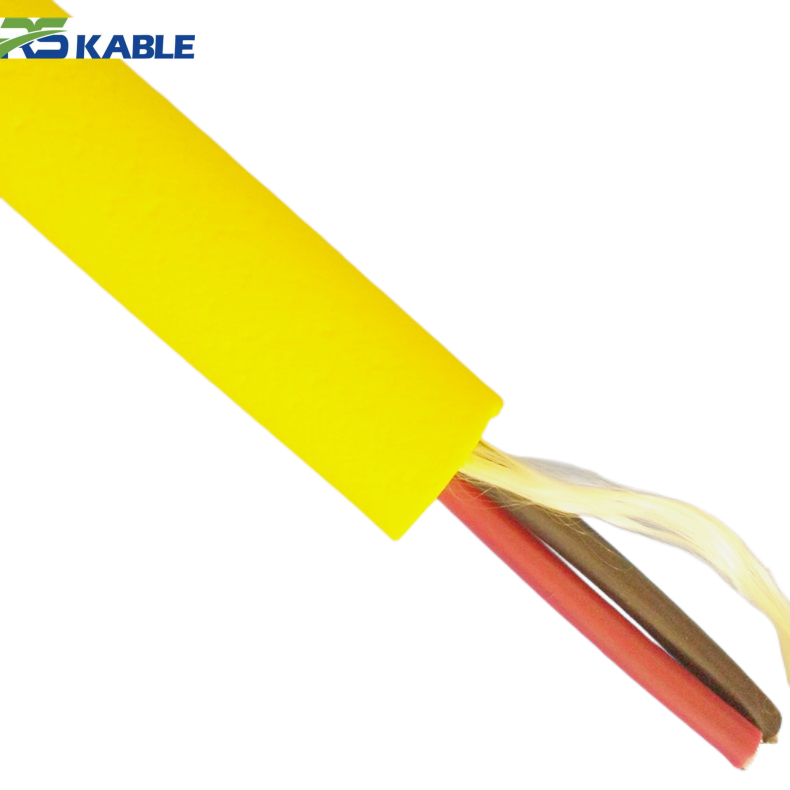

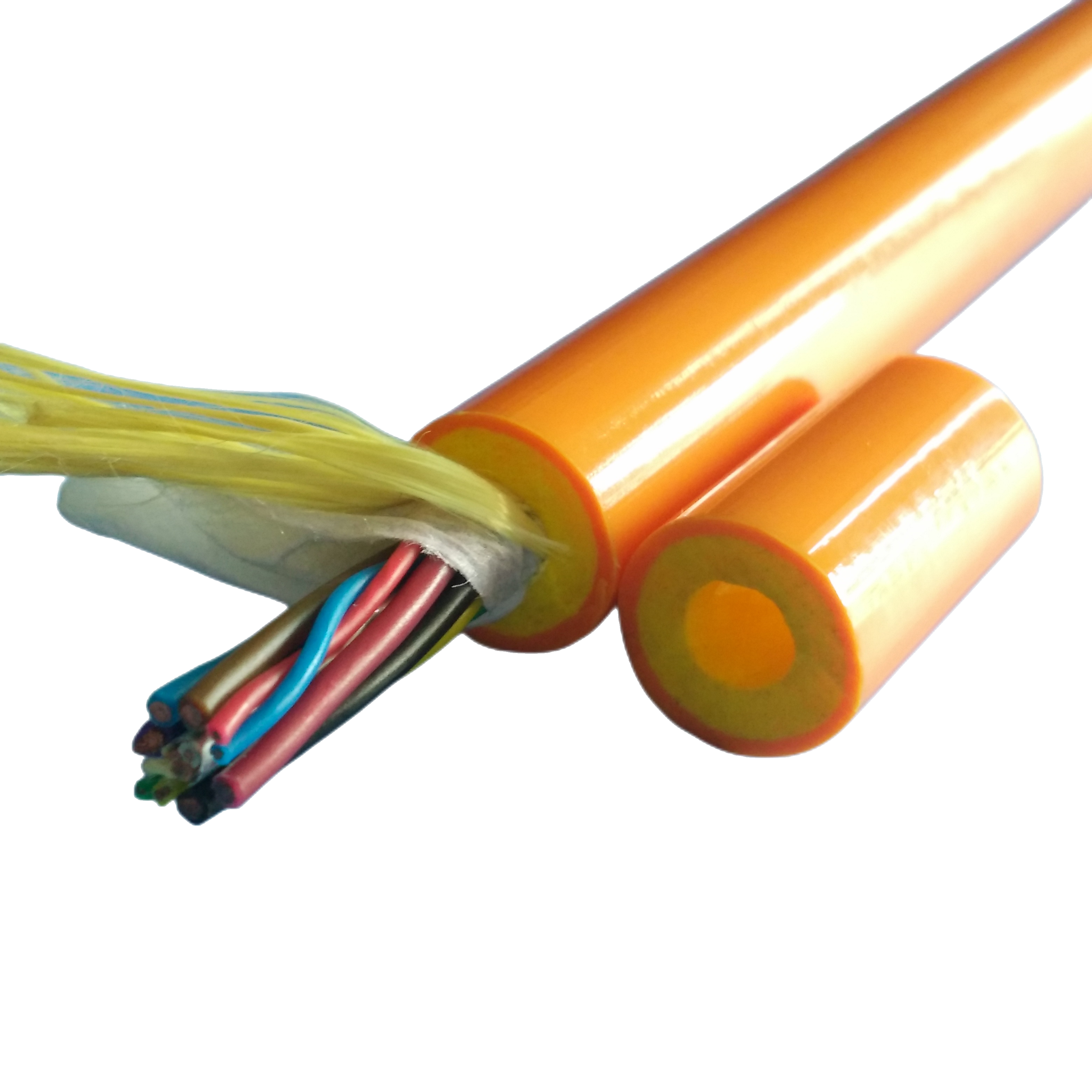

• Jacket: Abrasion-resistant TPU or equivalent polymer, engineered for mechanical wear, UV exposure, and long-term seawater deployment.

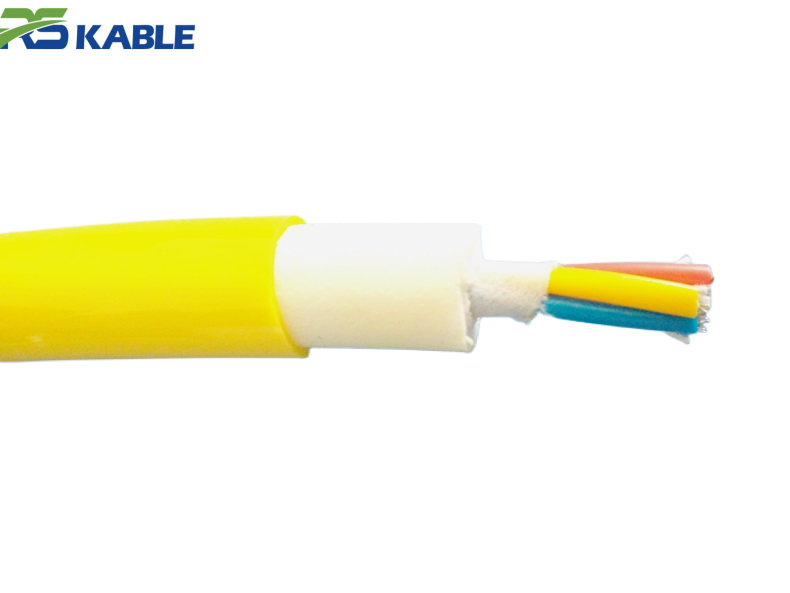

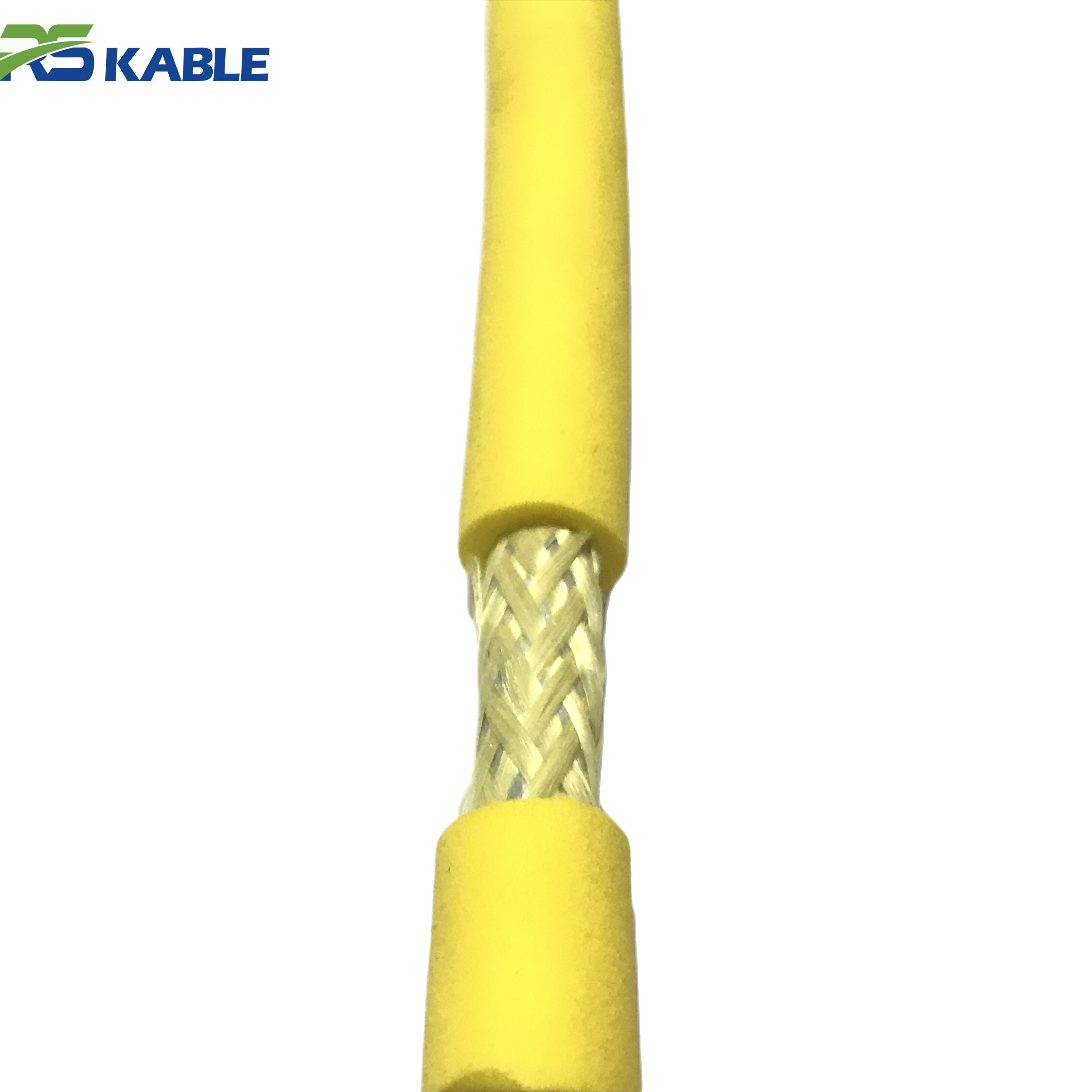

• Structure: Precision foamed insulation combined with aramid/Kevlar strength members ensures exact neutral buoyancy, EMI shielding, and compact stowage.

• Performance: Flexible design with bend radius 5–7×OD, minimizing drag and enabling energy-efficient operations and smooth ROV maneuvering at depths up to 6,000 meters.

• Environment: Fully optimized for harsh offshore subsea conditions, including pipelines, wind farms, and inspection sites, with long-term durability in IP68-rated continuous immersion.

Offshore Inspection Robots | Neutral Buoyancy Cable | High Durability | Abrasion Resistant Sheath

Enhance the performance of your offshore inspection robots with our premium Neutral Buoyancy Cable. Designed for high-durability and abrasion resistance, this cable ensures reliable power, control, and data transmission during long-term deployments in harsh marine environments. Its precision neutral buoyancy minimizes drag and tension, enabling smoother ROV maneuvering and extended mission endurance.

Manufactured under ISO 9001:2015 quality standards and compliant with RoHS and REACH, our cables are trusted by offshore operators, research institutions, and defense organizations worldwide.

Key Advantages of Our Neutral Buoyancy Cable

-

High-durability construction with abrasion-resistant outer sheath for repeated handling and subsea operations

-

Precision neutral buoyancy to reduce drag and prevent stress on robots and mooring lines

-

Enhanced flexibility for compact storage and dynamic deployments

-

Corrosion and seawater-resistant materials for long-term reliability

-

Stable electrical and signal transmission for high-performance robotic inspections

These features make it ideal for offshore ROV inspection, maintenance, and subsea survey missions.

Product Models and Core Attributes

| Model | Core Attributes | Conductor / Fiber Configuration | Rated Depth | Outer Diameter | Buoyancy in Water |

|---|---|---|---|---|---|

| NB-OR-4P | 4-core power, abrasion-resistant | 4 × 1.5 mm² tinned copper | 3,500 m | 16.8 mm | Neutral (~0 kg/m) |

| NB-OR-6CS | 6-core power + signal, hybrid shield | 4 × 1.5 mm² + 2 × 0.75 mm² | 4,500 m | 19.2 mm | Neutral (~0 kg/m) |

| NB-OR-4FO | 4-core power + fiber optic, flexible | 4 × 1.0 mm² + 2–4 fiber elements | 5,500 m | 20.6 mm | Neutral (~0 kg/m) |

| NB-OR-HD | Heavy-duty armored, enhanced wear-resistance | 6 × 2.0 mm² + multi-pair shielded | 6,000 m | 24.5 mm | Neutral (~0 kg/m) |

All models feature thermoplastic polyurethane (TPU) or equivalent abrasion-resistant jackets, optimized for offshore inspection operations.

Applications and Deployment Scenarios

Our Neutral Buoyancy Cable is ideal for offshore inspection robots performing:

-

Subsea oil & gas infrastructure inspections and maintenance

-

Pipeline and riser monitoring

-

Wind farm foundation and cable inspections

-

Environmental surveys and scientific observation

-

Deep-water salvage and recovery operations

-

ROV-assisted subsea construction and repair

Long-tail keywords: neutral buoyancy cable for offshore ROV inspection, high-durability abrasion-resistant tether for subsea robots, subsea neutral buoyancy cable 6000m offshore deployment.

Technical Specifications

| Parameter | Specification | Standard / Notes |

|---|---|---|

| Conductor | Tinned multi-stranded copper (Class 5/6) | IEC 60228 |

| Insulation | Foamed PE or XLPE | Low water uptake, stable dielectric properties |

| Strength Member | Kevlar/aramid braid | Tensile strength ≥2,500 kg |

| Shielding | Foil + braid ≥85% coverage | EMI/RFI protection for sensors and video signals |

| Outer Jacket | TPU or abrasion-resistant polymer | Resistant to mechanical wear, UV, and biofouling |

| Buoyancy | Neutral in seawater | Density 1.01 ± 0.02 g/cm³ |

| Operating Temperature | –30°C to +70°C | Suitable for long-term offshore operations |

| Voltage Rating | 300/500V (optional 1kV) | Safe for power and control circuits |

| Certifications | ISO 9001, RoHS, REACH | Optional ABS/DNV type approval |

Frequently Asked Questions (FAQ)

Q: Can the cable be customized for specific ROV models or mission profiles?

A: Yes. We provide tailored conductor/fiber configurations, lengths, and jacket materials to match your offshore requirements.

Q: How does the cable maintain neutral buoyancy under load?

A: Precision foamed insulation combined with calibrated jacket density ensures consistent neutral buoyancy even during dynamic subsea operations.

Q: Is this cable suitable for long-term subsea deployment?

A: Absolutely. TPU/PE jackets, corrosion-resistant materials, and IP68-rated protection ensure reliability over multi-year missions.

Q: Can optical fibers be integrated for high-speed data transmission?

A: Yes. Single-mode or multi-mode fibers can be incorporated for real-time sensor telemetry and video feeds.

Q: Do you offer factory-terminated assemblies?

A: Yes. All cables can be supplied with pre-terminated connectors and full electrical/pressure testing.