Offshore Construction Projects | ROV Cable | Heavy-Duty Jacket | Long-Distance Power Supply

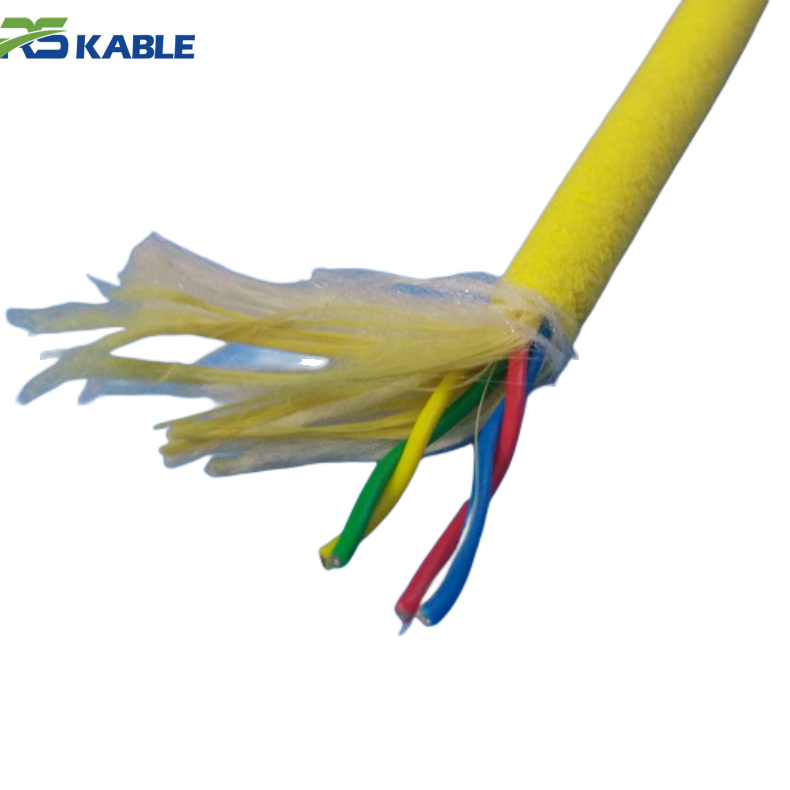

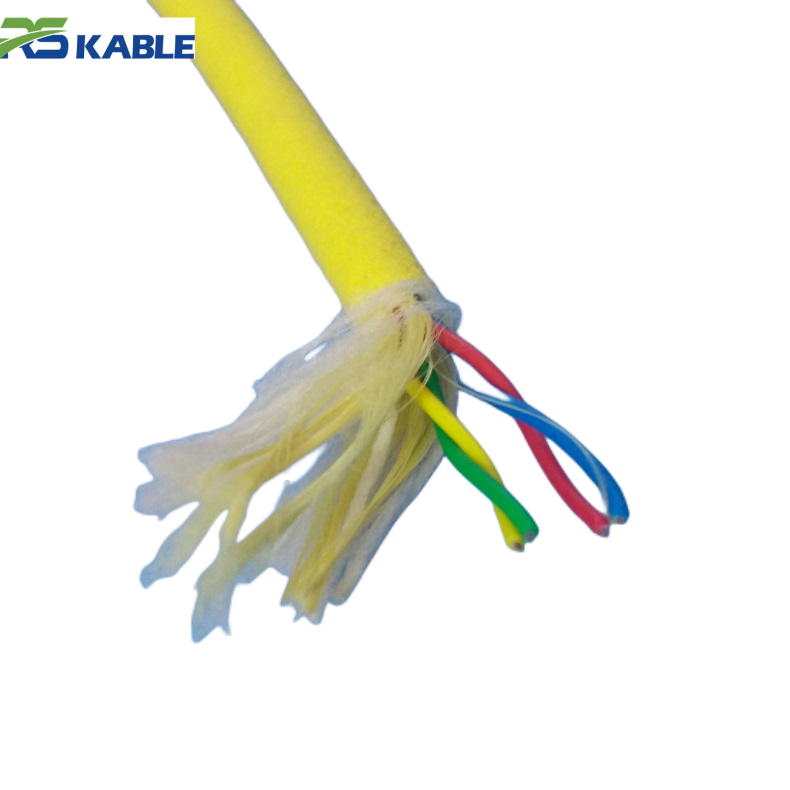

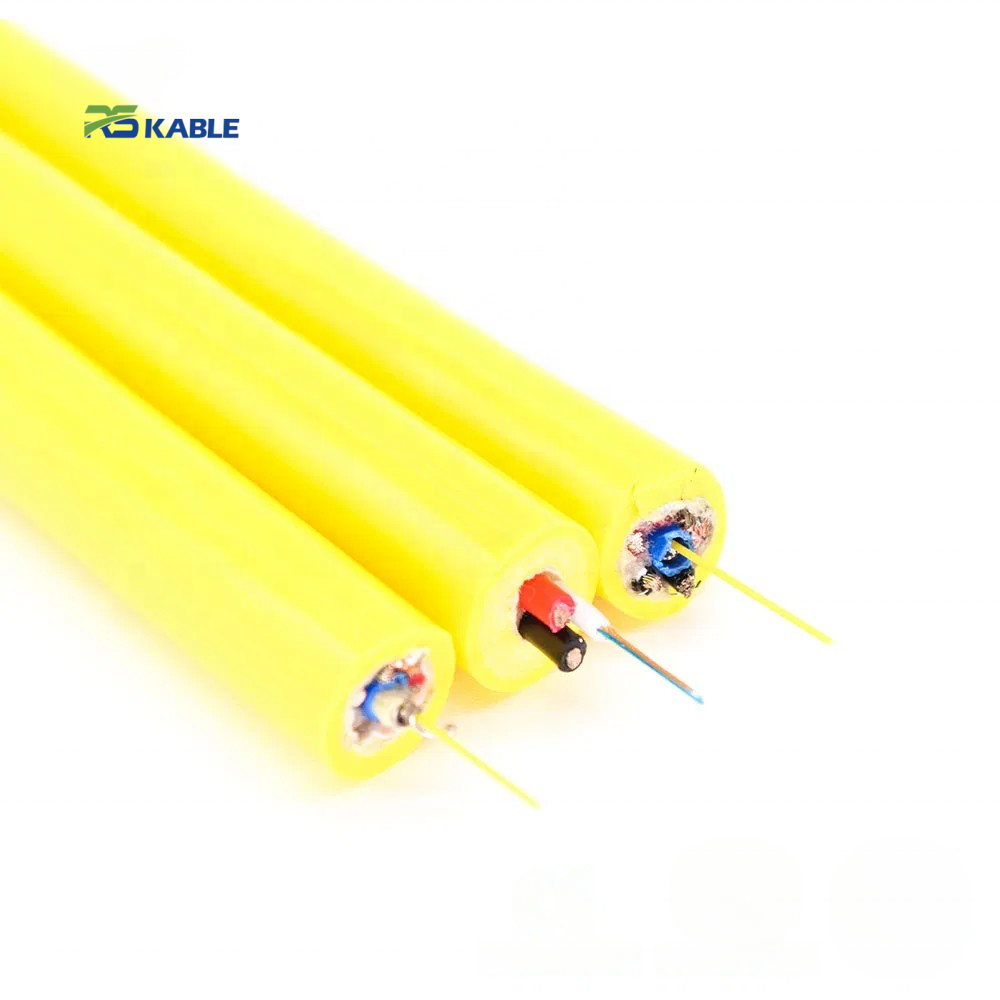

Rugged ROV Cable engineered for offshore construction projects, featuring a heavy-duty abrasion-resistant TPU jacket and reinforced multi-stranded cores. Designed for neutral buoyancy, it ensures minimal drag and reliable long-distance power and signal transmission. Ideal for deepwater ROV operations including subsea pipeline installation, platform inspection, underwater construction support, and heavy-lift interventions. Flexible yet durable, this cable withstands harsh marine environments while maintaining stable performance for extended offshore missions.

Offshore Construction Projects | ROV Cable | Heavy-Duty Jacket | Long-Distance Power Supply

Ensure reliable subsea operations with our rugged ROV Cable, engineered for offshore construction projects. Designed with a heavy-duty outer jacket, this cable supports long-distance power delivery and secure signal transmission for ROVs working in demanding marine environments. Built for durability, flexibility, and neutral buoyancy, it is ideal for inspection, intervention, and subsea installation missions.

Key Features & Advantages

-

Heavy-duty jacket: Abrasion and impact-resistant for harsh offshore conditions

-

Neutral buoyancy design: Minimizes drag and reduces thruster energy consumption

-

Long-distance power and signal: Stable transmission across extended tether lengths

-

Reinforced core structure: High tensile strength supports dynamic ROV operations

-

Flexible and durable: Withstands repeated bending and underwater handling

Product Models & Core Attributes

| Model | Core Attributes | Conductor Configuration | Rated Depth | Outer Diameter | Weight in Water |

|---|---|---|---|---|---|

| ROV-OC-4P | 4 power cores, heavy-duty jacket, neutral buoyancy | 4 × 2.5 mm² multi-stranded Cu | 5,000 m | 20.5 mm | ~0 kg/m |

| ROV-OC-6PS | 6 cores (power + signal), armored, zero-buoyancy | 4 × 2.0 mm² + 2 × 1.0 mm² | 6,000 m | 23.0 mm | ~0 kg/m |

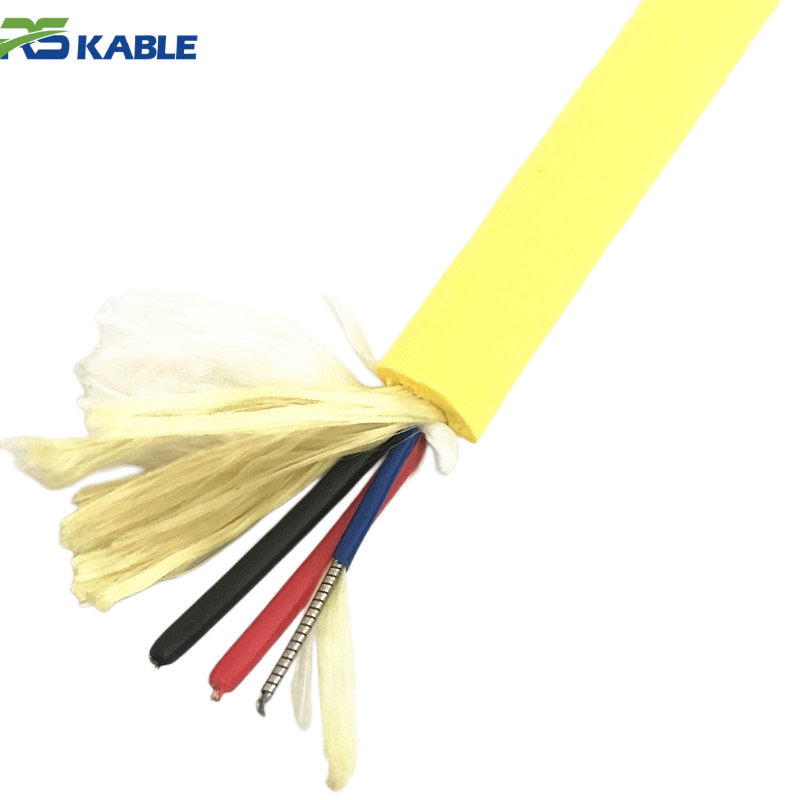

| ROV-OC-4F | 4 power + fiber optic, reinforced, long-distance | 4 × 2.0 mm² + 2–4 fiber elements | 6,500 m | 24.2 mm | ~0 kg/m |

| ROV-OC-HD | Heavy-duty, enhanced armor, high tensile | 6 × 3.0 mm² + twisted pairs | 8,000 m | 28.0 mm | ~0 kg/m |

All models feature seawater-resistant thermoplastic polyurethane (TPU) jackets and multi-stranded copper conductors for maximum durability.

Applications & Use Cases

Our ROV Cable excels in demanding offshore construction operations:

-

Subsea pipeline and infrastructure installation

-

Oil & gas platform inspection and maintenance

-

Underwater welding and construction support

-

Long-distance ROV power and control for deepwater projects

-

Heavy-lift intervention missions

Long-tail applications: “heavy-duty ROV cable for offshore construction,” “long-distance power and signal tether for subsea ROVs,” “neutral buoyancy cable for oil & gas subsea projects.”

Technical Specifications

| Parameter | Specification | Notes / Standard |

|---|---|---|

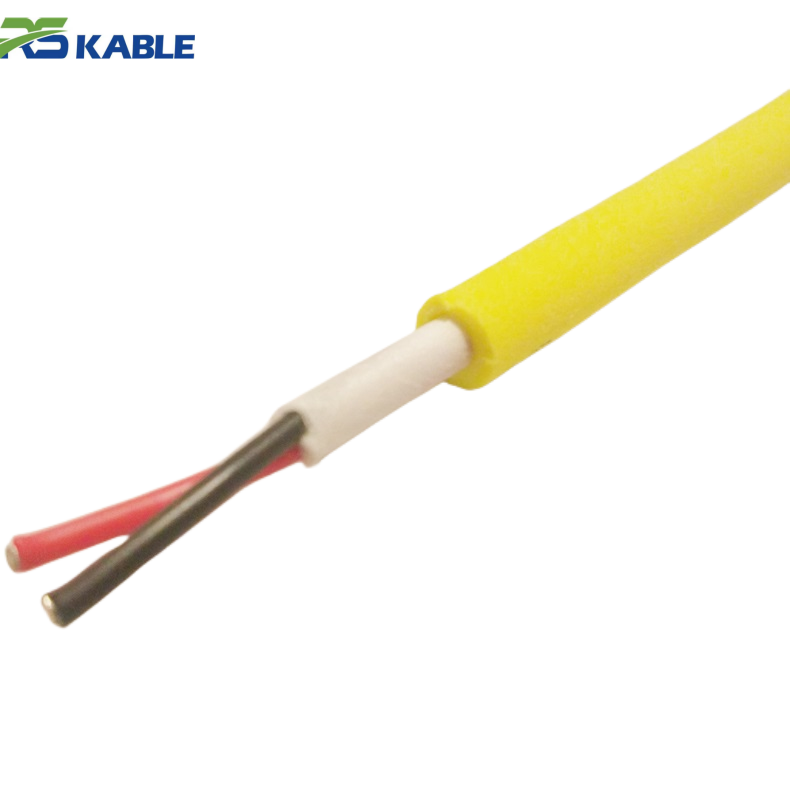

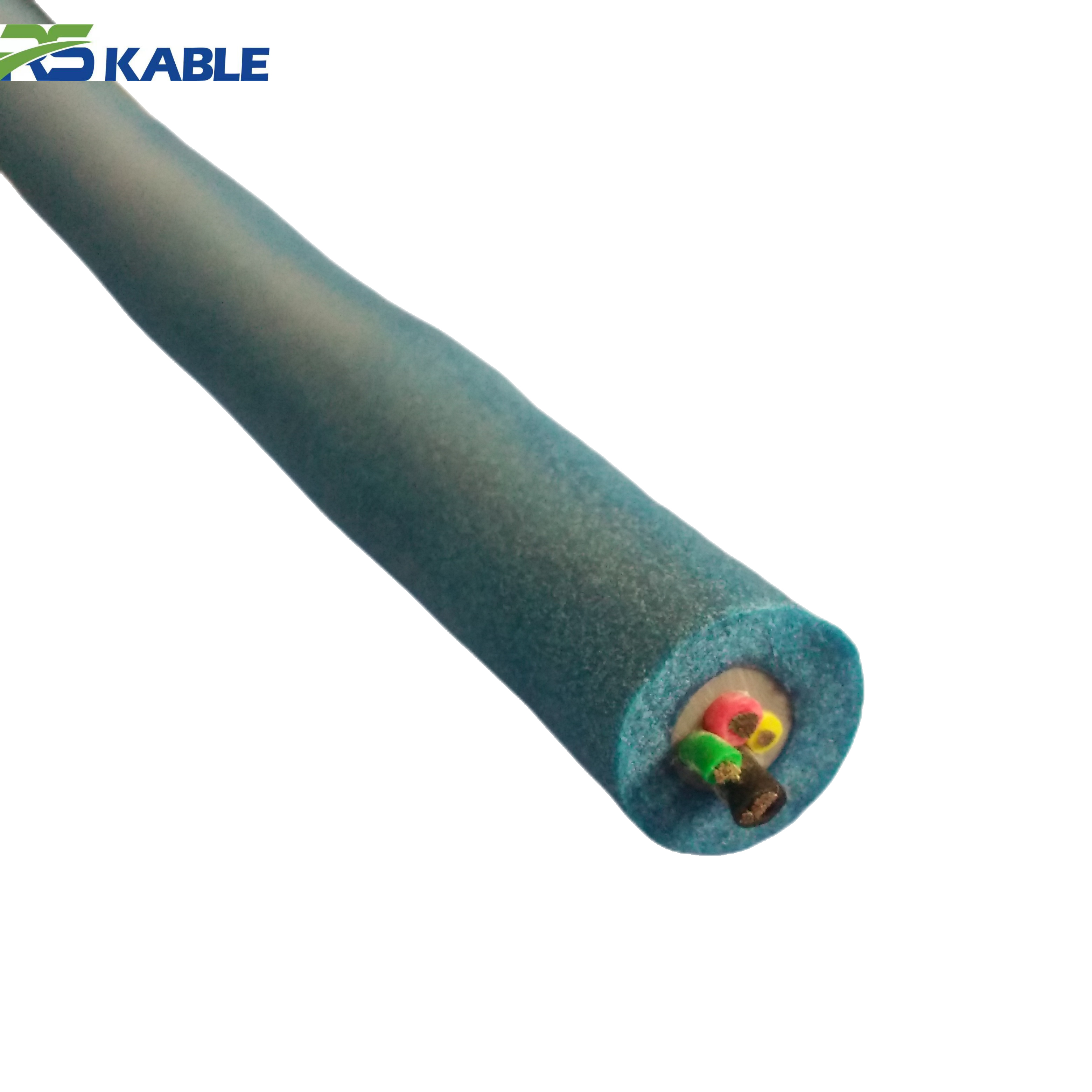

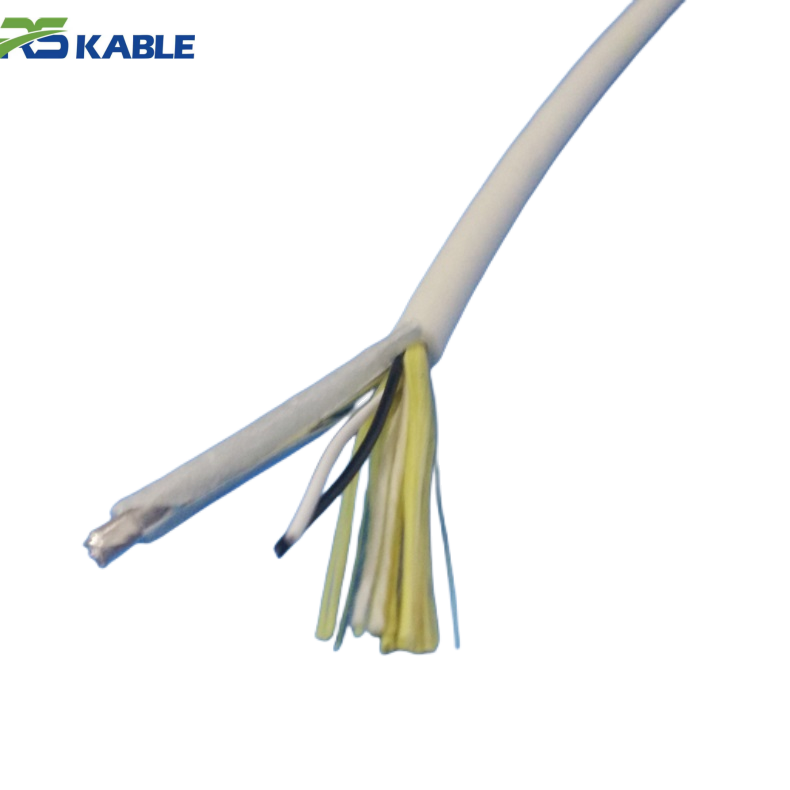

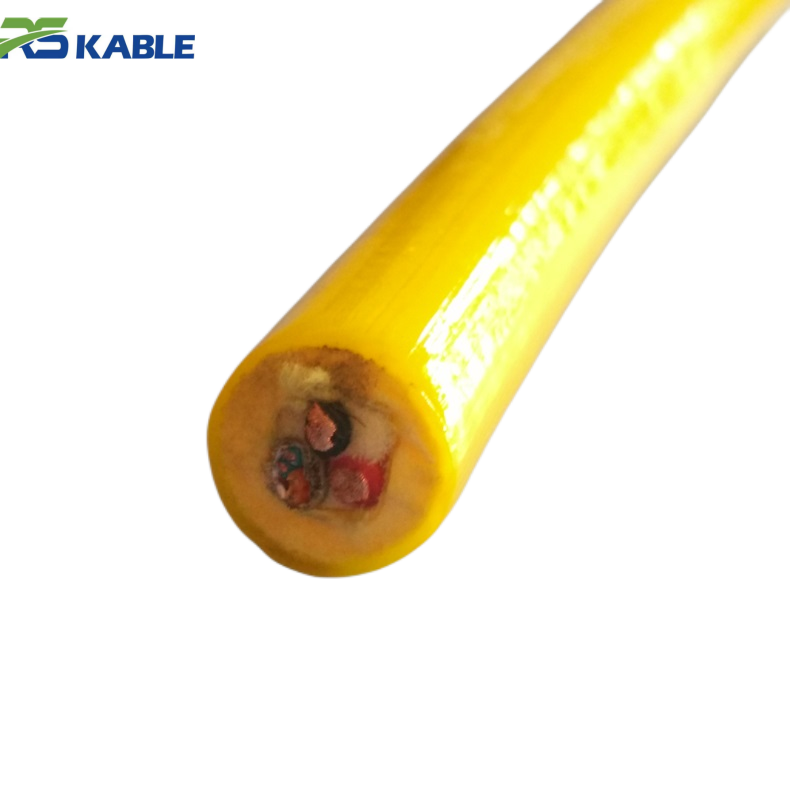

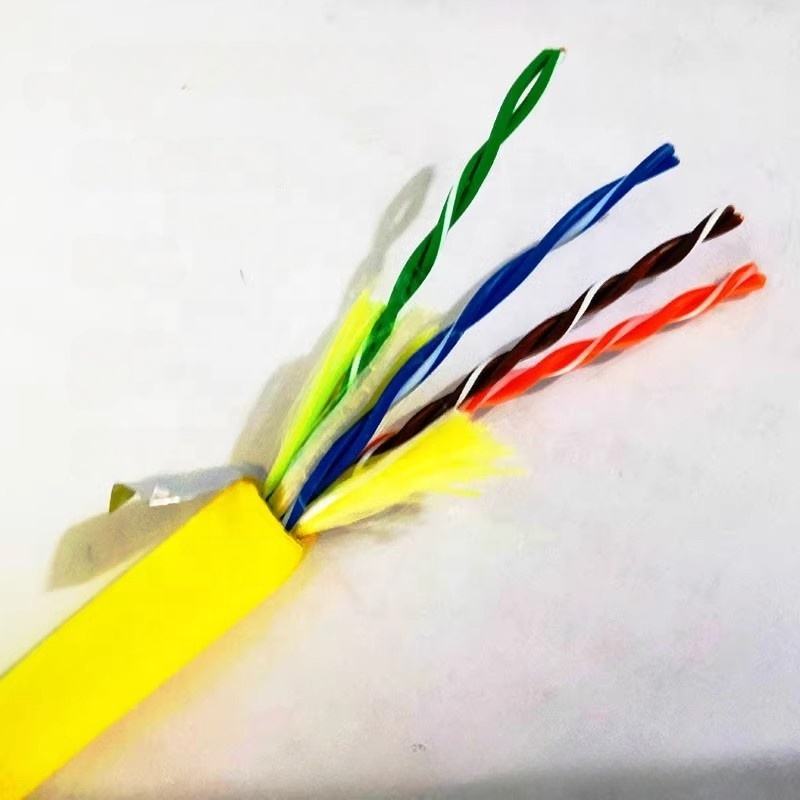

| Conductor | Tinned multi-stranded copper | IEC 60228, Class 5 |

| Insulation | XLPE or foamed PE for flexibility & buoyancy | Low dielectric loss, seawater resistant |

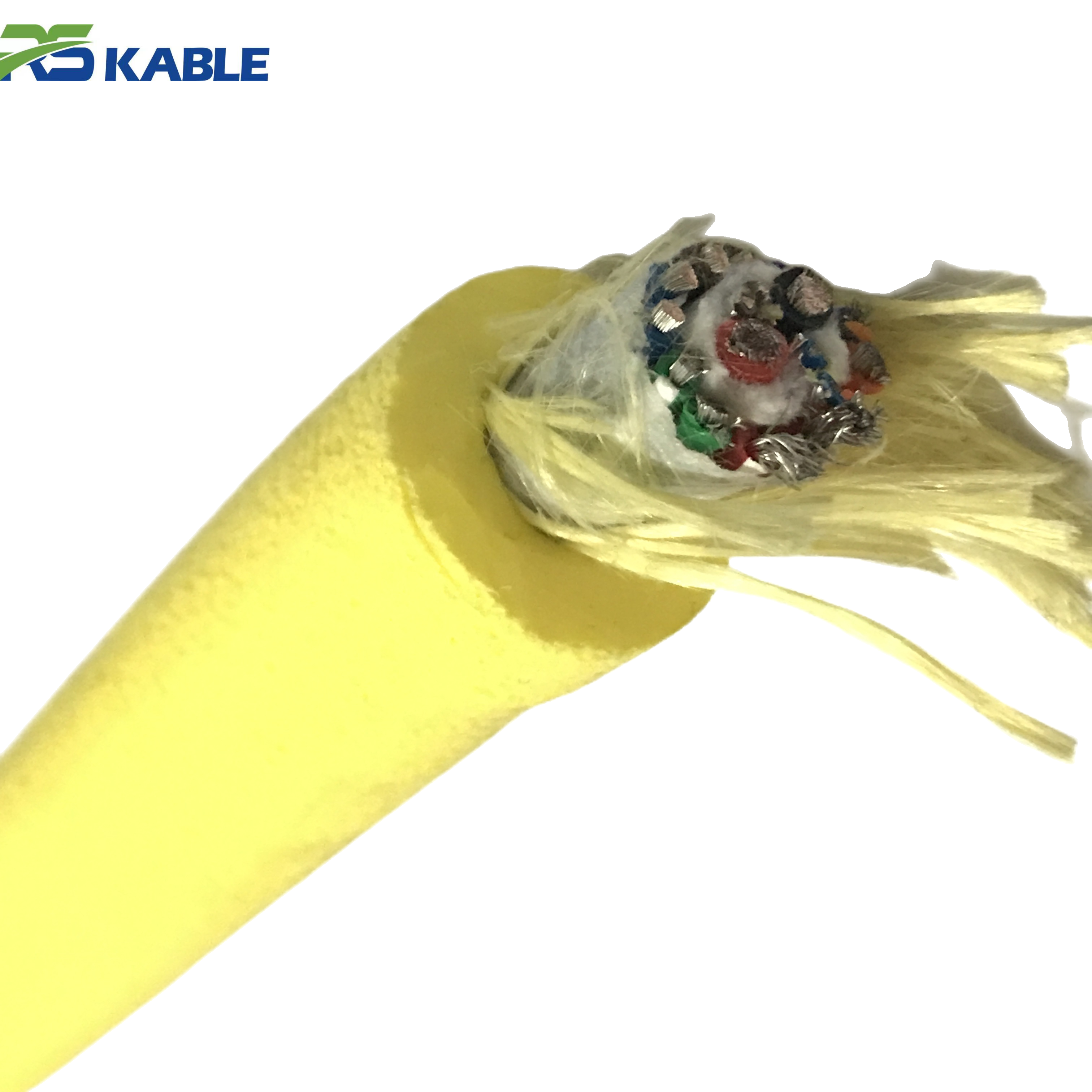

| Strength Member | Kevlar or aramid fibers | Tensile strength up to 2,500 kg |

| Shielding | Foil + tinned copper braid | EMI protection for signal integrity |

| Outer Jacket | TPU or equivalent heavy-duty compound | Abrasion, impact, UV and saltwater resistant |

| Buoyancy Control | Neutral in seawater | Density 1.01 ± 0.02 g/cm³ |

| Operating Temperature | –30°C to +80°C | Suitable for extreme offshore environments |

| Voltage Rating | 300/600V standard, optional 1,000V | Power and control compatible |

| Certifications | ISO 9001, RoHS, optional DNV/ABS approval | Verified by third-party testing |

Ready to Equip Your ROV?

Frequently Asked Questions (FAQ)

Q: Can this cable handle extended deepwater operations?

A: Yes, designed for continuous long-distance power and signal delivery with reinforced cores and neutral buoyancy to minimize drag.

Q: Is it suitable for both power and fiber-optic communication?

A: Absolutely. Models integrate fiber optic elements alongside power cores for hybrid data and control transmission.

Q: How resistant is the cable to abrasion and seawater corrosion?

A: Heavy-duty TPU jackets and reinforced structures ensure maximum abrasion, impact, and corrosion resistance in harsh offshore conditions.

Q: Can custom lengths or configurations be requested?

A: Yes, all models can be tailored to specific project requirements, including depth rating, core configuration, and jacket type.