OEM/ODM High-Flex Bending Encoder Cable, 8 10 12-Core Twisted Pair Shielded Cable for Servo Motor Driven Electrical Equipment

.High flexibility for drag chains

.Twisted-pair for signal integrity

.Oil-resistant PVC jacket

.85% optical coverage shielding

.Custom OEM/ODM specifications

OEM/ODM High-Flex Bending Encoder Cable

In automated industrial systems, the failure of a single feedback cable can halt an entire production line. For engineers and procurement specialists, the priority is not just finding a cable that fits, but finding one that withstands millions of bending cycles while maintaining absolute signal integrity.

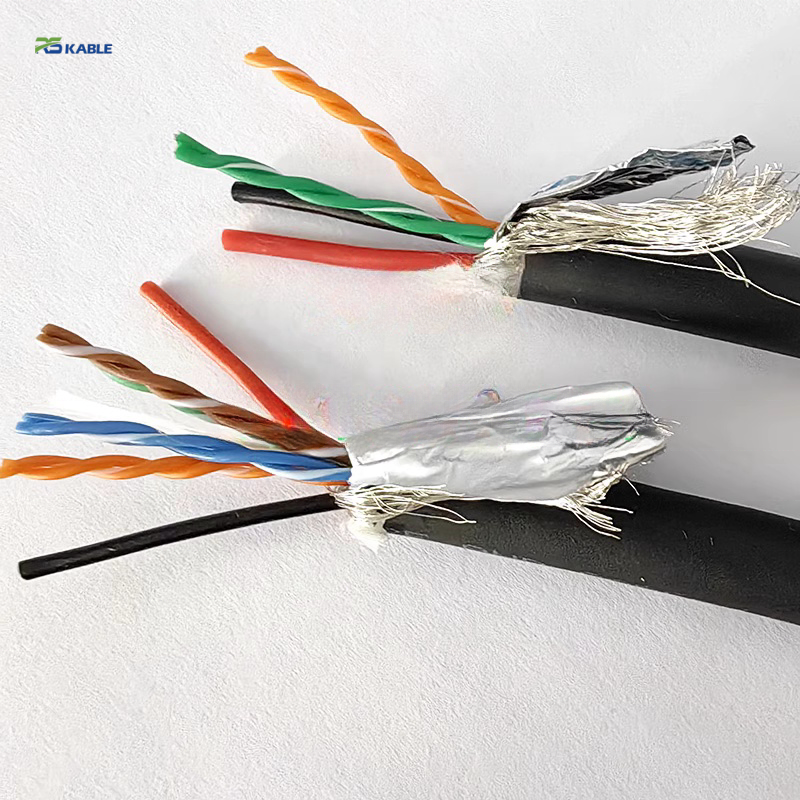

The TRVVPS High-Flex Bending Encoder Cable is engineered specifically to solve the challenges of dynamic motion control. Designed by Shanghai Rousheng Wire And Cable Co., Ltd., this twisted-pair shielded cable delivers reliable data transmission for servo motors, encoders, and drag chain systems. Whether you require 8, 10, or 12 cores, this solution combines flexibility with robust electromagnetic compatibility (EMC) to ensure your machinery operates with precision.

Engineered for Continuous Motion

Standard cabling cannot survive the repetitive stress of modern automation. This high-flex encoder cable is constructed to endure the rigorous demands of drag chains and robotic arms, preventing the common “corkscrewing” and core breakage failures associated with inferior products.

Superior Flexibility and Bending Resistance

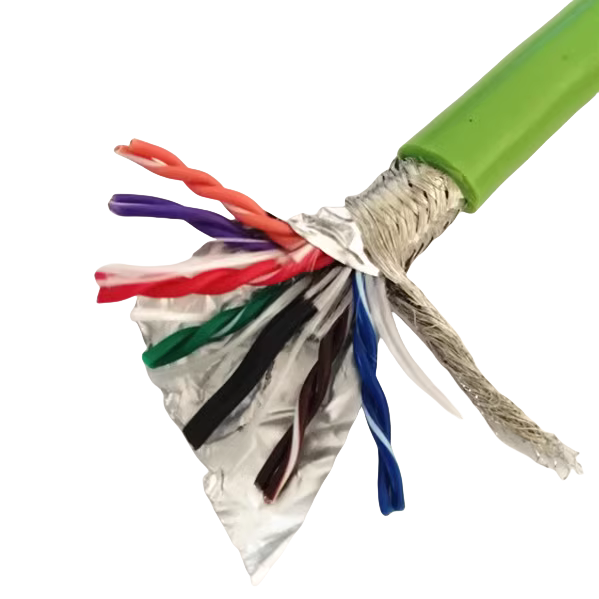

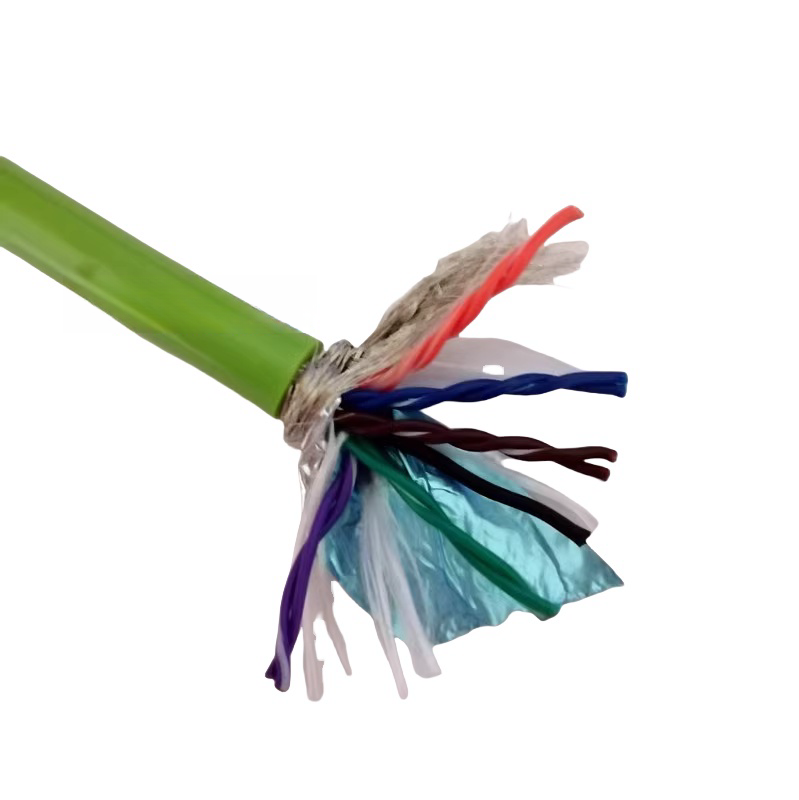

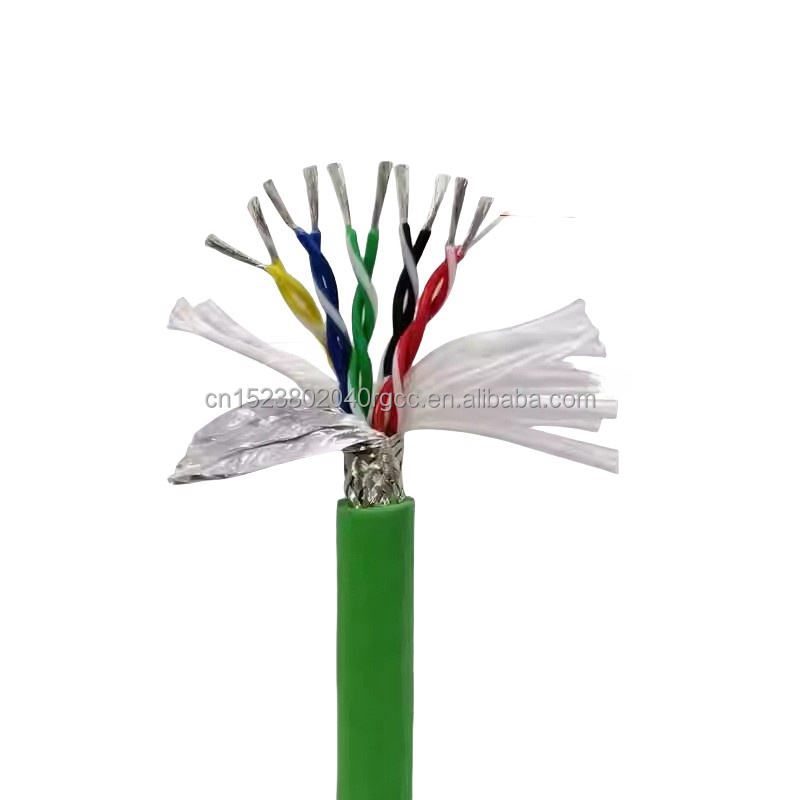

The core of this cable’s performance lies in its specialized construction. Using fine-stranded copper conductors (Class 6 compliance equivalent), the cable maintains high conductivity even under constant movement. The insulation and jacket materials are formulated for a tight bending radius, allowing the cable to flex freely within compact drag chains without cracking or degrading over time. This makes it an ideal choice for high-speed linear motors and multi-axis robots.

Maximum Signal Integrity (EMC Protection)

In servo feedback loops, data corruption is unacceptable. This cable features a high-coverage tinned copper braid shield combined with a twisted-pair configuration.

- Twisted Pairs: Adjacent cores are twisted together to cancel out electromagnetic interference (EMI) from external sources and crosstalk between internal signals.

- Braided Shielding: A dense copper mesh acts as a Faraday cage, grounding electrical noise and preventing it from distorting the sensitive encoder signals.

Built for Harsh Industrial Environments

Industrial floors are unforgiving. The outer jacket is crafted from a special PVC compound that provides excellent resistance to oil, coolants, and abrasion. Whether installed in a CNC machine exposed to cutting fluids or a conveyor system subject to dust and vibration, the cable’s sheath protects the internal conductors from environmental damage, extending the service life of your equipment.

Technical Specifications

The following table outlines the standard technical parameters for the TRVVPS High-Flex Encoder Cable. Customization options are available upon request.

|

Feature |

Specification |

|---|---|

|

Product Model |

TRVVPS (High-Flex Shielded Twisted Pair) |

|

Conductor Material |

Fine-stranded Bare or Tinned Copper (High Purity) |

|

Insulation Material |

Special PVC / PP (Low capacitance options available) |

|

Core Structure |

Twisted Pairs (helps reduce crosstalk) |

|

Shielding |

Tinned Copper Braid (High optical coverage >85%) |

|

Outer Jacket |

Special Oil-Resistant, Abrasion-Resistant PVC |

|

Rated Voltage |

300/300V, 300/500V |

|

Temperature Range |

Mobile: -5°C to +70°C; Fixed: -15°C to +80°C |

|

Bending Radius |

Mobile: ~7.5x Cable Diameter; Fixed: ~4-6x Cable Diameter |

|

Core Counts |

Standard: 8, 10, 12 cores (Custom: 2-20+ cores available) |

|

Flame Retardancy |

Compliant with IEC 60332-1 |

|

Compliance |

CE, RoHS, REACH, ISO9001 |

Primary Applications

This cable is versatile enough to serve as the nervous system for a wide range of automation equipment. Its primary function is to transmit position and speed data from the motor to the drive, but its durability makes it suitable for various power and signal uses.

- Servo Systems: Connecting rotary encoders and resolvers to servo drives.

- CNC Machinery: Drag chains in milling machines, lathes, and plasma cutters.

- Robotics: Internal wiring for articulated robot arms and Cartesian robots.

- Automated Production Lines: Conveyor feedback loops and pick-and-place units.

- Logistics: Automated warehousing and retrieval systems (AS/RS).

Why Choose Shanghai Rousheng?

Sourcing specialized industrial cabling requires a partner who understands manufacturing tolerances and material science. Shanghai Rousheng Wire And Cable Co., Ltd. brings specialized expertise to the table:

- Extensive Portfolio: With over 100 varieties of special cables, we understand the nuance between a standard control cable and a high-performance drag chain cable.

- OEM/ODM Capabilities: We don’t just sell off-the-shelf products. We offer full customization for jacket color, printing, core counts (e.g., mixing power and signal cores), and specific connector assemblies.

- Global Compliance: Our manufacturing processes adhere to IEC, VDE, and BS standards, ensuring our cables meet the safety and performance requirements of European and global markets.

- Quality Assurance: Every batch undergoes rigorous testing for continuity, insulation resistance, and high-voltage endurance before shipping.

Frequently Asked Questions (FAQ)

What is the difference between TRVV and TRVVPS cables?

TRVV is a standard high-flex cable, often used for power or general control. TRVVPS adds two critical features: Twisted Pairs (P) and Shielding (S). This makes TRVVPS specifically suitable for data and signal transmission (like encoders) where protection against electromagnetic interference is required.

Can this cable be used in outdoor environments?

The standard PVC jacket is designed primarily for indoor industrial use with resistance to oil and abrasion. For outdoor applications requiring UV resistance or extreme cold tolerance (below -15°C), please contact our engineering team to request a specialized PUR (Polyurethane) or weather-resistant PVC jacket.

What is the minimum bending radius for this cable?

For dynamic applications (inside a drag chain), we recommend a minimum bending radius of 7.5 times the cable’s outer diameter. Bending the cable tighter than this limit may shorten its lifespan and lead to internal conductor fatigue.

Do you offer custom cable assemblies?

Yes. As an OEM/ODM manufacturer, Shanghai Rousheng can provide the cable as raw bulk cable or as a pre-assembled harness complete with industrial connectors (e.g., M12, M23, D-Sub) to match your specific servo motor interface.

How do I order a sample?

We encourage testing our quality. You can request sample lengths to validate flexibility and stripping characteristics. Please contact our sales team with your required core count and conductor cross-section (e.g., 4x2x0.25mm²) to arrange shipment.

The integrity of your automation system relies on the quality of its connections. The TRVVPS High-Flex Bending Encoder Cable offers the perfect balance of flexibility, shielding, and durability, ensuring your data gets where it needs to go, even in the most active machinery.

If you are looking for a reliable manufacturing partner for your cabling needs, Shanghai Rousheng offers the technical depth and production capacity to keep your business moving forward.