Oceanographic Research Equipment | Neutral Buoyancy Cable | Lightweight Construction | Custom Length, Flexible Core

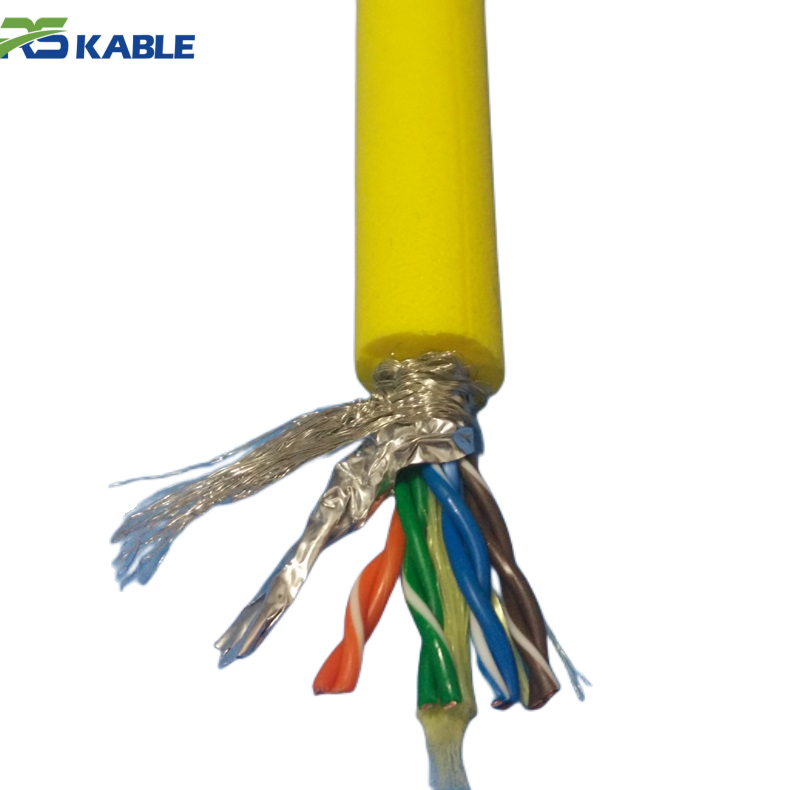

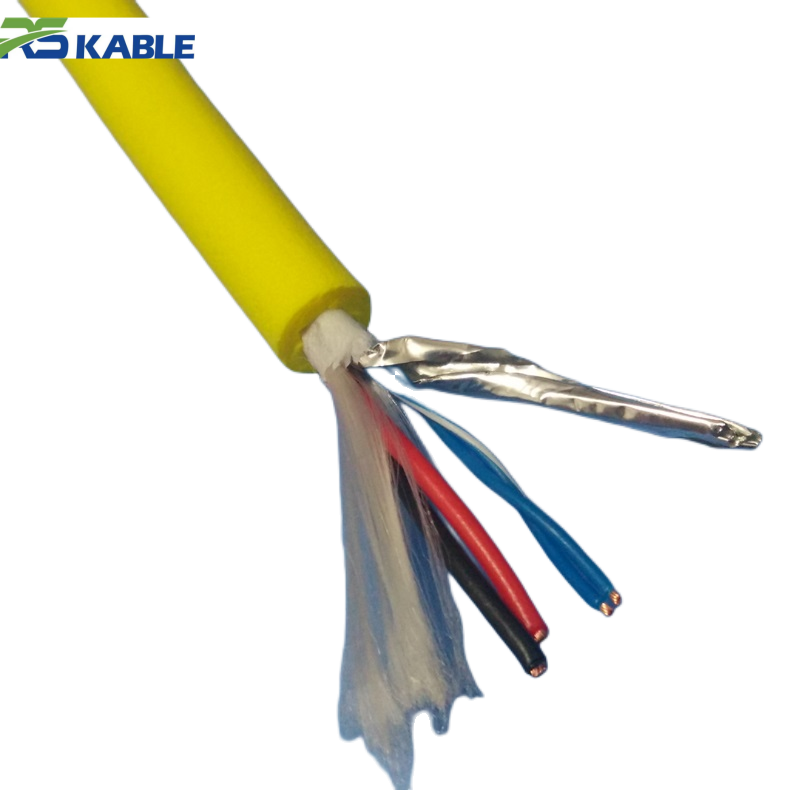

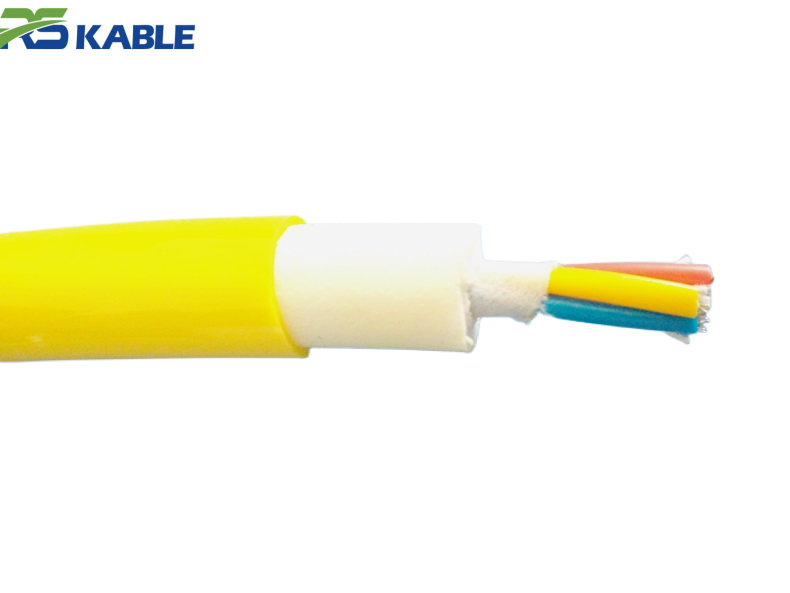

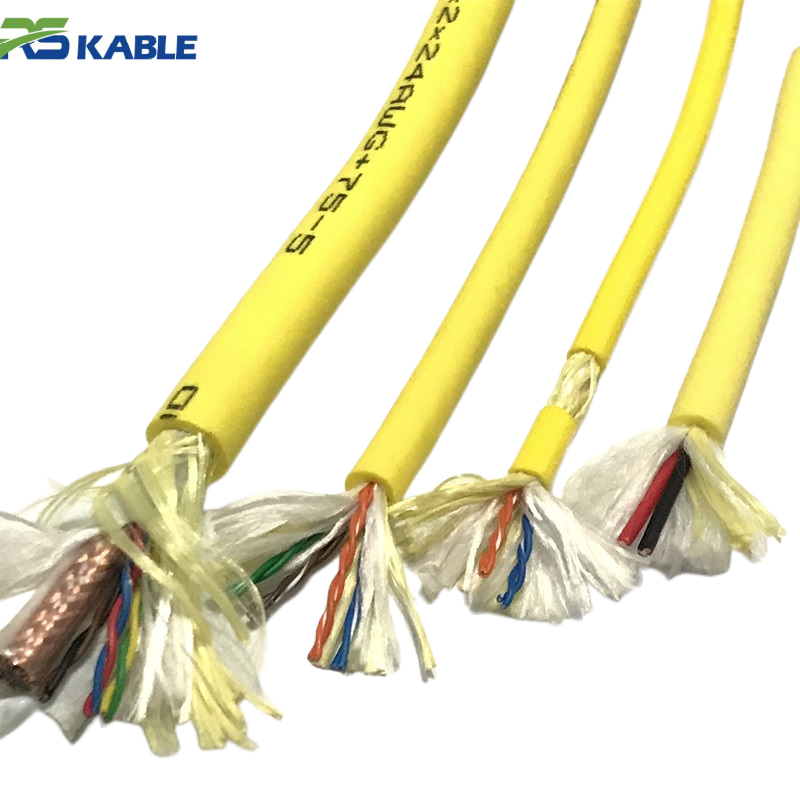

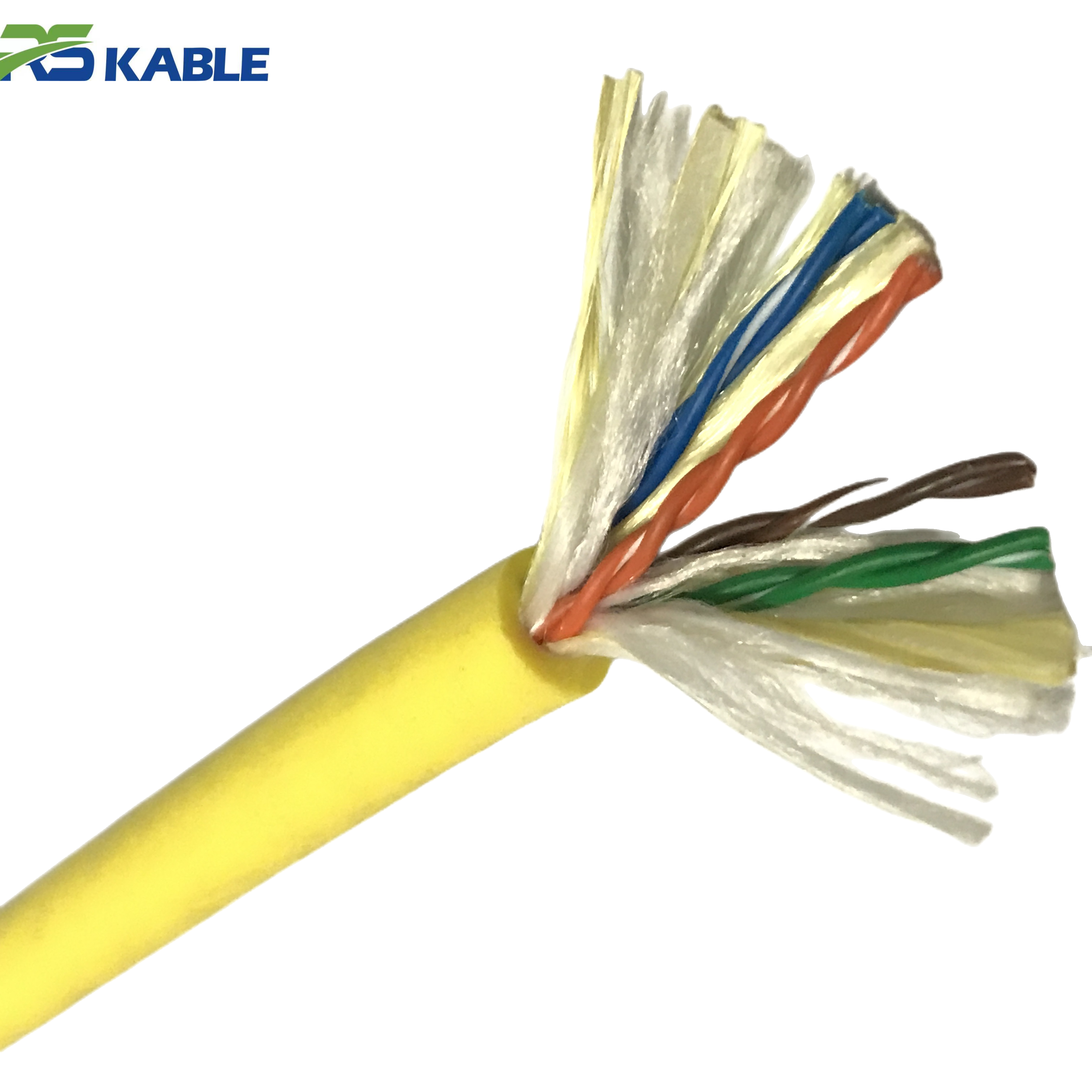

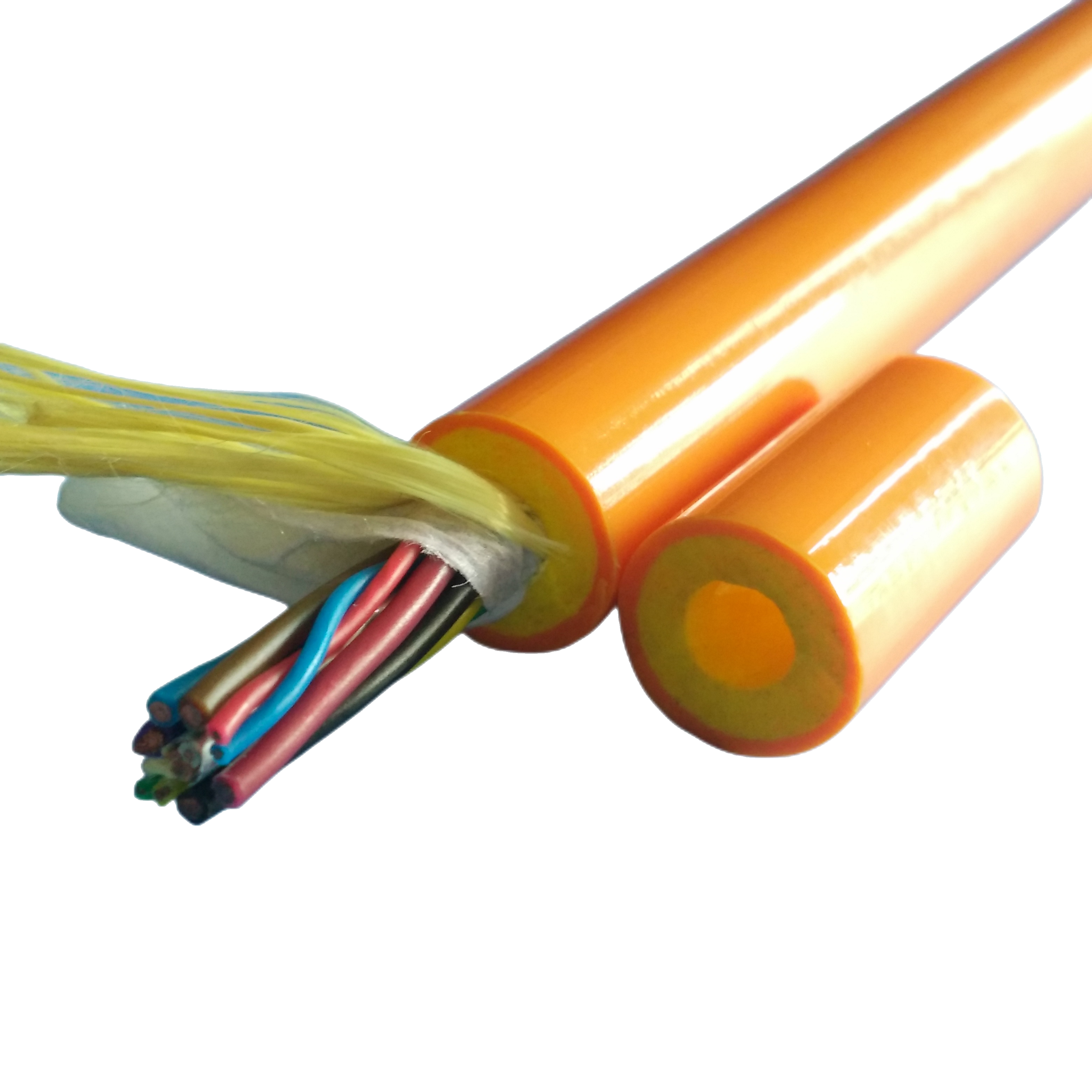

• Conductor: Multi-stranded tinned copper with optional single-mode or multi-mode optical fibers, delivering reliable power and high-speed data for oceanographic instruments.

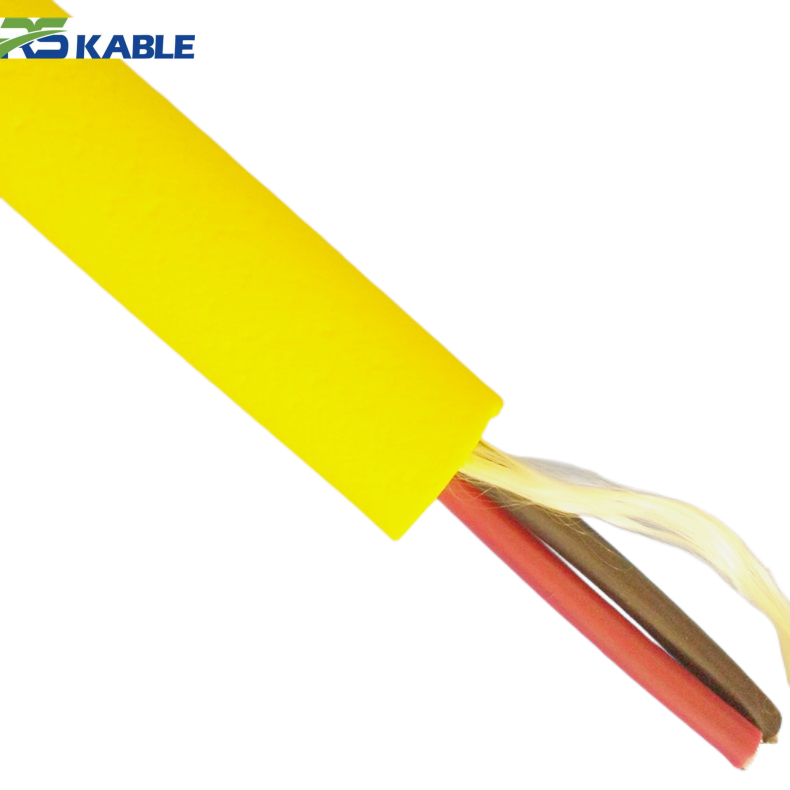

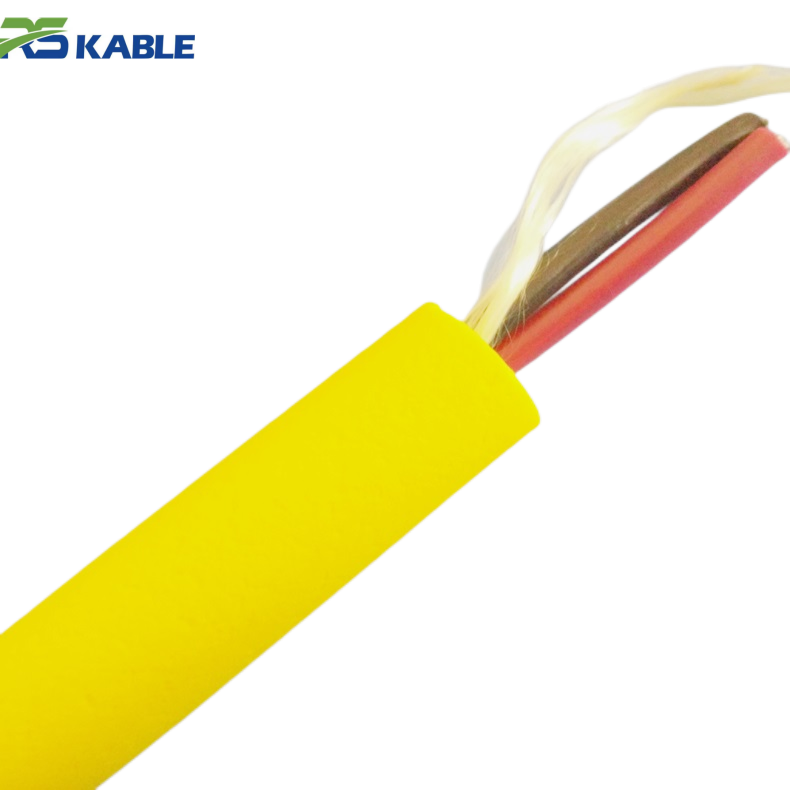

• Jacket: Lightweight, seawater-resistant TPU or PUR with low-drag, abrasion-proof finish, reducing hydrodynamic resistance and enabling easier handling.

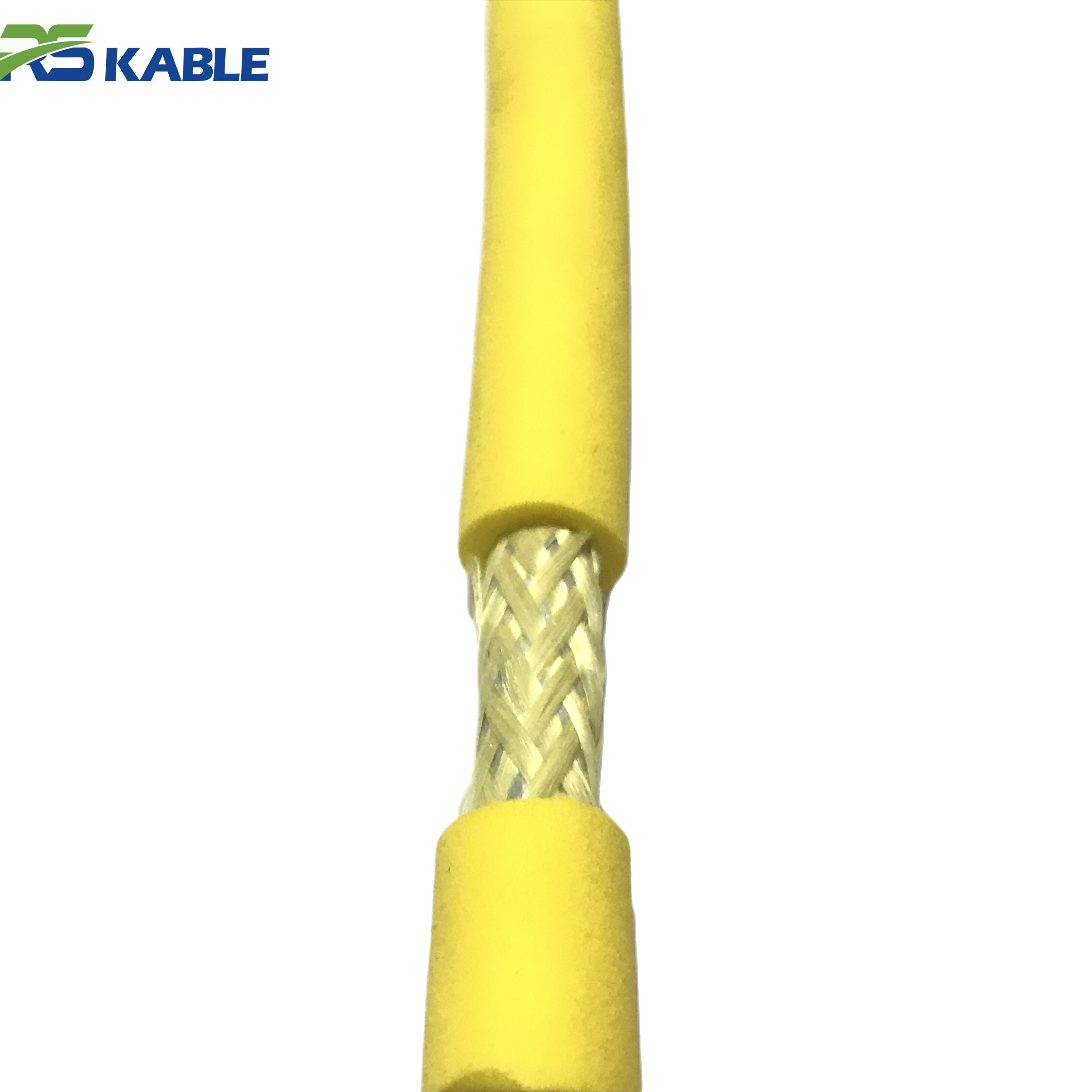

• Structure: Precision foamed insulation combined with high-strength aramid fibers ensures exact neutral buoyancy, compact stowage, and EMI shielding.

• Performance: Highly flexible with bend radius as low as 5–7×OD, supporting extended deployments, stable data, and energy-efficient operations.

• Environment: Optimized for long-term oceanographic research in varying salinity, temperature, and pressure conditions, with custom lengths for AUVs, sensors, and moored instruments.

Oceanographic Research Equipment | Neutral Buoyancy Cable | Lightweight Construction | Custom Length, Flexible Core

Enhance your oceanographic research operations with our high-performance Neutral Buoyancy Cable—engineered for lightweight construction, customizable lengths, and highly flexible cores. Designed to maintain exact neutral buoyancy, this cable ensures minimal drag while delivering reliable power and data transmission for oceanographic instruments, scientific sensors, and autonomous underwater platforms.

Trusted by leading research institutions worldwide, our cables are manufactured under ISO 9001:2015 certified quality systems, fully RoHS and REACH compliant, and optionally certified by ABS, DNV, or Lloyd’s Register for extreme ocean deployment reliability.

Key Benefits of Our Neutral Buoyancy Cable

Our Neutral Buoyancy Cable is optimized for oceanographic research missions, providing:

-

Customizable lengths and cores for integration with diverse sensor platforms and instrument arrays

-

Lightweight construction reducing handling difficulty and hydrodynamic drag

-

Flexible core design for compact stowage and easy deployment from ships or submersible vehicles

-

Exact neutral buoyancy control to avoid tension or compression on moorings and sensor lines

-

High durability with seawater-resistant jackets and abrasion protection

-

Stable electrical and data transmission even in variable salinity and temperature conditions

These advantages make it the preferred choice for long-term oceanographic deployments and scientific instrumentation projects.

Product Models and Core Attributes

| Model | Core Attributes | Conductor / Fiber Configuration | Rated Depth | Outer Diameter | Customization Options |

|---|---|---|---|---|---|

| NB-OR-4P | 4 power cores, lightweight, flexible | 4 × 1.5 mm² tinned Cu | 3,000 m | 16.5 mm | Lengths up to 1,500 m |

| NB-OR-6CS | 6 mixed cores, shielded, flexible | 4 × 1.5 mm² + 2 × 0.75 mm² + optional 2 fiber | 4,000 m | 19.0 mm | Core and fiber customization |

| NB-OR-4FO | 4 power + fiber hybrid, flexible jacket | 4 × 1.0 mm² + 2–4 fiber elements | 5,000 m | 20.5 mm | Fiber type selectable |

| NB-OR-PRO | Heavy-duty flexible core, extended length | 6 × 2.0 mm² + multi-pair + 4–6 fiber | 6,000 m | 24.0 mm | Custom length & outer jacket |

All models feature polyurethane (PUR) or thermoplastic (TPU) jackets optimized for low drag, long-term seawater exposure, and high flexibility.

Applications and Deployment Scenarios

Our Neutral Buoyancy Cable is ideal for oceanographic research equipment and scientific missions:

-

Subsurface moored instruments for long-term ocean monitoring

-

Autonomous and remotely operated research vehicles

-

Environmental and climate observation sensor networks

-

Deep-water oceanography instruments and sampling devices

-

Gliders and hybrid autonomous platforms for long-endurance surveys

-

Marine biology, hydrographic, and geophysical survey deployments

Popular long-tail applications: neutral buoyancy cable for oceanographic research instruments, lightweight flexible tether for deep-sea sensors, custom length neutral buoyancy cable for 5000m ocean deployments.

Technical Specifications

| Parameter | Specification | Standard / Notes |

|---|---|---|

| Conductor | Tinned multi-stranded copper | IEC 60228, Class 5/6 |

| Insulation | Foamed PE or XLPE | Optimized for buoyancy control |

| Optical Fibers | Optional single-mode or multi-mode | High-speed data for scientific instruments |

| Strength Member | Aramid or Kevlar braid | Tensile strength ≥1,800 kg |

| Shielding | Foil + braid (≥85% coverage) | EMI/RFI protection for sensitive instruments |

| Outer Jacket | TPU or PUR, seawater-resistant | UV, abrasion, and biofouling resistant |

| Buoyancy | Neutral in seawater | Density 1.00–1.03 g/cm³ |

| Operating Temperature | –30°C to +70°C | Global oceanographic conditions |

| Voltage Rating | 300/500V standard | Safe for instrument power |

| Certifications | ISO 9001, RoHS, REACH, optional DNV/ABS | Third-party verified performance |

Frequently Asked Questions (FAQ)

Q: Can these cables be customized for specific research equipment?

A: Yes. Length, core count, fiber integration, and jacket type can all be tailored to your deployment requirements.

Q: How is neutral buoyancy maintained in varying salinity?

A: Through precise material density calibration and foamed insulation during manufacturing, ensuring consistent buoyancy.

Q: Are these cables suitable for long-term ocean monitoring?

A: Absolutely. Designed for decades of continuous deployment with high durability against biofouling, corrosion, and mechanical stress.

Q: Can optical fibers be integrated for high-speed scientific data transmission?

A: Yes. Single-mode or multi-mode fiber options are available to meet the bandwidth needs of your instruments.

Q: Is pre-terminated assembly available?

A: Yes. Factory-terminated connectors with full pressure and electrical testing are available for seamless integration.