Oceanographic Instruments | Neutral Buoyancy Cable | Lightweight Build | Reduced Load on Equipment

This Neutral Buoyancy Cable is designed for oceanographic instruments requiring lightweight construction and reduced mechanical load. It supports stable, long-term underwater monitoring while protecting sensitive scientific equipment from excess stress.

Oceanographic Instruments | Neutral Buoyancy Cable | Lightweight Build | Reduced Load on Equipment

Oceanographic instruments are often deployed for extended periods in complex marine environments, where excessive cable weight can compromise measurement accuracy and structural integrity. This Neutral Buoyancy Cable is engineered with a lightweight construction that minimizes mechanical load on scientific instruments while ensuring stable power and data transmission underwater.

By reducing downward force and tension, it supports long-term oceanographic monitoring with improved reliability and lower risk of equipment stress.

The Challenge of Cable-Induced Load in Oceanographic Monitoring

In oceanographic deployments, cables are not just transmission components—they directly affect system performance. Traditional subsea cables can introduce:

-

Excessive vertical load on sensitive instruments

-

Structural stress on housings and mounting frames

-

Measurement drift caused by instrument displacement

-

Increased failure risk during long-term deployment

A lightweight, load-balanced Neutral Buoyancy Cable plays a critical role in preserving instrument accuracy and longevity.

Lightweight Structural Design Philosophy

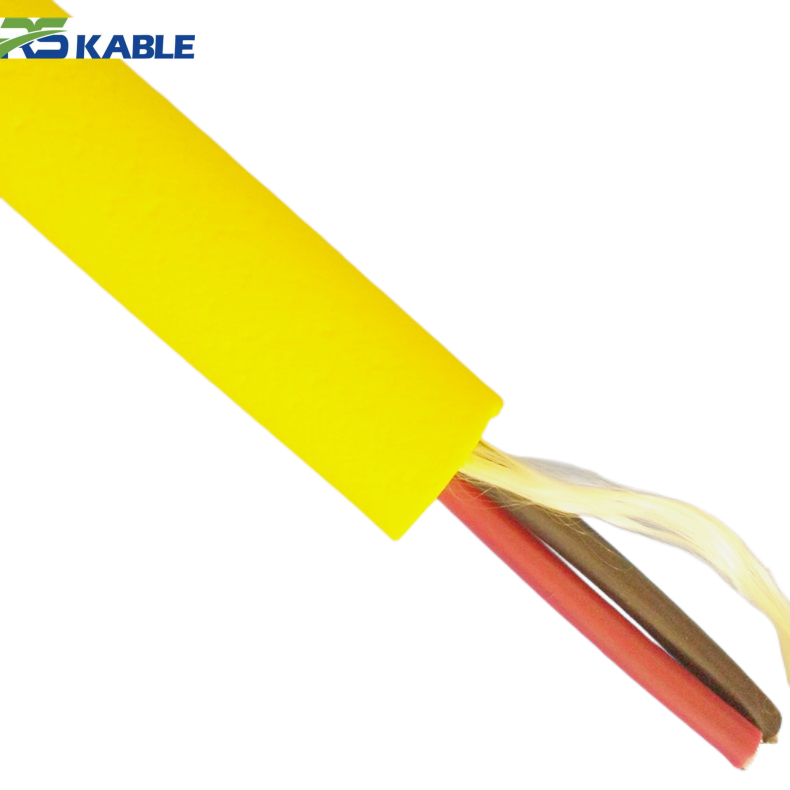

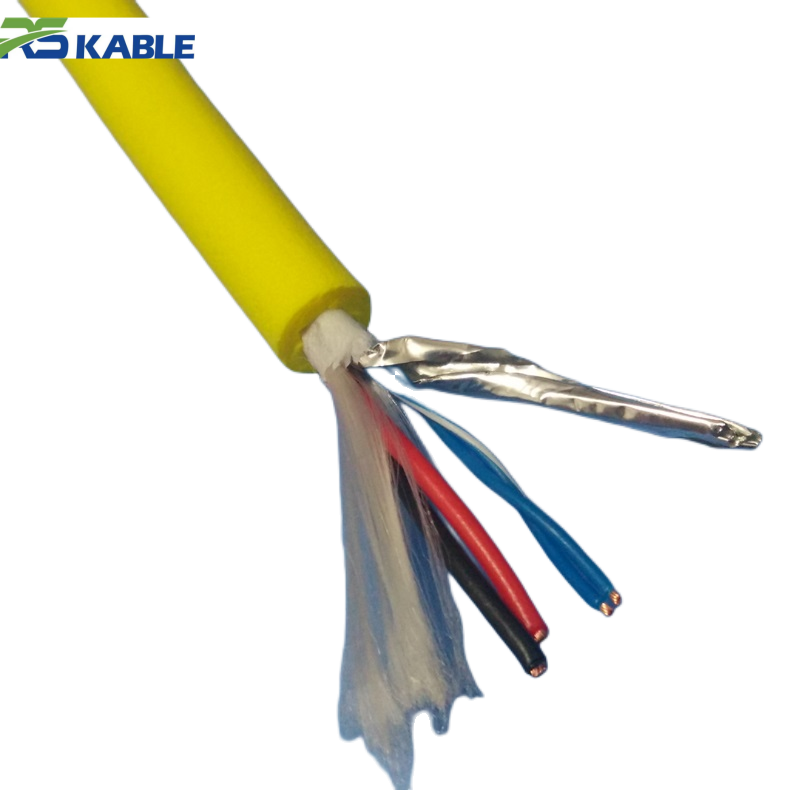

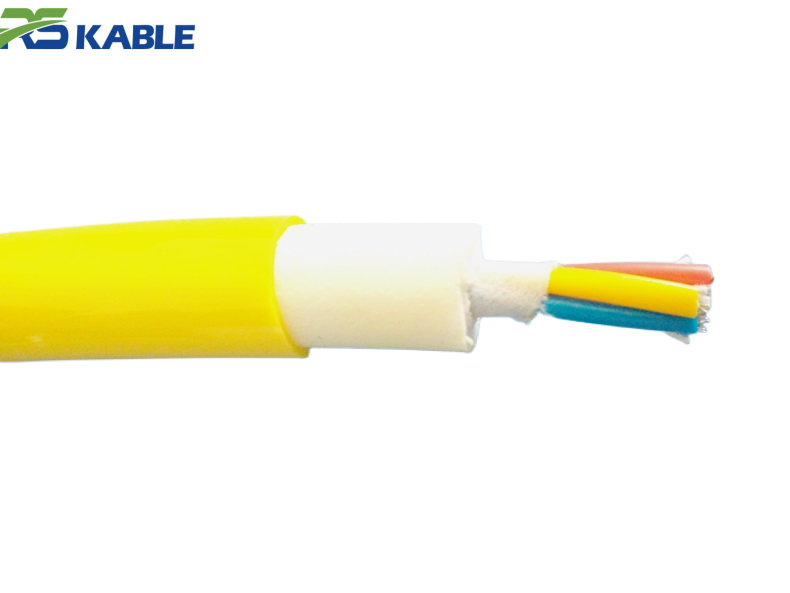

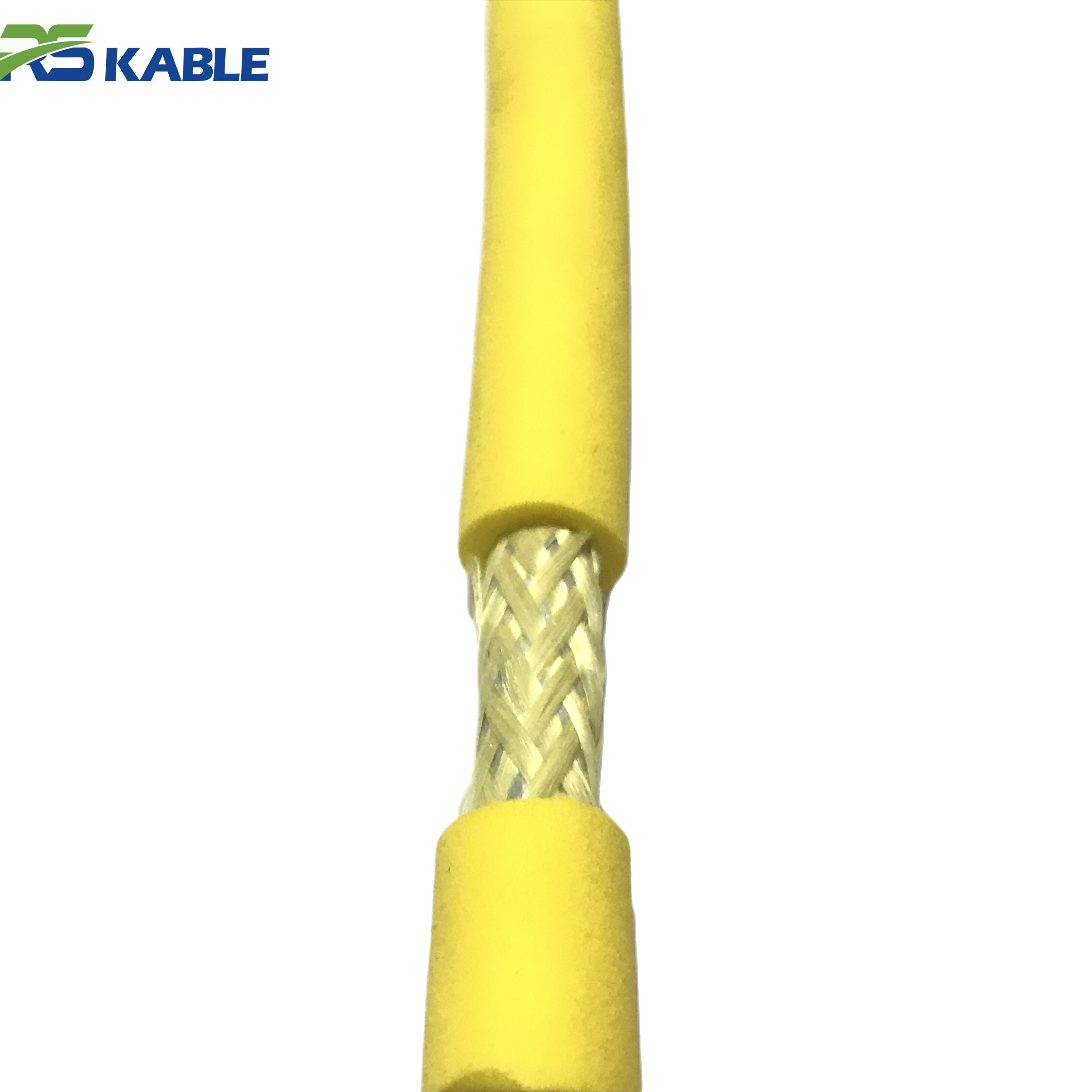

This cable is designed to balance mechanical strength with reduced mass through:

-

Optimized conductor sizing to minimize unnecessary weight

-

Lightweight insulation and filler materials

-

Controlled buoyancy distribution along the cable length

-

Flexible yet robust outer jacket construction

The result is a subsea instrument cable that supports stable deployment without overburdening oceanographic equipment.

Application Scenarios in Oceanographic Systems

This cable solution is widely applied across scientific and environmental monitoring projects, including:

-

CTD (Conductivity, Temperature, Depth) sensor arrays

-

Oceanographic data loggers and monitoring stations

-

Seafloor observatories and moored instrument systems

-

Water quality and environmental sensing platforms

-

Long-term marine research deployments

It is often specified as a lightweight oceanographic cable, instrument-grade subsea cable, or neutral buoyancy sensor cable.

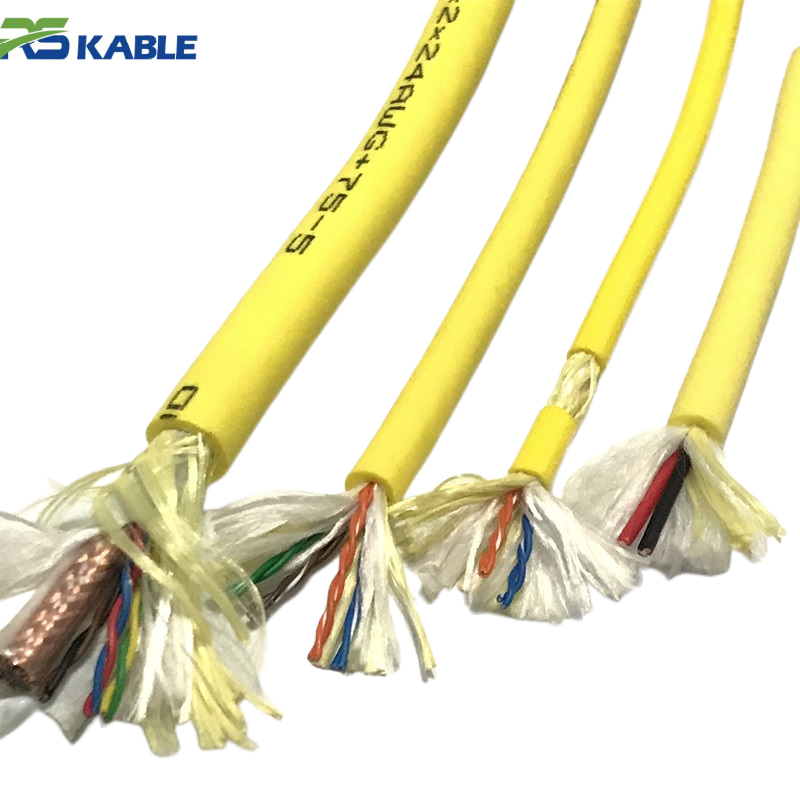

Product Configuration Overview

| Product Name / Model | Core Attributes |

|---|---|

| NB-OC Series Neutral Buoyancy Cable | Lightweight build, reduced equipment load, instrument-optimized |

Key Technical Parameters

| Parameter | Specification Options |

|---|---|

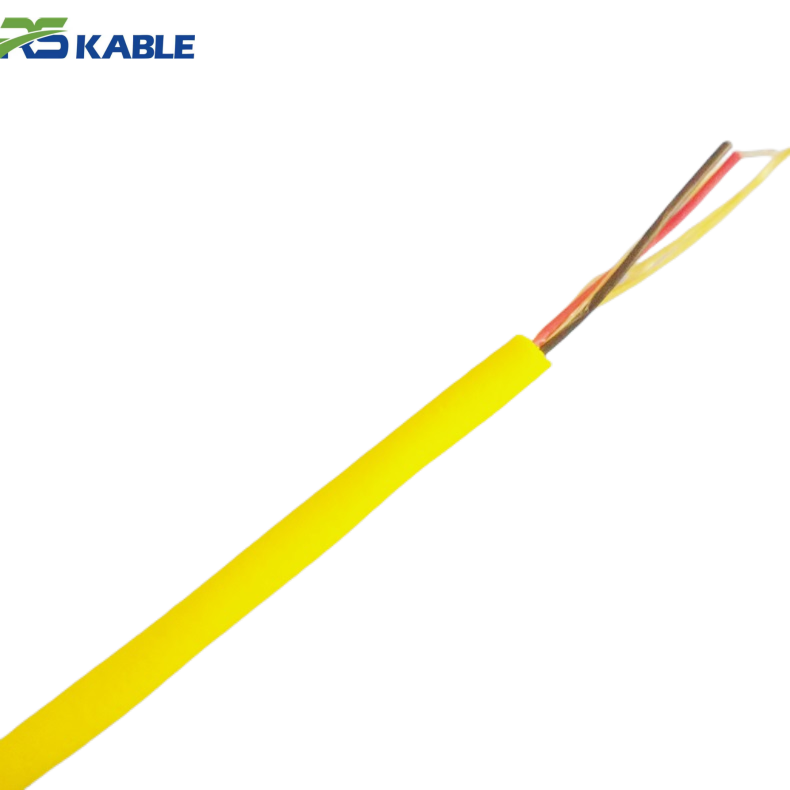

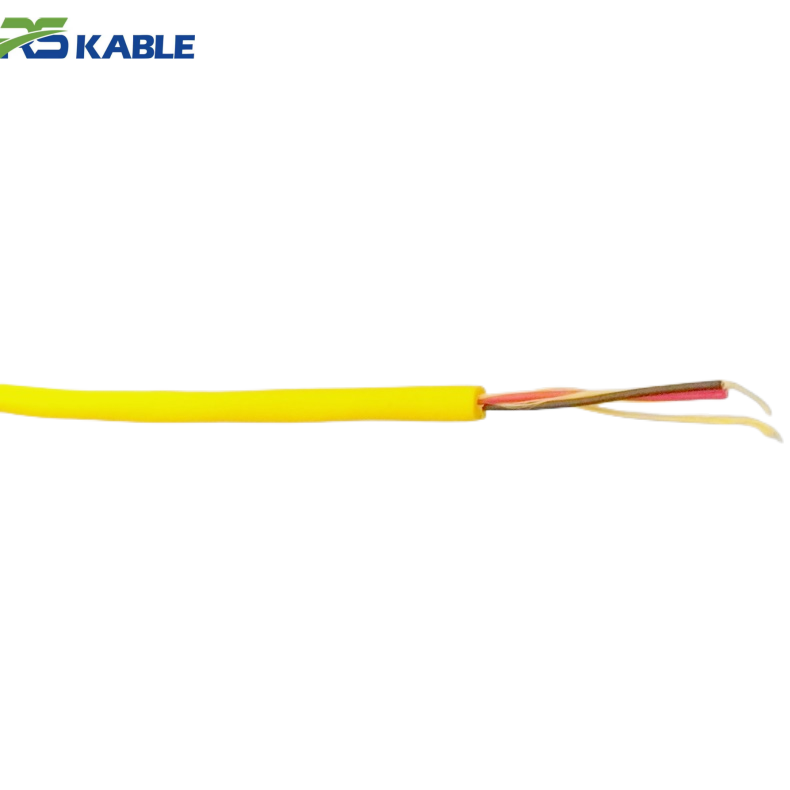

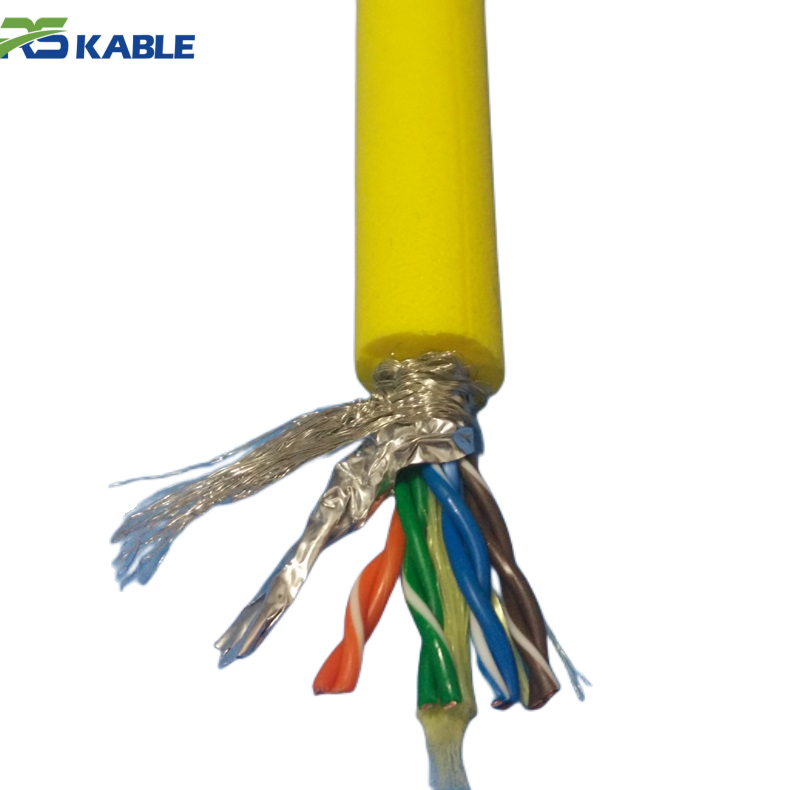

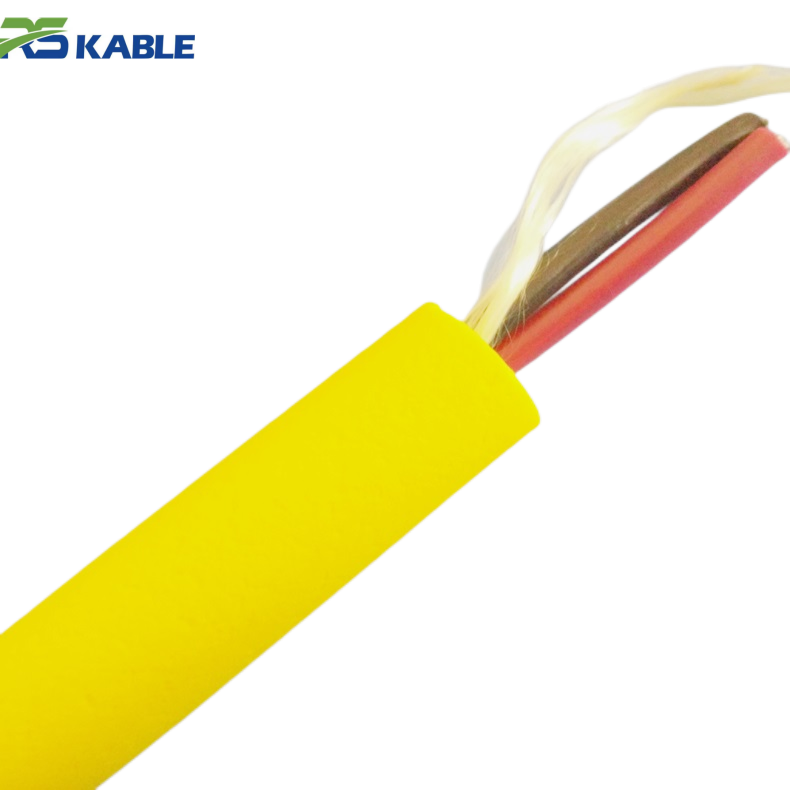

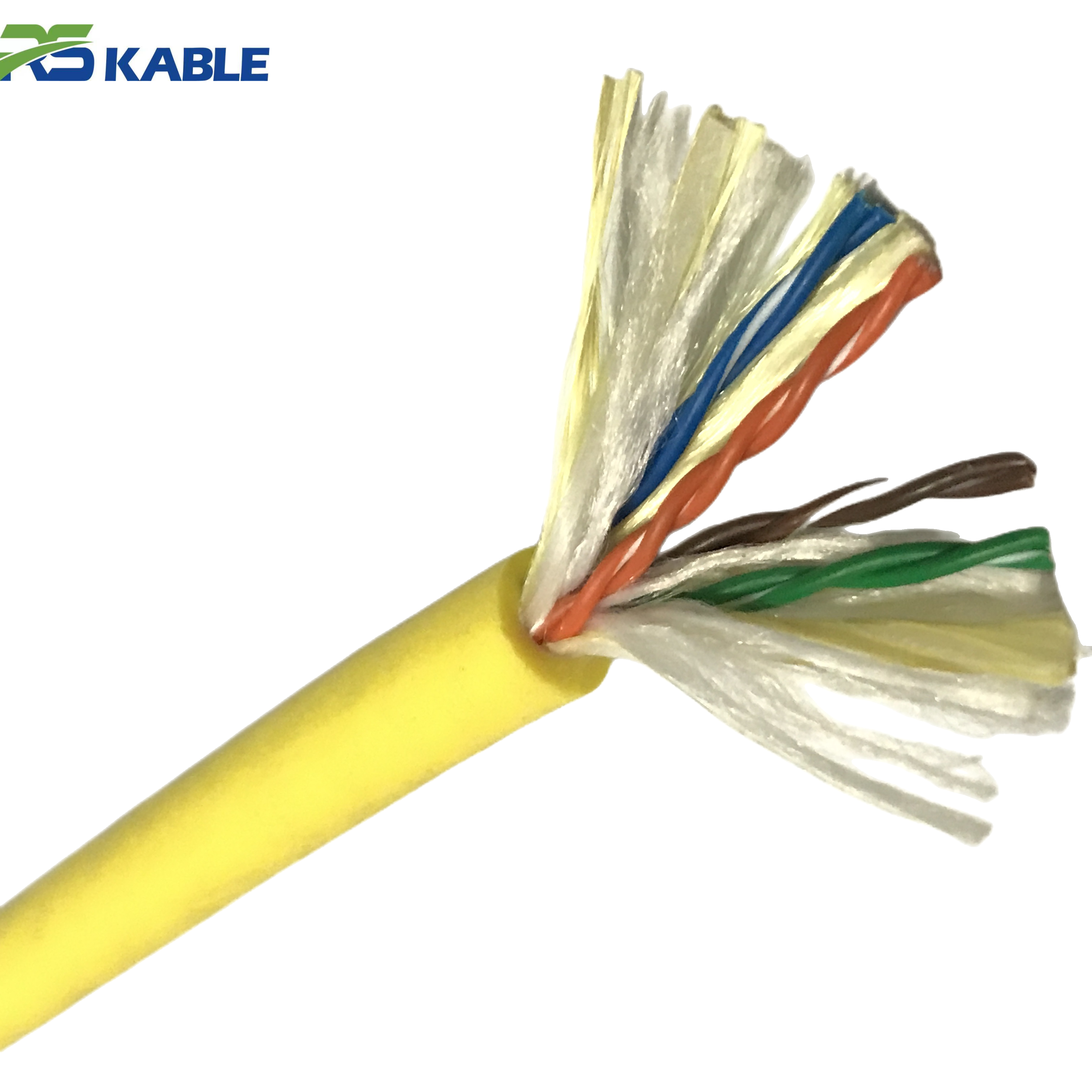

| Core Configuration | Signal cores, power cores, or hybrid layouts |

| Conductor Material | Fine-stranded tinned copper |

| Insulation | Lightweight PE / XLPE compounds |

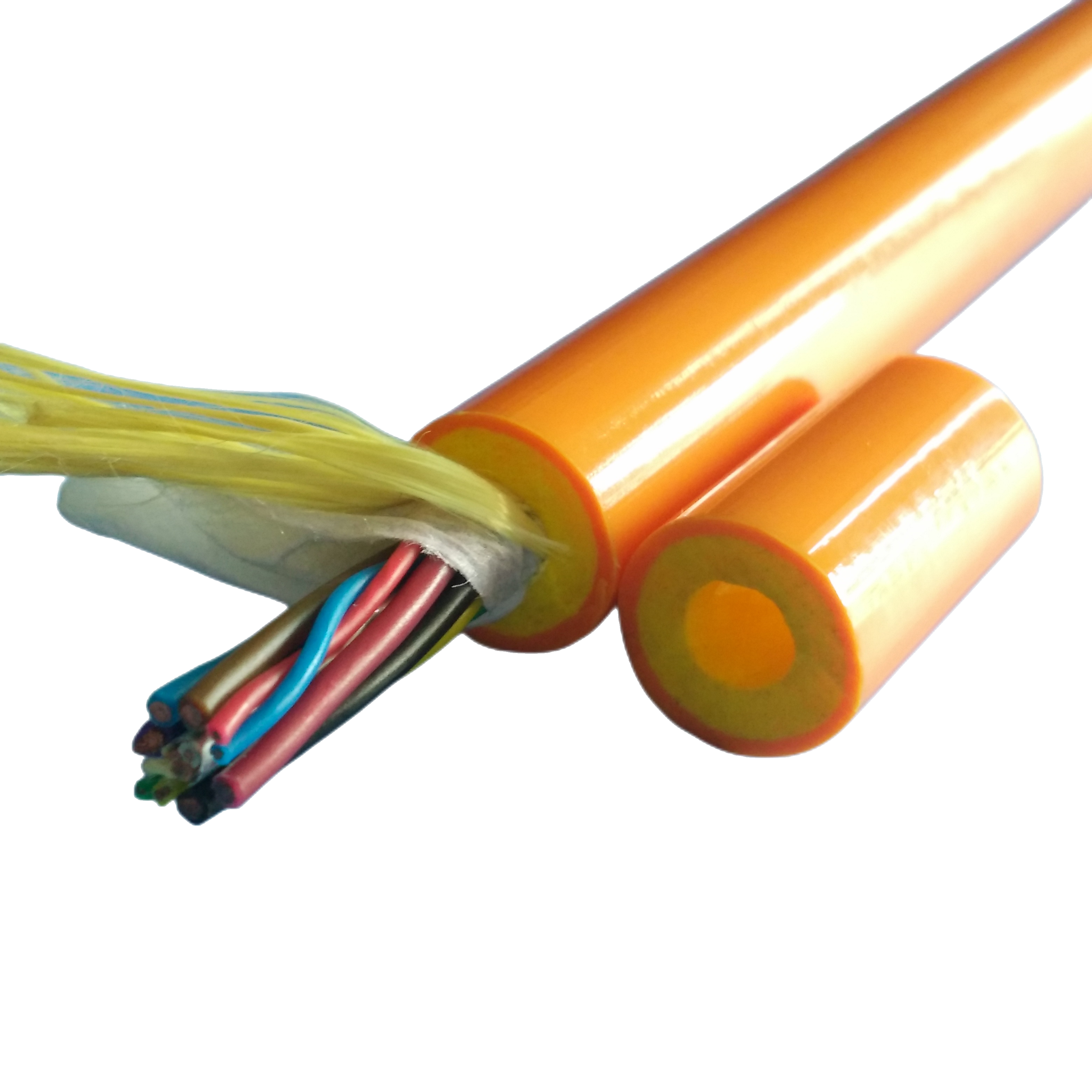

| Buoyancy Design | Precision-balanced fillers for near-neutral buoyancy |

| Outer Jacket | Marine-grade lightweight polyurethane |

| Mechanical Load Impact | Designed to minimize vertical and lateral instrument stress |

| Deployment Environment | Long-term oceanographic monitoring (freshwater & seawater) |

Cable diameter, core count, and buoyancy balance can be customized to match specific instrument sensitivity and deployment depth.

Reduced Load, Improved Measurement Stability

By using a Neutral Buoyancy Cable, oceanographic instruments experience:

-

Lower static and dynamic mechanical stress

-

Improved positional stability during currents

-

Reduced risk of mounting fatigue or deformation

-

More consistent data collection over time

These benefits are particularly valuable in long-duration scientific observation missions.

Advantages for Research Institutions & Integrators

Choosing this cable provides measurable operational benefits:

-

Extended service life of oceanographic instruments

-

Reduced maintenance and retrieval frequency

-

Improved deployment safety and predictability

-

Enhanced data reliability in sensitive measurements

This makes it suitable for both academic research programs and commercial marine monitoring projects.

Engineering Expertise & Quality Assurance (E-E-A-T)

-

Developed by engineers specializing in oceanographic cable systems

-

Manufactured under ISO-certified quality control processes

-

Tested for buoyancy balance, mechanical load impact, and electrical stability

-

Materials selected based on long-term scientific deployment requirements

Design decisions are informed by real-world oceanographic use cases.

Custom Engineering & Procurement Support

We support oceanographic researchers and system integrators with:

-

Cable weight and load optimization consultation

-

Custom signal and power configurations

-

Deployment environment assessment support

-

Technical documentation for project validation

👉 Contact our technical team to specify a cable optimized for your oceanographic instruments.

FAQ

Why is reduced cable load important for oceanographic instruments?

Lower cable load reduces mechanical stress and helps maintain accurate instrument positioning.

Is this cable suitable for long-term underwater deployment?

Yes. It is designed for extended monitoring applications.

Can it be customized for different sensors?

Yes. Core configuration and buoyancy can be tailored to specific instruments.

Does lightweight construction compromise durability?

No. Materials are selected to balance reduced weight with mechanical reliability.