Integrated Power & Control Solutions | ROV Cable | Power + Signal Combination | Efficient System Integration

This integrated ROV Cable combines electrical power transmission and control signal communication into a single streamlined tether system. Designed for efficient system integration, it reduces deck complexity while maintaining stable voltage delivery and low-noise data transfer. Featuring tinned copper conductors, reinforced aramid strength members, and a marine-grade outer jacket, it is suitable for inspection-class and work-class ROV platforms. Optional fiber optic modules enable high-bandwidth video and telemetry transmission, making it ideal for offshore, industrial, and scientific underwater operations.

Integrated Power & Control Solutions | ROV Cable | Power + Signal Combination | Efficient System Integration

The ROV Cable in this integrated power and control series is engineered to combine electrical supply and signal transmission within a single compact tether system. Designed for efficient system integration, this hybrid subsea solution reduces installation complexity, optimizes deck space, and enhances operational stability for inspection-class and work-class remotely operated vehicles.

By integrating power cores and communication lines into one structured assembly, this ROV Cable improves deployment efficiency while maintaining electrical integrity and signal clarity under demanding underwater conditions.

Why Choose an Integrated Power + Signal ROV Tether?

Modern underwater systems require streamlined connectivity. A combined power-and-control tether offers:

-

Reduced cable bulk and simplified system layout

-

Lower drag during deployment and retrieval

-

Stable voltage transmission with minimal attenuation

-

Shielded signal cores for low electromagnetic interference

-

Improved compatibility with control consoles and topside winches

This configuration supports seamless integration between subsea vehicles, topside control units, and monitoring systems.

Product Portfolio Overview

| Model Code | Product Name (Model + Core Attribute) | Application Scenario | Key Technical Parameters |

|---|---|---|---|

| IPC-ROV-6P2S | 6-Core Power + 2 Signal Integrated Cable | Light inspection ROV systems | 6 × 2.5 mm² power + 2 × twisted pair, 600 m depth |

| IPC-ROV-4P4S | Balanced Power & Control Hybrid Tether | Subsea tooling & camera systems | 4 × 4.0 mm² + 4 shielded signal cores, 1,000 m |

| IPC-ROV-HF | Power + Fiber Combination Cable | HD video & telemetry systems | 2 × 4.0 mm² + 2–4 optical fibers, 1,500 m |

| IPC-ROV-AR | Reinforced Integrated ROV Cable | Work-class ROV operations | Multi-core + aramid strength member, 2,000 m |

Each model is customizable in length, voltage class, shielding level, and tensile rating.

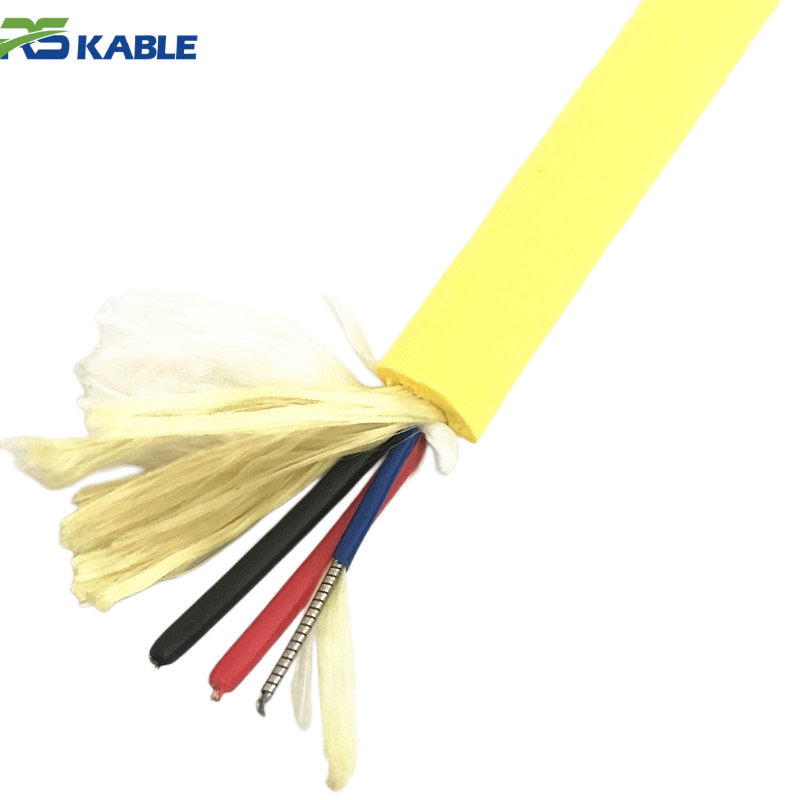

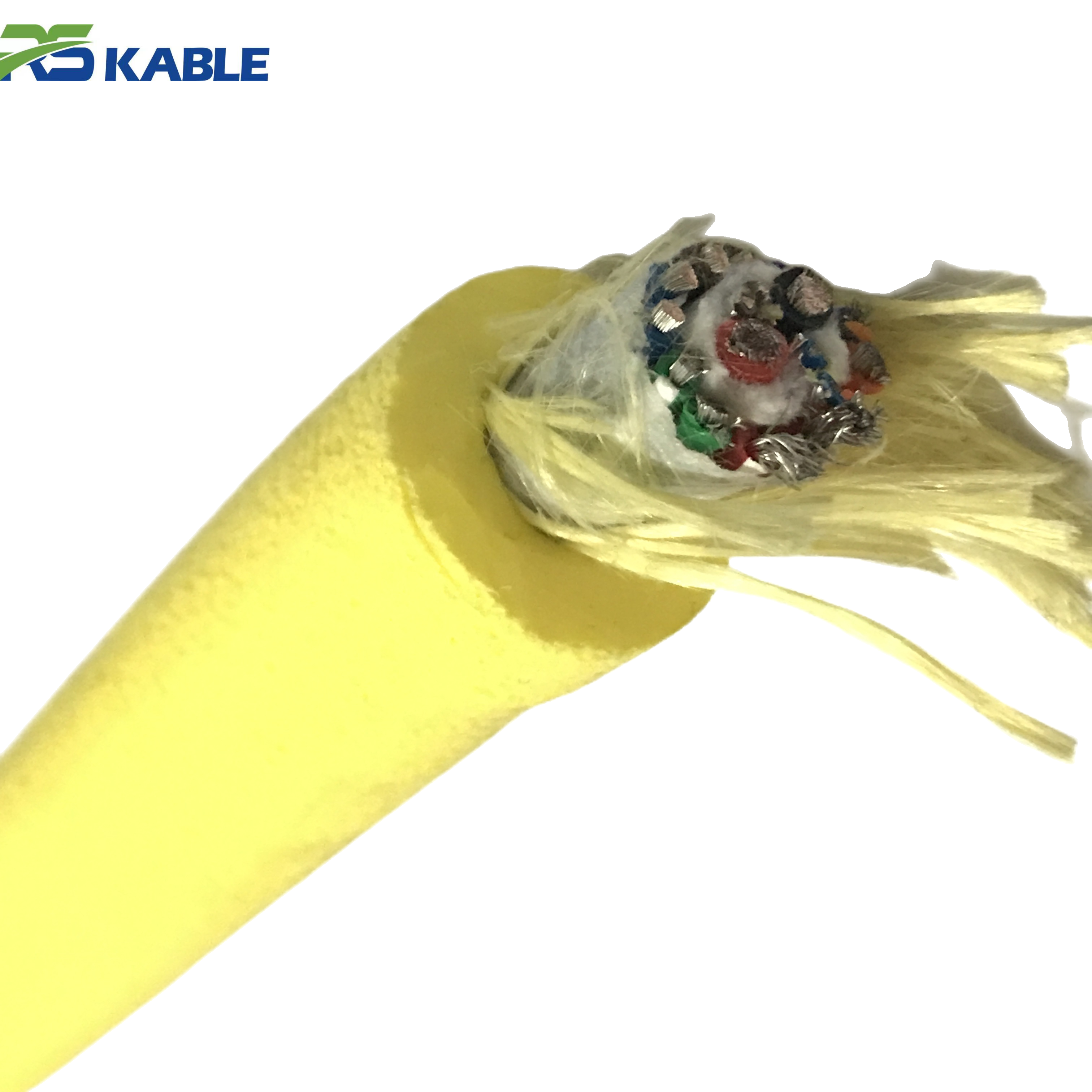

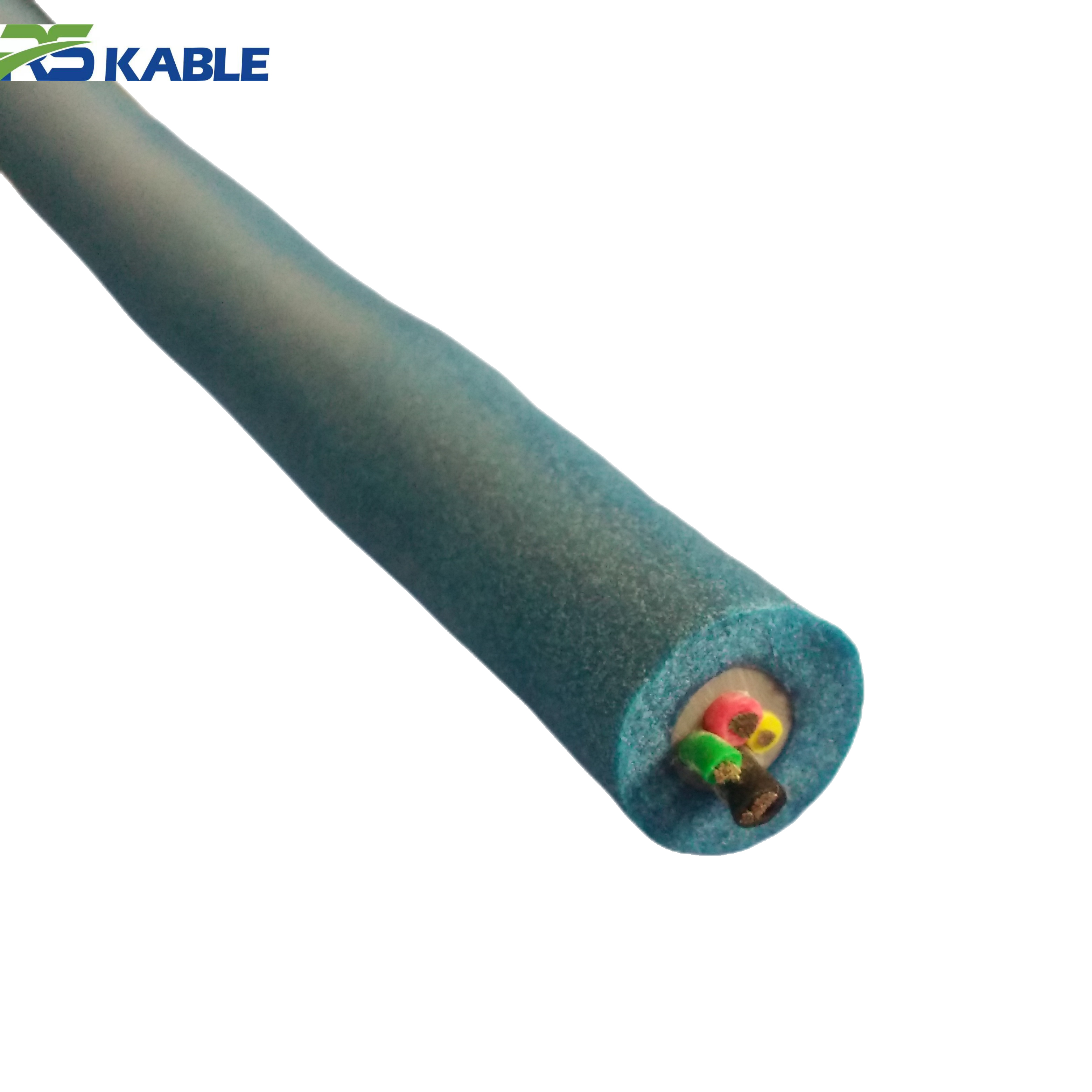

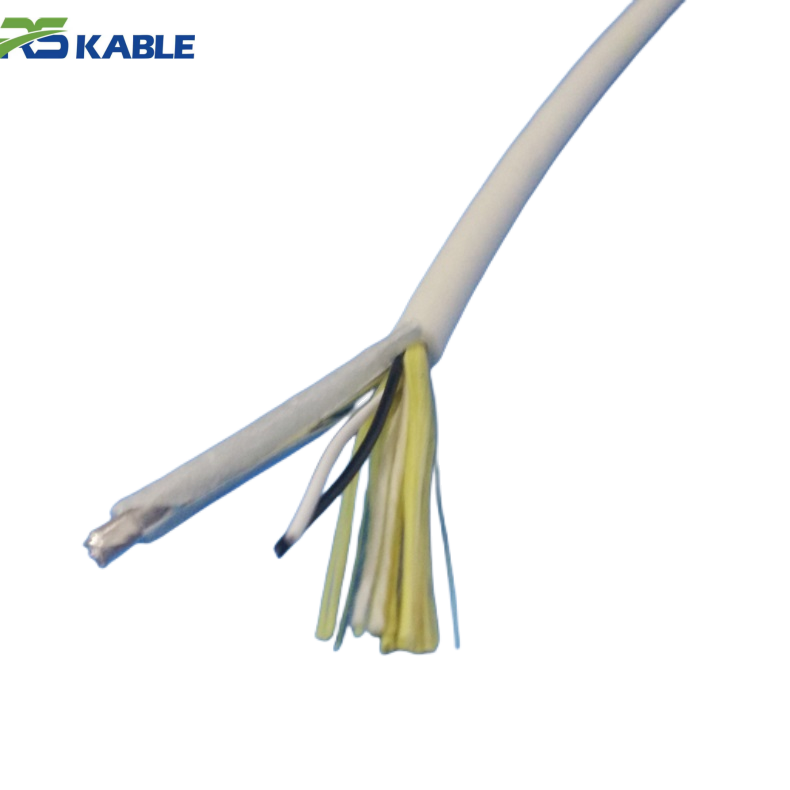

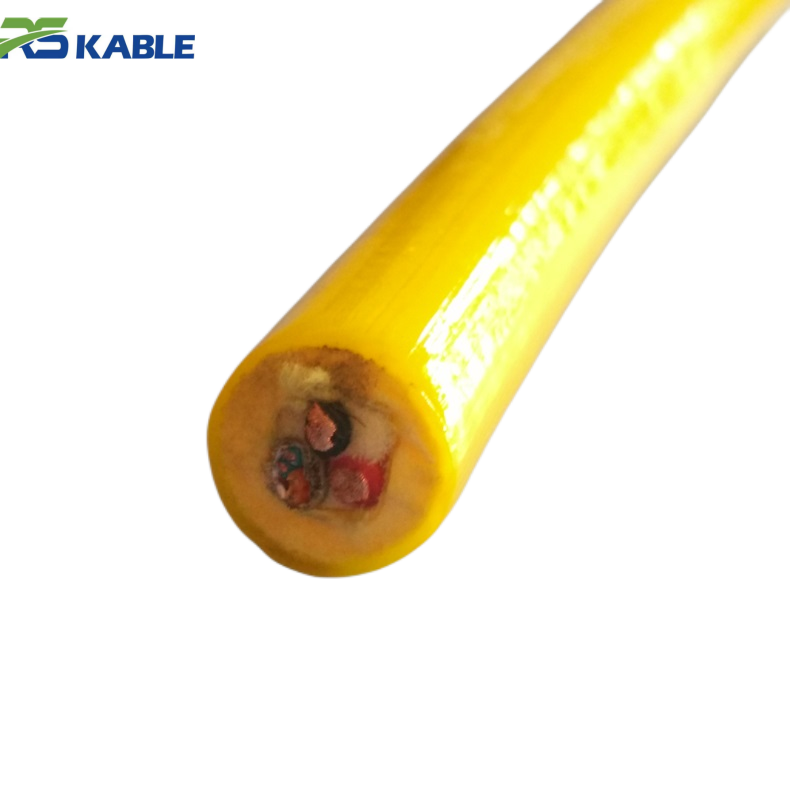

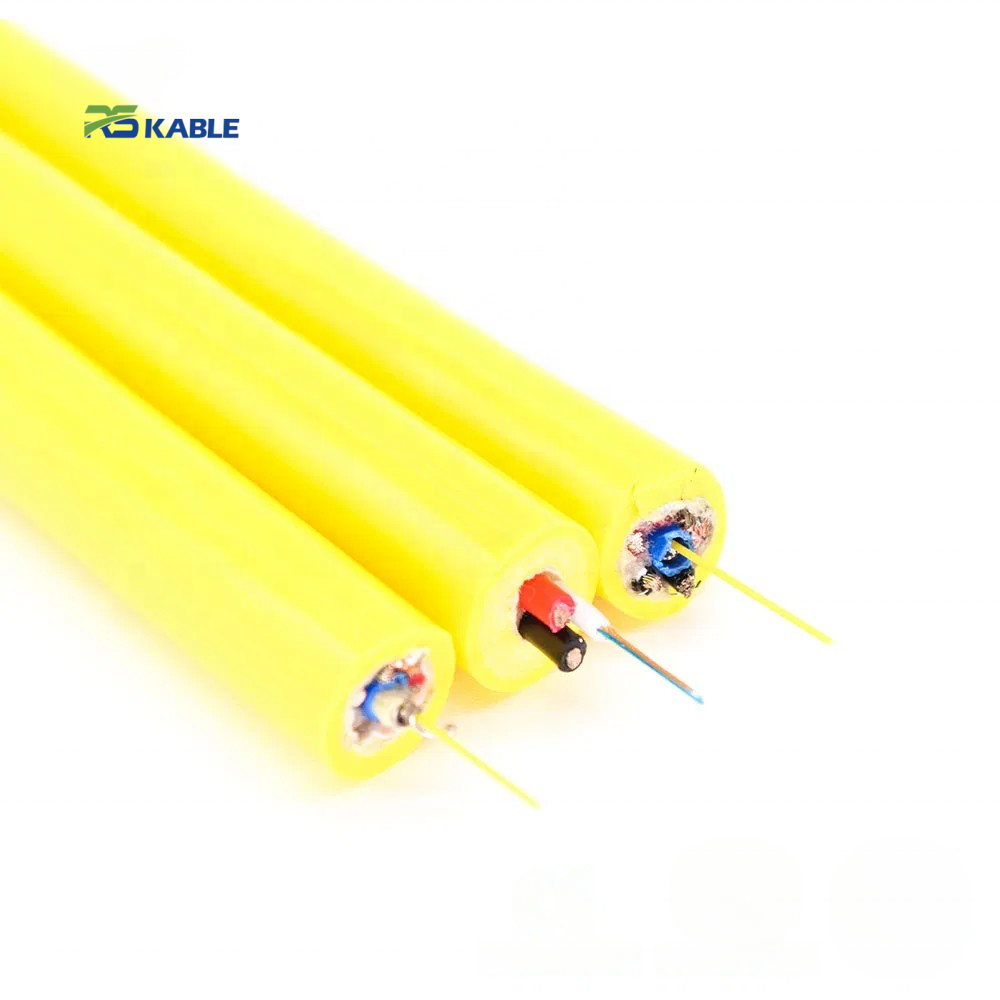

Structural Design & Material Composition

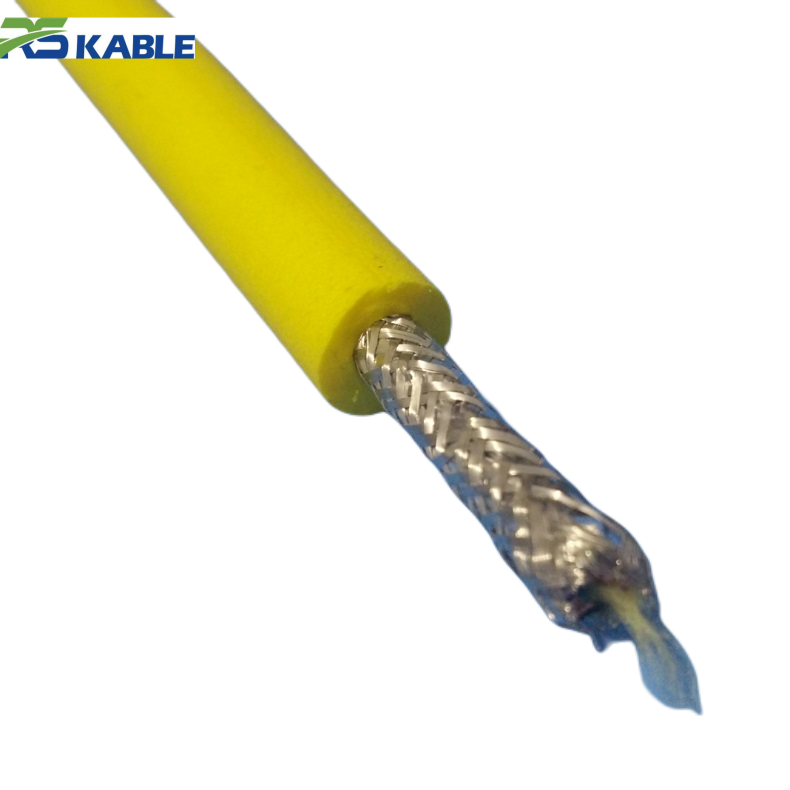

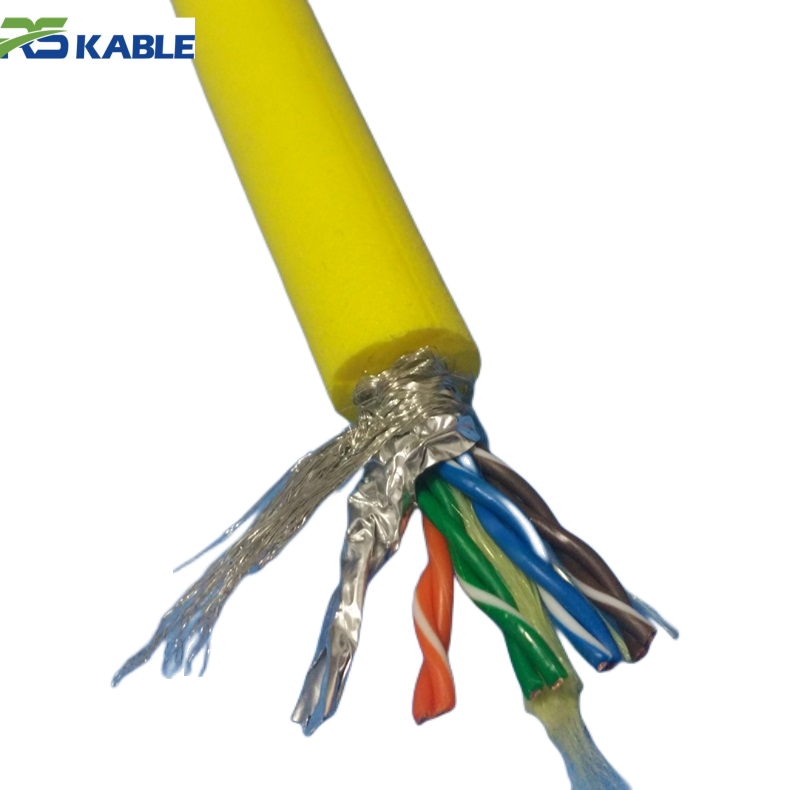

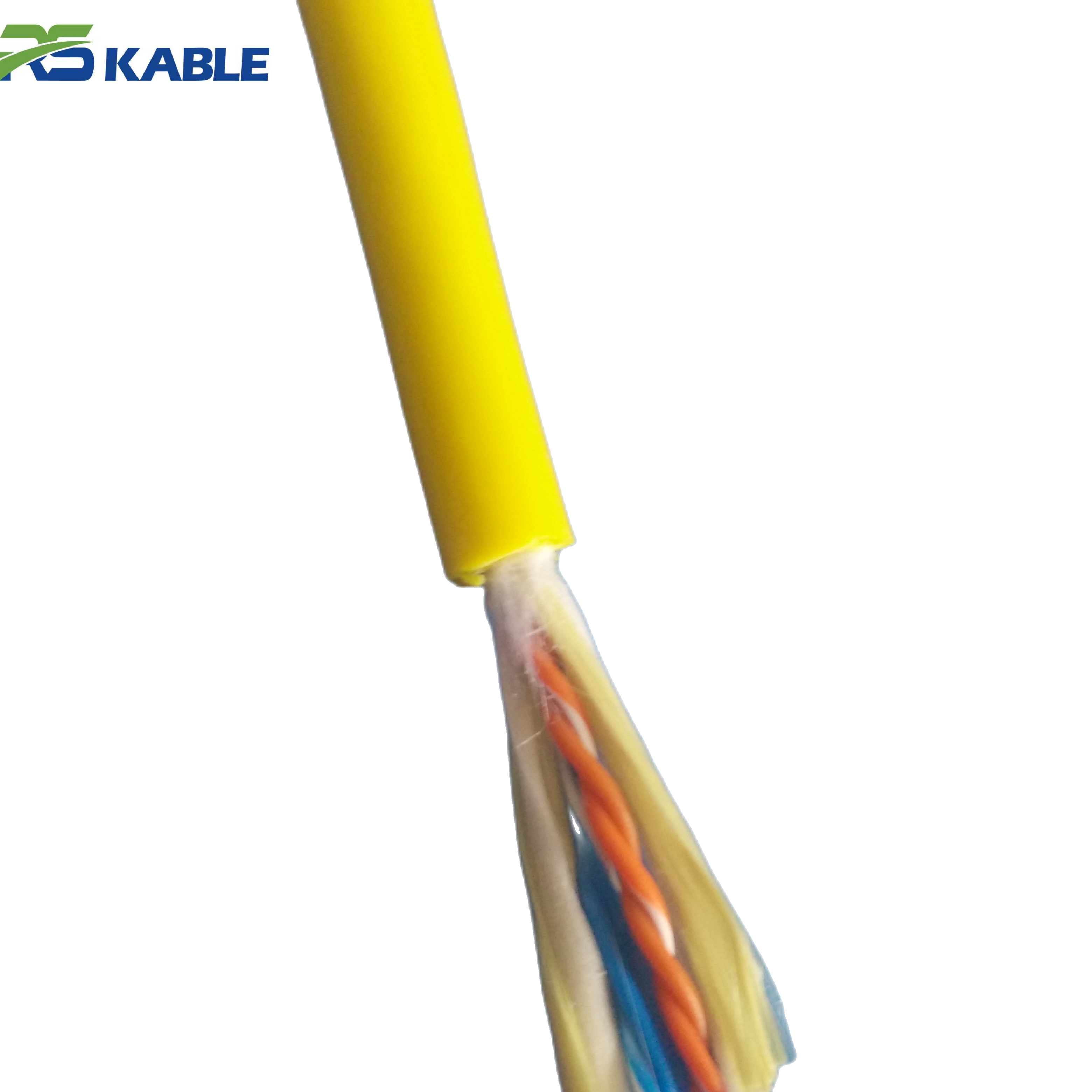

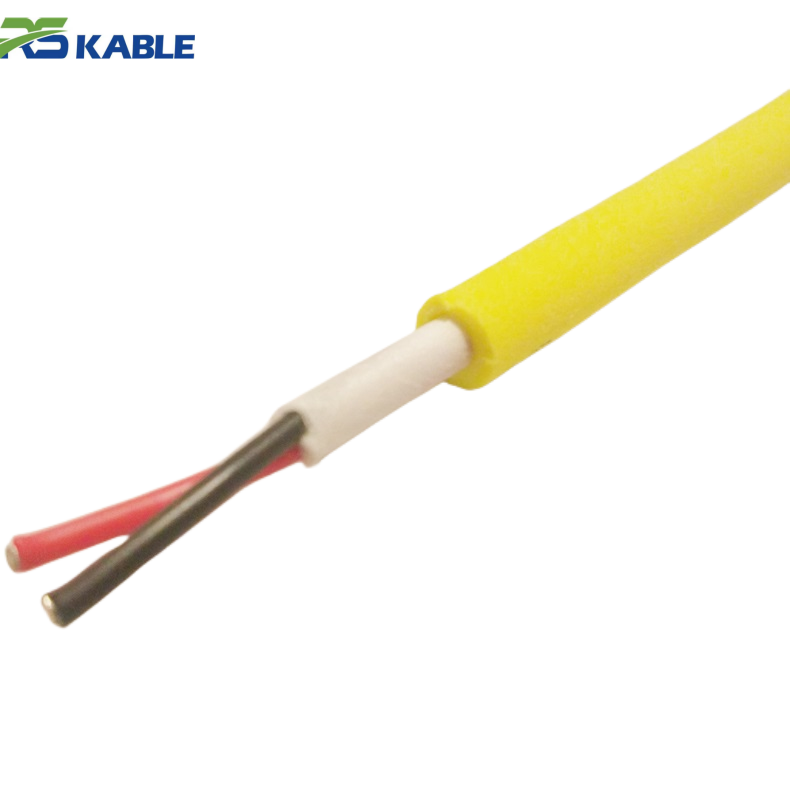

Conductor System

-

Fine-stranded tinned copper (IEC Class 5)

-

Optimized cross-sectional area for voltage stability

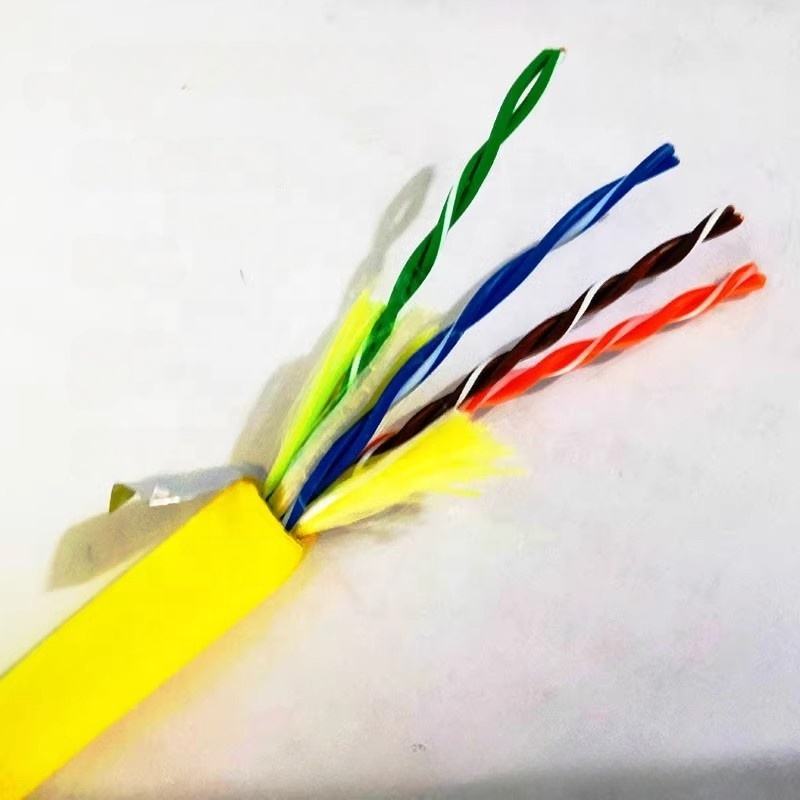

Signal & Data Layer

-

Twisted pair with aluminum foil shielding

-

Optional fiber optic module (single-mode or multi-mode)

Reinforcement

-

Aramid yarn strength member

-

Central load-bearing core for tensile protection

Outer Jacket

-

Marine-grade TPU or PUR

-

Abrasion-resistant, hydrolysis-resistant, UV-stable

Electrical Rating

-

Voltage: 300/500V to 0.6/1kV

-

Operating temperature: –30°C to +80°C

This ROV Cable structure ensures electrical performance without compromising flexibility or durability.

Application Scenarios

Integrated power and control tethers are widely used in:

-

Offshore oil & gas inspection

-

Subsea infrastructure maintenance

-

Harbor and port security monitoring

-

Marine renewable energy projects

-

Scientific oceanographic surveys

-

Pipeline and cable inspection

Long-tail keyword focus:

“power and signal ROV cable for subsea inspection,”

“hybrid ROV tether with fiber optic core,”

“integrated control cable for work-class ROV systems.”

Performance Advantages

-

Compact Integration – Eliminates the need for separate power and data lines.

-

Reduced Installation Time – Single-cable deployment architecture.

-

Signal Integrity – Shielded structure minimizes cross-talk and EMI.

-

Mechanical Strength – Designed for high-tension subsea operations.

-

System Compatibility – Suitable for modern ROV consoles and winch systems.

The integrated design enhances overall subsea system reliability while simplifying maintenance workflows.

Quality Assurance & Engineering Support

-

Manufactured under ISO 9001-certified quality management systems

-

100% electrical continuity testing before shipment

-

Tensile and bend-cycle testing conducted per batch

-

Material compliance: RoHS & REACH

-

Engineering consultation for custom configurations

Our technical team provides load calculation support, voltage drop analysis, and integration guidance tailored to your ROV platform.

Request a System Integration Consultation

Looking to streamline your subsea connectivity? Our integrated ROV Cable solutions are configurable to match voltage requirements, communication protocols, and operational depth.

👉 Contact our engineering team today for a tailored quotation and technical proposal.

Frequently Asked Questions (FAQ)

Q1: Can power and fiber optic cores be combined in one cable?

Yes. Hybrid electro-optical configurations are available depending on bandwidth and voltage requirements.

Q2: What depth ratings are supported?

Standard models range from 600 m to 2,000 m, with customization available.

Q3: How is signal interference controlled?

Shielded twisted pairs and optional braided layers reduce electromagnetic interference.

Q4: Is the cable compatible with work-class ROV systems?

Yes, reinforced models are designed for high-tension, heavy-duty subsea operations.

Q5: Can cable length and core configuration be customized?

Absolutely. Length, conductor size, shielding, and reinforcement can be tailored.