Industrial 8-Core Shielded Twisted Pair Drag Chain Cable, TRVVPS Servo Encoder Cable

Industrial 8-core shielded twisted pair drag chain cable designed for servo motor and encoder systems, offering high flexibility, excellent EMI protection, and stable signal transmission in continuous-motion industrial applications.

. High-flex drag chain rated design

. Shielded twisted pair structure for EMI resistance

. Reliable servo and encoder signal transmission

. Durable jacket for industrial environments

. Suitable for CNC, robotics, and automation systems

The Industrial 8-Core Shielded Twisted Pair Drag Chain Cable, TRVVPS Servo Encoder Cable is engineered for reliable signal transmission in high-motion industrial environments. Designed specifically for servo motor and encoder applications, this cable combines a robust shielded twisted-pair structure with a high-flex drag chain jacket to ensure stable performance under continuous movement, bending, and electrical interference.

Developed and manufactured by Shanghai Rosheng Cable Co., Ltd., a specialized manufacturer with extensive experience in high-flex drag chain and special industrial cables, this product reflects a deep understanding of real-world automation demands across CNC machinery, robotics, and intelligent production lines.

Why This Cable Matters in Servo and Encoder Systems

In modern automation systems, signal integrity is critical. Servo motors and encoders operate in environments where electromagnetic interference, mechanical stress, and long operating hours are unavoidable. The Industrial 8-Core Shielded Twisted Pair Drag Chain Cable, TRVVPS Servo Encoder Cable is designed to address these challenges directly.

Its multi-pair twisted structure reduces crosstalk, while the overall shielding layer minimizes EMI, ensuring precise feedback signals and stable servo control even in electrically noisy installations.

Key Product Features

High-Flex Drag Chain Design

-

Optimized for continuous movement and repetitive bending

-

Suitable for drag chain systems with tight bending radii

-

Excellent fatigue resistance for long service life

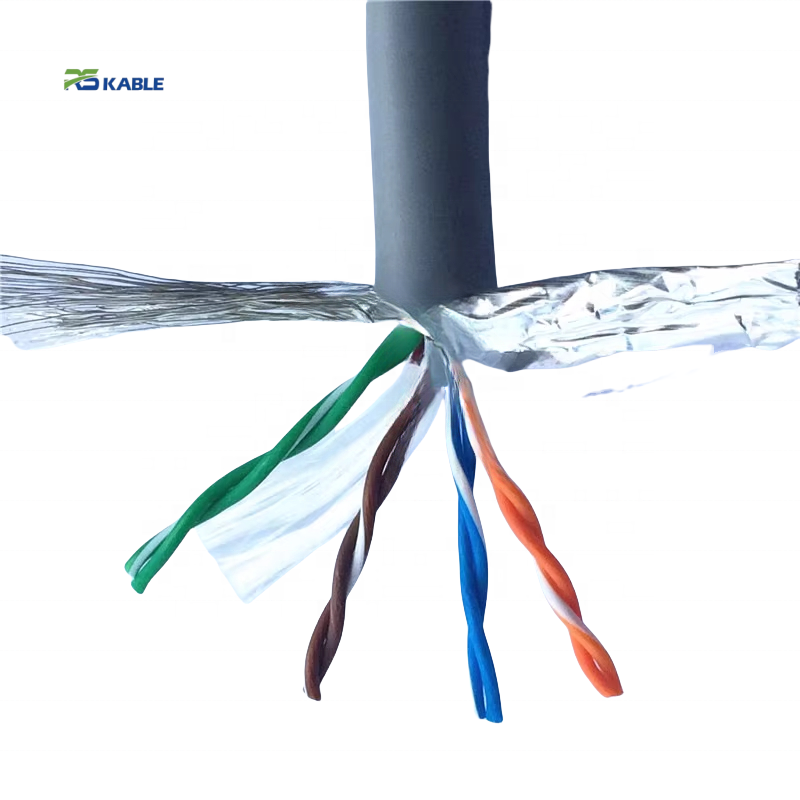

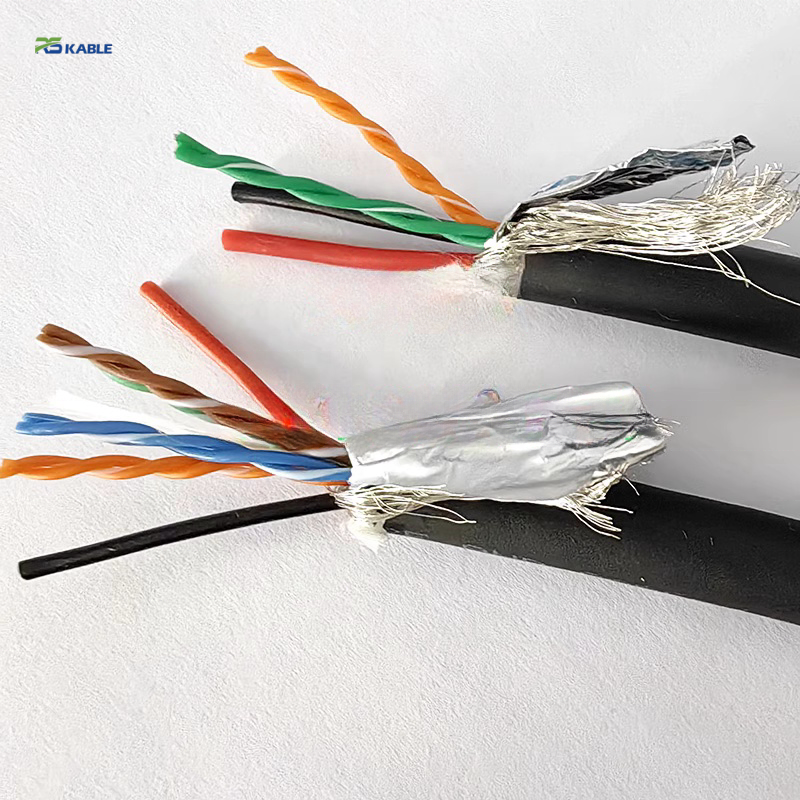

Shielded Twisted Pair Structure

-

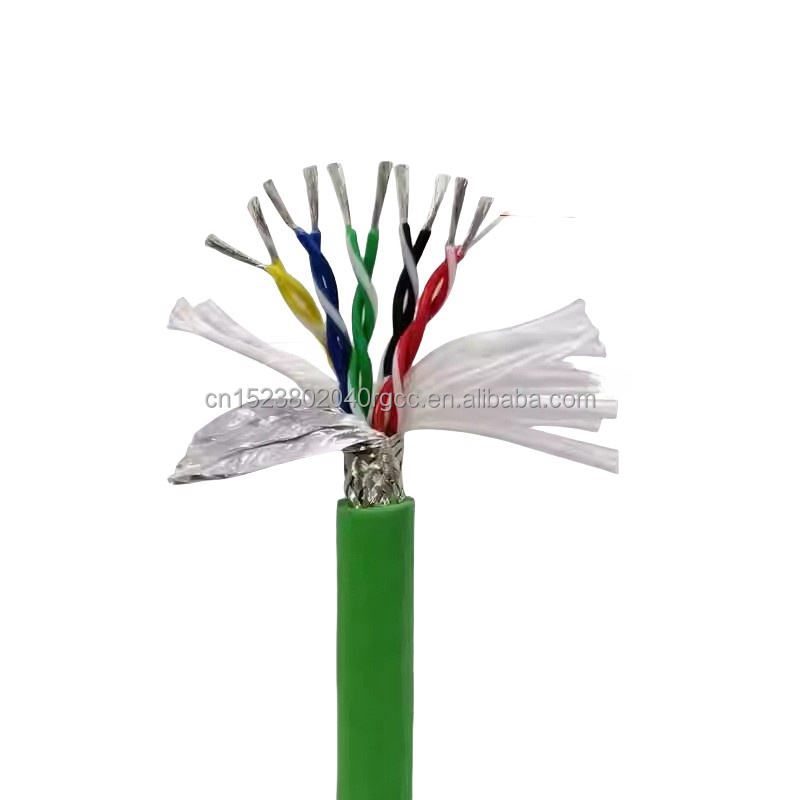

8-core configuration arranged in precision twisted pairs

-

Aluminum foil and braided shielding for effective EMI protection

-

Maintains signal accuracy for encoders and control systems

Industrial-Grade Materials

-

High-purity stranded copper conductors for stable conductivity

-

Durable outer jacket with resistance to oil, abrasion, and mechanical stress

-

Consistent performance in demanding industrial environments

Reliable for Servo & Encoder Applications

-

Designed for servo motor signal transmission and encoder feedback

-

Supports stable data communication in automation equipment

-

Compatible with TRVVPS cable structure requirements

Typical Applications

The Industrial 8-Core Shielded Twisted Pair Drag Chain Cable, TRVVPS Servo Encoder Cable is widely used in:

-

CNC machine tools

-

Industrial robots and robotic arms

-

Automated production lines

-

Packaging and material handling equipment

-

Motion control and positioning systems

Its construction makes it particularly suitable for applications requiring both electrical stability and mechanical durability.

Technical Specifications (Typical)

| Parameter | Specification |

|---|---|

| Conductor | Stranded bare copper |

| Core Count | 8 cores |

| Structure | Shielded twisted pairs |

| Shielding | Aluminum foil + braided shield |

| Jacket Type | High-flex industrial PVC / special compound |

| Motion Type | Drag chain, continuous flex |

| Application | Servo motor & encoder signal transmission |

Custom conductor sizes, jacket materials, and shielding options are available upon request.

Manufacturing Expertise You Can Trust

Shanghai Rosheng Cable Co., Ltd. focuses exclusively on the R&D, production, and service of high-flex drag chain cables and special industrial cables, offering more than 100 cable varieties. Every Industrial 8-Core Shielded Twisted Pair Drag Chain Cable, TRVVPS Servo Encoder Cable is manufactured with strict process control to ensure consistency, durability, and performance reliability.

Frequently Asked Questions (FAQ)

Q1: Is this cable suitable for continuous motion applications?

Yes. This cable is specifically designed for drag chain systems and continuous flexing, ensuring long service life under repetitive movement.

Q2: How does the shielding improve performance?

The shielding structure reduces electromagnetic interference and signal noise, helping maintain accurate encoder feedback and stable servo control.

Q3: Can this cable be customized?

Yes. Core structure, jacket material, color, and shielding configuration can be customized based on project requirements.

Q4: What industries commonly use this cable?

It is commonly used in CNC machining, robotics, industrial automation, packaging equipment, and motion control systems.