High‑Tensile Neutral Buoyancy ROV Umbilical Cable | Flexible Subsea Robotics Tether Cable

-

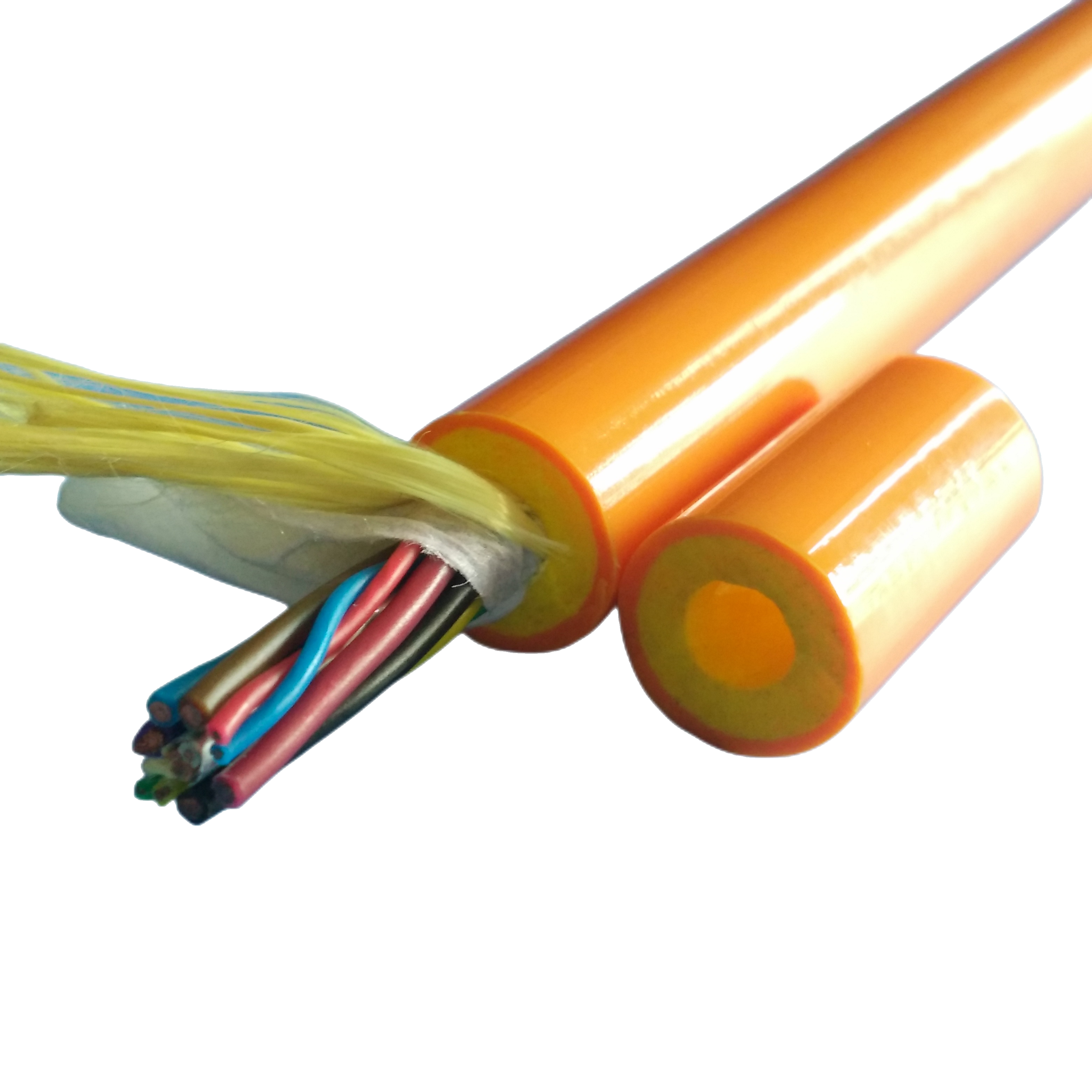

High‑Tensile Neutral Buoyancy ROV Umbilical Cable designed for subsea robotics.

-

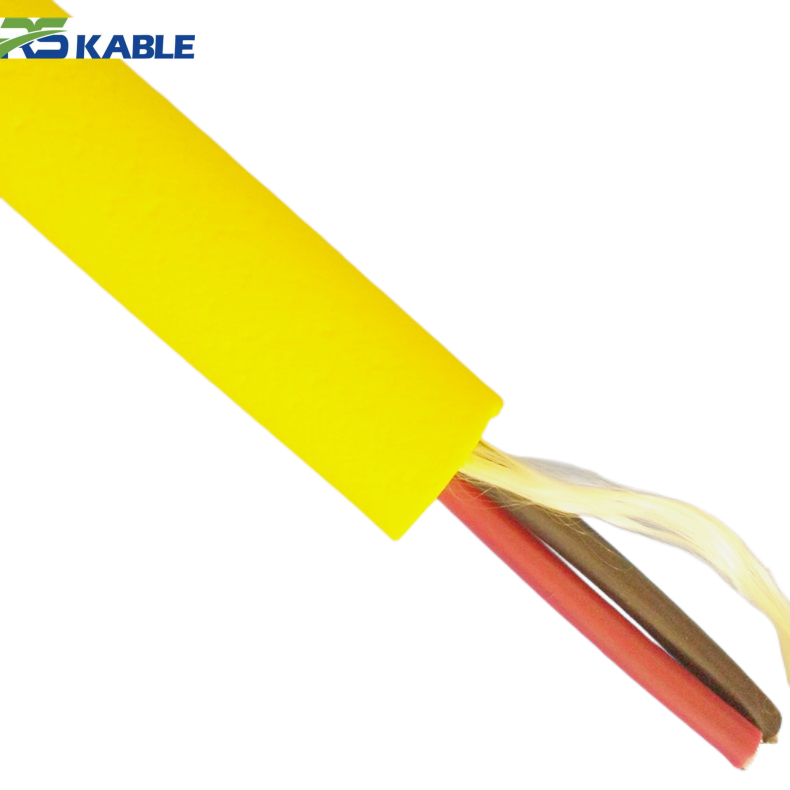

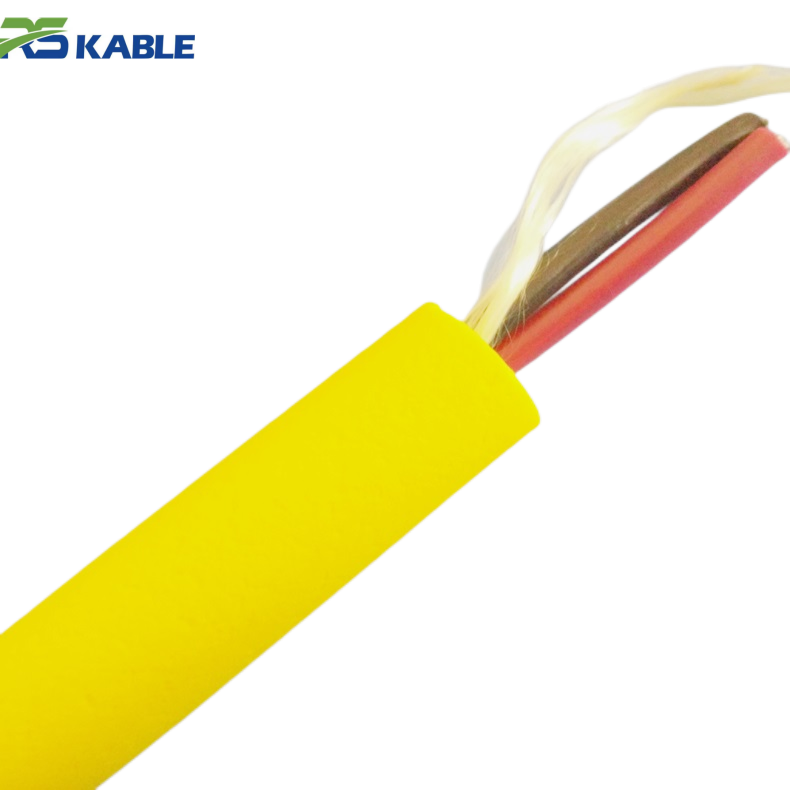

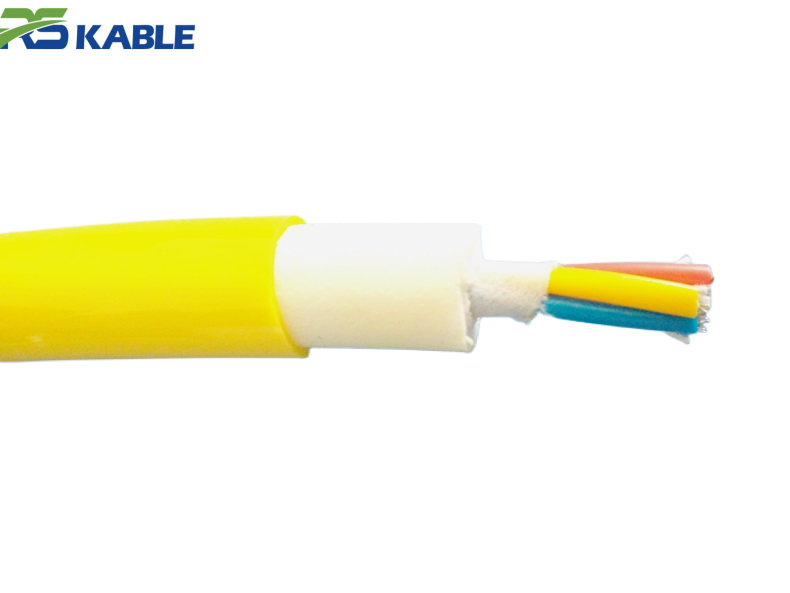

Jacket: Marine‑grade foamed polyurethane (neutral buoyancy).

-

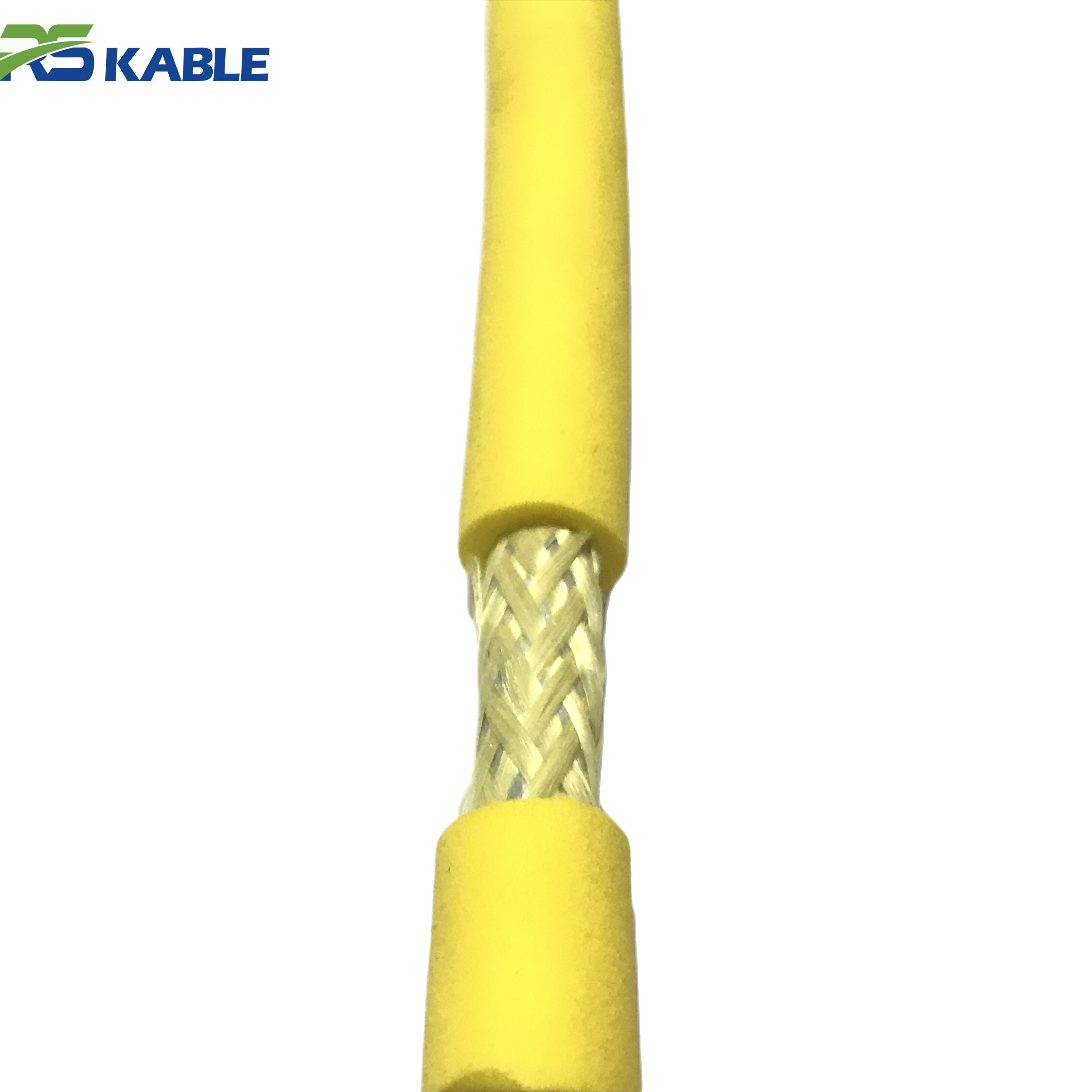

Reinforcement: Kevlar/Aramid fiber for emergency recovery and high tensile strength.

-

Application: Ideal for observation‑class ROVs, underwater camera systems, and inspection platforms.

-

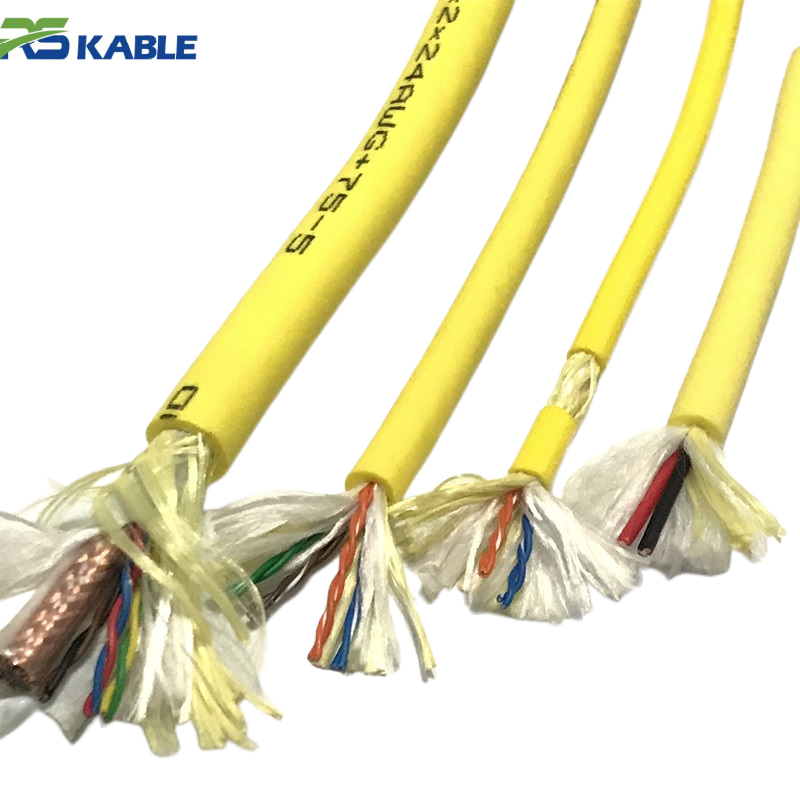

Customization: Available in various core counts, lengths, and hybrid fiber‑optic configurations.

Your ROV’s reliability is only as strong as the tether that connects it to the surface. In subsea operations, a standard cable becomes a liability — it drags, tangles, and places unnecessary strain on your vehicle’s thrusters.

The Rousheng High‑Tensile Neutral Buoyancy Cable is engineered to solve these precise challenges. Designed by Shanghai Rousheng Wire & Cable Co., Ltd., this tether acts as a nearly weightless lifeline, enabling smooth maneuverability in complex underwater environments. Whether you are conducting hull inspections, offshore maintenance, or scientific research, this cable ensures uninterrupted power and data transmission.

Why Neutral Buoyancy Matters

Conventional cables sink and form a “catenary” curve, dragging the ROV downward and forcing its thrusters to work harder. This increases power consumption and shortens effective mission time.

Our tether uses a specialized low‑density polyurethane (PUR) foam jacket engineered to closely match water density, resulting in neutral buoyancy in freshwater and slight positive buoyancy in seawater.

-

Zero Drag: The cable follows the ROV effortlessly, minimizing resistance.

-

Tangle Resistance: The balanced flexibility and stiffness prevent cable snarling and “bird‑nesting.”

-

Extended Battery Life: Your ROV spends energy executing tasks, not fighting the weight of its tether.

Built for Harsh Underwater Environments — Kevlar® Reinforced Durability

Subsea conditions are unforgiving. Sharp rocks, barnacles, and dynamic loads can snap inferior cables. We don’t rely on the jacket alone for strength.

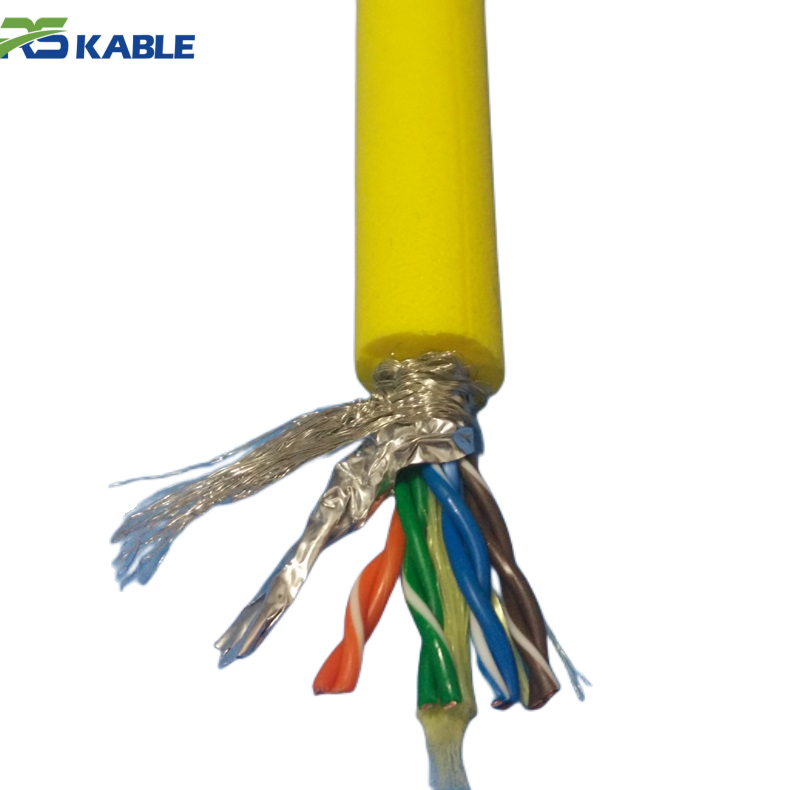

Inside the cable core, we integrate Aramid Fiber (Kevlar®) strength members, providing exceptionally high break strength without adding significant weight or diameter.

-

High Tensile Strength: Capable of withstanding significant pull forces (customizable from 100 kgf up to 1000 kgf+) for emergency retrieval.

-

Water‑Blocking Technology: If the jacket is nicked, internal water‑blocking fibers prevent moisture from migrating down the cable and damaging electronics.

-

Abrasion Resistance: The PUR jacket is highly resistant to hydrolysis, microbial attack, and saltwater corrosion for long service life.

Technical Specifications

Note: As a manufacturer with over 100 product varieties, Shanghai Rousheng can customize these specifications to your exact voltage and data requirements.

| Feature | Specification |

|---|---|

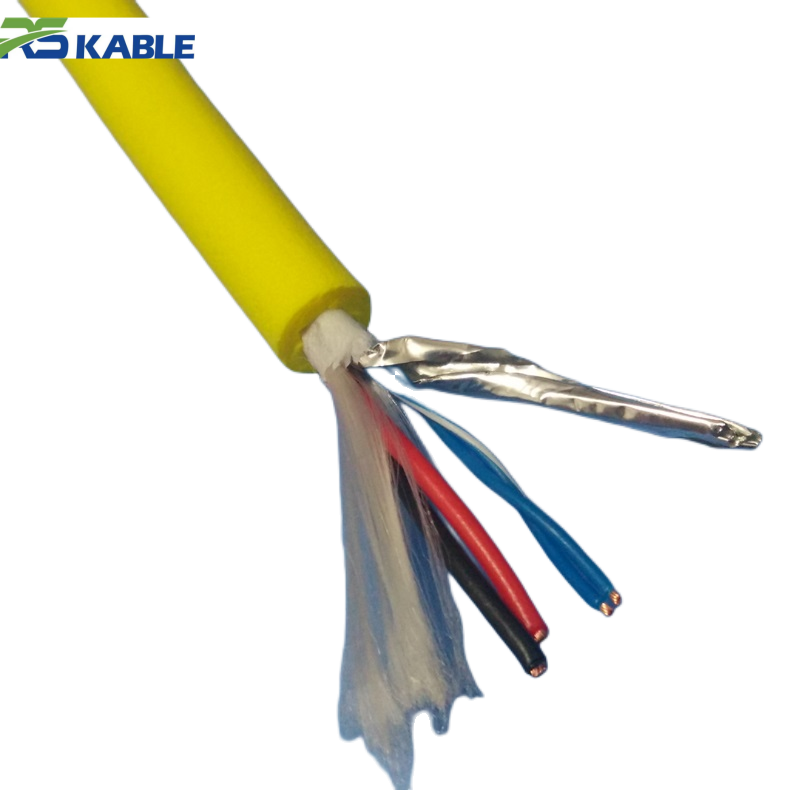

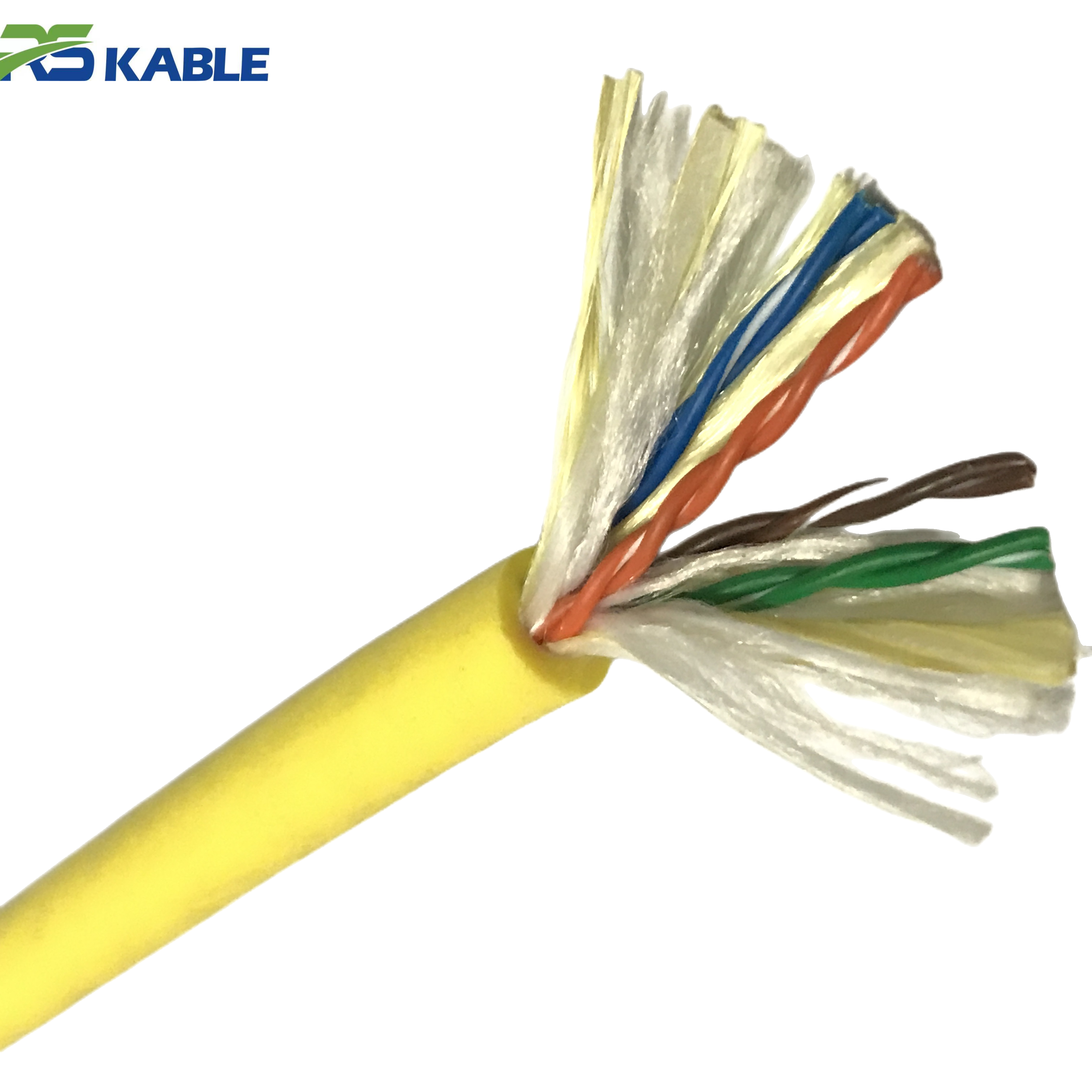

| Core Structure | Customizable (e.g., 2‑core power + 2‑pair data, or fiber optic hybrids) |

| Conductor Material | High‑flexibility tinned copper (Class 6 stranding) |

| Insulation | TPE / PE / Foam PE (optimized for data integrity) |

| Strength Member | Kevlar® (Aramid) braid or central strength member |

| Outer Jacket | Marine‑grade foamed polyurethane (TPU/PUR) |

| Buoyancy | Neutral in freshwater; slightly positive in seawater |

| Temperature Range | Static: -30°C to +90°C; Flexing: -20°C to +80°C |

| Voltage Rating | 300 V / 600 V / 1000 V (customizable) |

| Depth Rating | Tested to depths up to 500 m+ (depending on design) |

| Color | High‑visibility yellow or orange (safety standard) |

Direct from the Manufacturer — Customization Is Standard

Shanghai Rousheng is not just a distributor; we are a dedicated R&D and manufacturing facility. We understand that “one‑size‑fits‑all” cables rarely fit complex engineering projects, so we offer bespoke solutions tailored to your specific vehicle class:

-

Hybrid Configurations: Combine power, twisted‑pair data (CAT5e/CAT6), and fiber optics in a single tether.

-

Diameter Control: We can minimize the outer diameter for micro‑ROVs or increase it for heavy work‑class vehicles.

-

Connector Integration: Cables can be supplied pre‑terminated with wet‑mate connectors as required.

Frequently Asked Questions (FAQ)

Q: Is the cable neutrally buoyant in both freshwater and seawater?

A: Yes. The specific gravity of our PUR foam jacket is engineered to be extremely close to water (approximately 1.0). Typically, it is neutral in freshwater and slightly positive (floating) in seawater due to higher density — ideal for keeping the tether off the seabed.

Q: What is the minimum bend radius?

A: To protect copper strands and maintain data integrity, we recommend a minimum bend radius of 7.5× the cable diameter for flexing applications.

Q: Can this cable be used with a cable reel or winch?

A: Yes. The robust PUR jacket and Kevlar reinforcement make it suitable for use with both manual and motorized winch systems without crushing internal cores.

Q: Do you offer samples for testing?

A: As a quality‑committed factory, we can provide specification sheets and samples for validation upon request.