High‑Temperature Resistant Network Cable with HDPE Insulation & Kevlar Braided Tensile Reinforcement | Industrial PE Insulated High‑Density Cable

.High‑temperature resistant network cable with HDPE insulation and Kevlar braided reinforcement.

.Offers superior tensile strength, mechanical durability and stable signal integrity for industrial applications.

.Durable PVC jacket and flexible design enhance service life in dynamic installations.

.Ideal for factory automation, robotics, conveyor systems and outdoor environments.

.Customizable options available to meet OEM/ODM requirements.

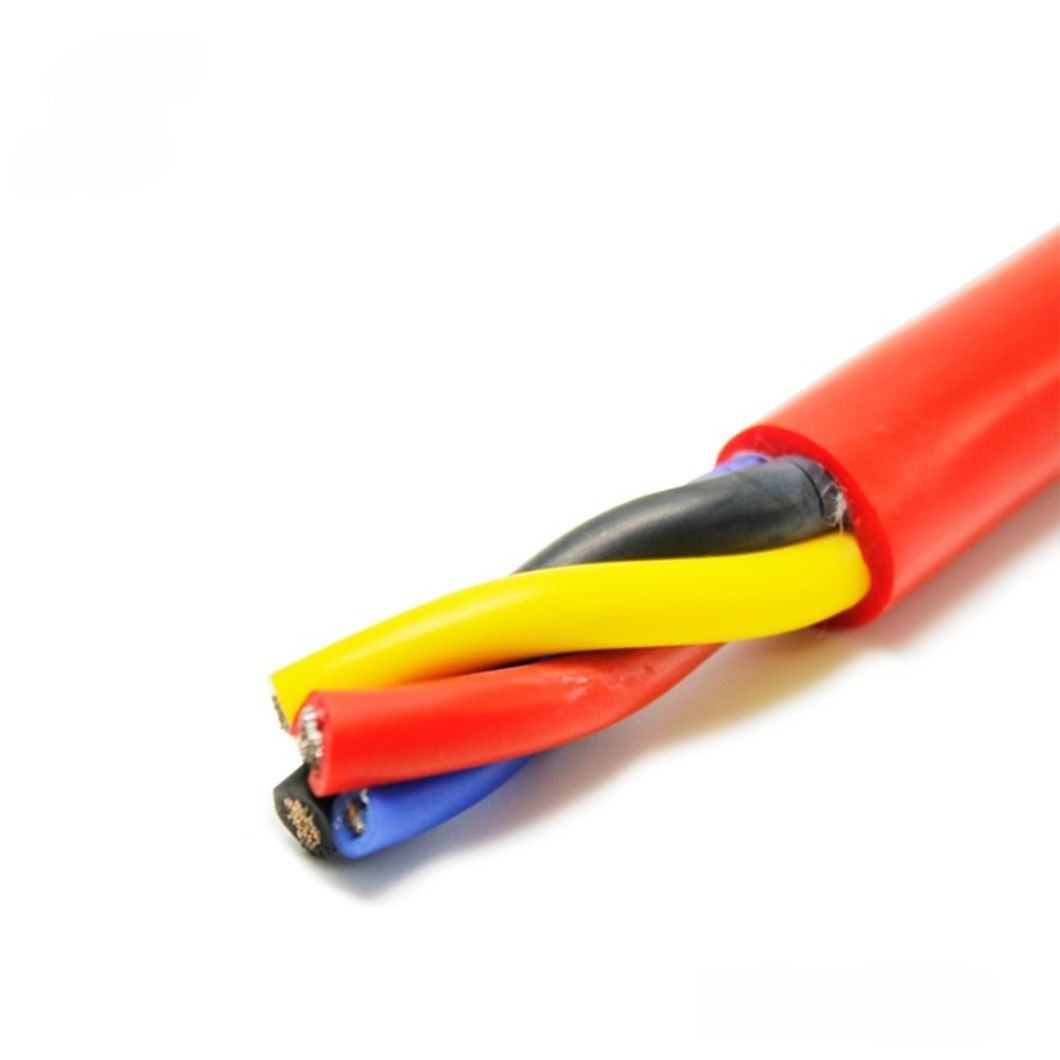

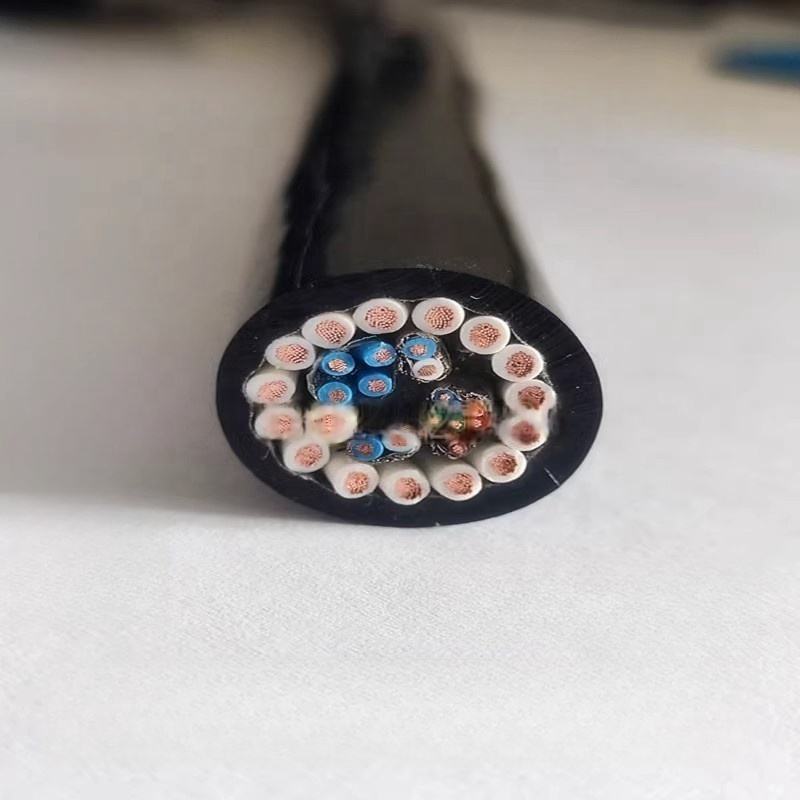

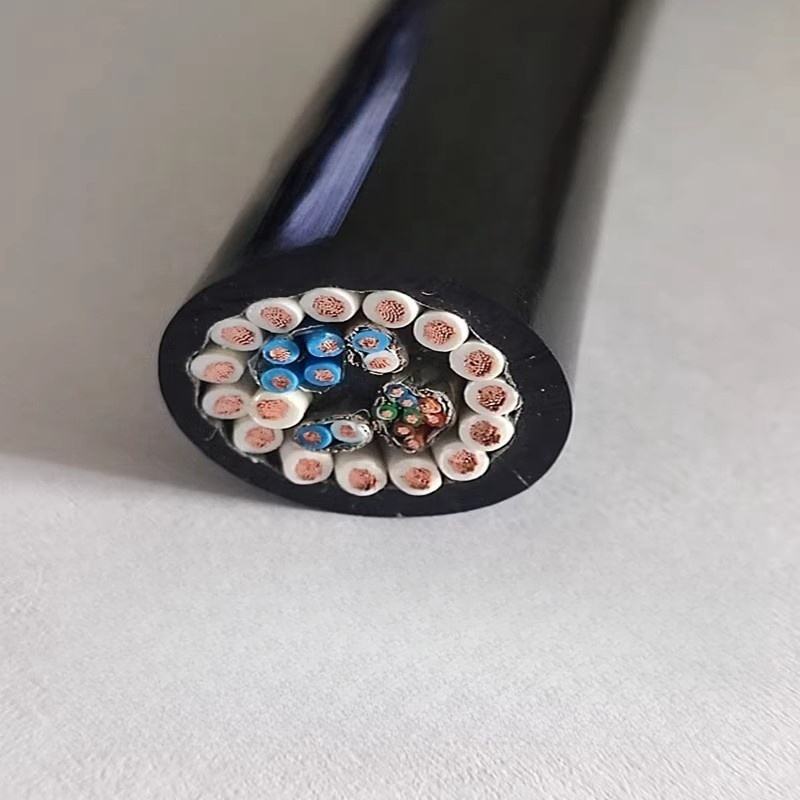

This High‑Temperature Resistant Network Cable combines high‑density polyethylene (HDPE) insulation with a Kevlar braided tensile reinforcement layer, engineered to tackle demanding industrial and automation environments where durability and signal integrity are paramount. The cable’s design focuses on strong mechanical performance, reliable data transmission and long‑term stability under temperature, vibration and tensile stress.

Shanghai Rousheng Wire & Cable Co., Ltd. brings over a decade of expertise in cable innovation, specializing in high‑flex drag chain systems, industrial communication cables and customized solutions tailored to OEM/ODM requirements across Europe and more than 100 countries.

Why This Cable Adds Value

Robust HDPE Insulation

High‑density polyethylene (PE) is known for its excellent dielectric properties and mechanical strength. When used as an insulation material, HDPE provides reliable insulation, moisture resistance and chemical durability, making it well suited for both indoor and challenging outdoor industrial environments. HDPE insulation also supports stable network signal transmission.

Kevlar Braided Tensile Reinforcement

Kevlar (aramid fiber) stands out for its high tensile strength, thermal stability and toughness. Integrating a Kevlar braid into the cable enhances its resistance to pulling forces, bending stress and abrasion — critical for installations involving motion or heavy mechanical loads.

Industrial‑Grade Performance

This cable is designed with industrial use in mind, equipped to withstand variable temperatures, vibration, and the physical demands of factory floors, automated systems, conveyors and dynamic routing setups.

Key Features

-

HDPE Insulation: Stable dielectric performance and mechanical protection for core conductors.

-

Kevlar Reinforcement: Provides tensile strength and strain relief, improving durability and service life in high‑stress installations.

-

High‑Temperature Resistance: Reliable operation in elevated temperature ranges, suitable for industrial environments with thermal fluctuations.

-

Durable PVC Jacket: Protects the cable from abrasion, chemical exposure and mechanical impact.

-

Industrial‑Ready Design: Ideal for network, control, and instrumentation wiring where both strength and signal integrity matter.

Applications

This cable is suitable for a wide range of industrial and automation situations:

-

Factory Automation & Control Systems — Stable data links for PLCs, HMIs and industrial networks.

-

Robotics and Motion Systems — Cables exposed to movement, bending and vibration.

-

Conveyor & Logistics Systems — Long‑run network and control wiring in dynamic installations.

-

Heavy Machinery & Equipment Wiring — Where mechanical reinforcement and temperature resilience are needed.

-

Outdoor or Harsh Environments — Moisture, chemical and abrasion‑prone installations.

Product Construction & Materials

| Component | Specification |

|---|---|

| Conductor Material | Multi‑strand Tinned Copper |

| Insulation Material | High‑Density Polyethylene (PE) |

| Tensile Reinforcement | Kevlar Aramid Fiber Braid |

| Outer Sheath | Durable PVC |

| Core Type | Network & Signal Conductors |

| Shielding (optional) | Foil or Braid for EMI Protection |

| Customizable Options | Jacket color, core count, conductor gauge |

Technical Specifications (Typical)

| Attribute | Specification |

|---|---|

| Rated Voltage | Up to Industrial Network Standards |

| Temperature Range | Standard: -20°C to +80°C (Custom options available) |

| Bending Radius | ≥8× cable diameter (flexible installation) |

| Tensile Strength | Reinforced by Kevlar Braiding |

| Mechanical Protection | High impact and abrasion resistance |

| Signal Integrity | Stable network performance with reduced noise |

| OEM/ODM | Support for design, lengths and material specs |

Frequently Asked Questions (FAQ)

Q1: What makes HDPE insulation preferable for industrial network cables?

A: HDPE delivers strong dielectric performance, moisture resistance and mechanical durability, making it suitable for environments with temperature variation and physical stress.

Q2: How does Kevlar reinforcement improve cable performance?

A: Kevlar’s high tensile strength and thermal stability protect the cable from pulling, stretching and abrasion, enhancing lifespan in dynamic installations.

Q3: Can this cable be used outdoors?

A: Yes — with its durable insulation and jacket, it withstands moisture, temperature fluctuation and mechanical wear common in outdoor or exposed industrial environments.

Q4: Is this cable suitable for drag chain use?

A: The design supports flexibility and mechanical resilience, making it suitable for drag chain systems when combined with proper routing and support.

Q5: Are customization options available?

A: Yes — Shanghai Rousheng offers tailored cable design including core count, materials, jacket color and lengths to match specific project needs.