High‑Flex Drag Chain Cable for Underwater Robots | OEM/ODM Subsea Robotic Cable

.Corrosion‑resistant fine multi‑strand copper cable with tinned/bare conductor options for industrial wiring.

.High flexibility and mechanical strength in automation, control, and robotic harness applications.

.Standard PVC jacket with TPE insulation; customizable for harsher environments.

.Meets key international standards for safety, flame retardance, and electrical performance.

.Provided by Shanghai Rousheng Cable Co., Ltd. — specialists in high‑flexibility and industrial cable solutions.

The Corrosion‑Resistant Multi‑Strand Fine Copper Cable is engineered for demanding industrial use where flexibility, conductivity, mechanical strength and environmental resistance are essential. Featuring fine multi‑strand copper conductors — available in bare copper or tinned copper — this cable delivers exceptional electrical performance while resisting oxidation and corrosion in harsh environments.

Whether for control systems, automation wiring, sensor networks, robotic harnesses or power distribution, this cable offers reliable performance backed by professional design and manufacturing expertise from Shanghai Rousheng Wire & Cable Co., Ltd., a specialist in high‑flex drag chain and specialty cables with over 100 product types.

Key Features & Benefits

✔ Premium Conductor Materials

-

Tinned Copper Conductors: Superior corrosion resistance and extended life in humid, coastal or chemically active environments.

-

Fine Multi‑Strand Structure: Enhances flexibility and reduces breakage risk during bending or repeated movement.

✔ Robust Insulation & Jacket

-

Insulation Material: High‑quality TPE (thermoplastic elastomer) offers strong mechanical resilience and thermal stability.

-

Outer Sheath: PVC jacket protects against abrasion, oils and mechanical wear for long‑term durability.

✔ Engineered for Industrial Reliability

-

Meets IEC60227‑5 and EN50525‑2‑5 standards for quality and safety.

-

Flame retardant performance compliant with IEC6.332‑1‑2 with excellent chemical resistance.

-

Wide temperature tolerance with customization options for extreme conditions.

✔ Flexible & Fatigue‑Resistant

-

Ideal for installations with motion, vibration, or frequent handling.

-

Multi‑strand fine copper enables smooth installation even in tight cable trays or conduit runs.

Applications

This cable is well suited for a variety of industrial and automation environments:

-

Control Panels & Switchgear — Safe and reliable wiring for industrial power and control systems.

-

Factory Automation — Wiring for PLCs, actuators, and automated equipment.

-

Industrial Robotics — Flexible harnessing in robotic arms and motion systems.

-

Instrumentation & Monitoring — Signal and sensor wiring in production lines.

-

Power Distribution — Low‑voltage power feeds in machinery and equipment.

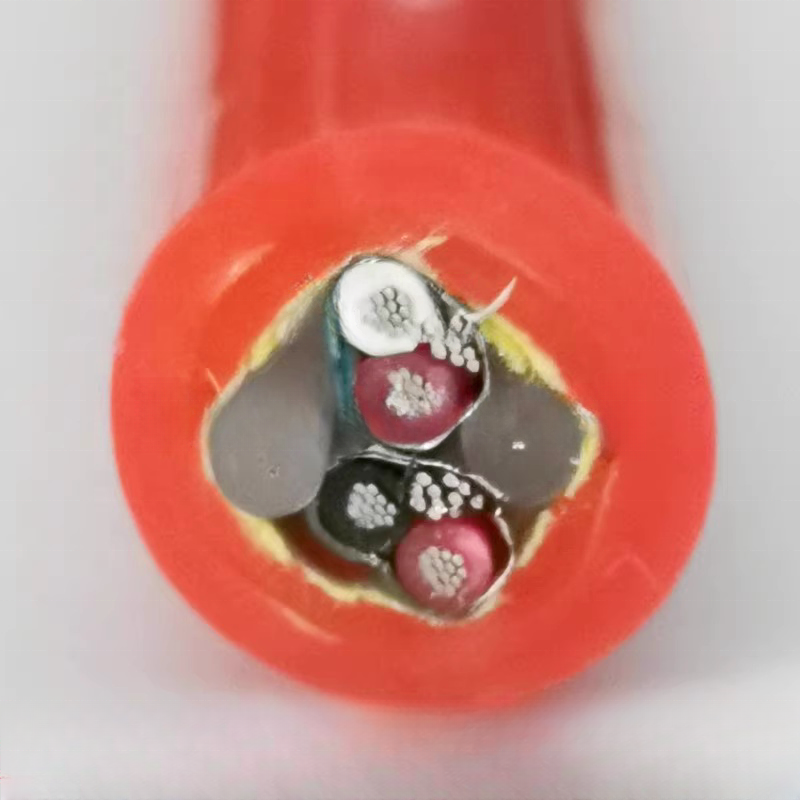

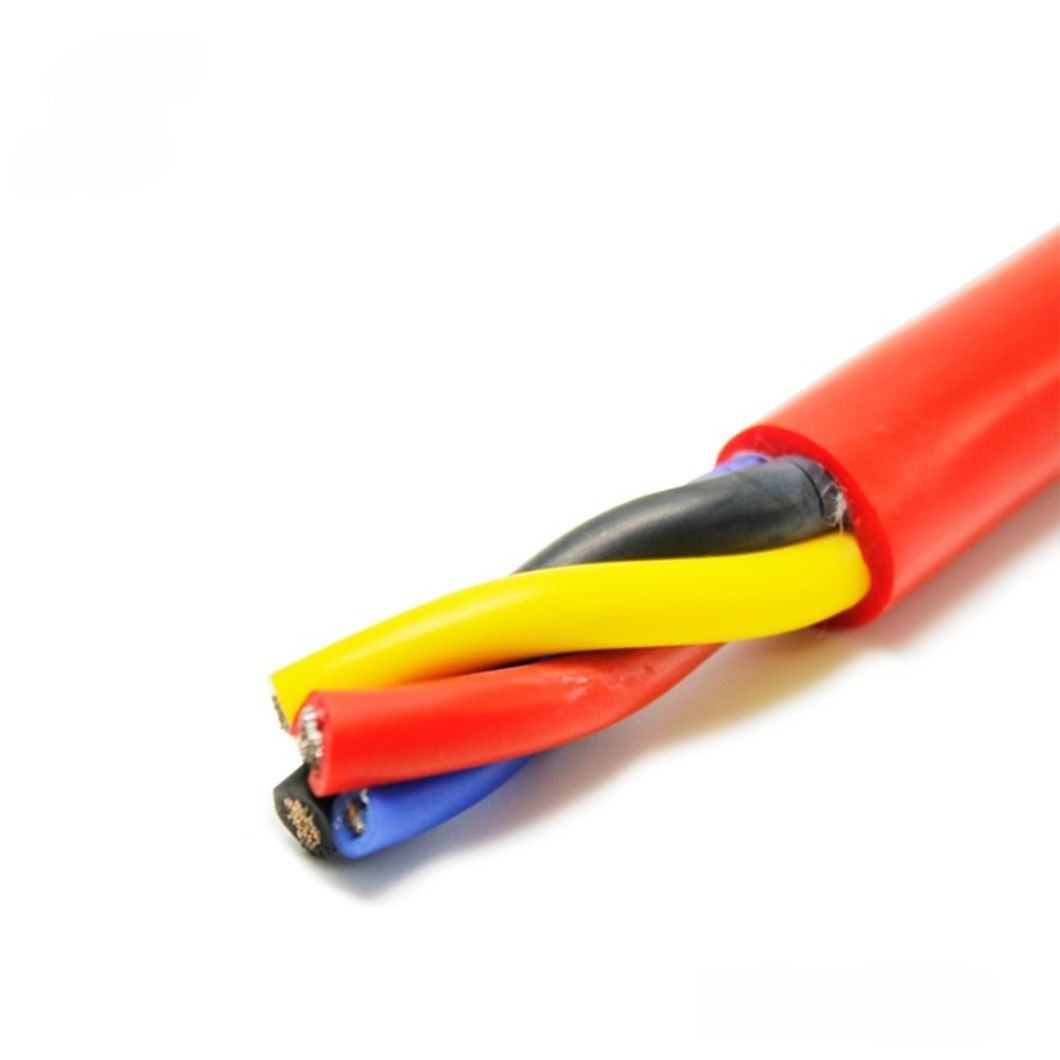

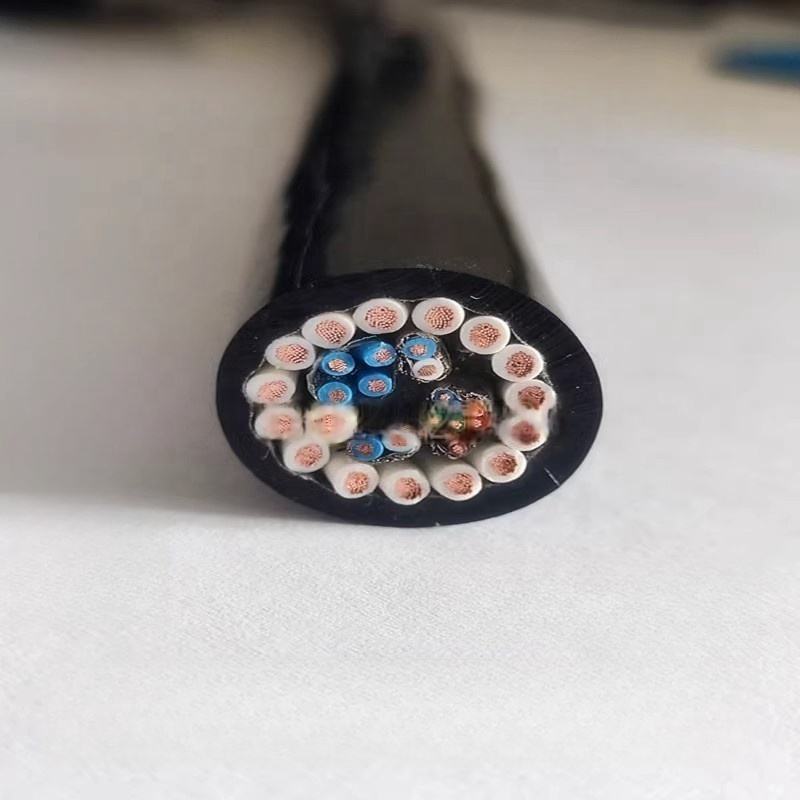

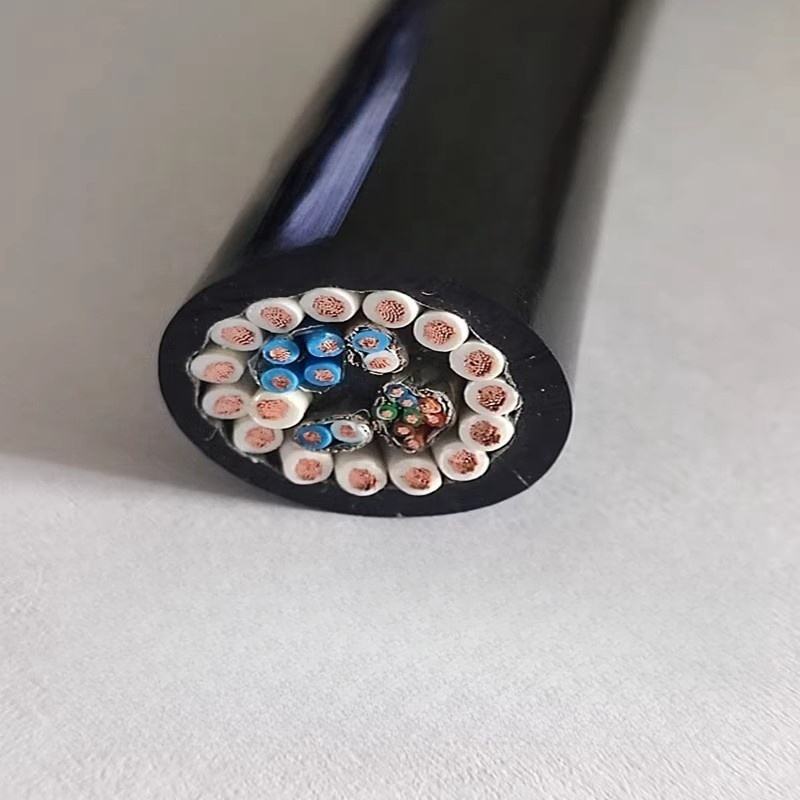

Product Construction

-

Conductor: Multi‑strand fine copper or tinned copper (according to VDE0295 / IEC60228 Class 5).

-

Core Arrangement: Color‑coded or coded cores per VDE0293 with filler and separator layers.

-

Insulation: TPE or customized elastomer.

-

Sheath: PVC (standard), with optional TPU/PUR options available in black or gray for enhanced abrasion resistance.

Technical Specifications

| Attribute | Specification |

|---|---|

| Conductor Material | Tinned Copper (standard) / Bare Copper (optional) |

| Conductor Structure | Fine Multi‑Strand (VDE0295 / IEC60228 Class 5) |

| Insulation Material | TPE (Thermoplastic Elastomer) |

| Sheath Material | PVC (default) |

| Voltage Rating | 0.3 mm²: 300/300 V0.5–4.0 mm²: 300/500 V>6.0 mm²: 600/1000 V |

| Test Voltage | 2,500 V – 4,000 V |

| Minimum Bend Radius | Occasional movement: ≥8× cable ODFixed installation: ≥4× cable OD |

| Temperature Range | -10 °C to +80 °C (standard)Custom: -30 °C to +90 °C / -40 °C to +105 °C |

| Flame Retardant | Meets IEC6.332‑1‑2 |

| Standards | IEC60227‑5, EN50525‑2‑5 |

| Customization | Core count, conductor type, insulation & jacket options, length |

Installation & Handling Tips

-

Maintain appropriate bend radius to maximize lifespan and prevent conductor stress.

-

Use cable clamps or trays to secure wiring and prevent abrasion against sharp edges.

-

For outdoor or chemical plant environments, consider additional jacketing or conduit.

Frequently Asked Questions (FAQ)

Q1: Why choose tinned copper over bare copper?

A: Tinned copper resists oxidation and corrosion far better than bare copper, especially in environments with humidity, salt air or chemical exposure. This extends cable life and reduces maintenance.

Q2: Is this cable suitable for continuous motion use?

A: Yes — the fine multi‑strand design enhances flexibility and fatigue resistance, making it suitable for many semi‑dynamic environments. For continuous drag chain use, ask about our high‑flex specialty variants.

Q3: What temperature conditions can this cable handle?

A: Standard ratings cover -10 °C to +80 °C, with customizable insulation available for lower or higher ranges per your application demands.

Q4: Can the cable be customized?

A: Absolutely. We support OEM/ODM configurations including conductor type, insulation material, jacket color, core count and length.

Q5: What standards does this cable meet?

A: It meets recognized safety and performance standards such as IEC60227‑5 and EN50525‑2‑5, and flame performance per IEC6.332‑1‑2.