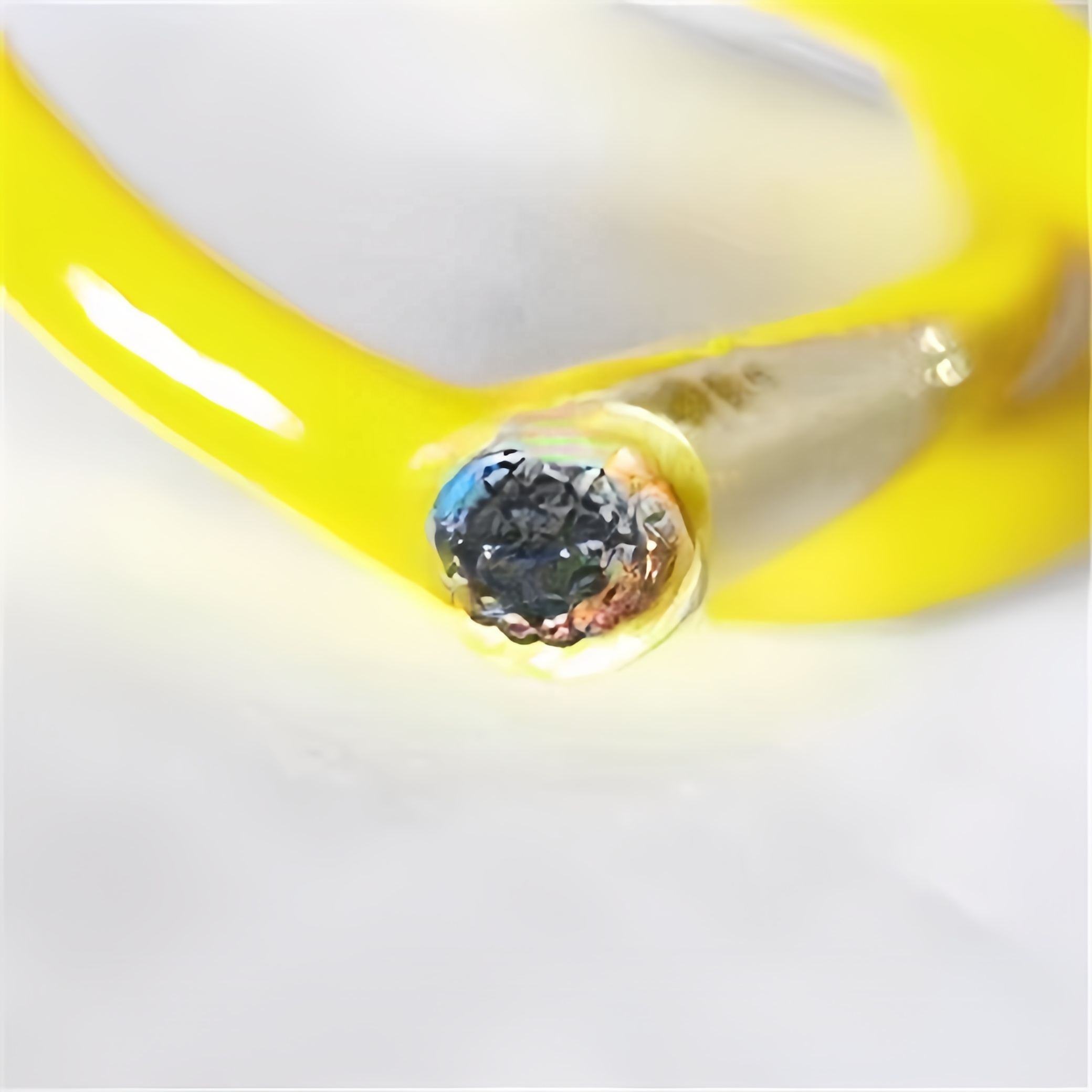

High-Flex TPU Pipeline Robot Cable / CCTV Coaxial Cable

High-Flex TPU Pipeline Robot Cable / CCTV Coaxial Cable is specifically designed for pipeline inspection robots and CCTV crawler systems. It integrates power supply, control signals, and video transmission into a single composite cable. With excellent flexibility, abrasion resistance, and torsion performance, the cable operates reliably in narrow, multi-bend, wet, and high-wear pipeline environments. It is widely used in municipal pipeline inspection, industrial pipelines, and customized robotic inspection systems.

Optional Configurations:

-

Composite structure (power + control signal + coaxial video)

-

50Ω / 75Ω CCTV coaxial unit

-

Fine-stranded oxygen-free copper conductors

-

High-abrasion TPU outer jacket

-

Reinforced tensile structure (optional)

-

Customized diameter, length, and color marking

High-Flex TPU Pipeline Robot Cable / CCTV Coaxial Cable

Reliable Power and Signal Transmission for Demanding Pipeline Inspections

Pipeline inspection robots and CCTV crawler systems operate in some of the harshest conditions found in industrial and municipal infrastructure. Tight bends, continuous pulling, abrasion against pipe walls, moisture, oil, and signal interference all place extreme demands on the cable connecting the system.

High-Flex TPU Pipeline Robot Cable / CCTV Coaxial Cable is purpose-built to meet these challenges. Rather than adapting a standard industrial cable, this solution is engineered specifically for robotic inspection environments where flexibility, durability, and signal integrity are equally critical.

Manufactured by Shanghai Rousheng Wire & Cable Co., Ltd., a specialist in high-flex drag chain and special-purpose cables, this product is designed to perform reliably over long service cycles in real-world inspection work.

Why the Cable Is a Critical Component in Pipeline Robotics

In pipeline inspection systems, the cable is more than a power line—it is the lifeline of the robot. Common failure points in conventional cables include conductor fatigue, jacket wear, water ingress, and unstable video signals.

A well-designed cable must:

-

Maintain flexibility under repeated bending and torsion

-

Withstand abrasion and pulling forces inside confined pipes

-

Deliver stable power and clear video signals over long distances

-

Resist water, oil, sewage, and chemical exposure

The High-Flex TPU Pipeline Robot Cable / CCTV Coaxial Cable addresses these requirements at both structural and material levels, ensuring consistent performance throughout the inspection process.

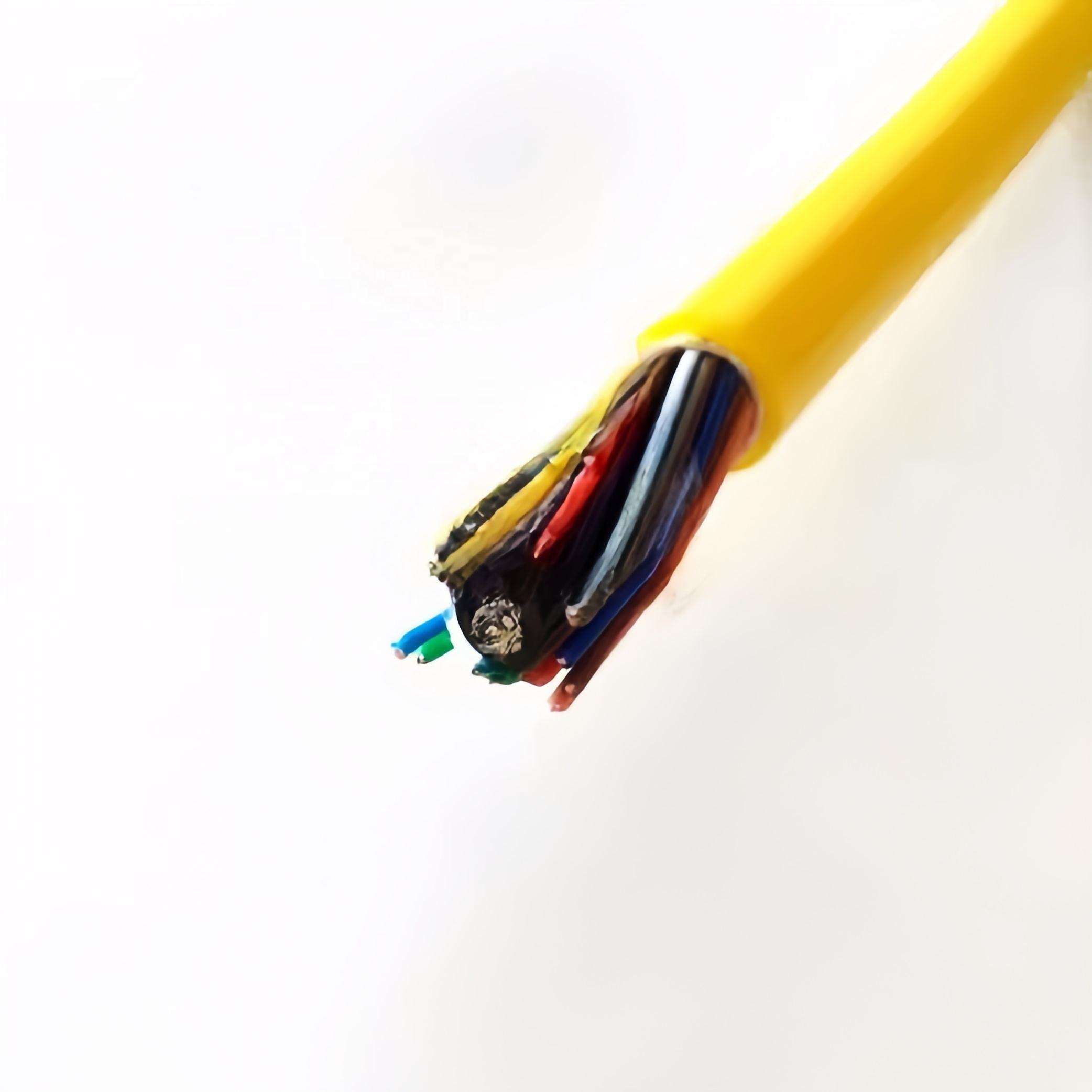

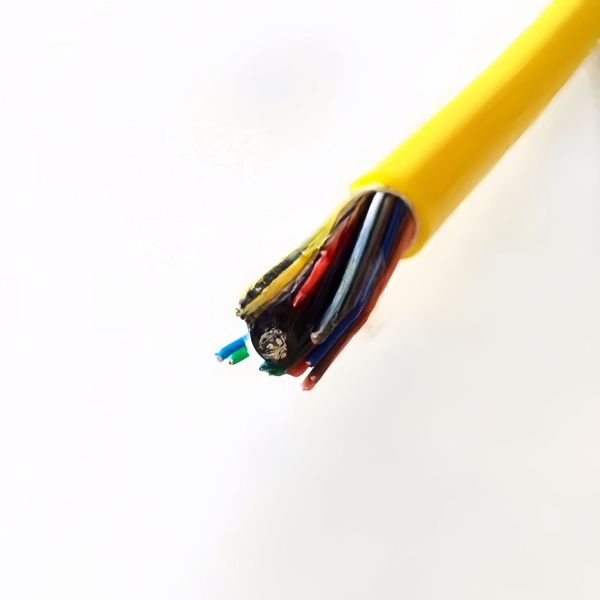

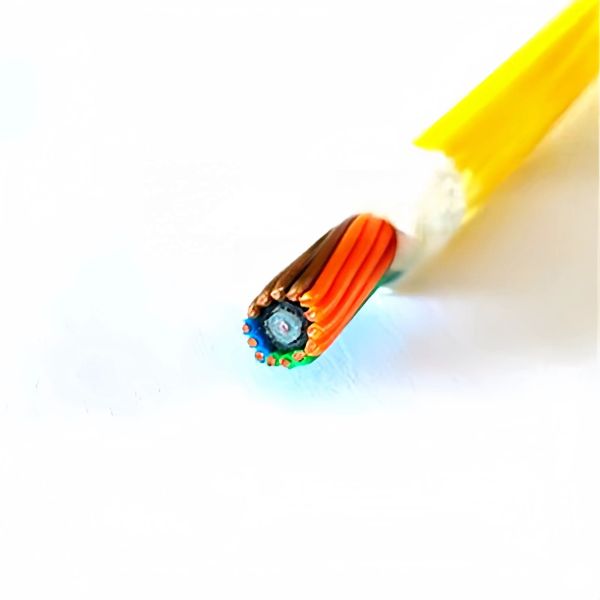

Composite Cable Structure Designed for Integration

Integrated Power, Signal, and Coaxial Transmission

This cable combines power conductors, control or signal cores, and dedicated coaxial elements into a single compact structure. The integrated design simplifies system layout, reduces overall diameter, and improves handling during deployment and retrieval.

High-Purity Copper Conductors

Fine-stranded oxygen-free copper conductors are used to ensure:

-

Low electrical resistance over extended cable lengths

-

Stable voltage supply to robotic drive and lighting systems

-

Reliable data and control signal transmission

Dedicated Coaxial Core for CCTV Video

The coaxial unit features optimized impedance and multi-layer shielding to minimize attenuation and electromagnetic interference, supporting clear and stable video transmission even in electrically complex environments.

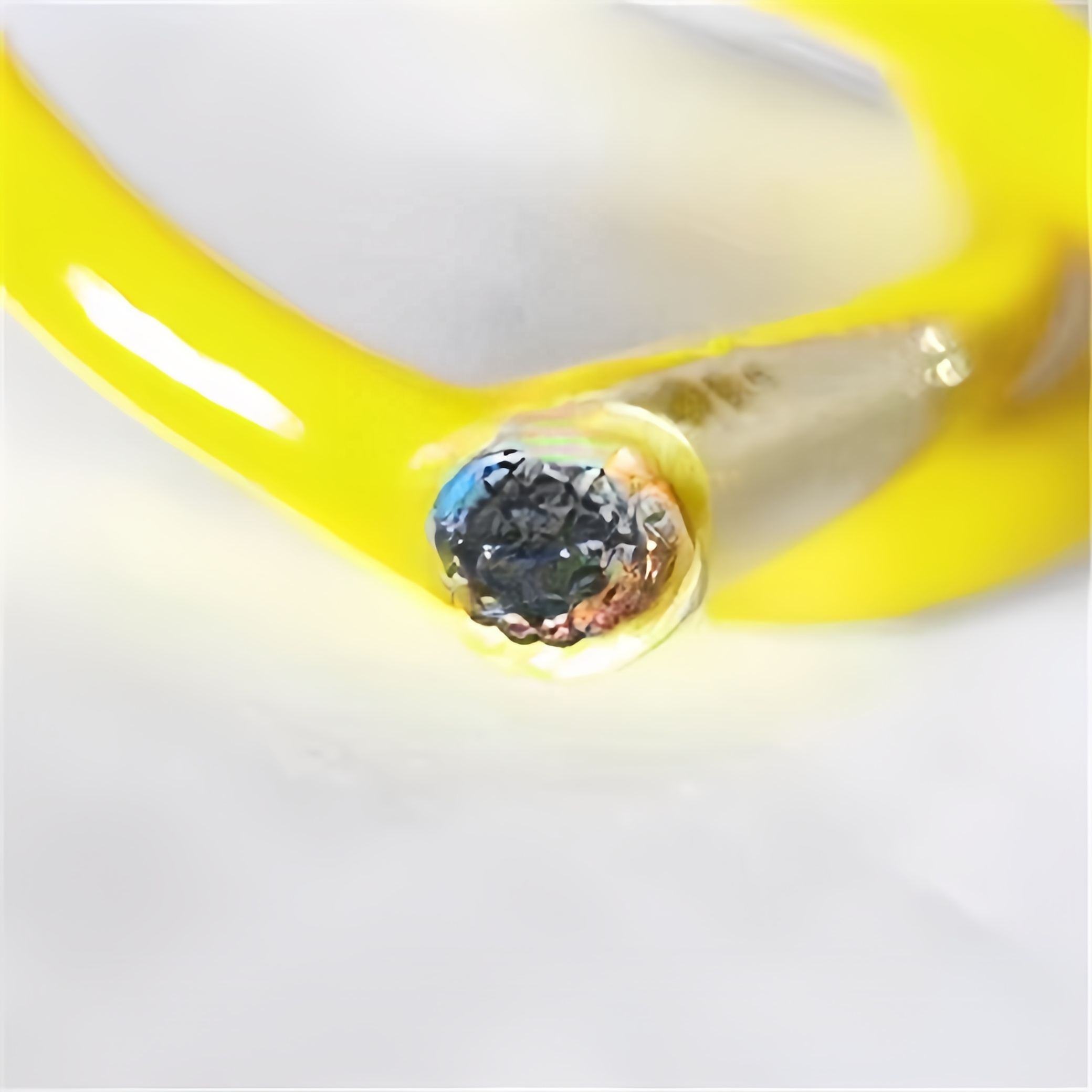

TPU Outer Jacket: Built for Harsh Pipeline Conditions

Advantages of TPU in Inspection Applications

The outer jacket is made from high-performance thermoplastic polyurethane (TPU), selected for its superior mechanical and environmental properties:

-

Excellent abrasion resistance against pipe walls and debris

-

High tear strength under dynamic load

-

Outstanding flexibility at low temperatures

-

Resistance to oil, sewage, grease, and mild chemicals

Compared with PVC or conventional rubber jackets, TPU significantly extends service life in confined and abrasive environments.

Reduced Drag Inside Pipelines

The smooth jacket surface lowers friction during operation, reducing mechanical stress on the robot and cable reel system while improving overall efficiency.

High-Flex Performance for Continuous Movement

Optimized for Repeated Bending

Internal stranding geometry and lay length are designed for continuous dynamic motion, allowing the cable to withstand frequent bending during deployment, navigation, and retrieval.

Torsion Resistance

The internal structure maintains stability during rotational movement, helping prevent conductor displacement and extending operational lifespan in crawler systems that twist or turn inside pipelines.

Technical Specifications Overview

Parameters can be customized according to application requirements.

Electrical Characteristics

-

Power conductors: Fine-stranded oxygen-free copper

-

Signal conductors: Twisted pairs or control cores

-

Coaxial impedance: 50Ω or 75Ω (optional)

-

Rated voltage: 300/500V or customized

Mechanical Performance

-

Minimum bending radius

-

Fixed installation: 5 × cable OD

-

Dynamic movement: 7.5 × cable OD

-

-

Designed for pulling, dragging, and reel operation

Environmental Resistance

-

Jacket material: TPU

-

Operating temperature: -30°C to +80°C

-

Suitable for wet, oily, and submerged conditions

Typical Application Scenarios

Pipeline Inspection Robots

Used in municipal sewer systems, industrial pipelines, and utility networks where long-distance inspection and reliability are essential.

CCTV Crawler Systems

Supports stable video transmission for real-time inspection, fault detection, and documentation.

OEM Robotic Platforms

An ideal solution for manufacturers developing custom inspection robots requiring integrated power and signal transmission in a single cable.

Customization to Match Real Projects

Shanghai Rousheng Wire & Cable Co., Ltd. offers extensive customization options to ensure compatibility with specific systems and operating conditions:

-

Conductor size and core count

-

Coaxial configuration and shielding level

-

Jacket thickness, color, and markings

-

Reinforcement layers for increased tensile strength

-

Length and integration with reels or connectors

Each High-Flex TPU Pipeline Robot Cable / CCTV Coaxial Cable can be engineered to meet exact mechanical and electrical requirements.

Manufacturing Expertise and Quality Assurance

With experience covering more than 100 types of high-flex and special-purpose cables, Shanghai Rousheng Wire & Cable Co., Ltd. combines in-house R&D, controlled manufacturing processes, and application-driven design.

Every cable undergoes testing for electrical performance, mechanical endurance, and jacket durability to ensure consistent field performance—not just compliance with specifications.

Frequently Asked Questions

Is this cable suitable for continuous robotic operation?

Yes. It is designed specifically for repeated bending, dragging, and torsion common in pipeline inspection robots.

Can it support high-resolution CCTV video?

Yes. The dedicated coaxial structure ensures stable video transmission over long distances with minimal signal loss.

Why choose TPU instead of PVC?

TPU offers superior abrasion resistance, flexibility, and service life in harsh pipeline environments.

Can the cable be customized for my system?

Yes. Both electrical and mechanical parameters can be tailored to match OEM and project-specific requirements.

A Practical Choice for Long-Term Reliability

Selecting the right cable directly impacts inspection accuracy, equipment uptime, and maintenance costs. High-Flex TPU Pipeline Robot Cable / CCTV Coaxial Cable is designed for professionals who prioritize reliability, durability, and real-world performance over short-term cost savings.

Backed by specialized manufacturing expertise and a deep understanding of robotic inspection environments, this cable provides a dependable foundation for modern pipeline inspection systems.