High-Flex Shielded Encoder Cable (TRVVPS)

High-Flex Shielded Encoder Cable (TRVVPS) engineered for dynamic industrial automation.

. Twisted pair construction cancels electromagnetic interference (EMI) for precise signal transmission.

. High-flex PVC jacket withstands millions of bending cycles in drag chain applications.

. Resistant to oil, abrasion, and coolants common in CNC and robotic environments.

. Available in 0.2mm² to 0.75mm² cross-sections with 4 to 18 cores customizable.

. Manufactured by Shanghai Rousheng, complying with VDE0250 and IEC60227 standards.

High-Flex Shielded Encoder Cable (TRVVPS)

Precision Signal Transmission for Dynamic Automation

In the world of industrial automation, a dropped signal isn’t just a glitch—it’s downtime. The TRVVPS High-Flex Shielded Encoder Cable is engineered to solve the two most critical challenges in motion control: maintaining signal integrity amidst electrical noise and surviving millions of bending cycles in drag chains.

Manufactured by Shanghai Rousheng Wire And Cable Co., Ltd., this cable series is designed for the rigorous demands of servo systems, CNC machinery, and robotic arms. whether you are powering a production line in Germany or upgrading equipment in Brazil, this cable delivers the reliability your operations demand.

Engineered for Continuous Motion

Standard cables fail under the stress of constant movement. They kink, the insulation cracks, and eventually, the copper conductors break. The TRVVPS series is different. It is built specifically for drag chain applications where high flexibility and small bending radii are non-negotiable.

Superior Electromagnetic Compatibility (EMC)

Encoder signals are sensitive. In an industrial environment packed with VFDs and high-voltage motors, electromagnetic interference (EMI) can cause positioning errors.

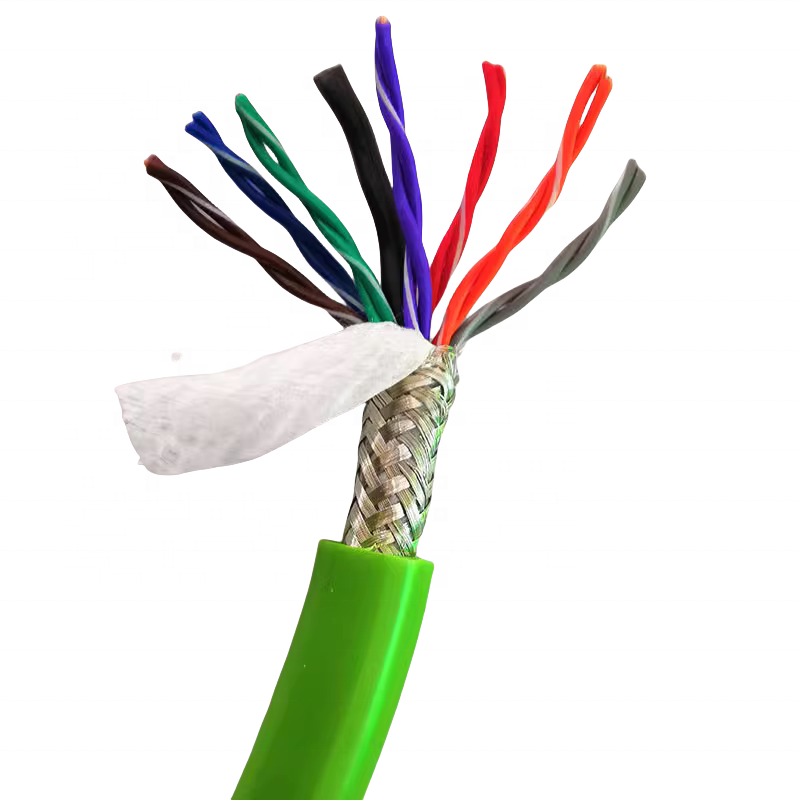

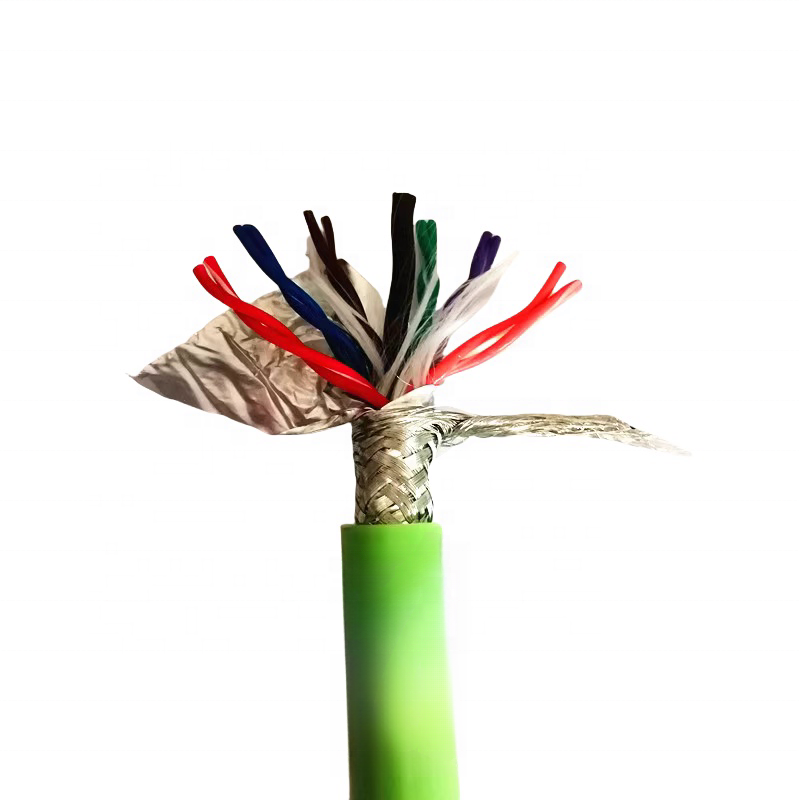

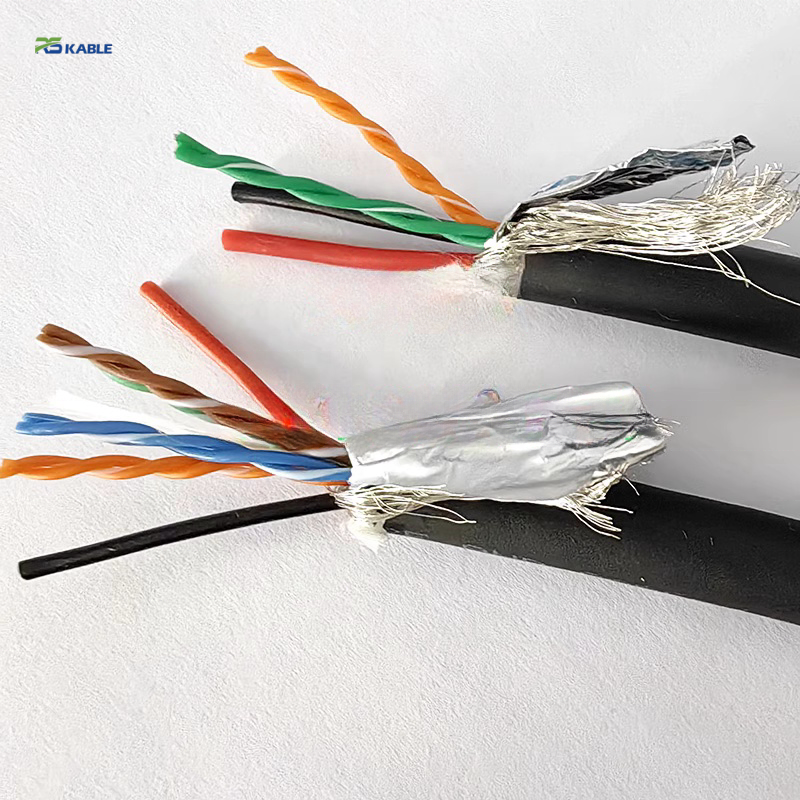

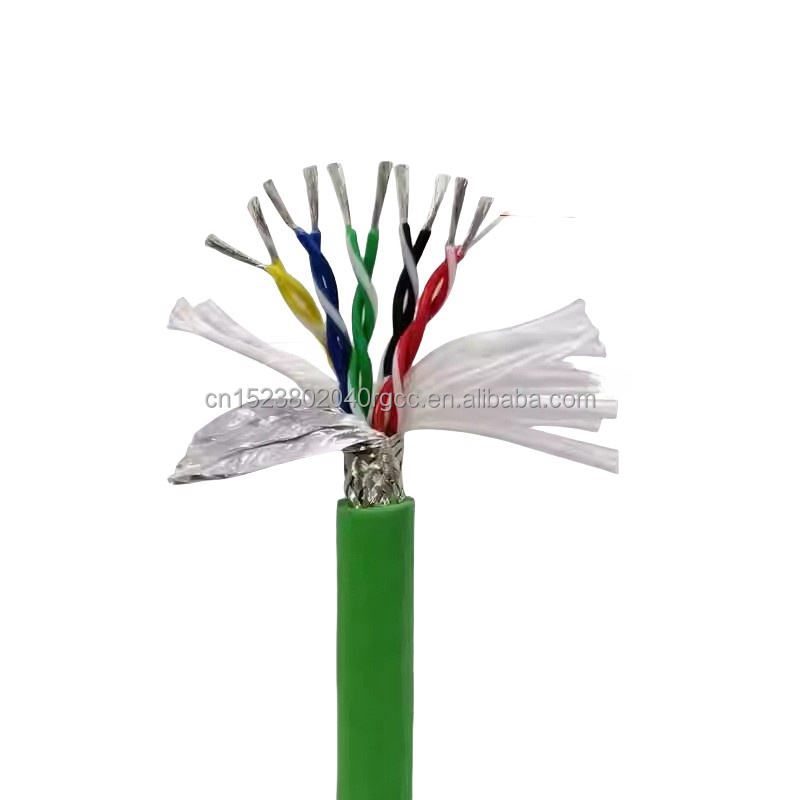

- Twisted Pair Construction: We twist the conductors in precise pairs to cancel out electromagnetic interference naturally.

- High-Coverage Shielding: An optional tinned copper braid or composite shield acts as a fortress around your data, grounding out noise and ensuring your encoder feedback remains accurate.

Durable PVC Jacket

The transparent PVC sheath isn’t just for aesthetics; it allows for visual inspection of the shield integrity while providing robust protection.

- Oil Resistance: Withstands exposure to industrial coolants and lubricants.

- Abrasion Resistance: Tough enough to glide inside cable carriers without wearing down.

- Flexibility: Formulated to remain flexible, preventing the jacket from cracking during repetitive bending.

Technical Specifications

Detailed parameters for the TRVVPS High-Flex Shielded Encoder Cable. Custom configurations are available upon request.

|

Feature |

Specification |

|---|---|

|

Model |

TRVVPS (Twisted Pair, Shielded, Flexible) |

|

Rated Voltage |

300/500V (Low Voltage), 450/750V |

|

Conductor Material |

Fine Stranded Bare Copper / Tinned Copper (Class 5/6) |

|

Insulation |

Special PVC / PE formulation |

|

Shielding |

Tinned Copper Braid (High coverage) / Aluminum Foil |

|

Jacket Material |

Special Flexible PVC (Transparent or Color Customizable) |

|

Cross-Section Area |

0.2mm², 0.3mm², 0.5mm², 0.75mm² (Custom sizes available) |

|

Core Count |

4, 6, 8, 10, 12, 14, 18 cores (Twisted Pairs) |

|

Temperature Range |

Mobile: -5°C to +70°C; Fixed: -15°C to +80°C |

|

Compliance |

IEC60227, BS6500, VDE0250, GB/T9330 |

|

Minimum Bending Radius |

Mobile use: 7.5x Cable Diameter |

Primary Applications

This cable is versatile enough for a wide range of industrial sectors requiring precise feedback loops and power transmission in motion.

- Servo Motor Systems: Connecting rotary encoders to servo drives.

- CNC Machinery: Critical axis control in milling and turning centers.

- Robotics: Internal wiring for robotic arms requiring torsional flexibility.

- Automated Storage Systems: Conveyor lines and stacker cranes.

- Woodworking & Packaging Machinery: High-speed motion components.

Why Choose Shanghai Rousheng?

Sourcing industrial cables is about trust. Shanghai Rousheng Wire And Cable Co., Ltd. specializes in R&D and production of over 100 varieties of high-flex and special cables.

- Global Reach: We export to over 100 countries, understanding the diverse compliance needs of markets from Europe to South America.

- Customization: Need a specific core count or a different jacket color? We offer “World Customizable” manufacturing to fit your exact machine specs.

- Quality Assurance: Adhering to strict standards like VDE and IEC ensures our cables perform safely and reliably.

Frequently Asked Questions (FAQ)

What is the difference between TRVVP and TRVVPS cables?

While both are shielded flexible cables, the S in TRVVPS typically denotes Twisted Pairs (Twisted Pair Shielding). Twisted pairs are crucial for data and signal transmission (like in encoders) because they are far more effective at cancelling out crosstalk and electromagnetic interference than standard parallel conductors found in TRVVP.

Can this cable be used in outdoor environments?

Standard PVC cables are designed primarily for indoor use. If your application involves direct exposure to UV radiation or extreme weather, please contact our engineering team. We can customize the jacket material (e.g., using PUR or special UV-resistant PVC) to ensure longevity outdoors.

How do I choose the right cross-section for my encoder?

For signal transmission over short to medium distances, 0.2mm² or 0.3mm² is often sufficient. For longer runs where voltage drop might be a concern, or for combined power/signal cables, consider stepping up to 0.5mm² or 0.75mm². Always consult your encoder manufacturer’s manual for their specific recommendation.

What is the minimum bending radius for this cable?

To ensure a long service life in a drag chain, we recommend a minimum bending radius of 7.5 times the outer diameter (OD) of the cable. Bending the cable tighter than this limit adds mechanical stress to the copper strands and shield, leading to premature failure.