High-Flex Shielded Encoder Cable, 0.2 / 0.3 / 0.5 / 0.75 mm² Stranded Electrical Equipment Cable

Optional Configurations:

-

Dual-Layer Shielding Structure: High-density tinned copper braiding (>85% coverage) combined with aluminum foil for 100% EMI protection.

-

Class 6 Ultra-Fine Conductors: Stranded oxygen-free copper wires designed for maximum flexibility and a flex life exceeding 10 million cycles.

-

Dynamic Torsion-Rated Design: Optimized core stranding and low-friction PTFE (Teflon) tape wrapping to prevent internal stress and “corkscrew” deformation.

-

Ruggedized High-Flex TPU Jacket: Superior resistance to abrasion, oil, and hydrolysis, with stable operation from -40°C to +90°C.

-

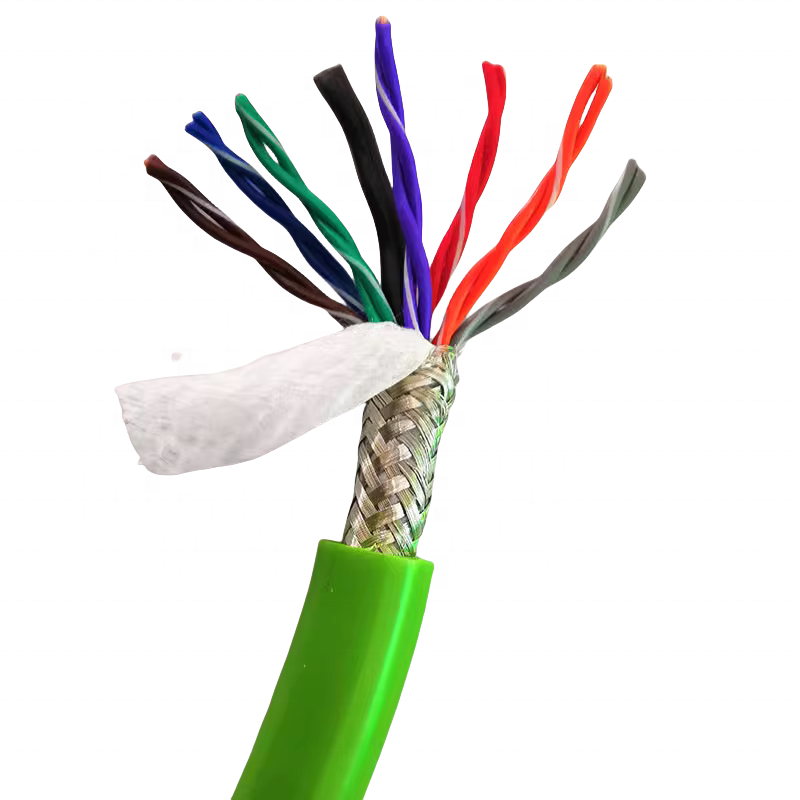

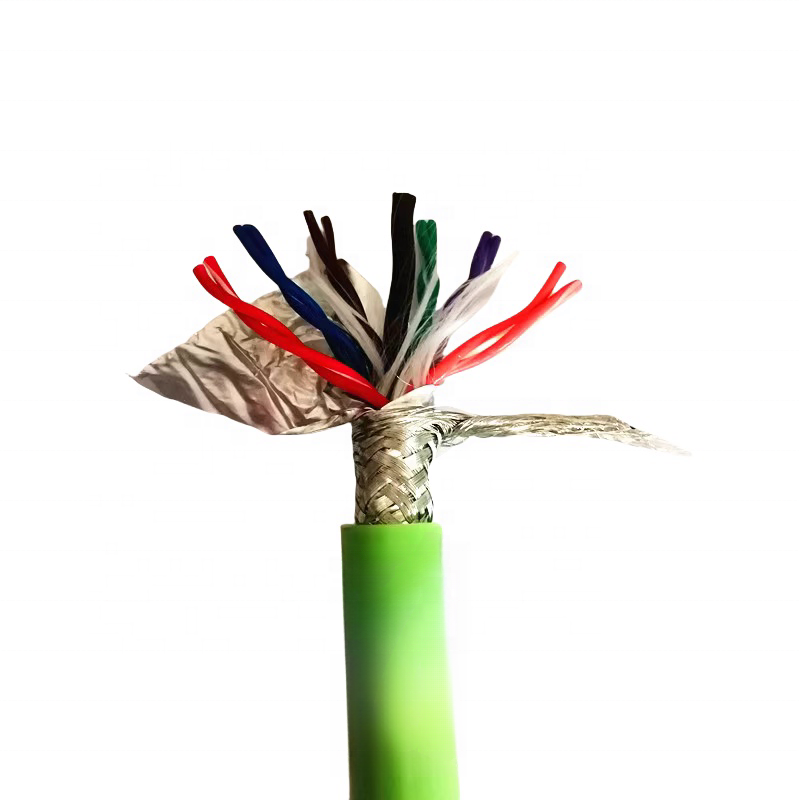

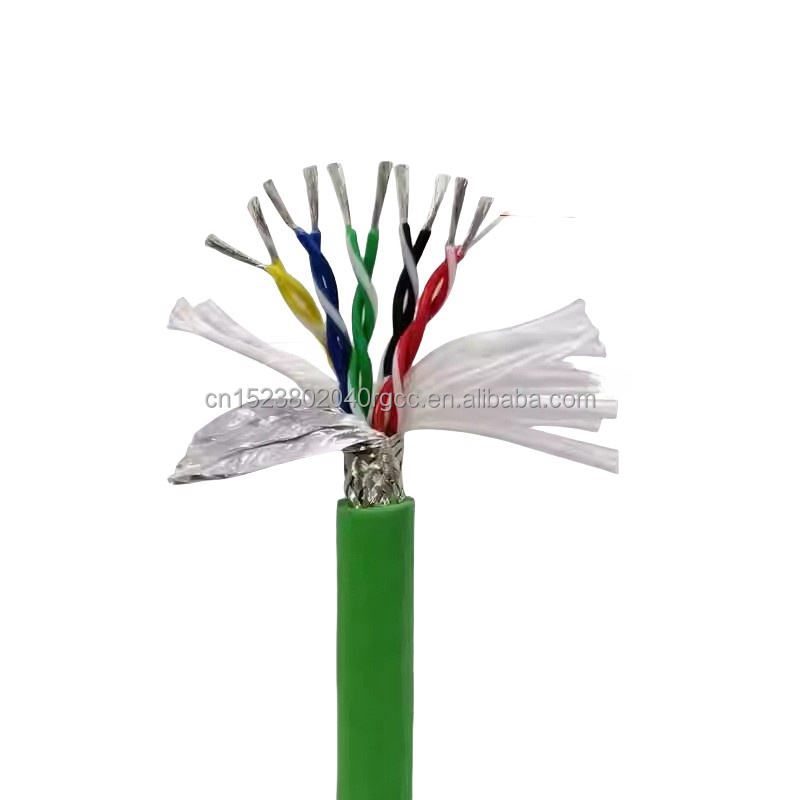

Customized Core Identification: Options for core numbering (Image 1), specific color coding (Image 2), or high-precision twisted pair layouts.

-

Flexible Manufacturing Specs: Customizable diameters, core counts (up to 20+), and jacket colors to meet specific OEM or system integrator standards.

High-Flex Shielded Encoder Cable: Precision Signal Integrity for Dynamic Industrial Automation

In the high-stakes world of industrial automation, a single millisecond of signal lag or one broken conductor can halt an entire production line. The 【High-Flex Shielded Encoder Cable】 is engineered specifically to be the reliable “nervous system” for multi-axis robots, CNC machinery, and high-speed servo systems. By combining superior electromagnetic interference (EMI) protection with extreme mechanical endurance, this cable ensures that your feedback loops remain crystal clear, even after millions of bending cycles.

Quick Summary for Industrial Engineers

The 【High-Flex Shielded Encoder Cable】 is a premium signal transmission solution featuring Class 6 ultra-fine stranded oxygen-free copper conductors and a dual-layer shield (Tinned Copper Braid + Aluminum Foil). Designed for drag chain environments, it supports over 10 million bending cycles and maintains stable performance in temperatures ranging from -40°C to +90°C. It is the ideal choice for minimizing downtime and increasing the Mean Time Between Failure (MTBF) in precision feedback systems.1

Why Signal Integrity Depends on Your Encoder Cable Selection

Encoder signals are notoriously sensitive to the “noise” generated by nearby power cables and high-frequency motors. Without proper shielding and structural design, signal attenuation and ghosting become inevitable.

Eliminating EMI with Dual-Layer Shielding

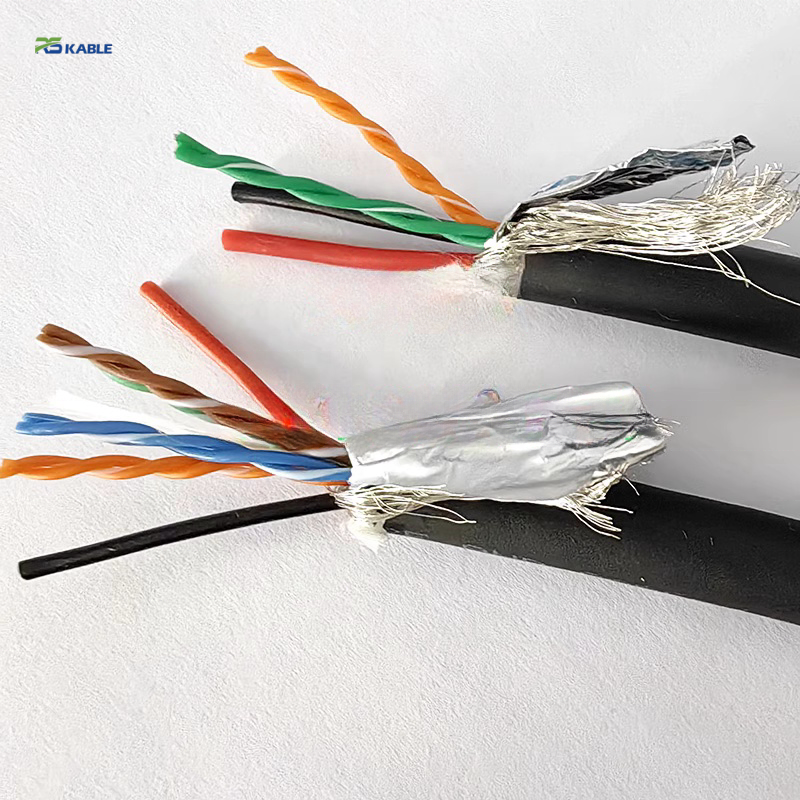

As shown in our technical cross-sections (see Image 2 and 3), our cables utilize a high-density tinned copper braid with a coverage rate exceeding 85%, combined with an aluminum foil wrap. This “dual-shield” approach creates a Faraday cage that effectively blocks both low-frequency magnetic interference and high-frequency radio interference, ensuring that your encoder data arrives at the controller without corruption.1

Managing the “Corkscrew Effect” in Motion

Standard industrial cables often fail when subjected to continuous torsion and linear motion, developing a permanent deformation known as the “corkscrew effect”.2 Our 【High-Flex Shielded Encoder Cable】 employs a specialized core stranding technique and low-friction PTFE (Teflon) tape wrapping.2 This allows the internal cores to slide freely against one another during movement, preventing internal stress buildup and conductor fatigue.2

Technical Specifications and Material Science

At Shanghai Rousheng, we believe that the foundation of a great cable lies in its materials. We offer a range of conductor sizes from 0.2 mm² to 0.75 mm² to fit various connector and power requirements.4

| Feature | Specification Details | Industrial Value |

| Conductor | Class 6 Stranded Oxygen-Free Copper | Maximum flexibility and conductivity |

| Shielding | Tinned Copper Braid + Aluminum Foil | >85% coverage for superior EMI protection |

| Jacket Options | High-Flex PUR / TPU or Special PVC | Oil, wear, and hydrolysis resistance |

| Bending Cycles | 5 Million to 10 Million+ (Drag Chain) |

Long-term reliability in dynamic tracks 2 |

| Temp Range | -40°C to +90°C (Fixed/Mobile) | Suitable for extreme cold and high-heat zones |

| Voltage Rating | 300V / 500V | Safe for standard encoder and signal levels |

Jacket Durability: TPU vs. PVC

For environments involving heavy oil exposure, chemical splashing, or high-speed friction, we recommend our TPU (Thermoplastic Polyurethane) jacketed versions. TPU offers significantly higher abrasion resistance and low-temperature flexibility compared to standard PVC, making it the preferred choice for 6-axis robotic arms and outdoor automation.

Engineering Expertise from Shanghai Rousheng Wire and Cable Co., Ltd.

Shanghai Rousheng is more than just a manufacturer; we are a dedicated R&D hub for high-performance cabling solutions. With over 100 specialized varieties in our portfolio, we bridge the gap between complex engineering requirements and cost-effective production.4

-

Deep Industry Roots: Our technical leadership includes senior engineers from the former Shanghai Cable Research Institute, bringing over 10 years of expertise to every design.4

-

Certified Quality: We strictly adhere to ISO9001 quality management systems and hold national CCC certifications, ensuring that every meter of cable meets international safety standards.4

-

Global Reach: Based in Shanghai, we serve the North American, European, and Southeast Asian markets, providing rapid prototyping and reliable logistics for global industrial projects.4

Frequently Asked Questions (FAQ)

What is the minimum bending radius for this encoder cable?

For mobile installations in drag chains, we generally recommend a bending radius of $7.5 \times D$ to $10 \times D$ (where $D$ is the cable outer diameter). For fixed installations, this can be reduced to $5 \times D$.

Is this cable compatible with major encoder brands like Fanuc or Siemens?

Yes. Our 【High-Flex Shielded Encoder Cable】 is designed with the same electrical and mechanical parameters as manufacturer-standard cables (A-E/F-L/M-W), making it a high-performance, drop-in replacement for OEM tethers.

How does the cable handle high-speed movement?

Our cables are tested for travel speeds up to 180°/S in torsional applications and millions of cycles in linear drag chains. The use of ultra-fine copper strands ensures the cable remains supple and does not “work-harden” over time.

Can I get a customized core count or jacket color?

Absolutely. We specialize in special cable customization. Whether you need a specific number of twisted pairs (as seen in Image 2 and 5) or numbered core identification (as seen in Image 1), we can tailor the structure to your exact BOM.

Reliability is built into every strand. Contact Shanghai Rousheng today to discuss your specific application needs and receive a comprehensive quote for your next automation project.