High-Flex Bending Encoder Cable, 8 / 10 / 12-Core Twisted Pair, Shielded Cable for Servo Motors and Drag-Chain Electrical Equipment

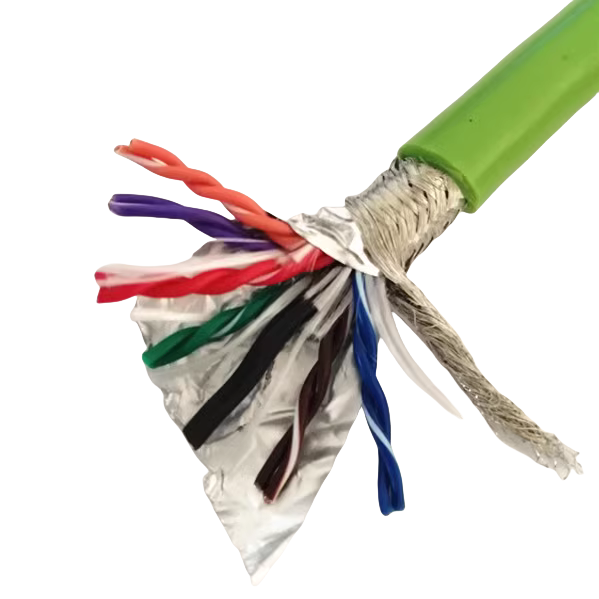

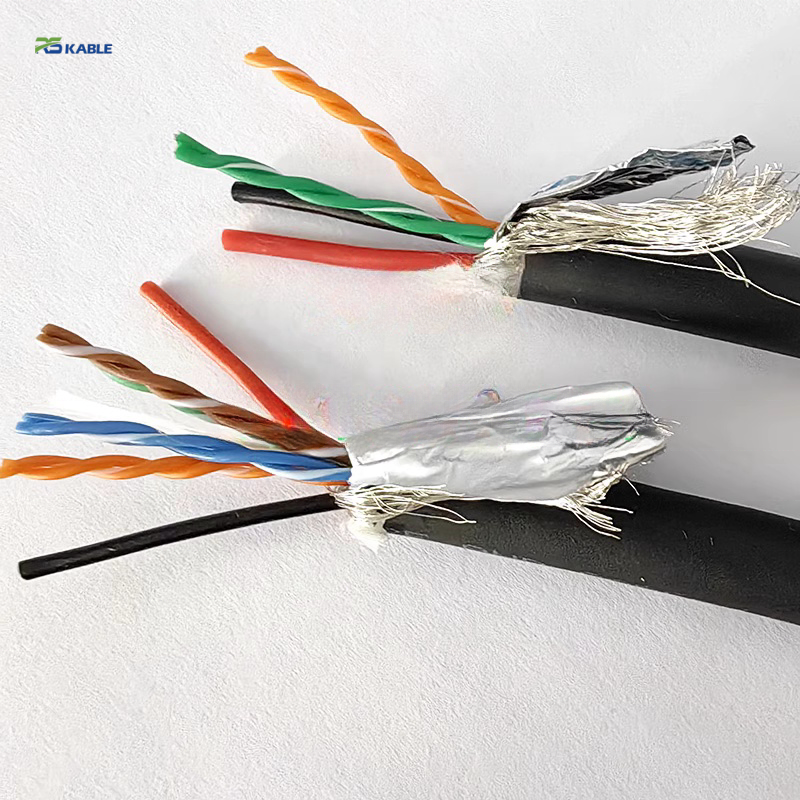

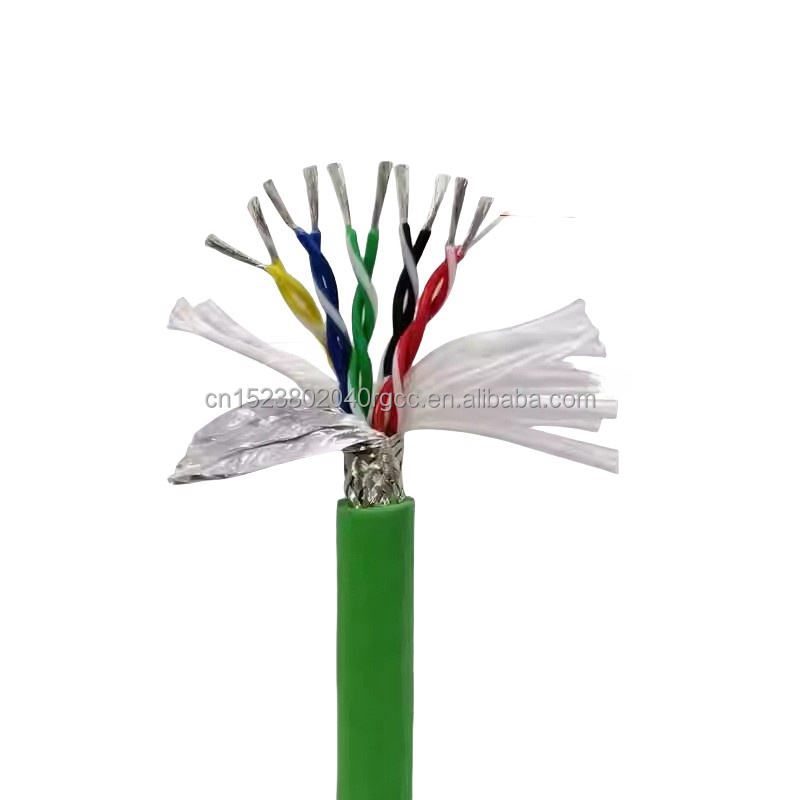

The High-Flex Bending Encoder Cable is a precision signal solution engineered for servo motors and dynamic drag-chain systems. Utilizing Class 6 ultra-fine oxygen-free copper conductors, it ensures stable feedback transmission through millions of high-speed bending cycles. The internal architecture (as seen in Images 1-6) combines high-density shielding with optimized core stranding to eliminate electromagnetic interference (EMI) and prevent mechanical fatigue in multi-axis robotic and CNC environments.

Key Features & Configurations:

-

Advanced Shielding: Features a dual-layer system with a tinned copper braid (>85% coverage) and aluminum foil to block high-frequency noise (Image 3, 5).

-

Precision Identification: Available with clear numerical core markings (Image 1) or color-coded twisted pairs (Image 2) for rapid, error-free installation.

-

Mechanical Endurance: Designed for tight-radius bending and high-frequency motion, resisting the “corkscrew effect” common in standard cables.

-

Industrial Ruggedness: Oil-resistant and abrasion-resistant TPU/PUR or PVC outer jackets (Image 4, 6) maintain flexibility from -40°C to +90°C.

-

Customized Layouts: Fully customizable core counts (8/10/12/20+), diameters, and internal strength members to match specific OEM requirements.

High-Flex Bending Encoder Cable

8 / 10 / 12-Core Twisted Pair, Shielded Cable for Servo Motors and Drag-Chain Electrical Equipment

In modern automation systems, signal accuracy is only as reliable as the cable carrying it. Shanghai Rousheng’s High-Flex Bending Encoder Cable is engineered for continuous motion environments where repeated bending, torsion, and electrical noise are unavoidable. Designed specifically for servo motors, feedback systems, and drag-chain applications, this cable delivers stable encoder signals even under long-term dynamic stress.

Designed for Continuous Bending and Signal Stability

Unlike standard control cables, a High-Flex Bending Encoder Cable must endure thousands—often millions—of movement cycles without conductor fatigue or signal degradation. This product is built around finely stranded copper conductors, precision twisted pairs, and a multi-layer shielding system that minimizes EMI while maintaining exceptional flexibility.

The internal structure shown in the product images reflects a deliberate engineering balance: mechanical endurance on the outside, electrical integrity at the core.

Key Product Advantages

High Mechanical Flexibility

-

Ultra-fine stranded copper conductors improve bending endurance

-

Optimized lay length reduces internal stress during motion

-

Suitable for continuous flexing in drag chains and moving assemblies

Reliable Encoder Signal Transmission

-

Twisted-pair construction stabilizes differential signals

-

Individual foil shielding reduces cross-talk between cores

-

Overall braided shield suppresses external electromagnetic interference

Industrial-Grade Durability

-

Oil-resistant and abrasion-resistant outer jacket

-

Withstands vibration, repetitive motion, and mechanical friction

-

Maintains performance in harsh factory environments

Cable Construction Overview

Conductor Design

-

High-purity stranded copper for flexibility and low resistance

-

Available in 8-core, 10-core, and 12-core configurations

Insulation & Pairing

-

Color-coded insulated cores for easy installation and maintenance

-

Precision twisted pairs ensure consistent impedance and signal accuracy

Shielding System

-

Aluminum foil shielding for each signal group

-

Overall tinned copper braid provides 360-degree EMI protection

Outer Jacket

-

Flexible industrial PVC or TPU (customizable)

-

Smooth surface optimized for drag-chain movement

Typical Applications

The High-Flex Bending Encoder Cable is widely used in applications where motion control precision and long service life are critical:

-

Servo motor feedback systems

-

CNC machinery and machining centers

-

Industrial robots and robotic arms

-

Automated production lines

-

Drag-chain and cable carrier systems

-

Packaging, labeling, and material handling equipment

In these environments, consistent encoder feedback directly affects positioning accuracy, cycle time, and equipment reliability.

Technical Specifications (Typical)

| Parameter | Specification |

|---|---|

| Core Count | 8 / 10 / 12 cores |

| Conductor | Fine-stranded copper |

| Pairing | Twisted pair |

| Shielding | Foil + overall braided shield |

| Voltage Rating | Typically 300/500 V (customizable) |

| Flexing Use | Continuous bending / drag chain |

| Jacket Material | PVC or TPU (optional) |

| Temperature Range | Designed for industrial environments |

Specifications can be customized based on project requirements.

Why Choose Shanghai Rousheng Cable

Shanghai Rousheng Wire & Cable Co., Ltd. focuses exclusively on high-flex drag-chain cables and specialty industrial cables, with over 100 cable types developed for automation, robotics, and motion control systems. Our engineering team understands that encoder cables are not generic components—they are performance-critical parts of your control system.

When you choose a High-Flex Bending Encoder Cable from Rousheng, you gain:

-

Proven experience in dynamic cable design

-

Stable quality across large-scale production

-

Custom engineering support for demanding applications

-

Reliable supply for long-term equipment programs

Customization & OEM Support

We offer OEM and ODM services to match your exact system requirements, including:

-

Core count and conductor size customization

-

Shielding structure optimization

-

Jacket material selection

-

Color, printing, and length configuration

Our goal is not only to supply a cable, but to ensure long-term operational stability for your equipment.