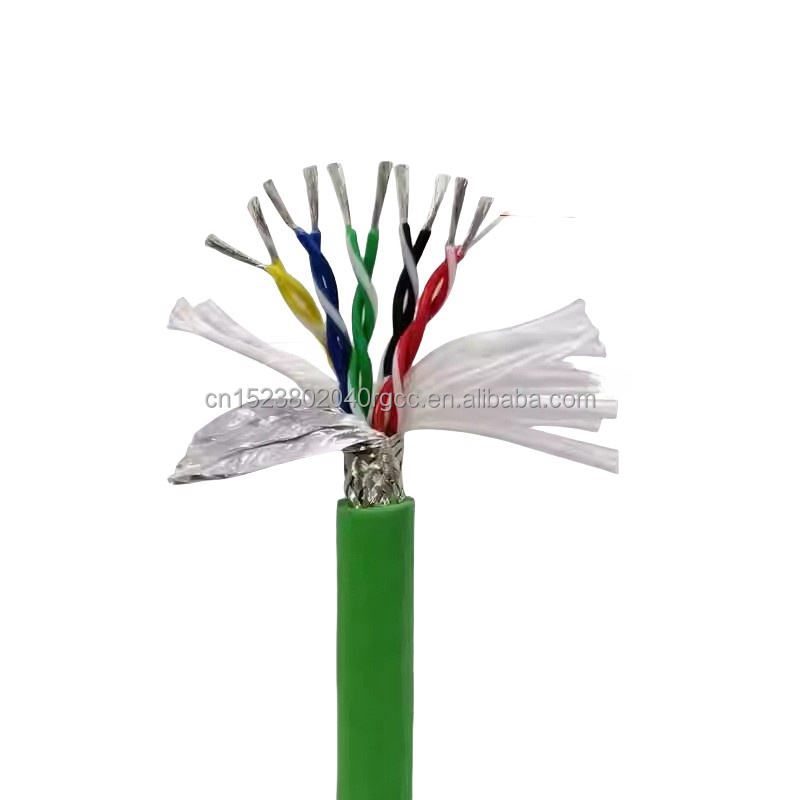

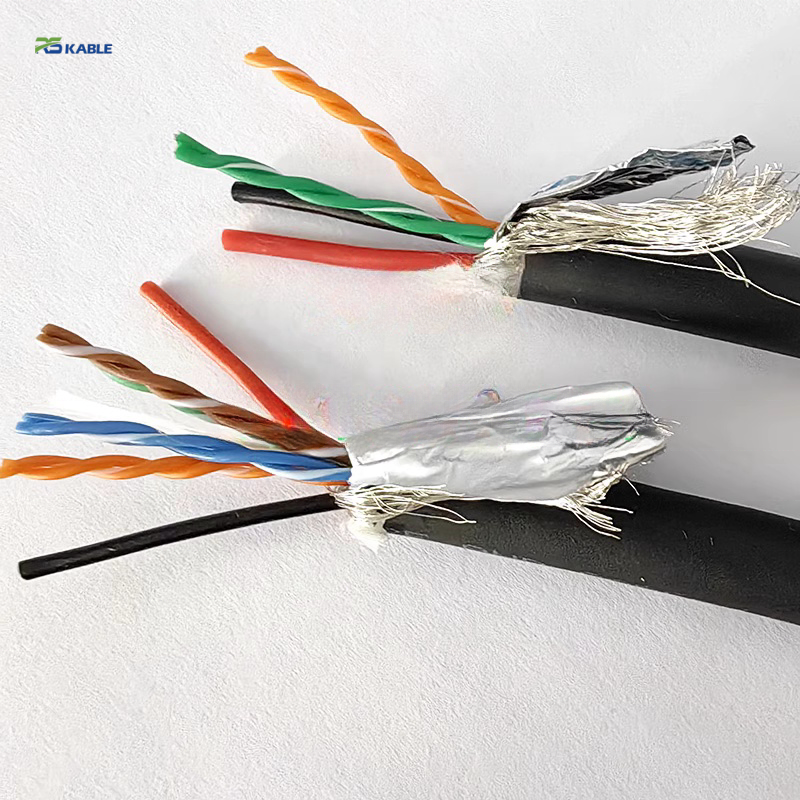

High-Flex 24 AWG Encoder Cable and Servo Motor Cable, Waterproof, Corrosion-Resistant, Bend-Resistant, Shielded Twisted Pair Cable

With a waterproof and corrosion-resistant outer jacket, the cable performs consistently in harsh conditions such as moisture, oil, and chemical exposure. The shielded twisted pair structure effectively reduces electromagnetic interference, ensuring stable and accurate encoder feedback and servo motor control signals.

Key Features:

-

High-flex design for drag chain and continuous motion applications

-

24 AWG stranded copper conductor for excellent flexibility and conductivity

-

Shielded twisted pair structure for reliable signal integrity

-

Waterproof and corrosion-resistant jacket

-

Bend-resistant construction for extended service life

-

Suitable for CNC machines, industrial robots, and automated production lines

Product Overview

The High-Flex 24 AWG Encoder Cable and Servo Motor Cable from Shanghai Rosheng Cable Co., Ltd. is engineered for demanding industrial automation and motion control applications. Designed as a high-flex drag chain-compatible cable, this product combines superior flexibility, robust shielding, and environmental durability for precise data and power transmission in servo systems.

Shanghai Rosheng Cable Co., Ltd. specializes in high-flex drag chain cable and specialty cable development, production, and service. With more than 100 cable varieties manufactured and globally shipped, our experience ensures both product reliability and engineering support.

Why Choose This Cable?

High Durability and Environmental Protection

-

Waterproof and corrosion-resistant jacket enables reliable operation in wet, chemical-rich, and harsh industrial environments often encountered in manufacturing, robotics, and automated assembly lines. Industry-grade cable jackets are crafted from advanced polymer compounds that resist hydrolysis, oil, and chemical attack.

-

Bend-resistant, high-flex design supports dynamic motion applications such as drag chains and robotic arms without compromising signal integrity or service life. High-flex cables are tested for millions of flex cycles, reducing downtime caused by cable failure. ChengJia Cable+1

Signal Integrity and Shielding

-

Shielded twisted pair construction ensures stable data & feedback signal transmission between controllers, servo motors, and encoders. Shielding significantly reduces electromagnetic interference (EMI), ensuring accurate speed and position feedback even in electrically noisy environments.

-

Tinned copper braided shield provides over 80% coverage to minimize noise and protect signal integrity. This structural design is critical in encoder feedback lines where even small distortions can impact motion control precision. ChengJia Cable+1

Application Versatility

The High-Flex 24 AWG Encoder Cable and Servo Motor Cable is suitable for:

-

CNC machines and production line equipment

-

Industrial robots and gantry systems

-

Automated warehousing and material handling systems

-

High-speed packaging machinery

-

Drag chain and continuous movement systems

Key Features

-

Quantity: Custom lengths available

-

Conductor: High-purity stranded copper (24 AWG) for excellent flexibility and conductivity

-

Shielding: Braided tinned copper shield with high coverage for superior EMI protection

-

Jacket: Durable polymer offering waterproof, chemical resistance, and abrasion resistance

-

Bend Radius: Designed for dynamic flexing with minimal signal distortion

-

Temperature Tolerance: Suitable for a wide range of industrial ambient conditions

-

Compliance: Conforms to industry cable standards for safety and performance

Technical Specifications

| Specification | Description |

|---|---|

| Cable Type | High-Flex Shielded Encoder & Servo Cable |

| Wire Size | 24 AWG Stranded Copper |

| Conductor Material | Tinned Copper |

| Shielding Structure | Braided Shield (≥80% coverage) |

| Jacket Material | Waterproof & Corrosion-Resistant PVC/PUR |

| Bend Life | Rated for high flexing cycles |

| Temperature Range | Industrial operating range |

| Application | Drag chain, Servo, Encoder interfaces |

Note: Specific values such as bend radius, temperature range, certified standards, and custom configurations are available upon request based on project requirements.

Installation & Usage Guidelines

Best Practices

-

Route cable avoiding sharp edges and tight bends to maximize service life.

-

Ensure shielding is properly grounded to minimize EMI interference.

-

Use strain relief at each termination point, especially in drag chains or dynamic motion systems.

-

For lengths over 5 meters, follow recommended drag chain routing to prevent early fatigue.

Compatibility

This cable is compatible with a wide range of servo drives, PLC encoders, motion controllers, and feedback systems. It serves as a high-performance alternative or upgrade path for OEM applications where signal reliability and durability are mission-critical.

FAQ (Frequently Asked Questions)

Q1: What distinguishes this High-Flex 24 AWG Encoder Cable and Servo Motor Cable from standard cables?

A1: Standard cables are typically designed for static installations. In contrast, this high-flex cable is engineered for dynamic motion, extended bend cycles, and continuous movement environments, ensuring long-term reliability and reduced replacement frequency.

Q2: Can I use this cable in outdoor or wet environments?

A2: Yes. The cable jacket is waterproof and corrosion resistant, suitable for environments where moisture and chemicals are present.

Q3: How does the shielding affect performance?

A3: The braided shield minimizes electromagnetic interference, which is crucial in encoder feedback loops and servo communication to maintain precise signal integrity.

Q4: Are custom lengths and configurations available?

A4: Yes. We provide custom cable lengths and interface options based on customer requirements and application scenarios.

Q5: What industries typically use this type of cable?

A5: Industries including automation, robotics, CNC machinery, packaging, and material handling all commonly use high-flex encoder and servo motor cables to support motion systems.