Flexible Waterproof Underwater ROV Cable | 8×0.5 mm² Power & Signal Tether

- Pipe Inspection Crawlers: Durable enough to be dragged through rough concrete or metal pipes.

- Aquaculture Monitoring: Permanent installation for sensors in fish farms.

- Port and Harbor Surveillance: Reliable power for underwater cameras.

- Wellbore Instrumentation: managing signals in wet, confined spaces.

Maintaining a reliable connection in deep-water environments isn’t just about power—it’s about confidence. When your equipment is submerged hundreds of meters below the surface, the last thing you need is a signal failure. The Flexible Waterproof Underwater ROV Cable is engineered specifically for these demanding conditions, providing a robust lifeline for Remotely Operated Vehicles (ROVs), underwater robots, and autonomous submersibles.

Designed by Shanghai Rousheng Wire and Cable Co., Ltd., a specialist in high-flex drag chain and special cables, this 8×0.5 mm² tether ensures your data and power transmission remain uninterrupted, even in transverse drag and high-pressure scenarios. Whether you are conducting hull inspections, oceanographic research, or industrial aquaculture monitoring, this cable delivers the durability and flexibility professionals demand.

Engineered for the Deep: Why Flexibility Matters

Underwater robotics require cables that can withstand more than just moisture. They need to endure constant movement, twisting, and tension. Standard cables often stiffen or crack under these conditions, leading to catastrophic system failures.

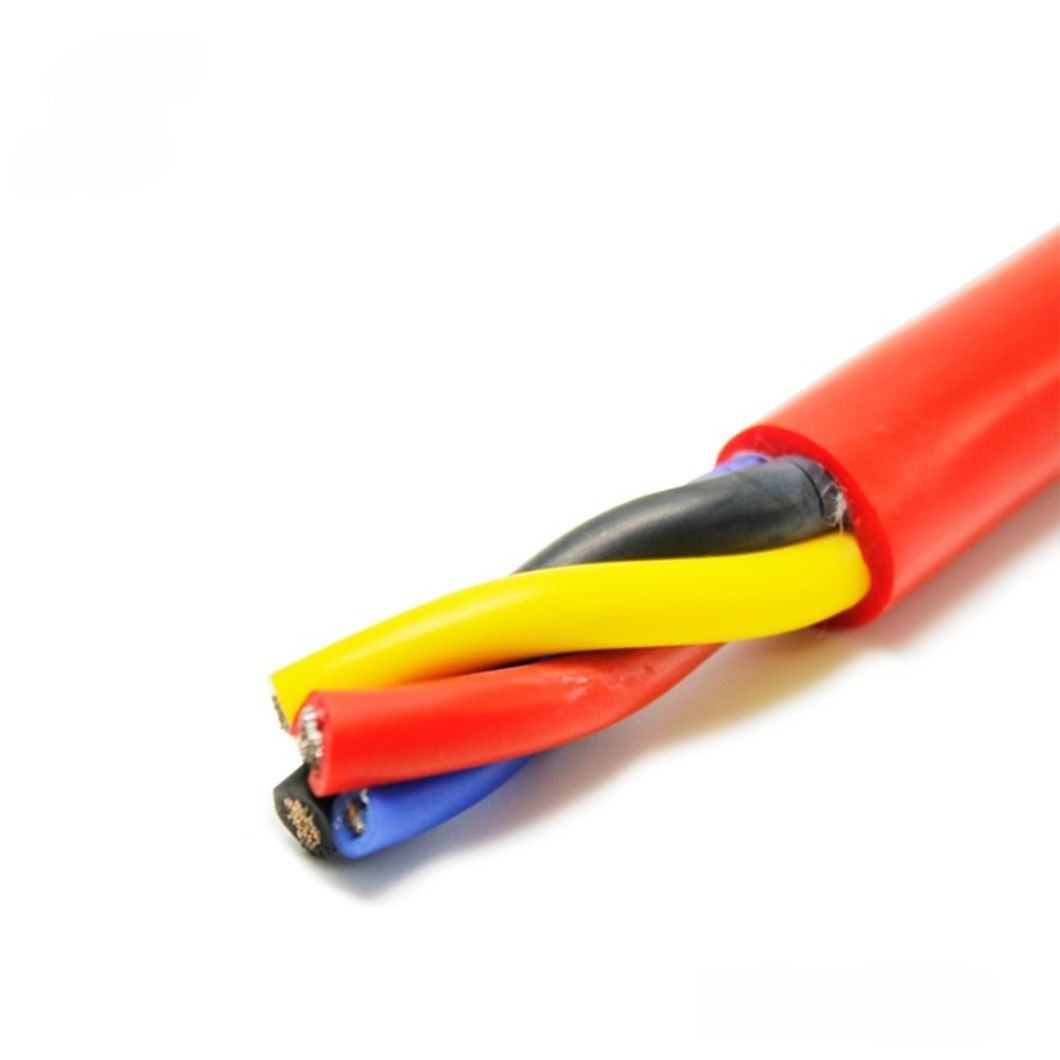

This ROV tether utilizes a specialized TPE (Thermoplastic Elastomer) insulation and a durable PVC jacket, creating a “zero buoyancy” or neutrally buoyant effect depending on your configuration. This design minimizes drag on your vehicle, allowing for smoother maneuverability and longer battery life for your ROV. The high flexibility prevents kinks and tangles, which are common issues during deployment and retrieval operations.

Key Technical Specifications

Understanding the build quality is essential for industrial applications. Here is a breakdown of the technical attributes that make this cable a top choice for marine engineers.

|

Specification |

Details |

|---|---|

|

Model |

Robot Cable / ROV Tether |

|

Conductor Material |

High-quality Tinned Copper (Resists corrosion) |

|

Insulation Material |

TPE (Thermoplastic Elastomer) for superior flexibility |

|

Jacket Material |

PVC (Waterproof, abrasion-resistant) |

|

Core Configuration |

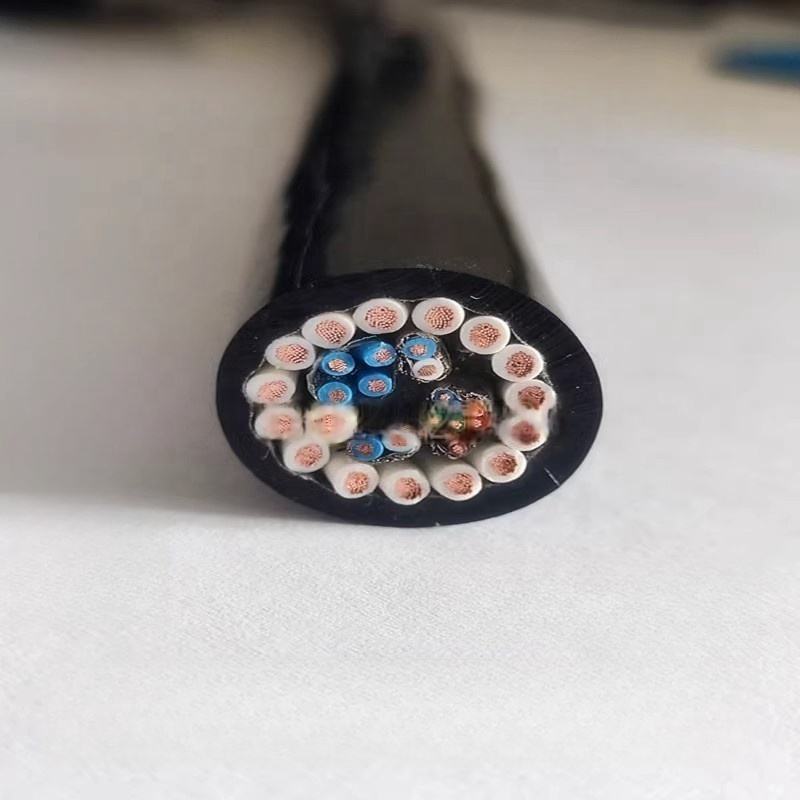

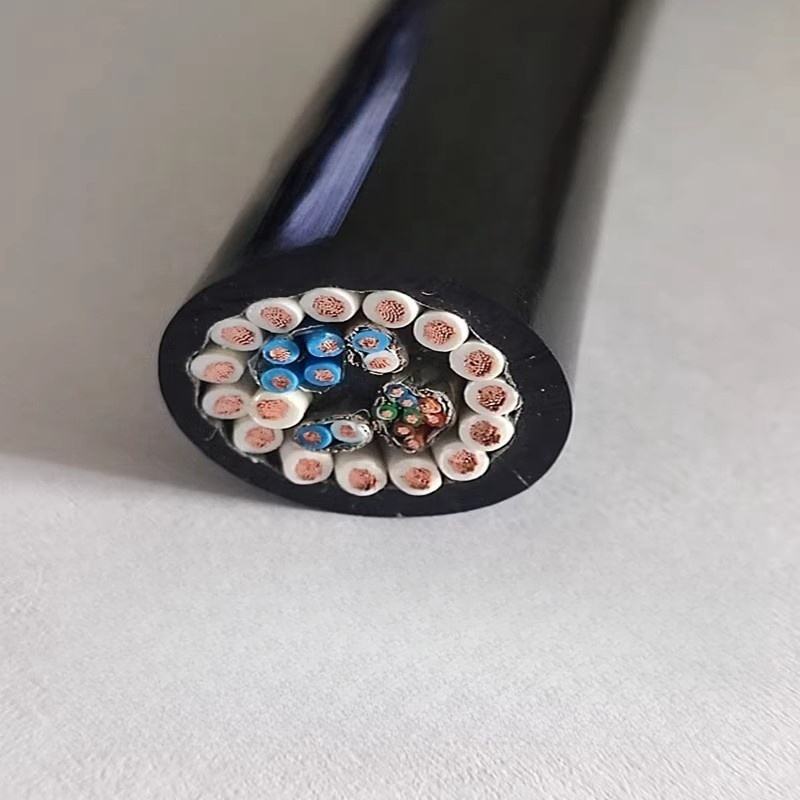

8 Cores × 0.5 mm² (Power + Signal transmission) |

|

Application |

Industrial, Underwater Robotics, Marine Surveying |

|

Waterproof Rating |

Transverse Waterproof / Watertight |

|

Origin |

Shanghai, China (Shanghai Rousheng Wire And Cable Co., Ltd.) |

Performance Benefits for Marine Operations

1. Superior Signal Integrity

The use of tinned copper conductors is a critical feature. Unlike bare copper, tinned copper offers enhanced protection against oxidation and corrosion—the primary enemies of marine electronics. This ensures that your video feeds remain crisp and your control signals remain responsive, even after prolonged exposure to humid or damp storage conditions.

2. High-Flex Durability

This cable isn’t just waterproof; it is built for motion. The internal structure is designed to withstand repetitive bending and twisting. This makes it ideal for drag chain systems or free-swimming ROVs where the tether is constantly moving relative to the vessel.

3. Chemical and Abrasion Resistance

The outer jacket is formulated to resist the harsh realities of industrial environments. It stands up to abrasion from seabed rocks, exposure to seawater, and even mild chemical contact, extending the operational lifespan of the tether and reducing replacement costs.

Frequently Asked Questions (FAQ)

What makes this cable different from standard PVC cables?

Standard PVC cables often become brittle in cold water or stiffen over time. This ROV cable uses a specialized TPE insulation and a marine-grade jacket compound designed specifically to maintain flexibility and watertight integrity in submerged environments.

Can this cable handle both power and data?

Yes. The 8×0.5 mm² configuration is ideal for hybrid transmission. You can dedicate specific cores for powering thrusters or lights, while using the remaining cores for data sensors and video signal transmission.

Is this cable suitable for seawater use?

Absolutely. The materials chosen, including the tinned copper conductors, are specifically selected to resist the corrosive effects of saltwater environments.

What is the minimum order quantity (MOQ)?

We support orders ranging from small prototype runs (1-1000 meters) to large-scale industrial supply (>1000 meters). Lead times are typically around 15 days for standard orders.

Can I get a custom length or color?

Yes, customization is a core part of our service. While Yellow and Orange are standard high-visibility options, we can manufacture lengths and colors to suit your specific project requirements.