Flexible PUR/TPU Spiral Power Cable for Automotive Intelligent Robot Arms | High‑Flex Coiled Cable

High-Flexible PUR/TPU Spiral Power Cable is a durable, oil-resistant coiled solution designed for robotics and automation.

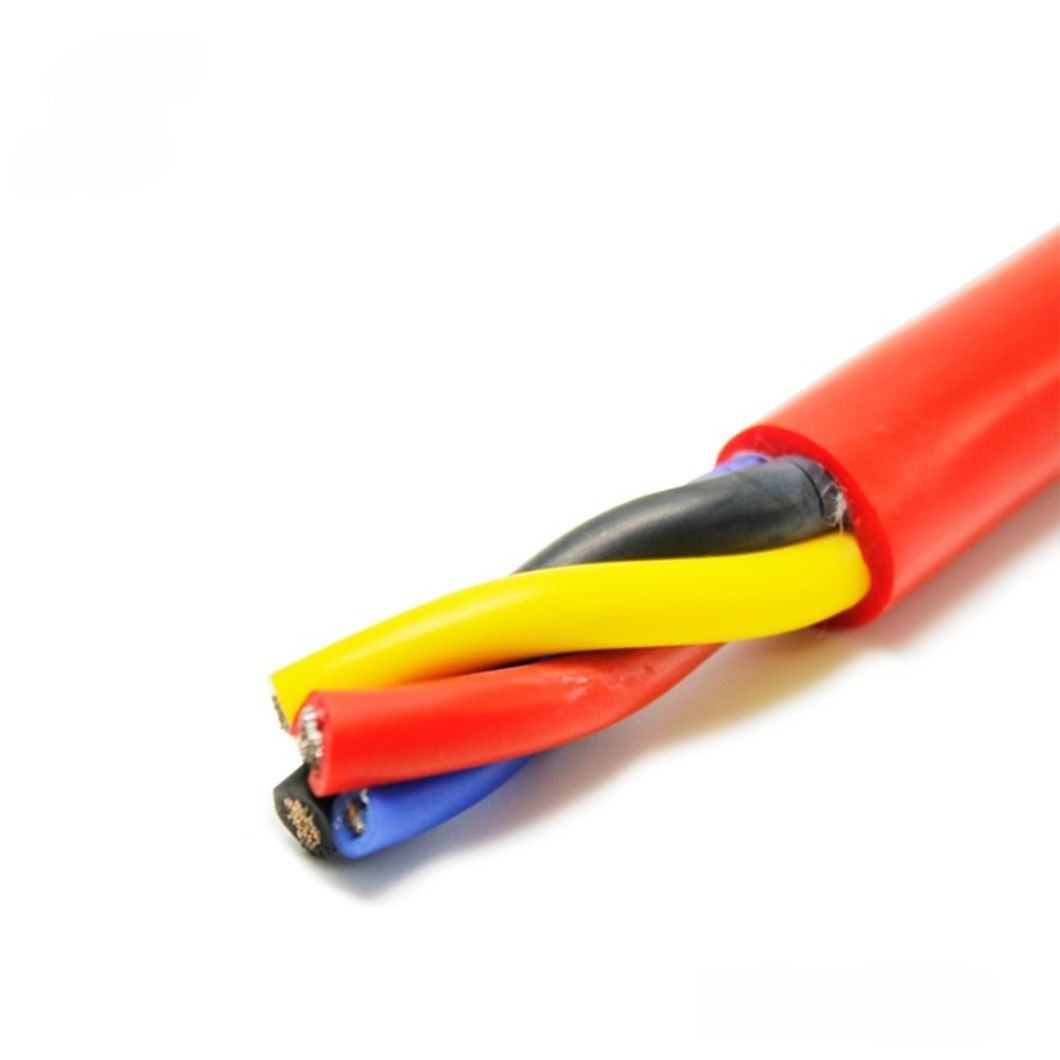

. Conductor: Fine stranded tinned copper

. Insulation: PP/PE/TPE for high elasticity

. Jacket: Abrasion-resistant PUR/TPU

. Temp Range: -40°C to +90°C

. Extension Ratio: Up to 1:4

. Application: Robot arms, CNC, Automotive

Engineered for Continuous Motion and Harsh Industrial Environments

In the automotive manufacturing and robotics sectors, equipment downtime caused by cable failure is a costly bottleneck. The Flexible PUR/TPU Spiral Power Cable by Shanghai Ruosheng Cable is designed specifically to withstand the rigorous demands of robotic arms and intelligent automation systems.

Unlike standard PVC cables that crack under repetitive stress or degrade when exposed to industrial oils, our PUR (Polyurethane) and TPU (Thermoplastic Polyurethane) jacketing ensures exceptional mechanical strength. These cables provide high restoring force—meaning they return to their original coiled shape even after thousands of extension cycles—making them the reliable choice for dynamic power and control applications.

Why Choose Ruosheng High-Flex Spiral Cables?

We specialize in high-flexibility solutions. Our R&D focuses on solving the common failure points in dynamic cabling: loss of elasticity (sagging coils) and jacket abrasion.

- Superior “Memory” and Elasticity: Using premium TPU materials, our spirals maintain a high recoil ratio. They can typically extend up to 3-4 times their closed length and retract without deformation, essential for robotic arms that require a full range of motion.

- Extreme Resistance: The outer PUR sheath is resistant to mineral oils, greases, coolants, and hydraulic fluids found in automotive assembly lines. It is also halogen-free, notch-resistant, and abrasion-resistant.

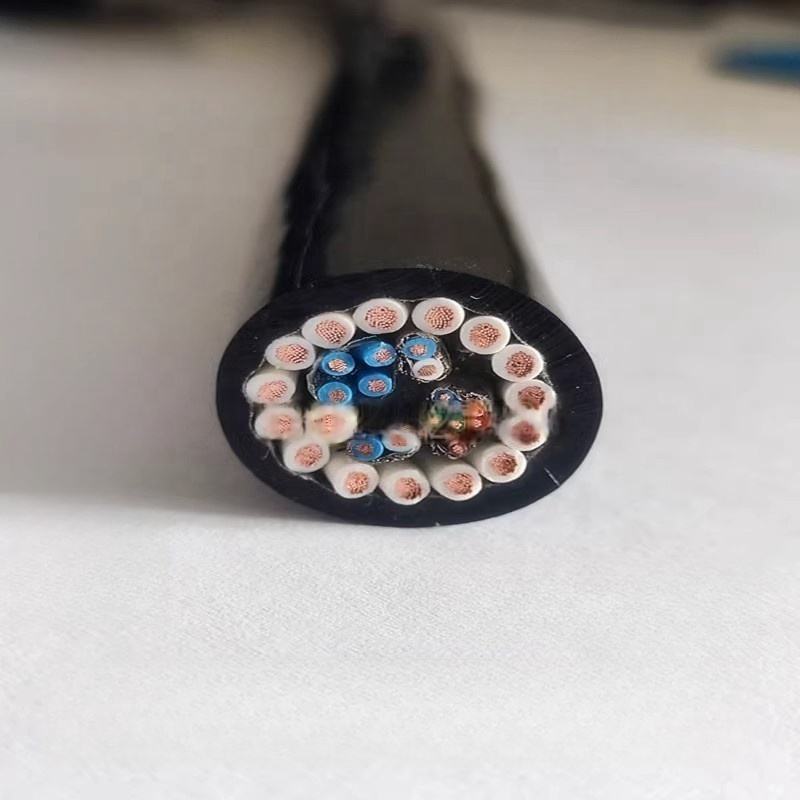

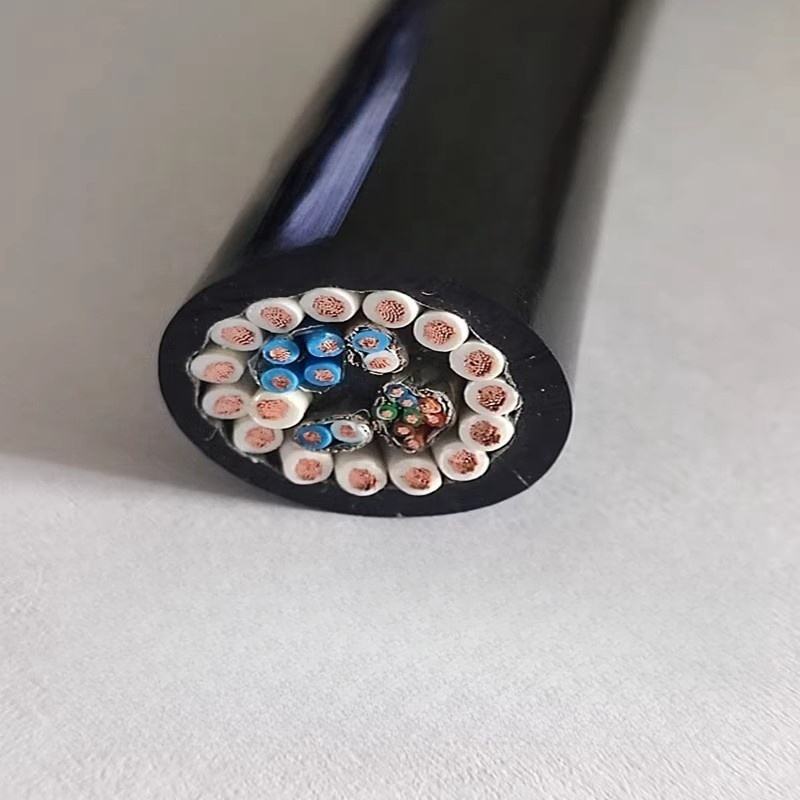

- Interference-Free Transmission: Available with tinned copper shielding (braid or spiral) to protect sensitive control signals from Electromagnetic Interference (EMI) in noisy factory environments.

- All-Weather Performance: Maintained flexibility in temperatures ranging from -40°C to +90°C, suitable for unheated warehouses or hot machinery zones.

Technical Specifications

This data covers our standard manufacturing capabilities. We can customize core counts, lengths, and dimensions to match your specific machinery requirements.

|

Feature |

Specification |

|---|---|

|

Conductor Material |

High-flex fine stranded bare or tinned copper (Class 5/6 VDE 0295) |

|

Insulation Material |

PP (Polypropylene), TPE, or PE for low capacitance and high durability |

|

Jacket Material |

PUR (Polyurethane) / TPU (Thermoplastic Polyurethane) – Matte or Glossy |

|

Shielding (Optional) |

Tinned copper braid or spiral wrap (coverage ≥ 85%) for EMC compliance |

|

Rated Voltage |

Control: 300/500V | Power: 450/750V |

|

Test Voltage |

2000V / 3000V |

|

Temperature Range |

Moving: -25°C to +80°C | Fixed: -40°C to +90°C |

|

Extension Ratio |

1:3 to 1:4 (Cable extends 3-4x its static coiled length) |

|

Coil Diameter (OD) |

Customizable based on cable thickness and pitch requirements |

|

Certifications |

CE, RoHS, REACH Compliant |

|

Flame Retardant |

Acc. to IEC 60332-1-2 / VW-1 |

Primary Applications

This cable is optimized for environments where combined power and signal transmission is required alongside high mechanical stress:

- Automotive Manufacturing: Assembly robots, welding robots, and painting arms.

- Industrial Automation: CNC machines, handling systems, and moving machine parts.

- Medical Equipment: Adjustable beds and diagnostic imaging devices requiring hygienic, durable cables.

- Automatic Doors & Gates: Sensors and power supply for moving barriers.

Frequently Asked Questions (FAQ)

What is the difference between PUR and PVC spiral cables?

PUR (Polyurethane) cables offer significantly higher mechanical strength, better tear resistance, and superior chemical resistance compared to PVC. While PVC is cost-effective for light use, PUR is essential for industrial robotics and dynamic applications where oil resistance and high elasticity are required.

Can you customize the tail lengths of the spiral cable?

Yes. The straight ends (tangents) at both ends of the coil can be cut to your specific length requirements (e.g., 100mm/200mm) and can be processed with insulation stripping or connector installation upon request.

How do I calculate the extended length I need?

A general rule for our high-quality PUR cables is a 3:1 or 4:1 ratio. If you have a static closed coil length of 1 meter, it can safely extend to approximately 3 to 4 meters. We recommend operating within 80% of the maximum extension to maximize the cable’s lifespan.

Does Shanghai Ruosheng offer shielded versions for data transfer?

Absolutely. For intelligent robot arms transmitting sensor data, we recommend our shielded (screened) series. This prevents electrical noise from motors and drives from corrupting the data signals.

What is the lead time for custom orders?

As a direct manufacturer with over 100 varieties of special cables, we can often produce custom specifications faster than general distributors. Contact our sales team with your core count and diameter requirements for an accurate timeline.