Electromagnetic Harsh Environments | ROV Cable | Shielded Anti-Interference | Low-Noise Performance

This shielded anti-interference ROV Cable is engineered for electromagnetic harsh offshore environments requiring low-noise and stable data transmission. Featuring multi-layer foil and braided shielding, optimized grounding design, and precision-balanced conductors, it effectively suppresses EMI while maintaining signal clarity. Reinforced with marine-grade materials for mechanical durability, it supports inspection-class and work-class ROV systems operating near high-voltage subsea infrastructure. Ideal for offshore platforms, renewable energy installations, and industrial marine projects, it ensures reliable subsea communication even in electrically challenging conditions.

Electromagnetic Harsh Environments | ROV Cable | Shielded Anti-Interference | Low-Noise Performance

The ROV Cable developed for electromagnetic harsh environments is specifically designed to maintain low-noise performance and stable communication in areas with high EMI exposure. Offshore platforms, subsea power infrastructure, and industrial marine zones often generate strong electromagnetic fields that can distort signals and disrupt ROV control systems.

This shielded anti-interference ROV Cable integrates multi-layer screening, optimized grounding architecture, and controlled conductor layout to ensure signal clarity and operational reliability under electrically noisy conditions.

Designed for High-EMI Offshore Conditions

Subsea environments near heavy electrical equipment present risks such as:

-

Signal distortion from high-voltage cables

-

Control instability due to electromagnetic coupling

-

Data packet loss in telemetry systems

-

Video noise in HD inspection cameras

To mitigate these risks, this ROV Cable incorporates advanced shielding strategies and balanced transmission structures.

Product Configuration Portfolio

| Model Code | Product Name (Model + Core Attribute) | Application Scenario | Shielding Structure |

|---|---|---|---|

| EMI-ROV-SP4 | Shielded 4-Pair Signal Protection Cable | Subsea monitoring systems | Individual foil shield + drain wire |

| EMI-ROV-PS6 | Power & Signal Anti-Interference Hybrid | Offshore platform inspection | Foil + braided copper shielding |

| EMI-ROV-TS8 | Triple-Shield Low-Noise ROV Cable | High-voltage proximity zones | Multi-layer foil + 85% braid coverage |

| EMI-ROV-FOE | Electro-Optical Shielded ROV Cable | HD data & sonar systems | Optical fiber + dual-layer shielding |

Each model supports configurable shielding density and grounding design based on system sensitivity requirements.

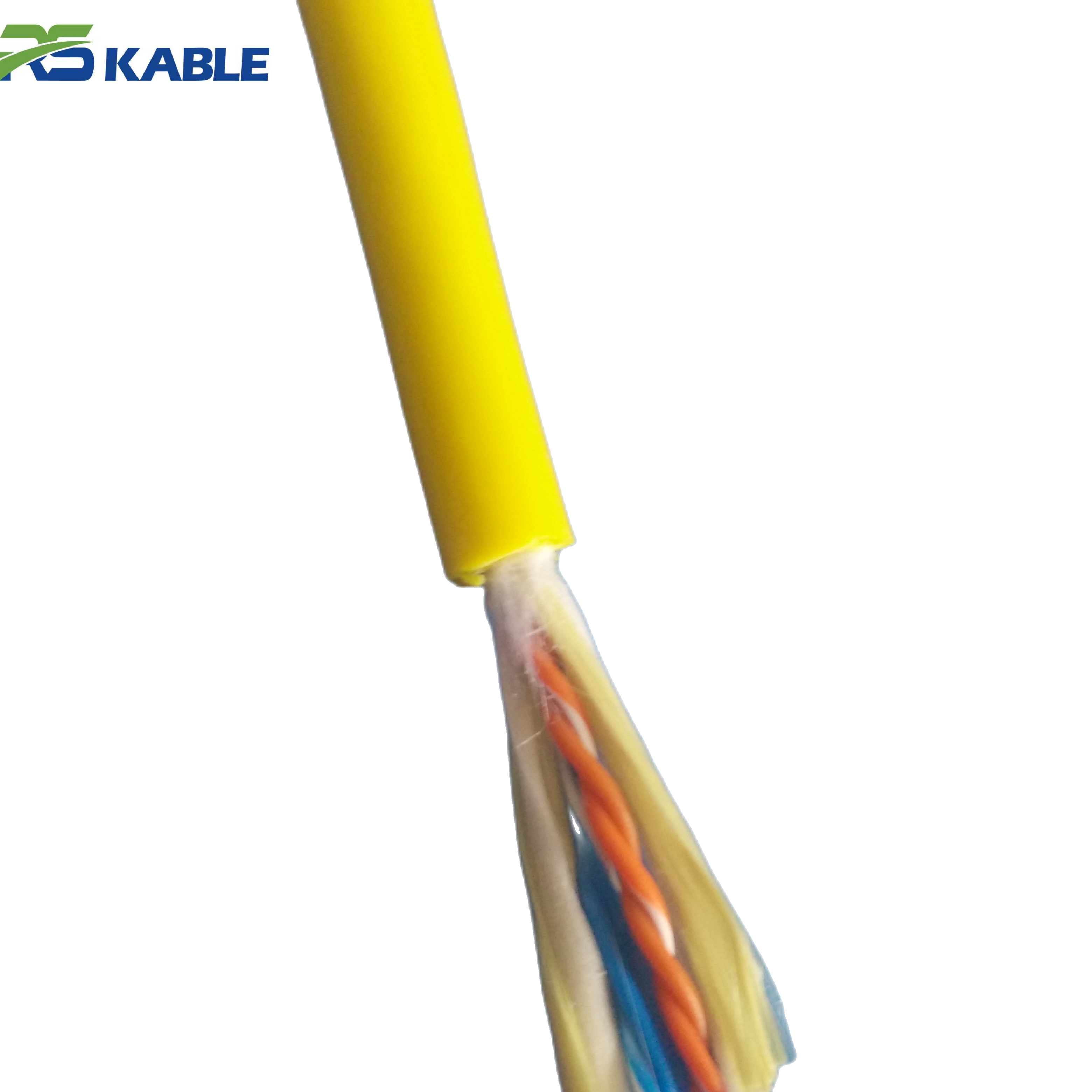

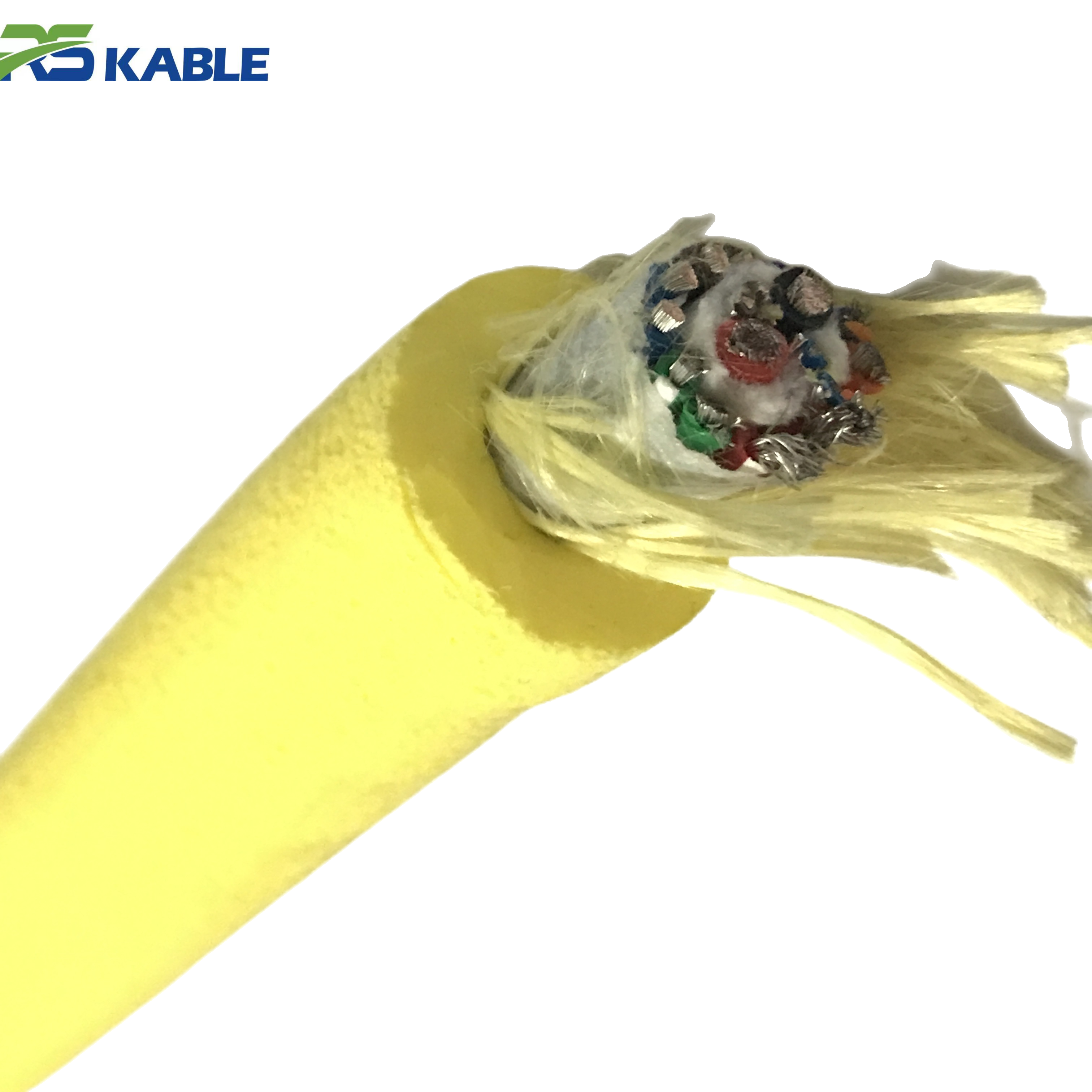

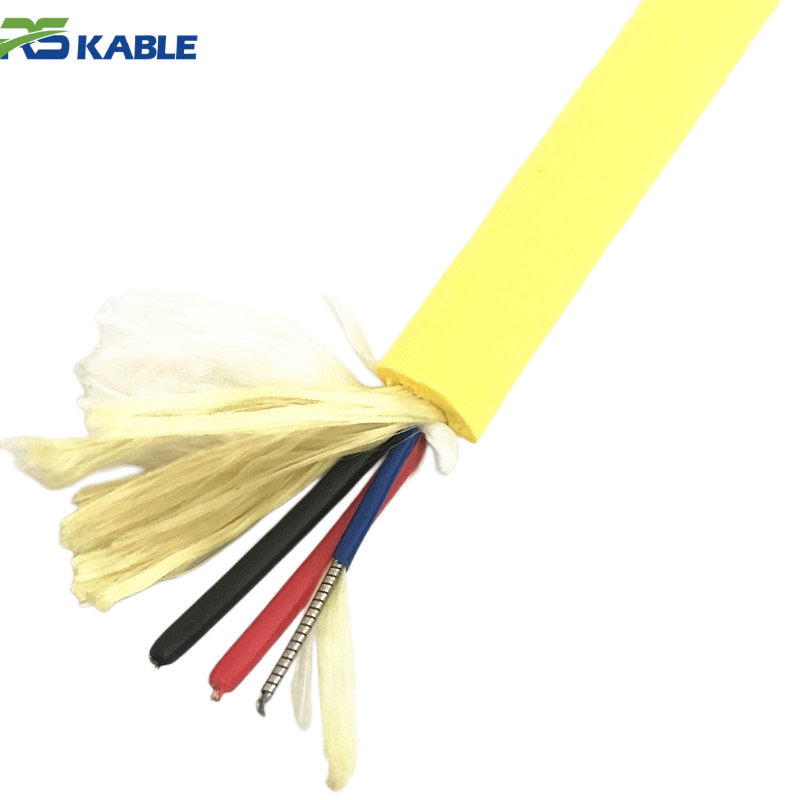

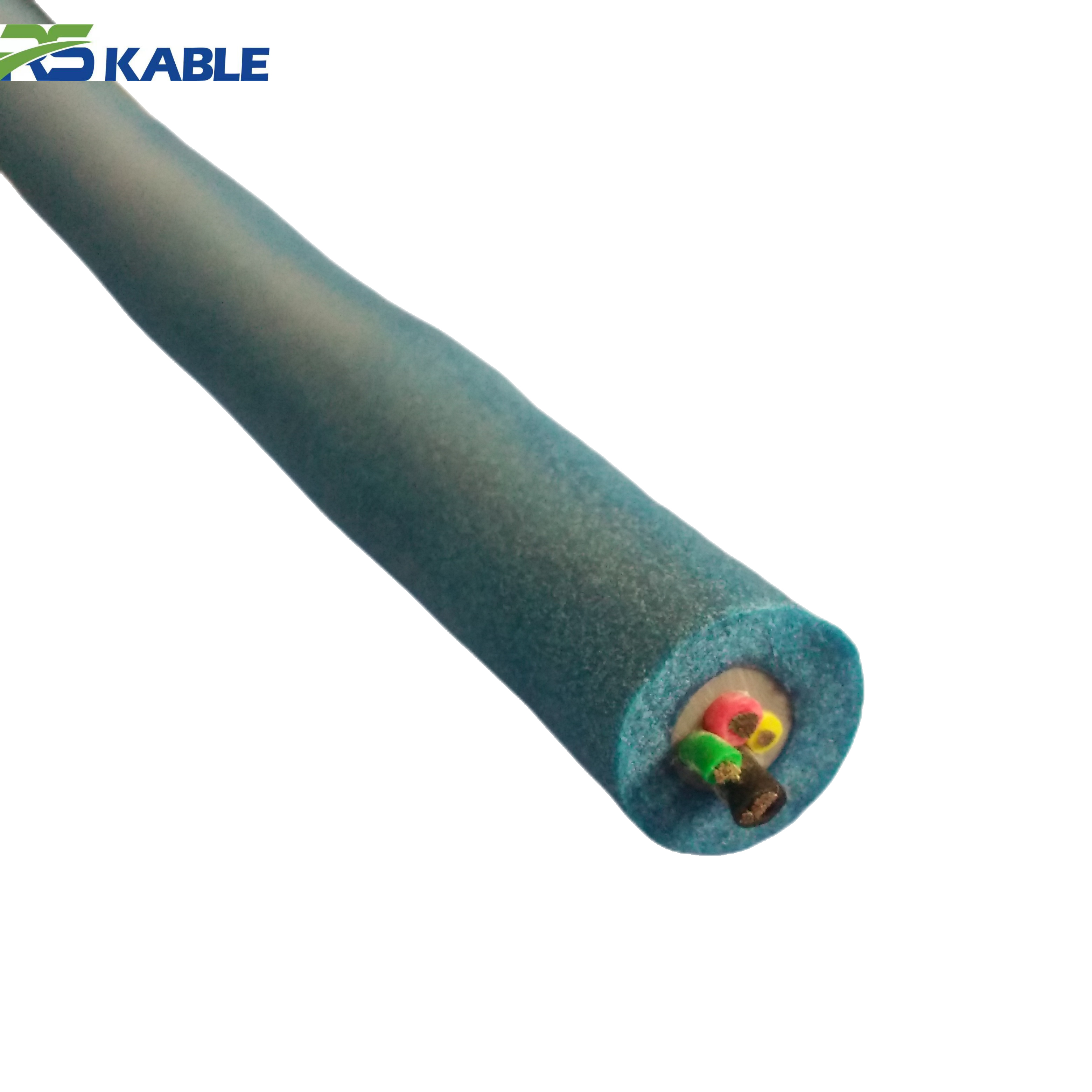

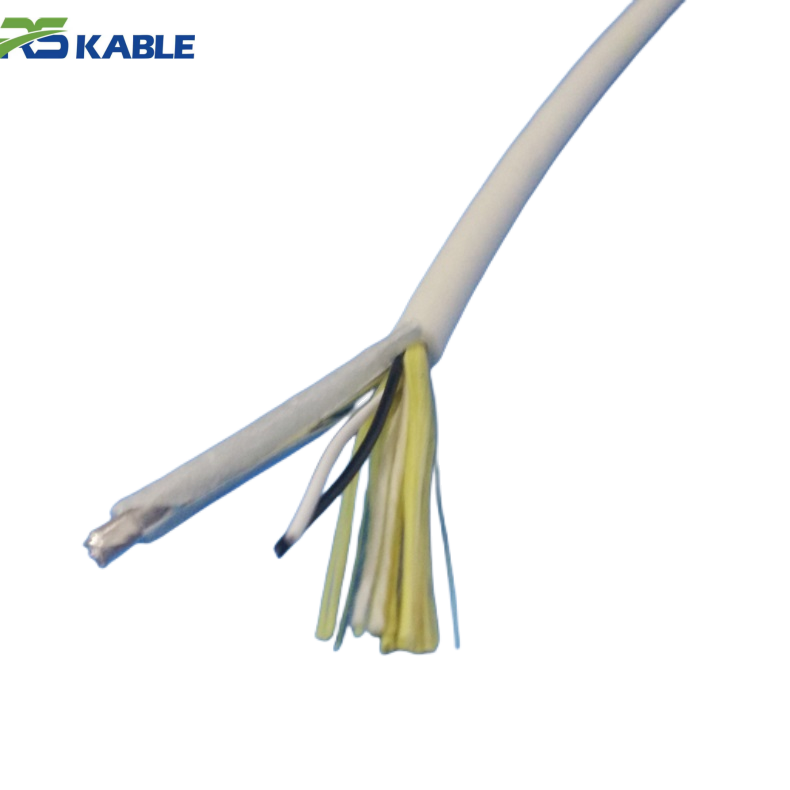

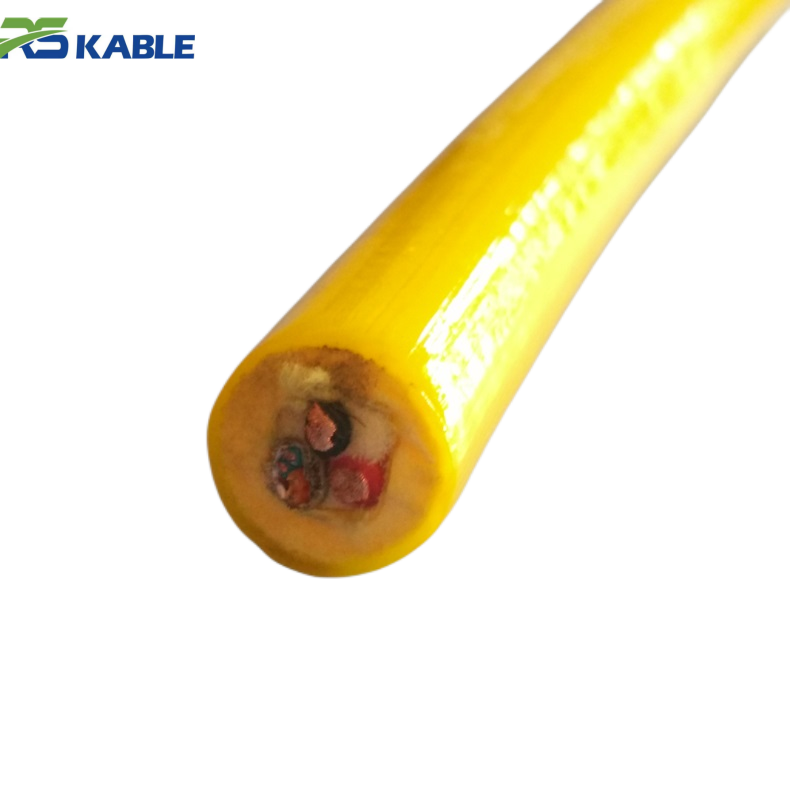

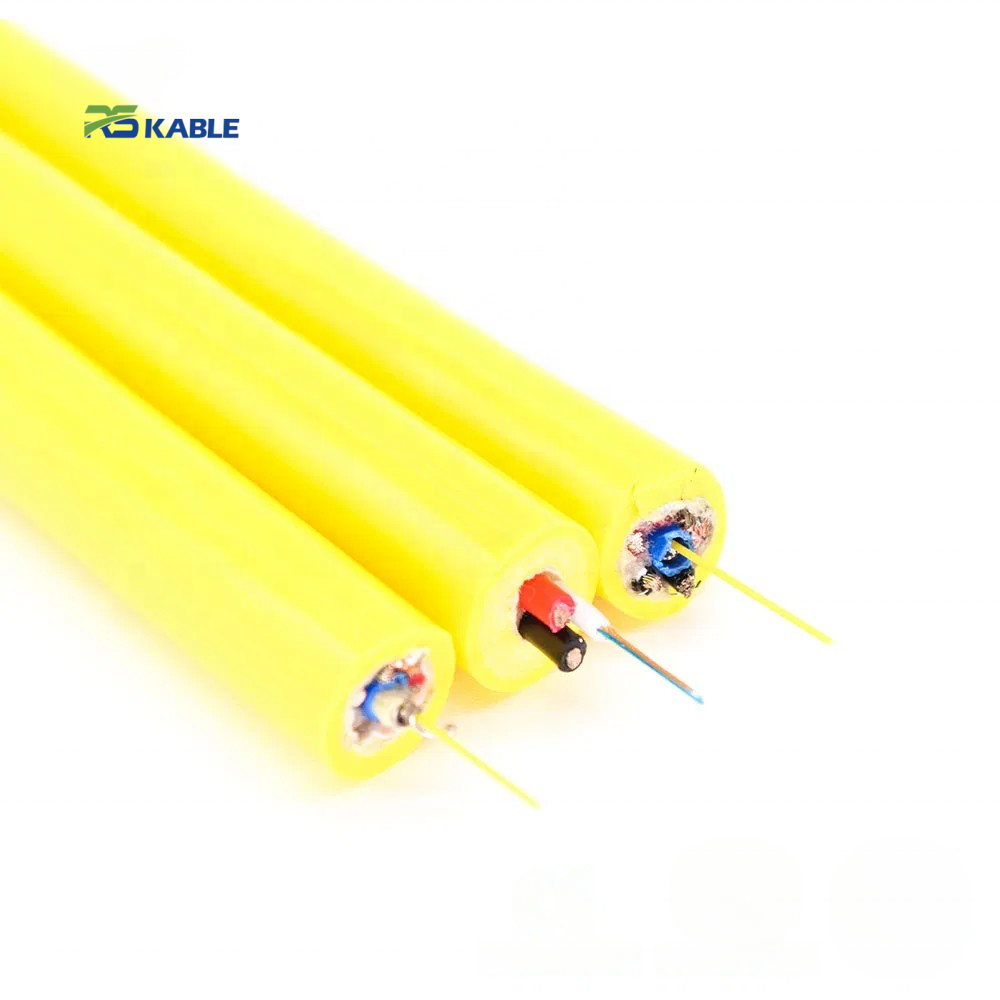

Anti-Interference Structural Architecture

Multi-Layer Shielding

-

Aluminum-polyester foil wrap (100% coverage)

-

High-density tinned copper braid (≥85% coverage)

-

Optional dual or triple shield construction

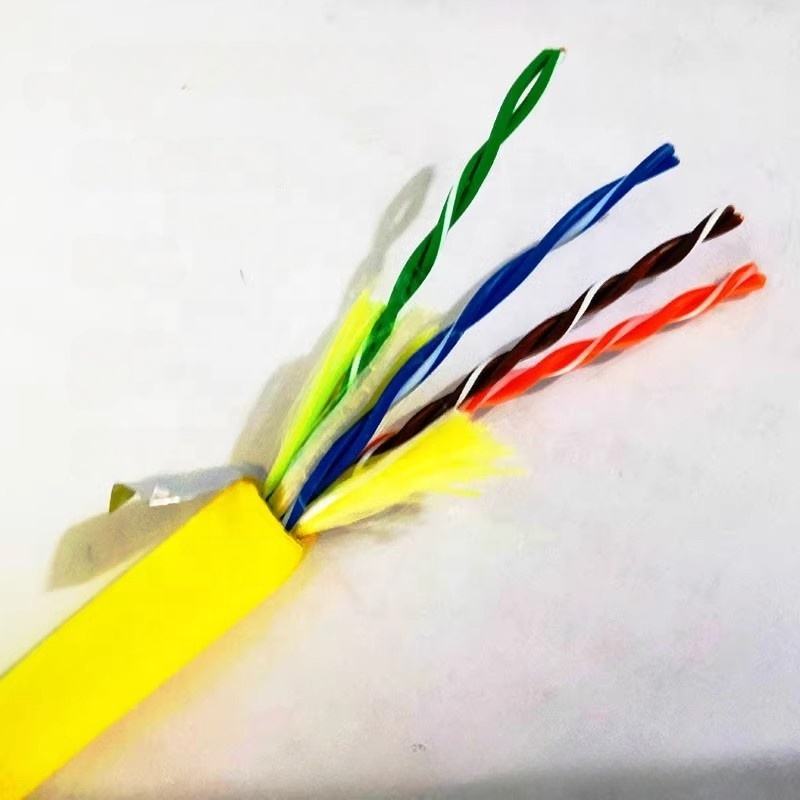

Balanced Conductor Geometry

-

Precision twisted pair configuration

-

Controlled lay length to reduce cross-talk

-

Low transfer impedance design

Grounding Optimization

-

Dedicated drain wires

-

Centralized ground reference architecture

-

Optional overall screen termination design

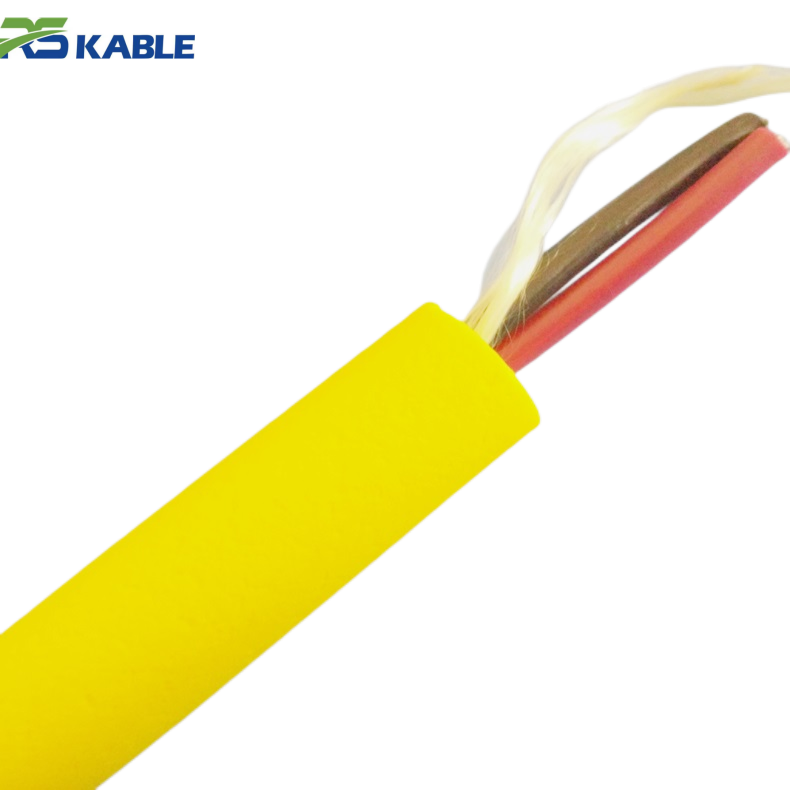

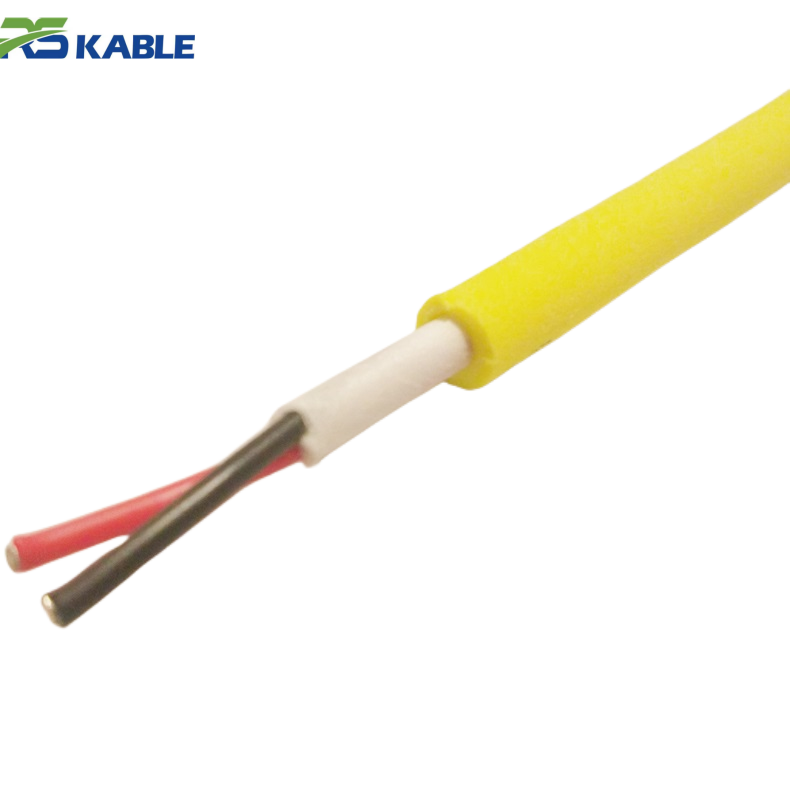

Protective Outer Jacket

-

Marine-grade PUR

-

UV-resistant and hydrolysis-resistant

-

Abrasion-resistant for offshore handling

This structure allows the ROV Cable to suppress EMI effectively while maintaining mechanical flexibility.

Technical Performance Parameters

| Parameter | Specification |

|---|---|

| Shield Coverage | ≥85% braided copper |

| Transfer Impedance | Optimized for low EMI coupling |

| Characteristic Impedance | 75Ω / 100Ω ±5% |

| Voltage Rating | 300/500V – 0.6/1kV |

| Depth Rating | Up to 2,500 m |

| Operating Temperature | –30°C to +85°C |

| Compliance | ISO 9001, RoHS |

Typical Deployment Environments

This anti-interference ROV Cable is widely used in:

-

Offshore oil & gas platforms

-

Subsea power cable inspection zones

-

Offshore wind farm substations

-

Industrial harbor infrastructure

-

Marine renewable energy installations

-

Electrically dense subsea construction sites

Long-tail keyword optimization:

-

“shielded ROV cable for high EMI offshore environments”

-

“low-noise subsea tether for platform inspection”

-

“anti-interference ROV cable for sonar systems”

Operational Advantages

-

Superior noise suppression

-

Stable real-time data transmission

-

Reduced video distortion

-

Improved control responsiveness

-

Enhanced system reliability in high-voltage proximity

In environments where electrical interference is unavoidable, selecting a shield-optimized ROV Cable is essential for maintaining communication integrity.

Quality Assurance & Engineering Validation

-

Shield effectiveness testing conducted per batch

-

Transfer impedance evaluation reports available

-

Signal integrity testing under simulated EMI exposure

-

Electrical continuity and insulation resistance verification

-

Manufactured in ISO-certified production facilities

Our technical team provides EMI risk assessment support and grounding configuration recommendations for complex subsea installations.

Enhance Your Subsea Signal Reliability

If your ROV system operates near high-voltage infrastructure or electrically dense environments, a shielded low-noise ROV Cable is critical for stable performance.

📩 Contact our engineering specialists for customized shielding configurations, technical documentation, and quotation support.

Frequently Asked Questions (FAQ)

Q1: What makes this cable suitable for high EMI environments?

Multi-layer shielding and optimized conductor geometry significantly reduce electromagnetic interference.

Q2: Can triple shielding be customized?

Yes. Shield density and structure can be tailored to project requirements.

Q3: Is it compatible with fiber optic systems?

Yes. Hybrid electro-optical versions are available.

Q4: How is shielding performance verified?

Through transfer impedance testing and simulated EMI exposure evaluation.

Q5: Is it suitable for deepwater operations?

Yes, depth ratings up to 2,500 meters are available.