Dynamic Drag Chain Systems | ROV Cable | High Flex & Bend Resistance | Extended Service Life

This high-flex ROV Cable is engineered for dynamic drag chain and automated deployment systems requiring continuous motion durability. Featuring extra fine-stranded copper conductors, reinforced anti-torsion construction, and a marine-grade PUR jacket, it withstands repetitive bending cycles while maintaining consistent power and signal transmission. Suitable for inspection-class and work-class ROV platforms, it enhances system longevity, reduces maintenance intervals, and supports efficient subsea operations in mechanically demanding environments.

Dynamic Drag Chain Systems | ROV Cable | High Flex & Bend Resistance | Extended Service Life

The ROV Cable designed for dynamic drag chain systems is engineered to withstand continuous flexing, tight bend radii, and repetitive motion cycles common in automated deployment and retrieval platforms. Built for high-flex endurance and structural resilience, this solution ensures stable power and signal transmission while significantly extending service life in mechanically demanding subsea operations.

Optimized for integration with cable carriers, winch drums, and dynamic handling systems, this ROV Cable maintains electrical integrity even under constant torsion and bending stress.

Designed for Continuous Motion Environments

Unlike standard static subsea tethers, dynamic drag chain applications require enhanced mechanical durability.

Core Performance Objectives:

-

High flex cycle resistance

-

Tight minimum bend radius capability

-

Anti-torsion structural stability

-

Abrasion-resistant outer sheath

-

Reduced conductor fatigue

This design minimizes downtime and maintenance costs in high-frequency operational scenarios.

Product Series Overview

| Model Code | Product Name (Model + Core Attribute) | Primary Application | Structural Highlights |

|---|---|---|---|

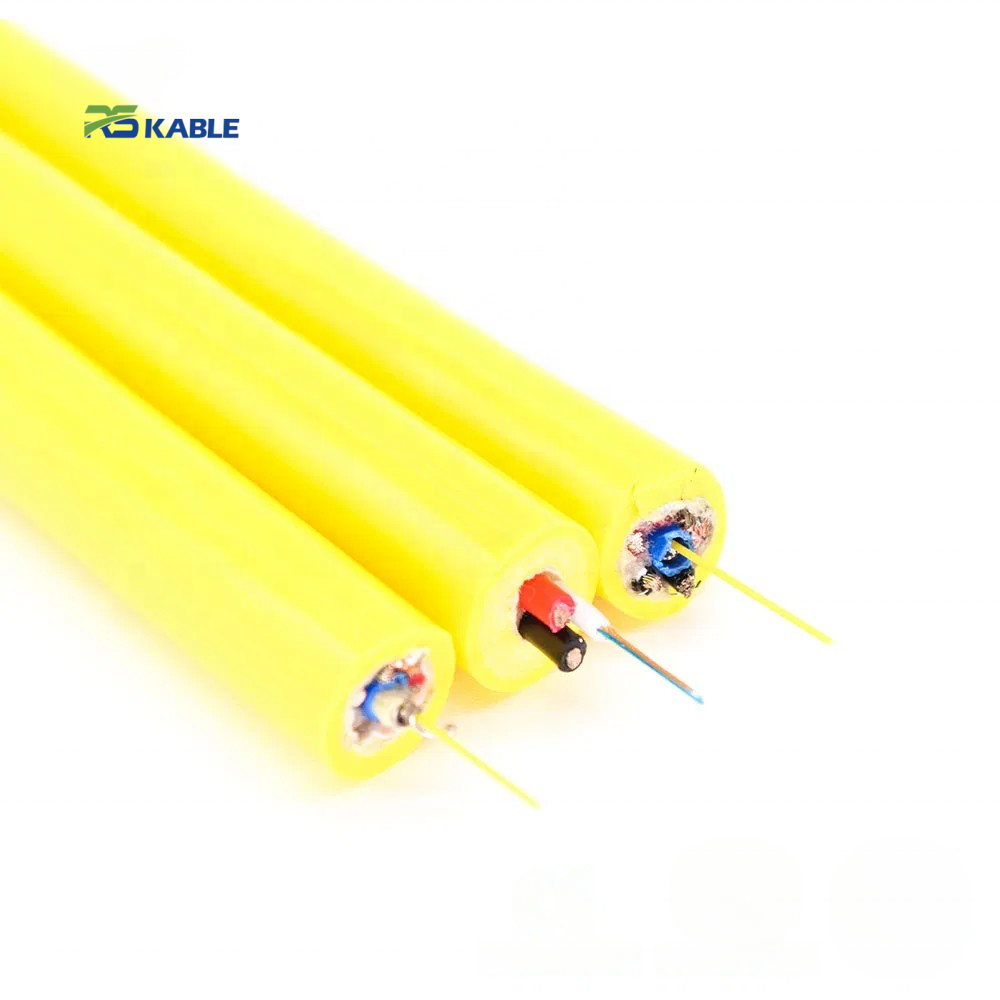

| DC-ROV-FX4 | 4-Core High-Flex Power Cable | Inspection ROV with automated reel | Fine-stranded copper + flexible insulation |

| DC-ROV-FX6S | Power + Signal Drag Chain Cable | Subsea tooling & control systems | 4 power cores + 2 shielded pairs |

| DC-ROV-HFT | Hybrid Fiber Dynamic ROV Cable | HD video & telemetry transmission | Power cores + optical fiber unit |

| DC-ROV-ARX | Reinforced Bend-Resistant Tether | Work-class ROV drag chain systems | Aramid strength layer + anti-twist core |

All configurations support custom lengths, voltage ratings, and reinforced tensile structures.

Technical Construction & Materials

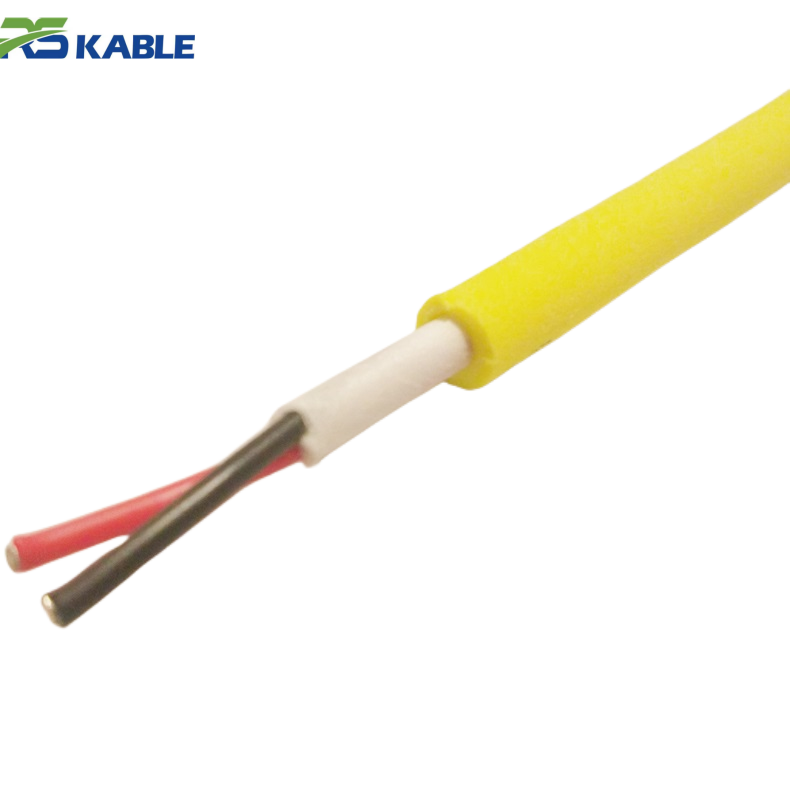

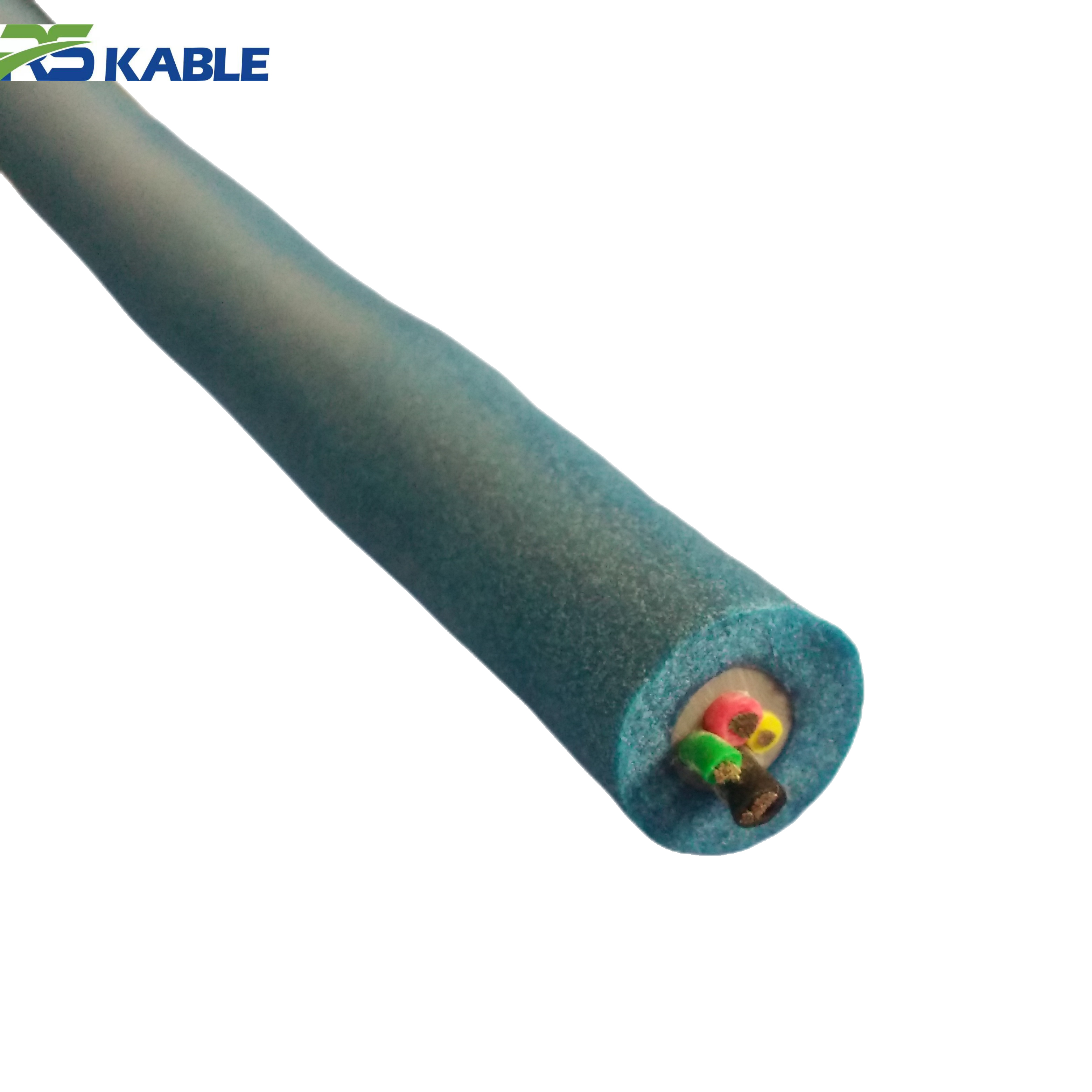

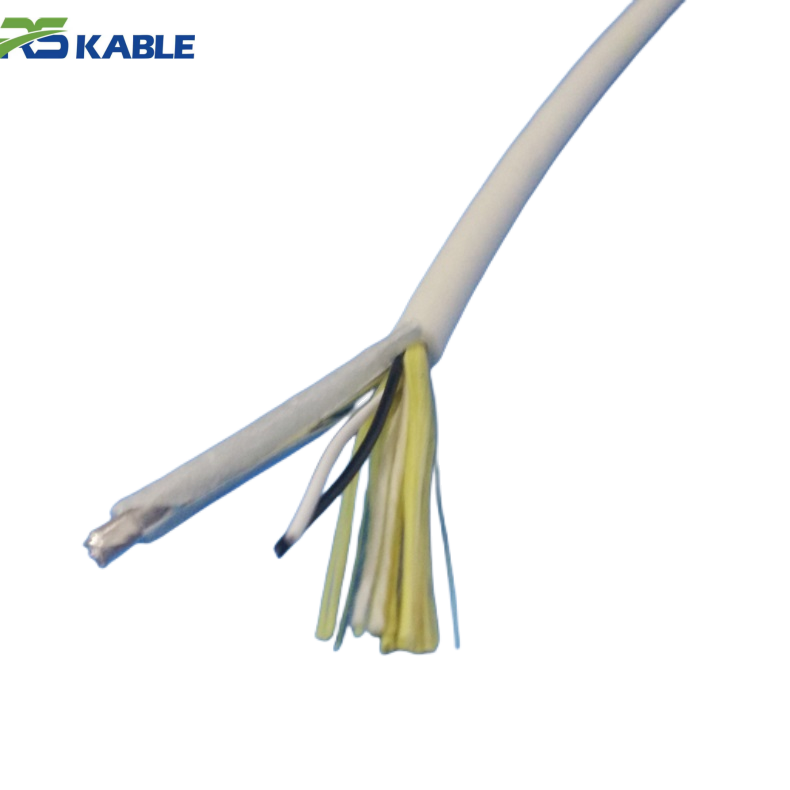

Conductor Design

-

Extra fine-stranded tinned copper (high strand count)

-

Optimized for repetitive bending

Insulation System

-

Flexible XLPE or TPE compounds

-

Low dielectric loss

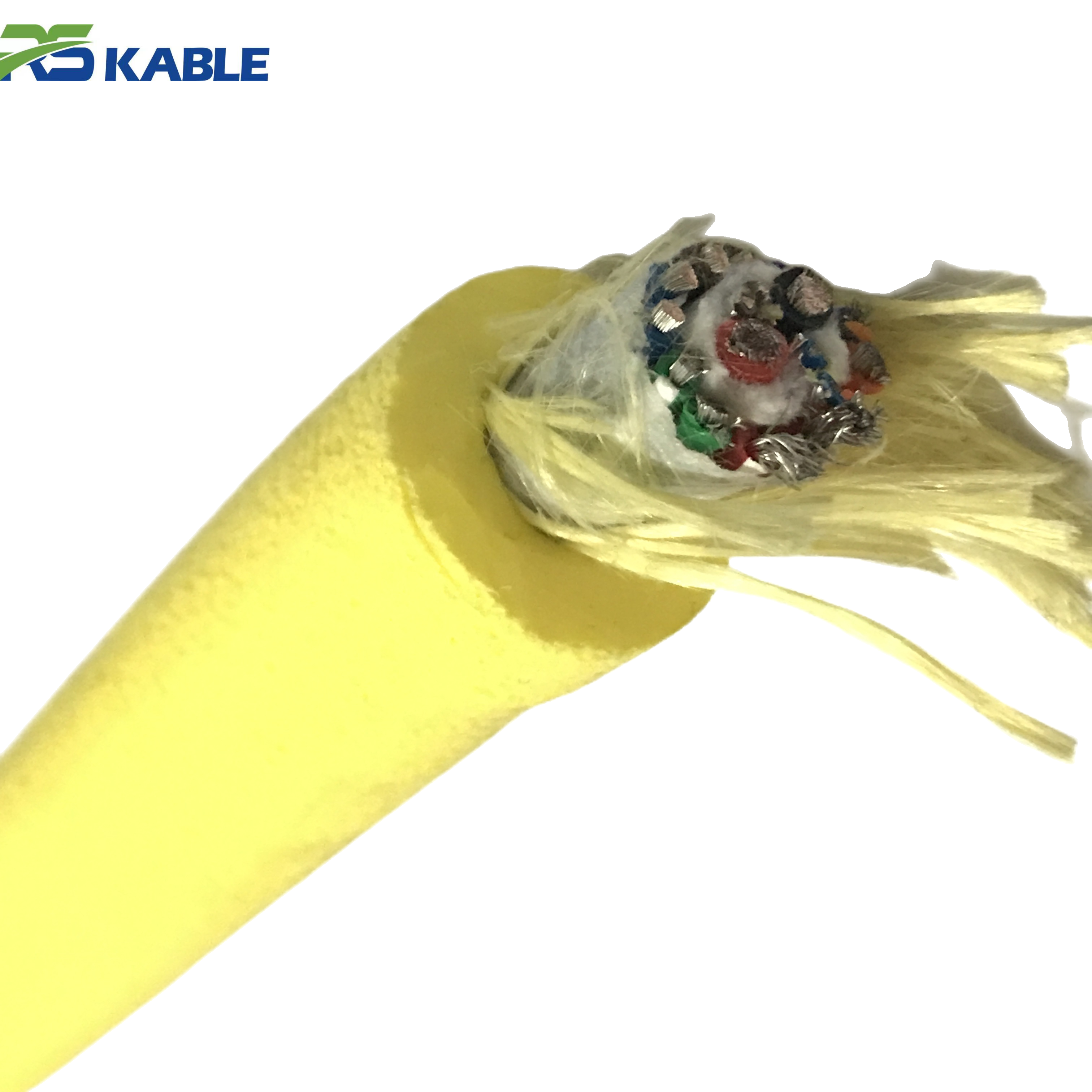

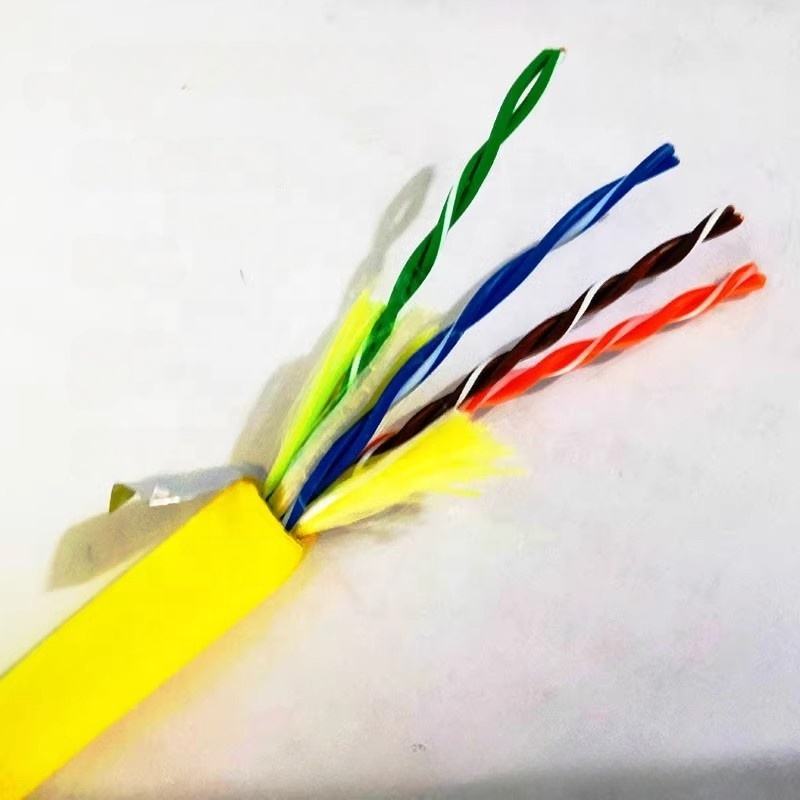

Shielding & Signal Layer

-

Individually shielded twisted pairs

-

Optional braided shielding for EMI control

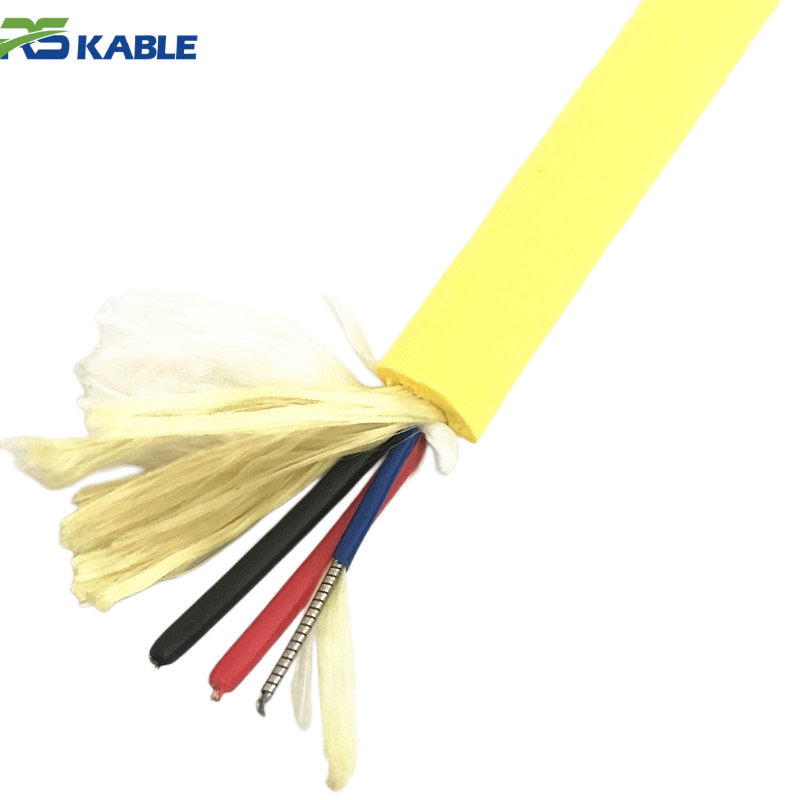

Strength & Stability

-

Aramid fiber reinforcement

-

Central anti-torsion separator

-

Load distribution core

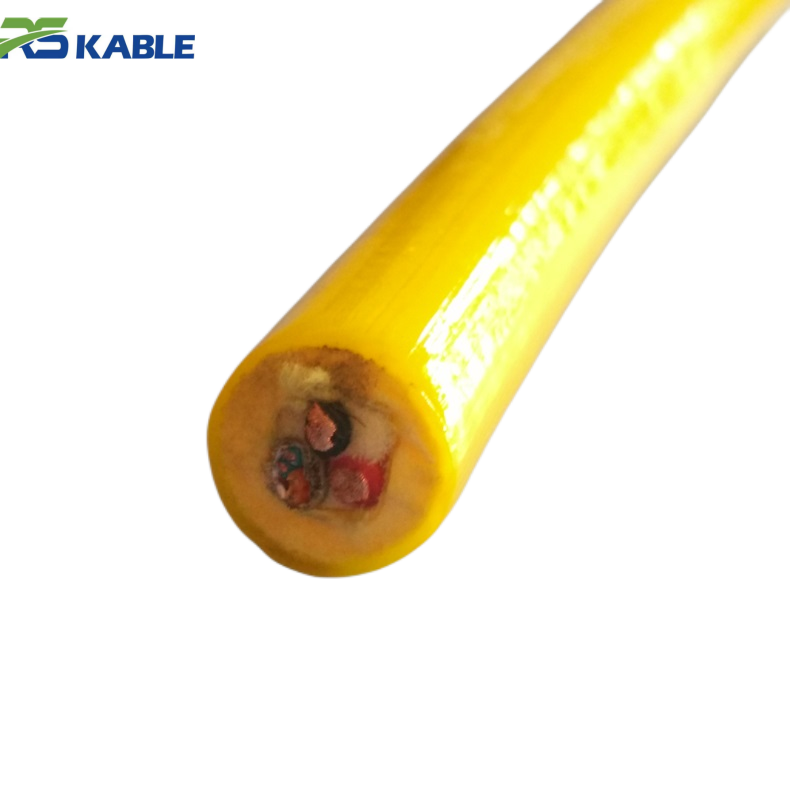

Outer Jacket

-

Marine-grade PUR

-

High abrasion resistance

-

Oil, saltwater, and UV resistant

This advanced construction enables the ROV Cable to operate reliably in dynamic cable carrier systems.

Key Technical Parameters

| Parameter | Specification |

|---|---|

| Minimum Bend Radius | 5–8 × cable diameter |

| Flex Cycle Rating | >5 million cycles (application dependent) |

| Depth Rating | Up to 1,500 m |

| Tensile Strength | Up to 3,000 kg |

| Voltage Rating | 300/500V – 0.6/1kV |

| Operating Temperature | –30°C to +80°C |

| Compliance | ISO 9001, RoHS |

Typical Application Scenarios

Dynamic drag chain ROV Cable systems are widely used in:

-

Automated ROV deployment platforms

-

Offshore drilling support vessels

-

Subsea construction systems

-

Remotely operated tooling arms

-

Cable reel and winch-integrated ROV units

-

Marine renewable energy inspection systems

Long-tail keyword focus:

-

“high flex ROV cable for drag chain systems”

-

“bend resistant subsea tether for dynamic deployment”

-

“continuous motion ROV cable for automated reel systems”

Performance Advantages

✔ Extended operational lifespan

✔ Reduced conductor breakage risk

✔ Improved resistance to cyclic fatigue

✔ Stable signal transmission during motion

✔ Lower long-term replacement costs

Through precision engineering and material optimization, this ROV Cable provides durability in high-motion marine environments.

Quality Validation & Engineering Expertise

Every production batch undergoes:

-

Dynamic bending simulation testing

-

Torsion resistance evaluation

-

Tensile load verification

-

Electrical continuity testing

-

Insulation resistance analysis

Manufactured under ISO-certified quality management systems, our cables meet international marine and industrial standards. Engineering consultation is available for drag chain dimension calculation, bend radius verification, and system compatibility analysis.

Improve Your System Reliability

If your ROV deployment platform involves continuous bending and motion, a high-flex ROV Cable is critical to maintaining long-term operational stability.

📩 Request technical drawings, flex test data, or a custom quotation from our engineering team today.

Frequently Asked Questions (FAQ)

Q1: What makes a cable suitable for drag chain systems?

High strand-count conductors, flexible insulation, and anti-torsion design improve cyclic durability.

Q2: How many bending cycles can it withstand?

Depending on configuration, over 5 million cycles under controlled conditions.

Q3: Is it compatible with automated reel systems?

Yes. It is specifically designed for integration with dynamic deployment platforms.

Q4: Can fiber optics be included?

Yes. Hybrid electro-optical versions are available.

Q5: Is customization supported?

Yes. Core count, conductor size, shielding, and tensile rating can be tailored.