Drag Chain ROV Systems | Neutral Buoyancy Cable | High Flex Endurance | Drag Chain Rated

This Neutral Buoyancy Cable is designed for drag chain ROV systems requiring high flex endurance and dynamic stability. With drag-chain-rated construction and controlled buoyancy, it delivers reliable power and signal transmission in repetitive motion and confined subsea environments.

Drag Chain ROV Systems | Neutral Buoyancy Cable | High Flex Endurance | Drag Chain Rated

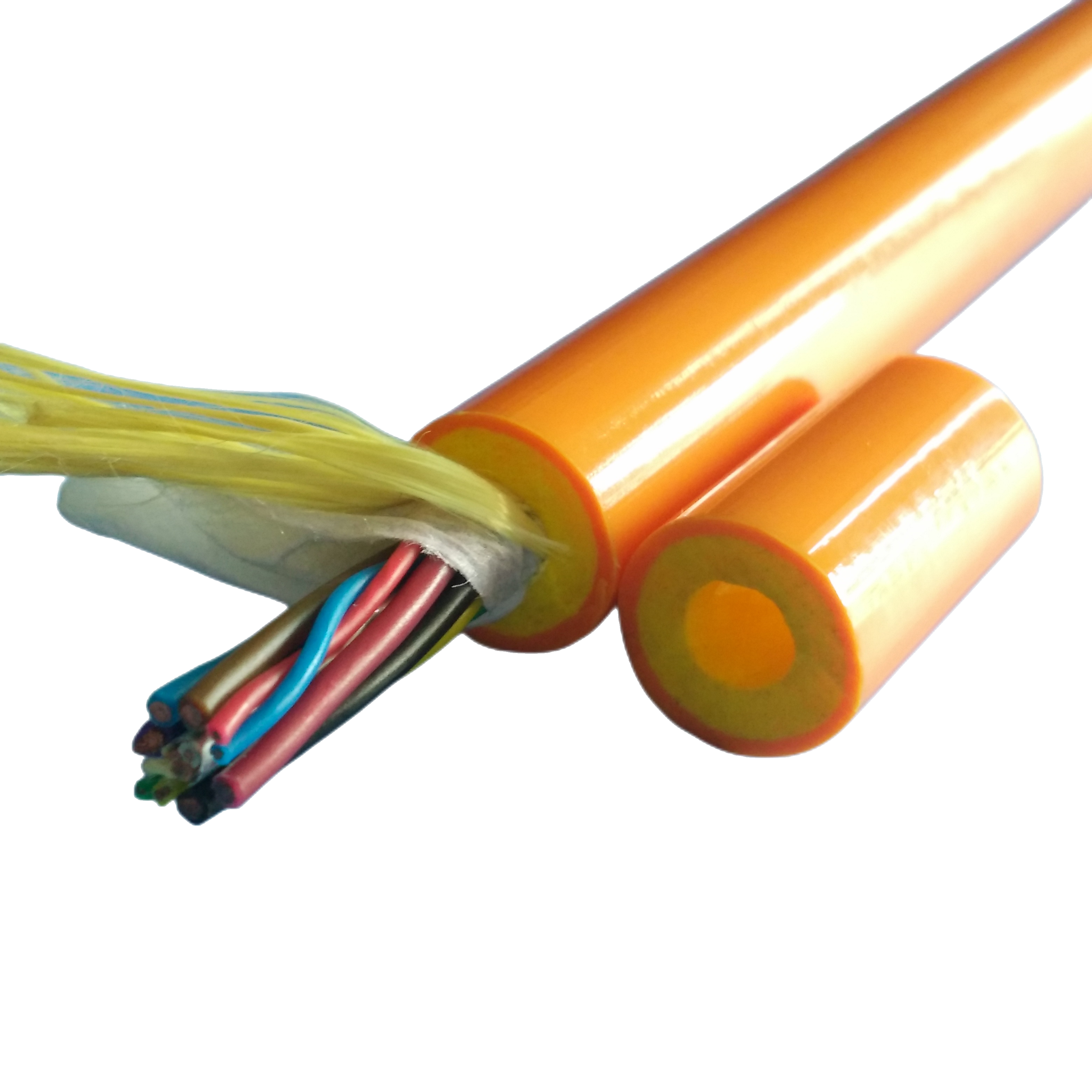

Drag chain ROV systems require cable solutions capable of enduring continuous bending, repetitive motion, and confined routing paths. This Neutral Buoyancy Cable is specifically engineered for drag chain applications, combining high flex endurance with controlled buoyancy to ensure stable performance during dynamic ROV operations.

Designed for repetitive movement environments, it supports reliable power and signal transmission while maintaining flexibility and mechanical integrity throughout extended service cycles.

Drag Chain Environments: Why Cable Flexibility Matters

In drag chain–based ROV systems, cables are subjected to constant bending, acceleration, and directional changes. Conventional subsea cables often fail prematurely due to:

-

Conductor fatigue from repeated bending cycles

-

Insulation cracking under dynamic stress

-

Increased drag and instability from improper buoyancy

-

Reduced service life in confined routing systems

A drag-chain-rated Neutral Buoyancy Cable is essential to ensure system reliability and predictable maintenance intervals.

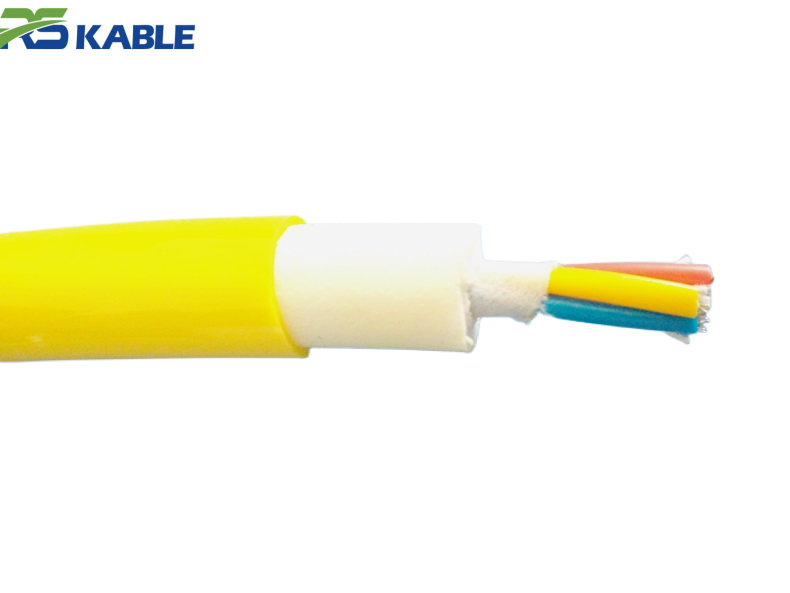

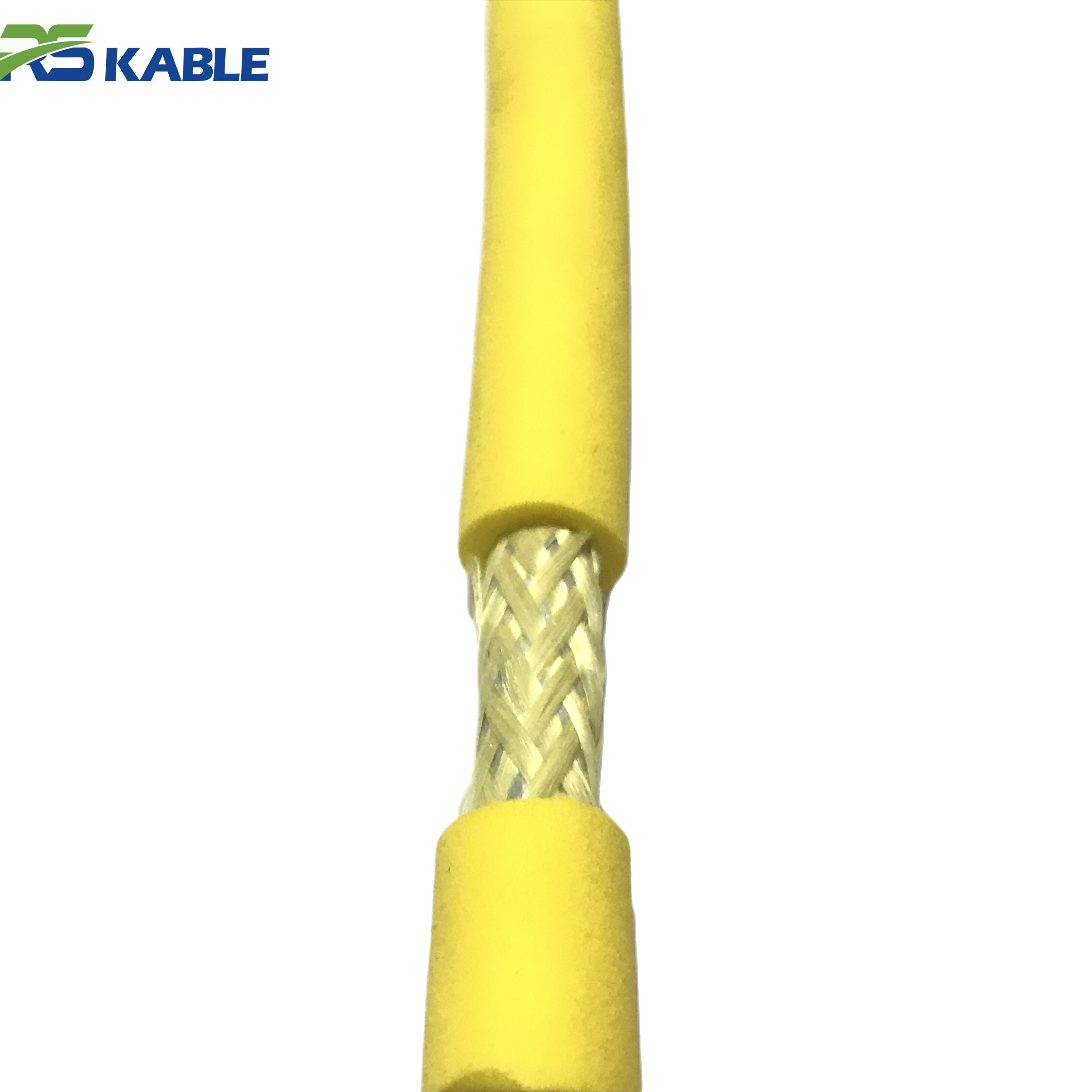

High Flex Endurance Design Concept

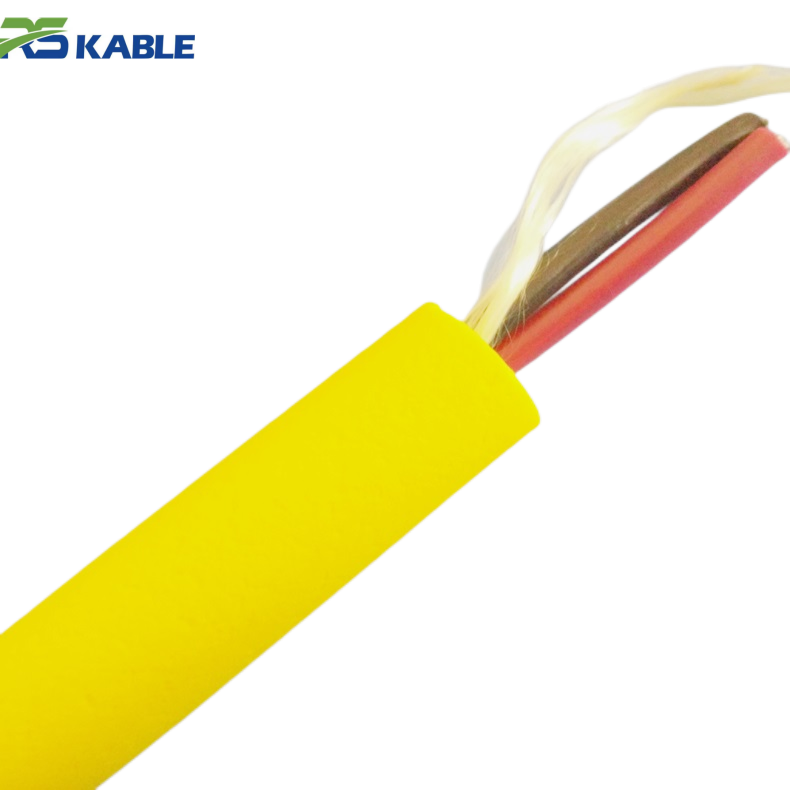

This cable is developed with a structure optimized for high-cycle dynamic motion, including:

-

Fine-stranded conductors to reduce bending stress

-

Optimized core lay length for smooth flex behavior

-

Flexible insulation compounds resistant to fatigue

-

Stable buoyancy fillers to prevent tension buildup

These features allow the Neutral Buoyancy Cable to maintain performance in high-flex subsea cable applications and ROV drag chain systems.

Typical Applications & System Integration

This solution is commonly used in ROV and underwater systems featuring drag chain routing, such as:

-

Work-class and inspection ROV drag chain assemblies

-

Tether management systems (TMS) with dynamic motion

-

Underwater robotic platforms with articulated movement

-

Test tanks and confined subsea operation setups

-

Industrial underwater automation systems

It is frequently specified as a high-flex ROV cable, drag chain rated subsea cable, and dynamic neutral buoyancy tether.

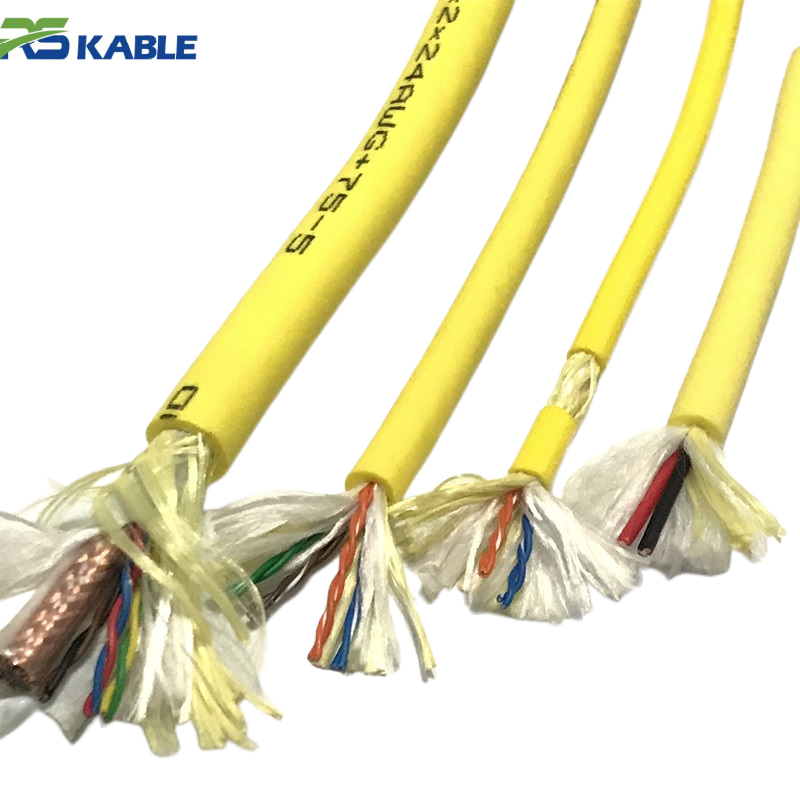

Product Configuration Overview

| Product Name / Model | Core Attributes |

|---|---|

| NB-DC Series Neutral Buoyancy Cable | High flex endurance, drag chain rated, stable buoyancy |

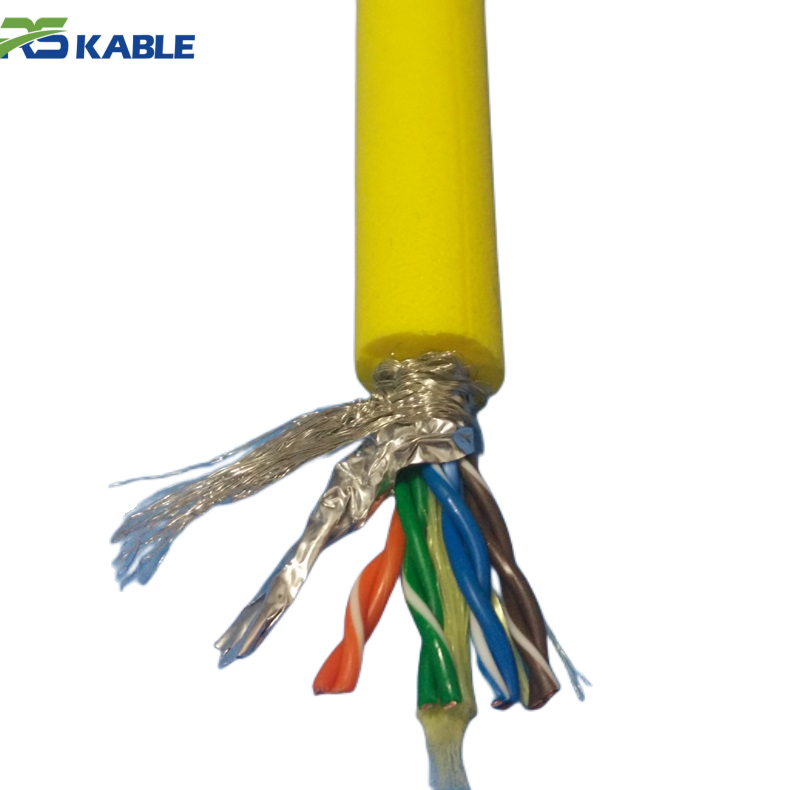

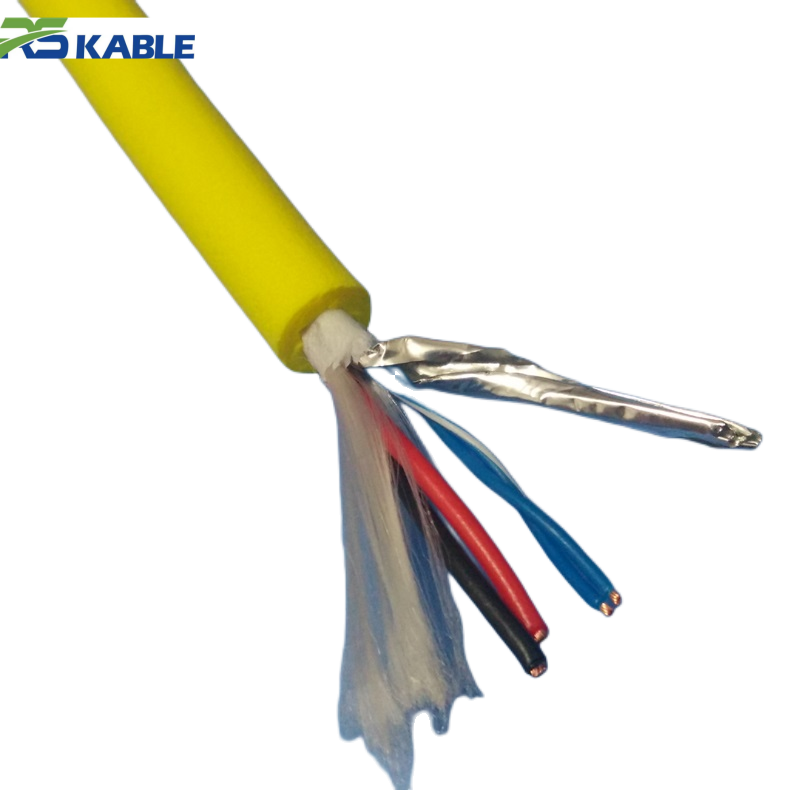

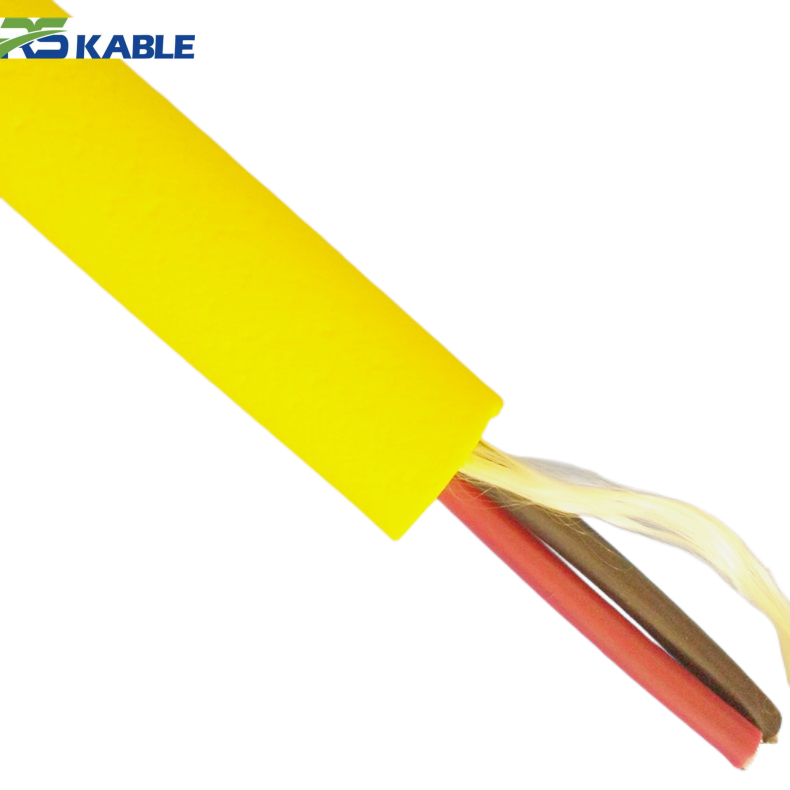

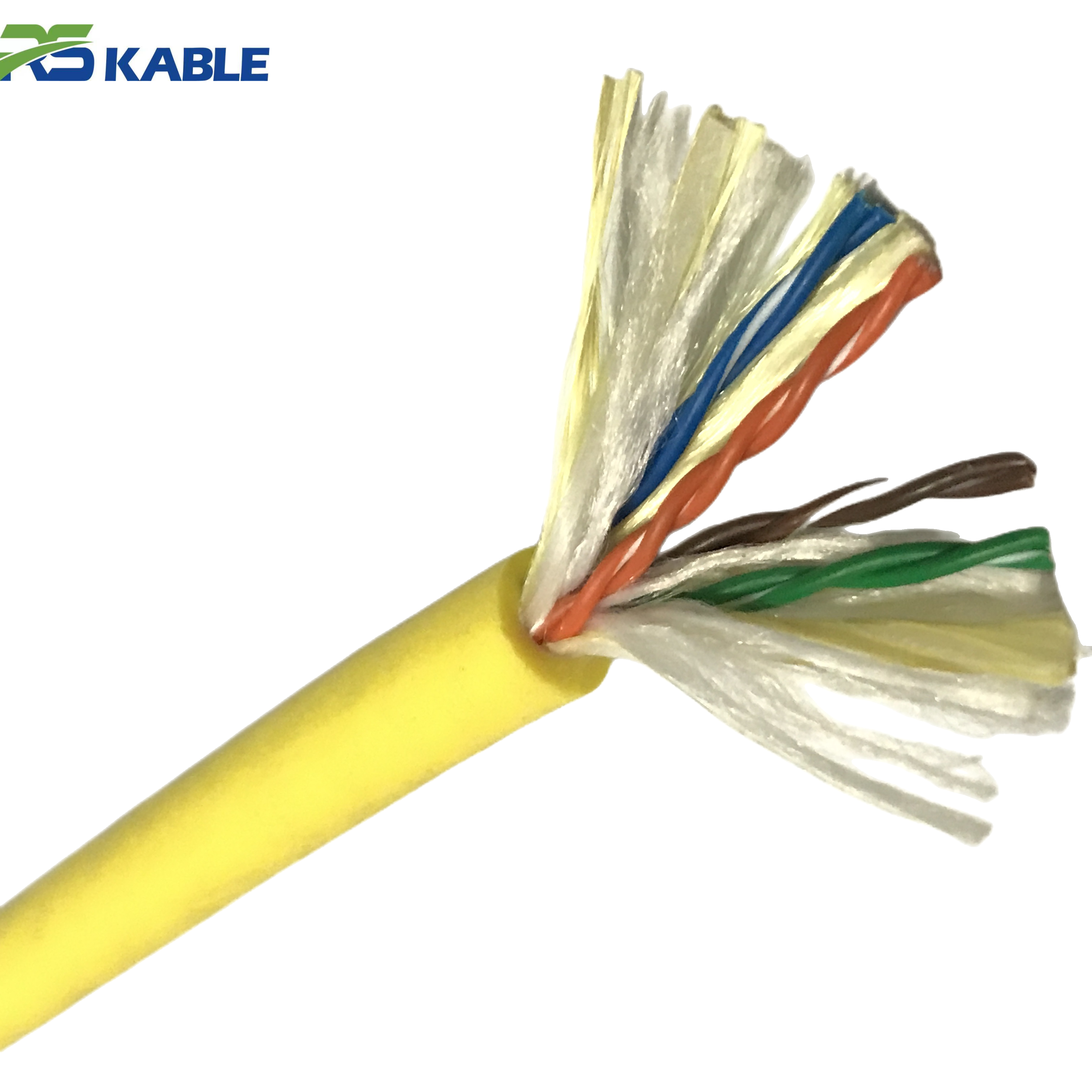

Key Technical Parameters

| Parameter | Specification Options |

|---|---|

| Core Configuration | Power cores, signal cores, or hybrid power & signal |

| Conductor Construction | Fine-stranded tinned copper |

| Insulation | Flexible PE / TPU compounds |

| Flex Life Design | Optimized for high-cycle bending applications |

| Buoyancy Control | Precision-balanced fillers for neutral buoyancy |

| Outer Jacket | Flexible, abrasion-resistant marine-grade polyurethane |

| Operating Environment | Dynamic subsea and drag chain systems |

| Minimum Bending Radius | Designed for tight routing in drag chain applications |

Core count, jacket thickness, and buoyancy characteristics can be customized for specific drag chain dimensions and motion profiles.

Dynamic Stability Through Buoyancy Control

Unlike standard high-flex cables, this Neutral Buoyancy Cable integrates buoyancy control to reduce the mechanical load typically introduced by cable self-weight. Neutral underwater behavior helps:

-

Lower stress on drag chain components

-

Reduce resistance during motion cycles

-

Improve overall ROV maneuverability

-

Extend the service life of the entire system

This integration is particularly valuable in long-duration ROV operations with continuous movement.

Performance Advantages in Drag Chain ROV Systems

By deploying this drag-chain-rated Neutral Buoyancy Cable, operators benefit from:

-

Extended flex life under repetitive bending

-

Reduced downtime from cable fatigue failures

-

Stable electrical performance during motion

-

Improved system reliability in dynamic environments

These advantages make it a practical choice for demanding ROV drag chain applications.

Engineering Authority & Quality Assurance (E-E-A-T)

-

Designed by engineers experienced in high-flex subsea cable systems

-

Manufactured under ISO-certified quality management standards

-

Tested for bending cycles, flex endurance, and buoyancy stability

-

Materials selected for long-term dynamic subsea operation

Each design is validated against real-world drag chain operating conditions.

Customization & Technical Support

We support ROV manufacturers and system integrators with:

-

Drag chain–specific cable design optimization

-

Hybrid power and signal configurations

-

Flex life and bending radius verification

-

Technical documentation and application guidance

👉 Contact our engineering team to discuss your drag chain ROV cable requirements.

FAQ

Is this cable suitable for continuous drag chain motion?

Yes. It is designed for high-cycle bending and dynamic motion environments.

Does neutral buoyancy improve drag chain performance?

Yes. It reduces tension and mechanical load on both the cable and the drag chain.

Can it combine power and signal transmission?

Yes. Hybrid configurations are available.

Is the cable flexible enough for tight routing paths?

Yes. The structure is optimized for small bending radii typical of drag chain systems.