Deepwater Operations | ROV Cable | Neutral Buoyancy Design | Reliable Subsea Transmission

Our deepwater ROV Cable features calibrated neutral buoyancy, reinforced aramid core, and multi-layer shielding to ensure reliable subsea power and data transmission up to 7,000 meters. Designed for offshore inspection, oil & gas, wind farms, and scientific exploration, it delivers low drag, high tensile strength, and long-term durability in harsh marine environments.

Deepwater Operations | ROV Cable | Neutral Buoyancy Design | Reliable Subsea Transmission

For complex deepwater operations, a high-performance ROV Cable is critical to ensure stable power delivery and uninterrupted subsea data transmission. Our neutral buoyancy design minimizes drag, reduces mechanical stress on remotely operated vehicles, and enhances maneuverability at extreme depths. Engineered for offshore energy, scientific exploration, and defense applications, this cable supports long-duration missions with reliable subsea transmission integrity.

Engineered for Deepwater Stability

Unlike standard subsea tethers, this ROV Cable integrates calibrated buoyancy control, reinforced structural members, and optimized signal shielding. The result is:

-

Reduced vertical load on ROV thrusters

-

Lower hydrodynamic resistance in strong currents

-

Stable video, control, and telemetry signals

-

Extended operational lifespan in saltwater environments

-

Improved safety during deployment and retrieval

This solution is ideal for operators requiring dependable subsea cable systems for 3,000–7,000 meter deployments.

Product Portfolio Overview

| Model | Core Configuration & Key Attribute | Rated Depth | Diameter | Tensile Strength |

|---|---|---|---|---|

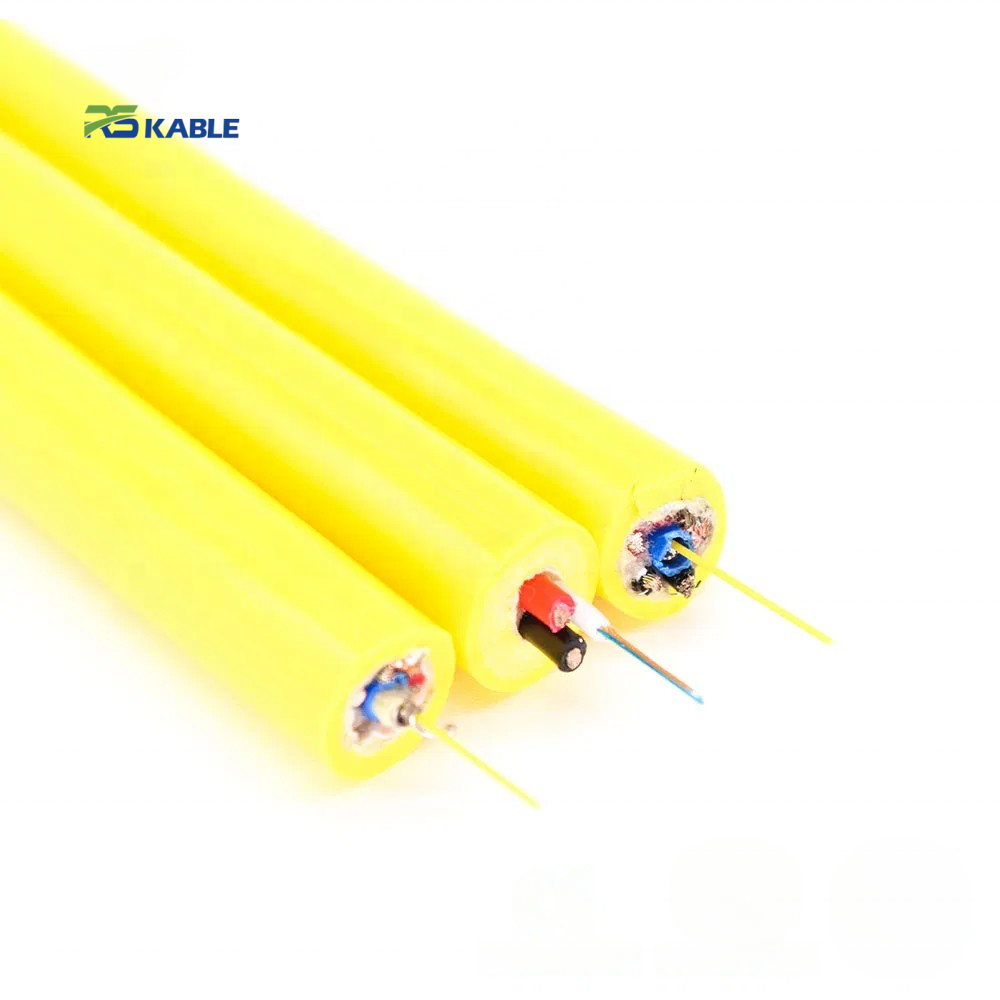

| ROV-DW-4P | 4 power cores, neutral buoyancy, flexible | 3,000 m | 17.5 mm | ≥2,000 kg |

| ROV-DW-6H | 6-core hybrid (power + signal), shielded | 4,500 m | 19.8 mm | ≥2,500 kg |

| ROV-DW-FO | Power + fiber optic integration, low attenuation | 6,000 m | 22.0 mm | ≥2,800 kg |

| ROV-DW-PRO | Reinforced deepwater structure, multi-layer shielding | 7,000 m | 25.5 mm | ≥3,200 kg |

Custom lengths up to 2,000 meters available. Fiber optic options support high-bandwidth subsea communication.

Typical Applications

This ROV Cable is widely used in:

-

Deepwater oil & gas inspection and maintenance

-

Offshore wind farm foundation surveys

-

Subsea pipeline and riser integrity checks

-

Oceanographic and bathymetric mapping missions

-

Military and defense underwater operations

-

Long-duration ROV umbilical tether systems

Long-tail keyword coverage includes:

deepwater ROV cable 6000m, neutral buoyancy ROV tether for offshore inspection, hybrid power and fiber ROV cable for subsea transmission.

Technical Specifications

| Parameter | Specification |

|---|---|

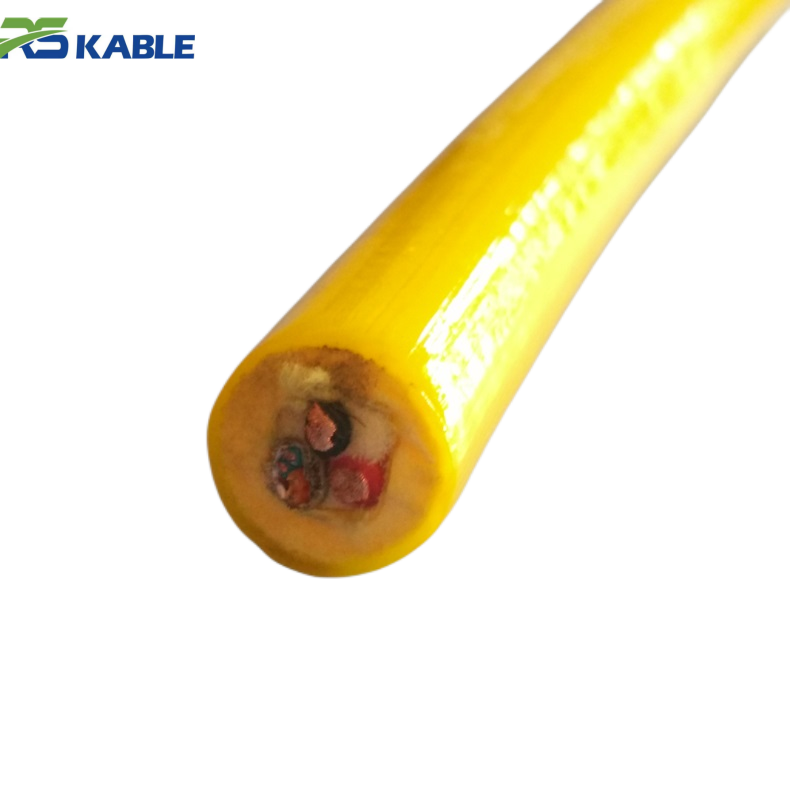

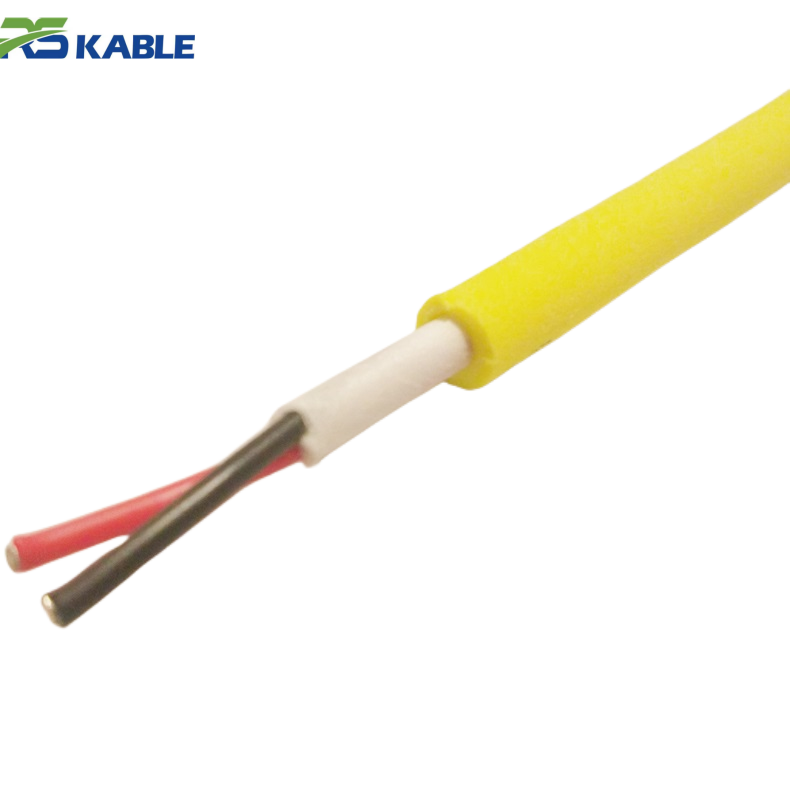

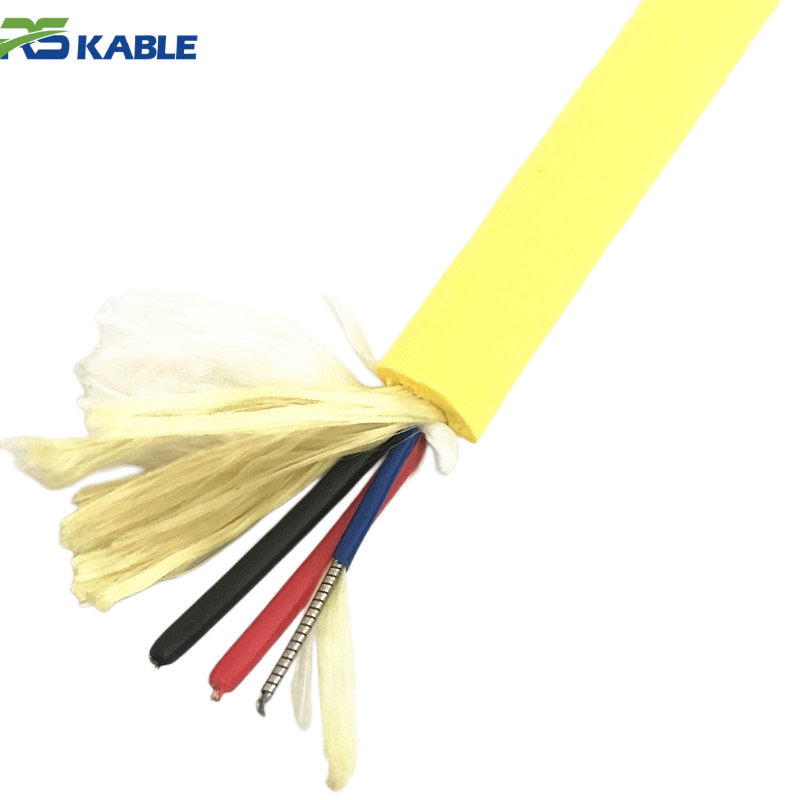

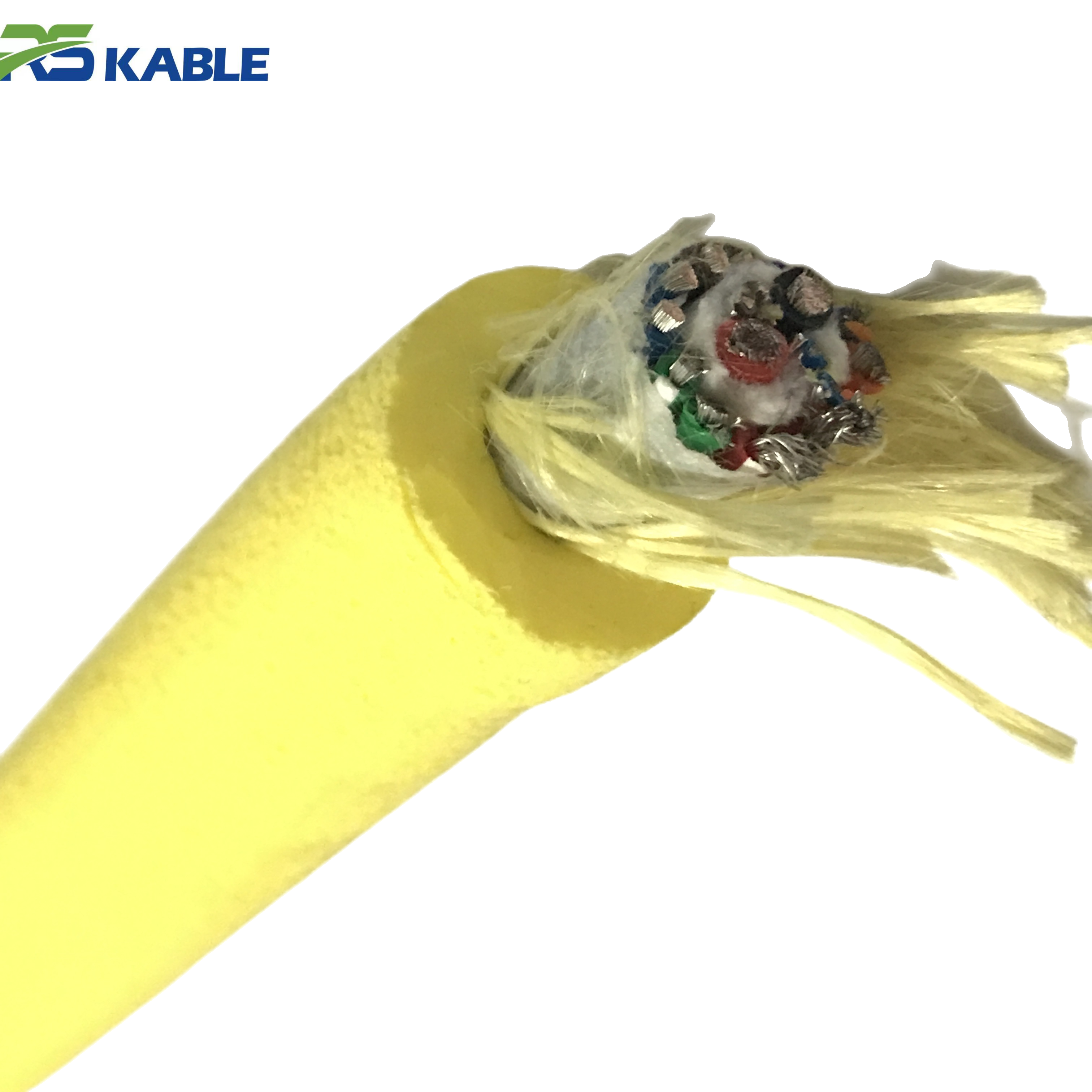

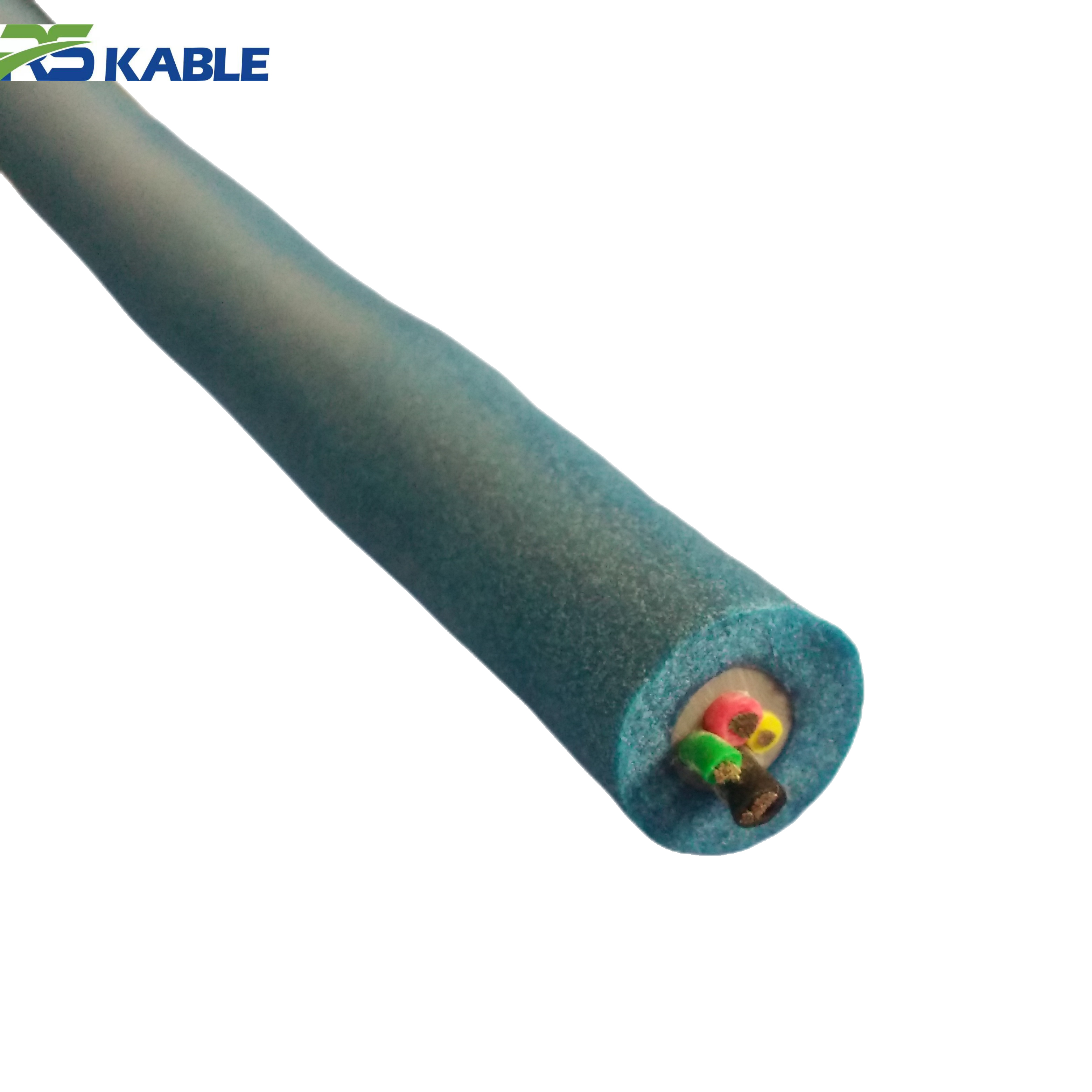

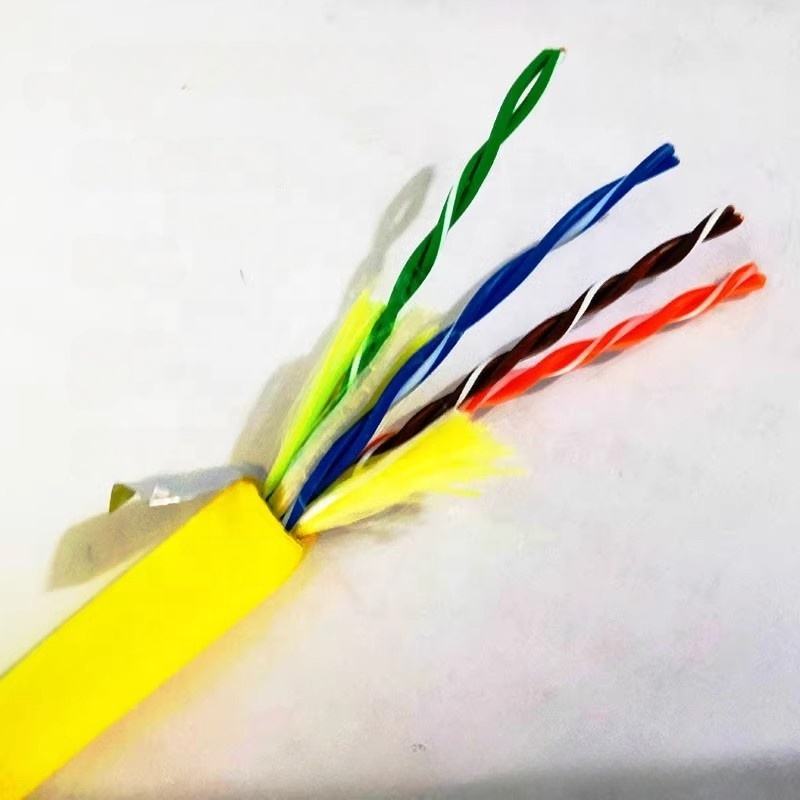

| Conductor | Tinned stranded copper, IEC Class 5/6 |

| Insulation | Foamed PE / XLPE for density control |

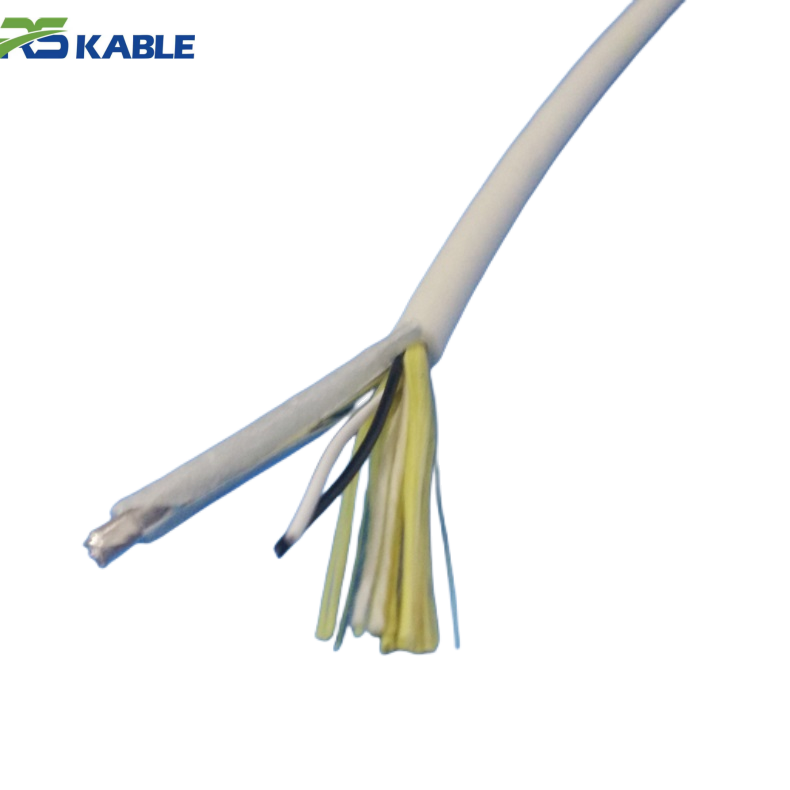

| Fiber Option | Single-mode or multi-mode (optional) |

| Strength Member | Aramid/Kevlar braided reinforcement |

| Shielding | Multi-layer foil + braided shield (≥90%) |

| Outer Jacket | Seawater-resistant TPU / PUR |

| Buoyancy | Calibrated neutral buoyancy in seawater |

| Temperature Range | –40°C to +75°C |

| Voltage Rating | 300/500V (1kV optional) |

| Compliance | ISO 9001, RoHS, REACH, optional ABS/DNV |

Performance Highlights

-

Precision neutral buoyancy reduces tether drag

-

High tensile capacity for dynamic offshore handling

-

Low signal attenuation for HD video and telemetry

-

Abrasion and corrosion resistance for multi-year use

-

Flexible construction with 5–7×OD bend radius

Every ROV Cable undergoes electrical continuity testing, tensile verification, and pressure simulation prior to shipment.

Why Partner With Us?

-

20+ years of subsea cable engineering experience

-

Dedicated R&D for deepwater robotic systems

-

Custom manufacturing capability

-

Third-party inspection available upon request

-

Global technical support and fast quotation turnaround

Frequently Asked Questions

Q1: Can the buoyancy be customized for specific salinity levels?

Yes. Density calibration can be adjusted during production to match regional seawater conditions.

Q2: Do you offer hybrid fiber + power designs?

Yes. We provide integrated fiber optic cores for high-speed video and data transmission.

Q3: What is the maximum operating depth?

Standard models support up to 7,000 meters; custom reinforcement is available for specialized projects.

Q4: Are factory terminations available?

Yes. SubConn®, SEACON, and custom connector assemblies are available with full testing.

Q5: Is this suitable for long-term offshore deployment?

Absolutely. The abrasion-resistant jacket and reinforced core ensure durability in harsh subsea environments.

Request Technical Details or a Custom Quote

Planning a deepwater project? Our engineering team can recommend the right ROV Cable configuration based on depth, load requirements, and signal bandwidth.

👉 Request a Quote

👉 Download Technical Datasheet

👉 Speak with a Marine Cable Engineer

Reliable subsea transmission starts with precision engineering. Contact us today to configure your deepwater ROV tether solution.